Tsarin shaye-shaye yana taka muhimmiyar rawa a aikin mota da tasirin muhalli. Theyawan shaye-shaye, a matsayin kashi na farko a cikin wannan tsarin, yana tattara iskar gas daga injin silinda kuma ya tura su zuwa bututun mai. Fahimtar yadda tarin shaye-shaye ke aiki yana da mahimmanci don kiyaye ingancin injin da rage hayaki.

Menene Exhaust Manifold?

Ma'ana da Manufar

Ma'anar asali

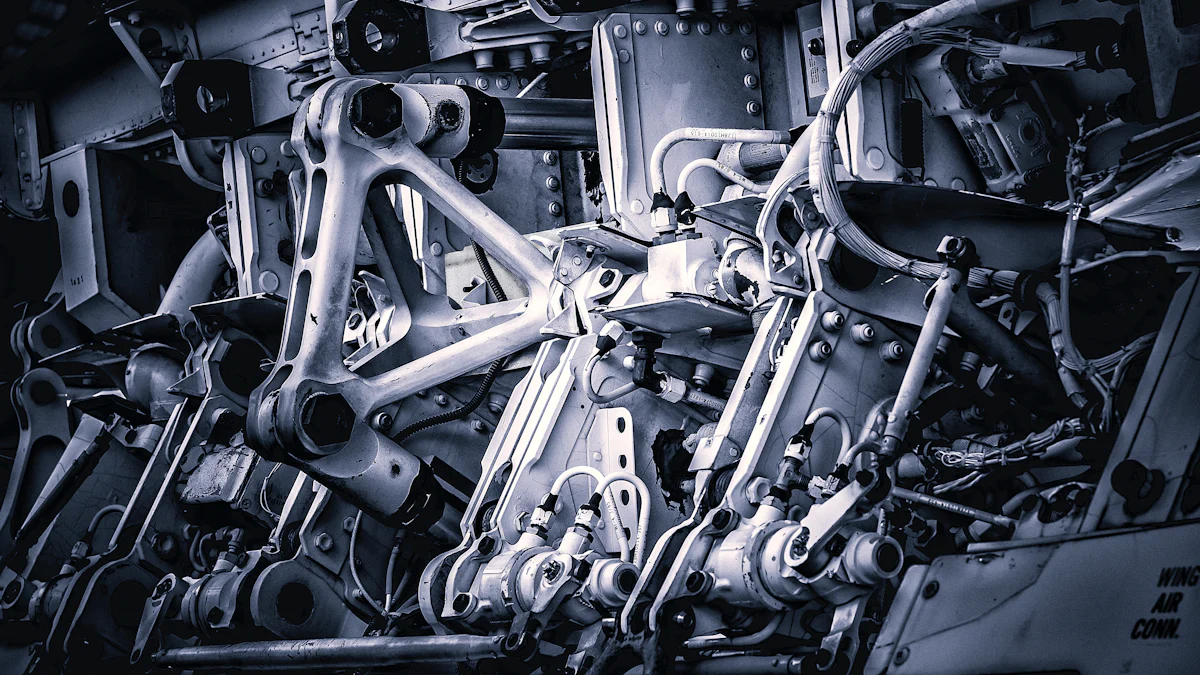

An yawan shaye-shayewani abu ne mai mahimmanci a tsarin sharar mota. Yana tattara iskar gas daga injin silinda da yawa kuma yana jagorantar su zuwa bututun mai. Wannan tsari yana tabbatar da cewa iskar gas masu cutarwa suna fita cikin abin hawa yadda ya kamata.

Manufa a cikin Tsarin Ƙarfafawa

Manufar farko nayawan shaye-shayeshi ne don tada iskar gas nesa da injin. Ta yin haka, yana taimakawa wajen kiyayewaingantaccen aikin injinkuma yana rage fitar da hayaki mai cutarwa. Manifold kuma yana taimakawakula da zafita hanyar watsar da yanayin zafi mai zafi da aka haifar yayin konewa.

Nau'o'in Ƙarfafa Manifold

Cast Iron Manifolds

Simintin ƙarfe na ƙarfe ya zama ruwan dare a cikin motoci da yawa. Waɗannan nau'ikan nau'ikan suna da dorewa kuma suna iya jure yanayin zafi. Gine-ginen simintin gyare-gyare yana ba da kyakkyawan juriya na zafi, yana sa waɗannan nau'ikan su zama abin dogaro don amfani na dogon lokaci.

Bakin Karfe Manifolds

Bakin karfe da yawa yana ba da ingantaccen aiki da tsawon rai. Waɗannan nau'ikan nau'ikan suna tsayayya da lalata kuma suna samar da mafi kyawun zubar da zafi idan aka kwatanta da simintin ƙarfe. Sau da yawa ana amfani da kayan aikin ƙarfe na ƙarfe a cikin manyan abubuwan hawa saboda ƙarfin ƙarfinsu.

Manifolds Performance

Manifolds na ayyuka, kuma aka sani da masu kai, an ƙirƙira su don haɓaka aikin injin. Waɗannan nau'ikan nau'ikan suna haɓaka kwararar iskar gas, rage matsa lamba na baya da haɓaka ingantaccen injin. Yawan aiki da yawa ana yin su ne daga abubuwa masu inganci kamar bakin karfe ko gami na musamman. Waɗannan nau'ikan nau'ikan galibi suna nuna suturar yumbu don ƙarin juriya na zafi.

Yaya Manifold Exhaust ke aiki?

Tarin Iskar Gas

Daga Injin Silinda

Wurin shaye-shaye yana tattara iskar gas daga silinda na injin. Kowace Silinda tana fitar da iskar gas bayan konewa. Manifold yana tattara waɗannan iskar gas yadda ya kamata. Wannan tsari yana tabbatar da cewa iskar gas mai cutarwa ba ta daɗe a cikin injin.

Jagoran zuwa bututun da aka cire

Wurin shaye-shaye yana jagorantar iskar gas da aka tattara zuwa bututun mai. Wannan matakin yana da mahimmanci don kiyaye kwararar iskar gas mai laushi. Manifold tashoshi na iskar gas nesa da injin. Wannan jagorar yana taimakawa wajen rage matsa lamba na baya, wanda zai iya rinjayar aikin injin.

Gudanar da Zafi

Rage zafi

Nau'in shaye-shaye yana taka muhimmiyar rawa wajen zubar da zafi. Manifold yana sha kuma yana tarwatsa yanayin zafi da aka haifar yayin konewa. Wannan kula da zafi yana hana dumama kayan injin. Ingantacciyar zubar da zafi kuma yana tsawaita tsawon rayuwar manifold.

Tasiri kan Ayyukan Injin

Gudanar da zafin da ya dace ta hanyar yawan shaye-shaye yana tasiri aikin injin daidai. Babban yanayin zafi na iya lalata sassan injin. Ƙarfin manifold don sarrafa zafi yana tabbatar da ingantaccen aikin injin. Wannan sarrafa yana taimakawa wajen kiyaye inganci da amincin injin.

Sarrafa fitarwa

Gudunmawar Rage Fitarwa

Rukunin shaye-shaye yana ba da gudummawa sosai ga sarrafa hayaki. Manifold yana tattarawa da sarrafa iskar gas da kyau. Wannan tsari yana rage yawan fitar da hayaki mai cutarwa a cikin muhalli. Ingantacciyar sarrafa hayaki yana taimakawa wajen bin ka'idojin muhalli.

Haɗin kai tare da Catalytic Converter

Rukunin shaye-shaye yana haɗawa ba tare da wani lahani ba tare da mai juyawa catalytic. Manifold yana jagorantar iskar gas zuwa mai canzawa don ƙarin aiki. Wannan haɗin kai yana tabbatar da cewa iskar gas masu cutarwa sun canza zuwa abubuwa marasa lahani. Haɗin ƙoƙarce-ƙoƙarce na ɗimbin yawa da mai canzawa yana rage yawan hayaƙin abin hawa gabaɗaya.

Matsalolin gama gari tare da Manifolds na ƙura

Cracks da Leaks

Dalilan kararraki

High thermal danniyasau da yawa yakan haifar da tsagewa a cikin magudanar ruwa. Zagayen dumama da sanyaya akai-akai suna raunana kayan akan lokaci. Wannan rauni na iya haifar da ci gaban fasa. Rashin ƙira ko lahani na masana'anta kuma na iya ba da gudummawa ga wannan batu.

Alamomin Leaks

Fitowar fitar da ruwa yana bayyana ta hanyoyi daban-daban. Faɗuwar faɗuwar aikin injin yakan nuna yabo. Hayaniyar da ba a saba gani ba, kamar juwa ko bugun sautuna, na iya faruwa. Tushen shaye-shaye da ke bayyane a ƙarƙashin murfin na iya sigina yayyo. Wani wari mai ƙonawa sau da yawa yana tare da waɗannan alamun.

Warping

Dalilan Warping

Warping yana faruwa saboda rashin daidaituwar dumama da sanyaya. Babban yanayin zafi yana sa ƙarfe ya faɗaɗa. Saurin kwantar da hankali sannan yana haifar da kumburi. Wannan sake zagayowar na iya karkatar da siffar magudanar ruwa. Shigar da ba daidai ba ko kayan da ba su da kyau na iya haifar da rikici.

Ganewa da Gyara

Gano warping yana buƙatar dubawa na gani. Nemo duk wani alamun murdiya ko rashin daidaituwa. Matsakaicin abin sha na iya haifarwagazawar gasket. Gyara warping sau da yawa ya ƙunshi sake farfado da ma'auni. A lokuta masu tsanani, maye gurbin zai iya zama dole.

Rashin Gasket

Muhimmancin Gasket

Gasket suna taka muhimmiyar rawa wajen rufe tarin shaye-shaye. Waɗannan abubuwan sun hana iskar gas daga zubowa. Daidaitaccen hatimi yana tabbatar da ingantaccen aikin injin. Gasket kuma suna taimakawa wajen kiyaye ƙa'idodin sarrafa hayaƙi.

Alamomin gazawar Gasket

Rashin gazawar Gasket yana nuna alamu da yawa. Rage aikin injin yakan nuna matsala. Ƙara ƙarar shaye-shaye kuma na iya nuna alamar matsalar gasket. Sot da ake iya gani a kusa da yankin gasket yana nuna yabo. Wani wari mai ƙonawa na iya rakiyar waɗannan alamun.

Tukwici na Kulawa da Gyara

Dubawa akai-akai

Abin da ake nema

Dubawa akai-akai na tarin shaye-shaye na taimakawa wajen kula da aikin injin. Nemo fashe-fashe ko ɗigo a bayyane. Bincika wasu kararraki da ba a saba gani ba, kamar su shuɗe ko taɗa sauti. Bincika duk wani alamun soot ko ƙamshi mai ƙonawa a kusa da wurin da yawa. Waɗannan alamomin sau da yawa suna nuna yiwuwar al'amura.

Yawan Dubawa

Gudanar da bincike na yawan shaye-shaye aƙalla sau biyu a shekara. Binciken akai-akai na iya zama dole don manyan ayyuka ko tsofaffin motocin. Binciken akai-akai yana taimakawa gano matsalolin da wuri, yana hana gyare-gyare masu tsada.

gyare-gyaren sana'a

Lokacin Tuntuɓar Makaniki

Tuntuɓi kanikanci idan akwai fashewar gani ko ɗigo a cikin mashin ɗin shaye-shaye. Hayaniyar da ba a saba gani ba ko ƙamshi mai ƙonawa shima yana ba da kulawar ƙwararru. Makanikai suna da ƙwarewa da kayan aikin don tantancewa da gyara al'amura da yawa yadda ya kamata.

La'akarin Farashi

Kudin gyare-gyare na ma'aunin shaye-shaye ya bambanta dangane da girman lalacewa. Ƙananan gyare-gyare, kamar maye gurbin gasket, ba su da tsada. Manyan gyare-gyare, kamar gyaran tsatsa ko maye gurbin da yawa, na iya zama mafi tsada. Zuba hannun jari a cikin gyare-gyaren lokaci yana hana ƙarin lalacewa da ƙarin kuɗi.

DIY Mai Kulawa

Tukwici Na Musamman na Kulawa

Yin gyare-gyare na asali a kan mashin ɗin yana taimakawa tsawaita rayuwar sa. A kai a kai tsaftace manifold don cire soot da tarkace. Tabbatar cewa kusoshi da gaskets suna amintacce. Guji yin amfani da tsattsauran sinadarai waɗanda za su iya lalata abubuwa da yawa.

Ana Bukata Kayan Aikin

Kayan aiki na yau da kullun don kiyaye nau'in shaye-shaye sun haɗa da saitin soket, maƙarƙashiya mai ƙarfi, da goge goge. Hasken walƙiya yana taimakawa bincika wuraren da ba a iya gani ba. Samun littafin gyare-gyare na musamman ga samfurin abin hawa yana ba da jagora mai mahimmanci.

Rukunin shaye-shaye yana taka muhimmiyar rawa a cikin tsarin sharar mota ta hanyar tattarawa da jagorantar iskar gas. Kulawa na yau da kullun da gyare-gyare na lokaci yana tabbatar da ingantaccen aikin injin da rage hayaki mai cutarwa. Yakamata a nemi taimakon ƙwararru don kowane fashe-fashe na bayyane, ɗigogi, ko ƙarar da ba a saba gani ba. Kulawar da ta dace na kayan shaye-shaye yana haɓaka ingancin abin hawa da tsawon rai.

Lokacin aikawa: Yuli-23-2024