Lokacin zurfafa cikin fagengm yawan simintin lambobi, fahimtar cikakkun bayanai masu rikitarwa ya zama mahimmanci. Muhimmancin yana cikin waɗannan lambobi, aiki azaman mahimman bayanai don buɗe asirai a bayaInjin Chevyaka gyara. Wannan shafin yanar gizon yana da nufin ba da haske a kan ainihin waɗannan lambobi, yana jagorantar masu sha'awar ta hanyar yin yanke shawara da ganowa.simintin lambobietted a kanmanyan injin ci. Ta hanyar fahimtar wannan muhimmin al'amari, mutane za su iya kewaya duniya naAbubuwan Injiniyatare da amincewa da daidaito.

Fahimtar Lambobin Casting Manifold GM

Lokacin bincika daularLambobin Castakan nau'ikan abubuwan da ake amfani da su na GM, dole ne mutum ya fahimci ainihin su don buɗe asirin da suke riƙe. Waɗannan lambobin suna aiki azaman masu gano mahimmanci, suna ba da fa'ida mai mahimmanci ga duniyar abubuwan injin.

Menene Lambobin Casting?

Ma'ana da Muhimmanci

TheLambar Yin Castakan nau'in abun sha shine mai ganowa na musamman wanda ke nuna asalinsa da ƙayyadaddun sa. Fahimtar waɗannan lambobi yana da mahimmanci don daidaitaccen ganewa da daidaitawa.

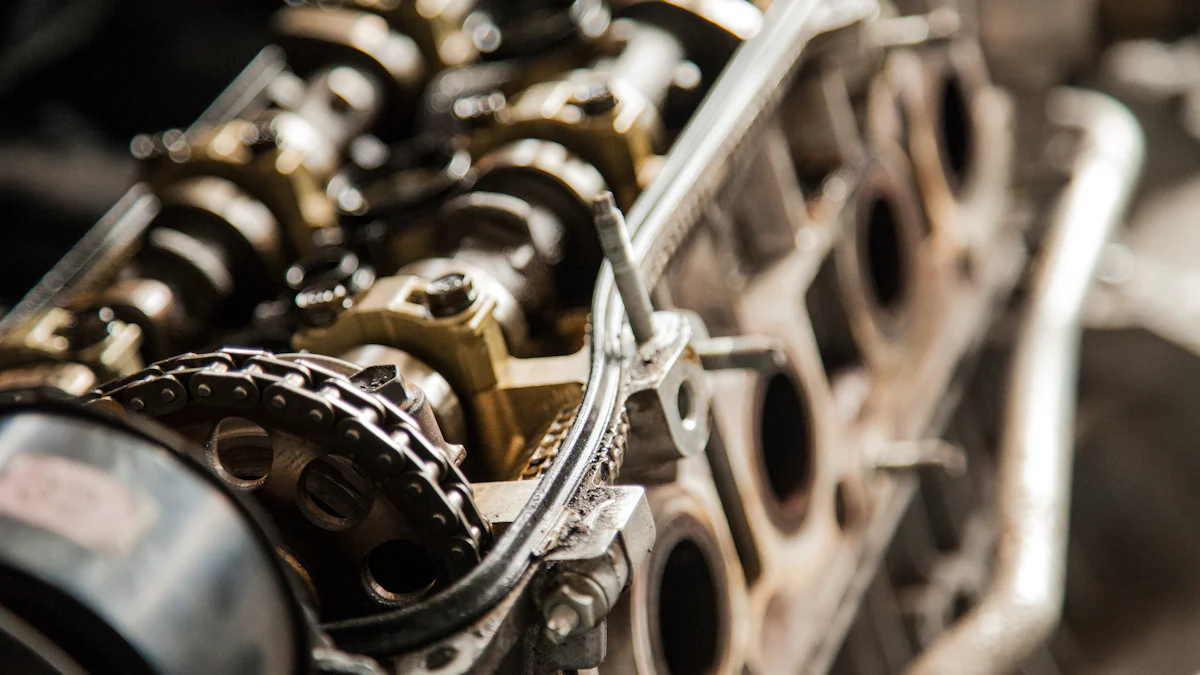

Wuraren gama gari akan Manifold

Lambobin Castyawanci suna cikin takamaiman wurare a kan manifold, kusa da ranar yin simintin gyare-gyare ko kusa da saman hawan carburetor. Gano waɗannan wuraren shine mabuɗin don yanke bayanan da suka bayar daidai.

Tarihin Lambobin Casting na GM

Juyin Halitta Tsawon Shekaru

Juyin Halitta naLambobin Casting GMyana nuna ci gaba a cikin fasahohin masana'antu da abubuwan da aka zaɓa sama da zamani daban-daban. Bibiyar waɗannan canje-canjen na iya ba da fa'idodi masu mahimmanci game da haɓakar nau'ikan abubuwan amfani da GM.

Sanannen Canje-canje da Sabuntawa

A cikin tarihi,Lambobin Casting GMsun sami sabuntawa mai mahimmanci don dacewa da canje-canjen fasaha da buƙatun kasuwa. Gane waɗannan canje-canje na iya taimaka wa masu sha'awar nuna takamaiman ƙira da lokutan samarwa.

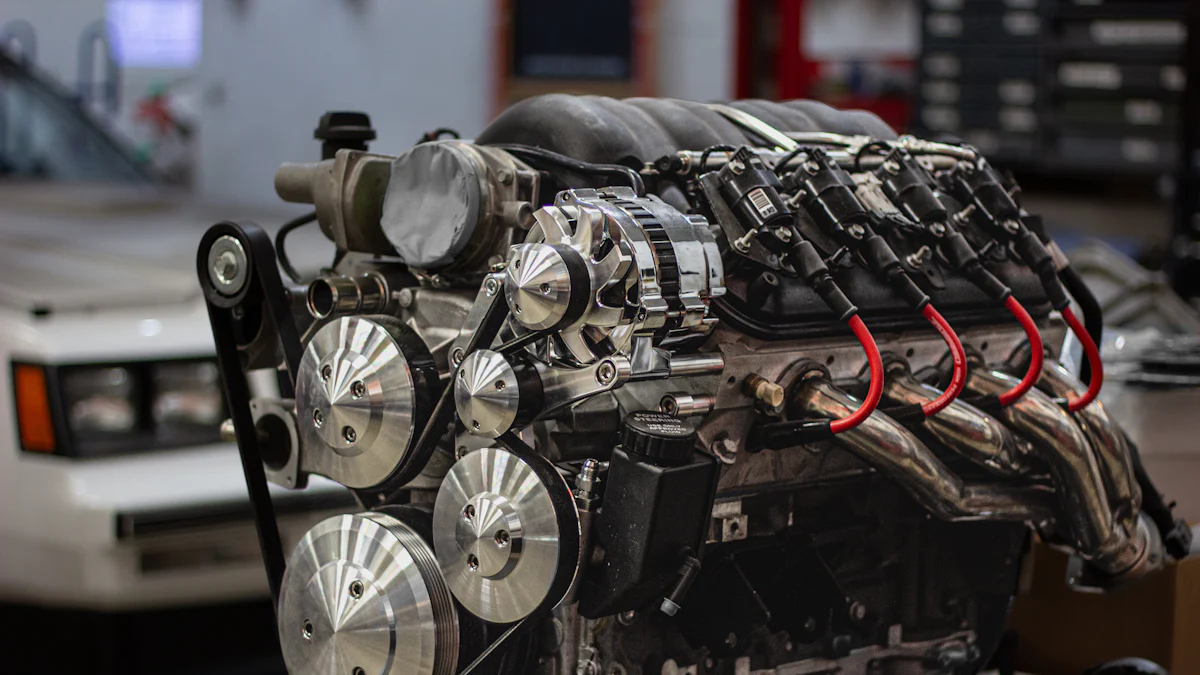

Nau'o'in Manifolds na GM

Samfura daban-daban da Lambobin Fim ɗin su

Daban-daban nau'ikan nau'ikan nau'ikan nau'ikan kayan abinci na GM an bambanta su ta musammanLambobin Cast, yana nuna takamaiman aikace-aikace da daidaitawa. Fahimtar waɗannan bambance-bambancen yana da mahimmanci don zaɓar madaidaitan maɓalli don saitin injin.

Gano Siffofin Kowane Samfura

Kowane nau'in nau'in cin abinci na GM yana alfahari da halaye daban-daban waɗanda suka bambanta shi da wasu dangane da aiki da dacewa. Ta hanyar gane waɗannan fasalulluka tare da daidaitattun suLambobin Cast, Masu sha'awar za su iya yanke shawarar yanke shawara lokacin zabar abubuwan da aka gyara.

Yadda ake Nemo Lambobin Casting

Ana Bukatar Kayan aiki da Kayan aiki

Kayan aiki na asali

- Fara da tsaftataccen wurin aiki.

- Yi amfani da walƙiya don ingantacciyar gani.

- Shirya saitin wrenches don cire da yawa.

- Yi alama ko alli a shirye don yiwa lambar simintin alama.

Manyan kayan aikin don lambobi masu wuyar karantawa

- Yi la'akari da yin amfani da gilashin ƙara girma ko ruwan tabarau don bincika cikakkun bayanai masu rikitarwa.

- Yi amfani da kyamarar dijital don ɗaukar lambar jefa don ƙarin bincike.

- Yi amfani da kayan aikin mai karanta lambar simintin musamman don tantance ainihin.

Jagorar Mataki-Ka-Taki

Ana shirya manifold

- Fara da tabbatar da cewa injin ya yi sanyi kafin sarrafa nau'in abin sha.

- Cire haɗin duk wani abu da aka haɗe, kamar hoses ko haɗin lantarki, don samun dama ga maɓalli cikin sauƙi.

- Taimaka wa injina amintacce don hana duk wani motsi na bazata yayin aiwatarwa.

Tsaftacewa da kuma duba saman

- Da kyautsaftace wurin da ake sha da yawata yin amfani da goge goge da goge waya don cire datti da datti.

- Bincika sararin samaniya a hankali don kowane alamun lalacewa, lalata, ko rashin daidaituwa wanda zai iya shafar iya karantawa.

- Shafa wurin da ke kusa da lambar simintin gyare-gyare tare da tsaftataccen zane don haɓaka gani.

Nemo da karanta lambar jefa

- Gano wurinlambar jefawa a saman abin shakusa da carburetor hawa surface.

- Yi amfani da isassun haske da haɓakawa idan ya cancanta don tantance ƙananan lambobi ko sawa daidai.

- Yi rikodin cikakken lambar simintin, gami da kowane prefixes ko kari, don tunani na gaba.

Yana Yanke Lambobin Simintin Samun Ciki Na GM

Tafsirin Lambobi

Fahimtar tsarin

- Fara da nazarin tsarinsimintin lambobidon bayyana ma'anarsu ta ɓoye.

- Gano jeri da tsari na lambobi don yanke mahimman bayanai game da babban fayil ɗin.

- Kula da kowane takamaiman tsari ko ƙa'idodi da aka yi amfani da su a cikin GMsimintin lambobidomin ingantacciyar tawili.

Magani na gama-gari da kari

- Gane mahimmancin prefixes da ƙari a cikiLambobin simintin gyare-gyare na GM iri-iri.

- Bambance tsakanin prefixes daban-daban da kari don tantance tasirinsu akan tantance sashe.

- Sanin kanku da prefixes gama gari da kari don daidaita tsarin yankewa.

Amfani da Kayayyakin Magana

GM Littattafai da Jagora

- Tuntuɓi jami'inGM manualsdon cikakkun bayanai a cikilambobin simintin abun sha da yawa.

- Koma zuwa jagororin da masana'anta suka bayar don yin bitar bitar ku da tabbatar da bincikenku yadda ya kamata.

- Yi amfani da littattafan GM azaman ingantaccen tushen bayanai don haɓaka fahimtar kusimintin lambobi.

Rukunin bayanai na kan layi da taron tattaunawa

- Bincika bayanan bayanan kan layi da aka keɓe don kasidaLambobin simintin gyare-gyare na GM iri-iridomin m tunani.

- Haɗa tare da dandalin kera motoci don yin amfani da ilimin gama kai da gwaninta wajen yanke hukunci mai rikitarwasimintin lambobi.

- Matsa cikin albarkatun kan layi don sabuntawa na ainihin-lokaci da tattaunawa ta hanyar al'umma akan gano nau'ikan ci na GM.

Matsalolin gama gari da magance matsala

Lambobin simintin gyare-gyaren da suka ɓace ko lalacewa

Dabaru don sabuntawa

- Yi amfani da hanya mai laushi mai laushi don maido da dusasheyin simintin gyare-gyarelambobi ba tare da haifar da lalacewa ba.

- Yi amfani da takarda mai laushi mai laushi ko ƙulli don cire iskar oxygen a hankali.

- Yi amfani da maganin tsaftacewa na musamman don haɓaka ganuwa da fitar da cikakkun bayanai nayin simintin gyare-gyarelambobi.

- Guji munanan sinadarai ko gogewa mai tsauri wanda zai iya ƙara lalacewayin simintin gyare-gyaretsabtar lamba.

Lokacin neman taimakon ƙwararru

- Yi la'akari da neman taimakon ƙwararru idan ƙoƙarin maidowa ya haifar da sakamako mara daɗi.

- Tuntuɓi ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararru ko ƙwararrun gyare-gyare don lallausanyin simintin gyare-gyaresabunta lamba.

- Yi la'akari da girman lalacewa da rikitarwa nayin simintin gyare-gyarelamba kafin yanke shawara kan sa baki na sana'a.

- Zaɓi don jagorar ƙwararru lokacin da ake mu'amala da mahimmin mahimmanci ko na tarihiyin simintin gyare-gyarelambobi.

Lambobin yaudara ko kuskure

Gano sassan jabu

- Bincika abubuwan da ba su da tsada masu rahusa waɗanda za su iya nuna jabuToshe Chevy Castinglambobi.

- Nemo rashin daidaituwa a cikin inganci, gamawa, ko abun da ke ciki wanda zai iya nuna alamar samarwa na jabu.

- Tabbatar da sahihancinFordsassa ta kwatantaToshe Castinglambobi tare da sanannun tushe ko bayanan bayanai.

- Yi taka tsantsan lokacin siyan abubuwan haɗin gwiwa tare da ƙananan farashin da ba a saba gani ba idan aka kwatanta da ƙa'idodin kasuwa.

Girke-girke tare da amintattun kafofin

- Tabbatar dayin simintin gyare-gyarelambobi ta hanyar giciye su tare da takaddun masana'anta ko kasida.

- Tuntuɓi masana masana'antu, taro, ko albarkatun kan layi don tabbatar da daidaito da sahihancin da aka ganoToshe Chevy Castinglambobi.

- Yi amfani da ƙaƙƙarfan abubuwan tunani don tabbatar da halaccinFordsassa dangane da daidaitattun abubuwan gano simintin su.

- Tabbatar da cikakken bincike da tabbatarwa daga amintattun tushe kafin kammala sayan sashe.

A taƙaice, fahimtar ƙaƙƙarfan cikakkun bayanai nasimintin lambobia kan nau'ikan kayan abinci na GM yana da mahimmanci ga masu goyon baya. Daidaitaccen tantance waɗannan lambobi yana ba da fahimi masu mahimmanci game da abubuwan injina da dacewarsu. Ta amfani da wannan bayanin don maidowa ko tabbatarwa, daidaikun mutane na iya tabbatar da daidaito a zaɓi da kulawa. Werkwell yana ƙarfafa masu karatu su bincika duniyarToshe Castinglambobi tare da amincewa kuma suna maraba da amsawa da tambayoyi don haɓaka raba ilimi a cikin al'umma.

Lokacin aikawa: Juni-27-2024