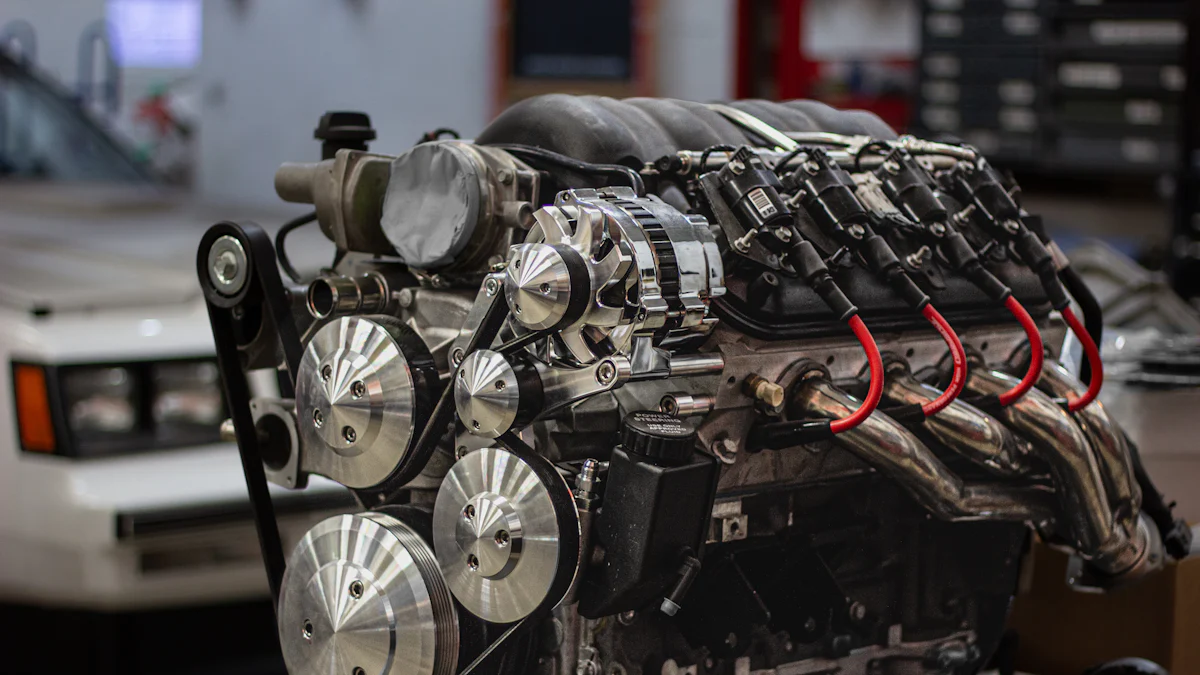

Muhimmancin fahimtaLS harmonic balancermasu girma dabamba za a iya wuce gona da iri. Tabbatar dadaidai daceyana da mahimmanci don ingantaccen aikin injin da tsawon rai. A cikin wannan cikakkiyar jagorar, masu karatu za su zurfafa cikin rikitacciyar duniyarinjin ma'aunin daidaitawakusoshi, bincika daidaitattun masu girma dabam, tasirin madaidaicin ƙima, da shawarwarin masana don zaɓi da kiyayewa.

Fahimtar LSHarmonic Balancer BoltGirman girma

Lokacin zurfafa cikin fagenLS harmonic balancer bolt sizes, ya bayyana cewa fahimtar ma'auni na daidaitattun ma'auni shine mahimmanci don ingantaccen aikin injin. Bari mu bincika masu girma dabam na injunan LS kuma mu rarraba nuances waɗanda ke bambanta waɗannan kusoshi a cikin nau'ikan iri daban-daban.

Daidaitaccen Girman Girma

Girman gama gari don Injin LS

- TheGM LS1/LS6injuna yawanci suna buƙatar aM16 x 2.0bola da a27mm wrenching sizekuma ankarkashin tsawon kai of 4.330".

- Don injunan Gen 3/4 LS kamar su4.8L, 5.3L, 5.7L, 6.0L, da 6.2L, a16mm x 2.0 GM Harmonic Balancer Boltana bada shawarar.

Bambance-bambance Tsakanin Samfura

- KowanneInjin LSsamfurin na iya buƙatar takamaiman girman ma'auni mai jituwa don tabbatar da dacewa daidai da aiki.

- Yana da mahimmanci don gano ainihin ƙayyadaddun bayanan da ake buƙata don bambance-bambancen injin ku na LS don guje wa batutuwan dacewa.

Muhimmancin Girman Madaidaicin

Tasiri kan Ayyukan Injin

- Yin amfani da daidaitaccen girman ma'aunin ma'auni na jituwa yana da mahimmanci kamar yadda yake tasiri kai tsaye da kwanciyar hankalin injin da aikin gaba ɗaya.

- Kullin da bai dace ba ko girmansa ba daidai ba zai iya haifar da girgiza, yana shafar ingancin injin kuma yana iya haifar da lalacewa na dogon lokaci.

Hana Lalacewa

- Zaɓin madaidaicin ƙarar ƙararrawa ba kawai yana haɓaka aiki ba har ma yana kiyayewa daga yuwuwar cutarwa ga abubuwan injina masu mahimmanci.

- Tabbatar da dacewakarfin juyi bayani dalla-dallaan hadu a lokacin shigarwa na iya hana batutuwa kamar zamewa ko rashin daidaituwa a cikin taron ma'auni masu jituwa.

Samar da Dama Bolt

Abubuwan da aka Shawarar

- Lokacin zabar ƙulli mai daidaita daidaiton jituwa, samfuran ƙira kamarWerkwellbayar da ingantattun zaɓuɓɓukan da aka tsara don saduwa da ƙaƙƙarfan matsayin masana'antu.

- Zaɓin amintaccen alama yana tabbatar da dorewa, ingantaccen aikin injiniya, da dacewa tare da nau'ikan injin LS iri-iri.

Inda za a saya

- Harmonic balancer bolts wanda aka keɓance don injunan LS ana samun su daga ɗimbin kantunan kan layi waɗanda ke ba da abinci ga masu sha'awar mota da ƙwararrun injiniyoyi.

- Ko neman maye gurbin OEM ko haɓaka ayyuka masu girma, ana iya samun waɗannan kusoshi cikin dacewa daga dillalai masu izini ko ƙwararrun dillalan mota.

Zabar Bolt Dama

Abubuwan da za a yi la'akari

Lokacin zabar wanda ya dacekusoshidon kusamfurin injin, yana da mahimmanci don kimanta takamaiman abubuwan da za su tabbatar da kyakkyawan aiki da tsawon rai. Fahimtar bambance-bambancen kowane bambance-bambancen injuna na iya jagorance ku wajen yin ingantaccen shawara wanda ya dace da buƙatun abin hawa.

Injin Model

Gano daidaiLS harmonic balancer bolt sizemai jituwa da ƙirar injin ku shine mataki na farko don haɓaka ayyukansa gaba ɗaya. Injunan LS daban-daban na iya buƙatar takamaiman ƙayyadaddun kusoshi don tabbatar da ingantaccen aiki da ingantaccen aiki. Ta hanyar yin nuni ga jagororin masana'anta ko tuntuɓar ƙwararrun kera motoci, zaku iya nuna ainihin girman guntun da ya yi daidai da ƙirar injin ku.

Bukatun Amfani

Yin la'akari da kubukatun amfaniyana da mahimmanci lokacin ƙayyade madaidaicin kullin don injin LS ɗin ku. Ko kuna amfani da abin hawan ku don zirga-zirgar yau da kullun, tseren waƙa, ko balaguron balaguro daga kan hanya, zaɓin kullin da ya dace da buƙatun halayen tuƙi yana da mahimmanci. Ya kamata a yi la'akari da abubuwa kamar ƙarfin ƙarfi, ƙarfin hali, da juriya ga abubuwan muhalli don tabbatar da ingantaccen aiki a ƙarƙashin yanayi daban-daban.

Kwatanta Kayayyakin Bolt

Lokacin bincikekayan kwalliyadon taron daidaita ma'auni na LS ɗinku, fahimtar bambance-bambance tsakanin zaɓin ƙarfe da gami na iya taimakawa wajen yin zaɓin da ya dace. Kowane abu yana ba da halaye na musamman waɗanda ke ba da buƙatun ayyuka daban-daban da la'akari da kasafin kuɗi.

Karfe vs. Alloy

- Karfe Bolts: An san su don ƙarfin su da ƙarfin ƙarfin ƙarfi, ƙananan ƙarfe na ƙarfe suna da fifiko don aikace-aikacen da ke buƙatar ƙwarewa na musamman da ƙarfin ɗaukar nauyi. Wadannan kusoshi sun dace don lokuta masu nauyi masu nauyi inda amintacce da tsawon rai ke da mahimmanci.

- Alloy Bolts: Alloy bolts suna da daraja don ginin su mara nauyi da kaddarorin juriya na lalata. Suna ba da ma'auni tsakanin ƙarfi da ajiyar nauyi, suna sa su dace da aikace-aikace inda rage girman taro ba tare da lalata tsarin tsarin yana da mahimmanci ba.

Ribobi da Fursunoni

- Karfe Bolts:

- Ribobi: Ƙarfi na musamman, dorewa, da araha.

- Fursunoni: Mafi nauyi fiye da kusoshi gami, mai saukin kamuwa da tsatsa idan ba a kiyaye shi da kyau ba.

- Alloy Bolts:

- Ribobi: Zane mai sauƙi, juriya na lalata, manufa don aikace-aikacen babban aiki.

- Fursunoni: Mafi girman farashi idan aka kwatanta da kusoshi na karfe, na iya buƙatar kayan aiki na musamman don shigarwa.

Shawarwari na Kwararru

Samun fahimta daga ƙwararrun ƙwararrun ƙwararru a cikin masana'antar kera motoci na iya ba da jagora mai mahimmanci lokacin zaɓar madaidaicin kullin don taron daidaita ma'aunin LS na ku. Yin amfani da shawarwarin ƙwararru daga gogewar injiniyoyi da shiga cikin tattaunawar zaure na iya ba da shawarwari masu amfani waɗanda suka dace da yanayin yanayi na zahiri.

Fahimtar Makanikai

Kwararrun injiniyoyi galibi suna raba nasiha masu mahimmanci akan zaɓin ma'aunin daidaita daidaiton jituwa dangane da gogewar hannayensu tare da nau'ikan injin LS daban-daban. Ƙwarewarsu a cikin dabarun shigarwa, ƙayyadaddun juzu'i, da la'akari da dacewa zasu iya taimaka muku kewaya tsarin ƙaƙƙarfan tsari na zabar ingantacciyar kusoshi don takamaiman buƙatun injin ku.

Tattaunawar Zaure

Shiga cikin tattaunawar dandali da aka keɓe ga injunan LS yana ba masu sha'awa da makanikai damar musanyar ilimi kan zaɓin ma'aunin ma'auni da shigarwa. Waɗannan dandamali suna aiki azaman cibiyoyi na bayanai inda ɗaiɗaikun ke raba bita-da-kullin samfur, shawarwarin magance matsala, da mafi kyawun ayyuka masu alaƙa da ci gaba da ingantaccen aikin injin ta hanyar zaɓin da ya dace.

Tukwici na Shigarwa da Kulawa

Dabarun Shigar Da Ya dace

Ana Bukatar Kayan Aikin

- A maƙarƙashiya mai ƙarfiyana da mahimmanci don daidaita madaidaicin ma'aunin daidaita daidaiton jituwa zuwa ƙayyadaddun masana'anta, tabbatar da aikin injin da ya dace.

- Saitin soket: Samun nau'i-nau'i iri-iri a cikin nau'i-nau'i daban-daban zai ba ku damar samun dama da kuma tabbatar da kullin tare da madaidaici.

- Makullin zaren: Aiwatar da makullin zaren akan zaren kulle kafin shigarwa na iya hana sassautawa saboda rawar jiki, haɓaka kwanciyar hankali gabaɗaya.

- Ratchet: Yin amfani da ratchet tare da saitin soket yana sauƙaƙa ingantaccen da sarrafa madaidaicin ma'aunin daidaitawa.

- Gilashin tsaro da safar hannu: Ba da fifiko ga aminci yayin shigarwa yana da mahimmanci, kuma sanya kayan kariya kamar tabarau da safar hannu suna kare ku daga haɗarin haɗari.

Jagorar Mataki-Ka-Taki

- Shirya filin aiki: Tabbatar injin yayi sanyi kafin fara aiki. Share duk wani shinge a kusa da wurin daidaita ma'aunin jituwa don samun sauƙi.

- Tabbatar da abin hawa: Kiki motar ku a kan matakin matakin sannan ku shiga birki don hana duk wani motsi yayin shigarwa.

- Nemo madaidaicin ma'auni mai jituwa: Gano ainihin matsayin ma'aunin ma'auni masu jituwa akan injin LS ɗin ku don samun niyya.

- Cire duk wani cikas: Idan ya cancanta, cire abubuwan da ke hana shiga kai tsaye zuwa madaidaicin ma'auni, kamar bel ko ja.

- Yi amfani da kayan aikin da suka dace: Zaɓi madaidaicin girman soket wanda yayi daidai da kai don gujewa zamewa ko lalacewa yayin ƙarawa.

- Aiwatar da makullin zaren: Kafin shigar da sabon bolt ɗin, sai a shafa ɗan makullin zaren a zaren sa don tabbatar da shi sosai.

- Ƙaddamar da ƙayyadaddun ƙiraYi amfani da maƙarƙashiya mai ƙarfi don ƙara ƙarar ma'auni mai jituwa bisa ga ƙayyadaddun buƙatun juzu'i wanda masana'antun injin ku suka ba da shawarar.

- Yi cak na ƙarshe: Bincika duk haɗin kai sau biyu, tabbatar da cewa babu wani abu da aka bar sako-sako ko ɓarna bayan an tabbatar da kullin daidaita ma'aunin jituwa.

- Gwajin aikin injin: Fara injin ku kuma saka idanu akan aikin sa bayan shigarwa don tabbatar da cewa komai yana aiki lafiya ba tare da wani girgiza ko sauti ba.

Kyawawan Ayyuka na Kulawa

Dubawa akai-akai

- Gudanar da duban gani na lokaci-lokaci na taron ma'aunin daidaitawar ku don gano duk wani alamun lalacewa, lalata, ko daidaitawa wanda zai iya nuna matsala masu yuwuwa.

- Bincika ga girgizar da ba ta dace ba yayin tuki, saboda wannan na iya zama farkon nunin sako-sako da ma'aunin daidaita daidaiton jituwa yana buƙatar kulawa nan take.

Alamomin Sawa

- Nemo ganuwa ko nakasar gani a saman taron ma'auni masu jituwa, yana nuna raunin tsari wanda zai iya lalata aikin sa akan lokaci.

- Kula da duk wasu kararrakin da ba a saba gani ba da ke fitowa daga mashin injin ku, saboda waɗannan na iya nuna matsalolin da ke da tushe tare da taron ma'aunin daidaitawar ku waɗanda ke buƙatar kimantawa cikin gaggawa.

Magance Matsalar gama gari

Sako da Bolts

- Idan kun lura da wani sako-sako a cikin taron ma'aunin daidaitawar ku, bincika da sauri kuma ku ja da baya bolts ta amfani da maƙarƙashiya mai ƙarfi don hana ƙarin rikitarwa.

- Magance saƙon kusoshi da sauri na iya hana girgizar da ta wuce kima wanda zai iya haifar da lalacewa a cikin tsarin injin ku.

Matsalolin Jijjiga

- Ci gaba da girgizawa yayin aikin injin zai iya nuna rashin daidaiton daidaiton daidaituwa wanda ya haifar da kuskure ko shigar da ma'aunin ma'auni ba daidai ba.

- Tuntuɓi ƙwararren makaniki idan kun fuskanci al'amuran girgizar ƙasa mai gudana bayan shigarwa don cikakken bincike da dabarun ƙuduri waɗanda suka dace da buƙatun ƙirar injin ku na LS.

- Don taƙaitawa, tabbatar da daidaiLS harmonic balancer bolt sizeyana da mahimmanci don ingantaccen aikin injin da tsawon rai. Daidaitaccen dacewa yana hana girgizawa da yuwuwar lalacewa, yana kiyaye mahimman abubuwan injin.

- Ƙaddamar da mahimmancin amfani da sabon kusoshi don saita ma'auni a kan crankshaft, tare da ƙayyadaddun buƙatun juzu'i, yana haɓaka kwanciyar hankali gaba ɗaya.

- Ci gaba, duban kulawa na yau da kullun da bin ƙa'idodin masana'anta don zaɓin kulle da shigarwa ana ba da shawarar don ɗaukan ingancin injin da amincin.

Lokacin aikawa: Juni-04-2024