Processum Prototyporum Revolutionantes

Prototypa Celeris

Celeritas et Efficacia

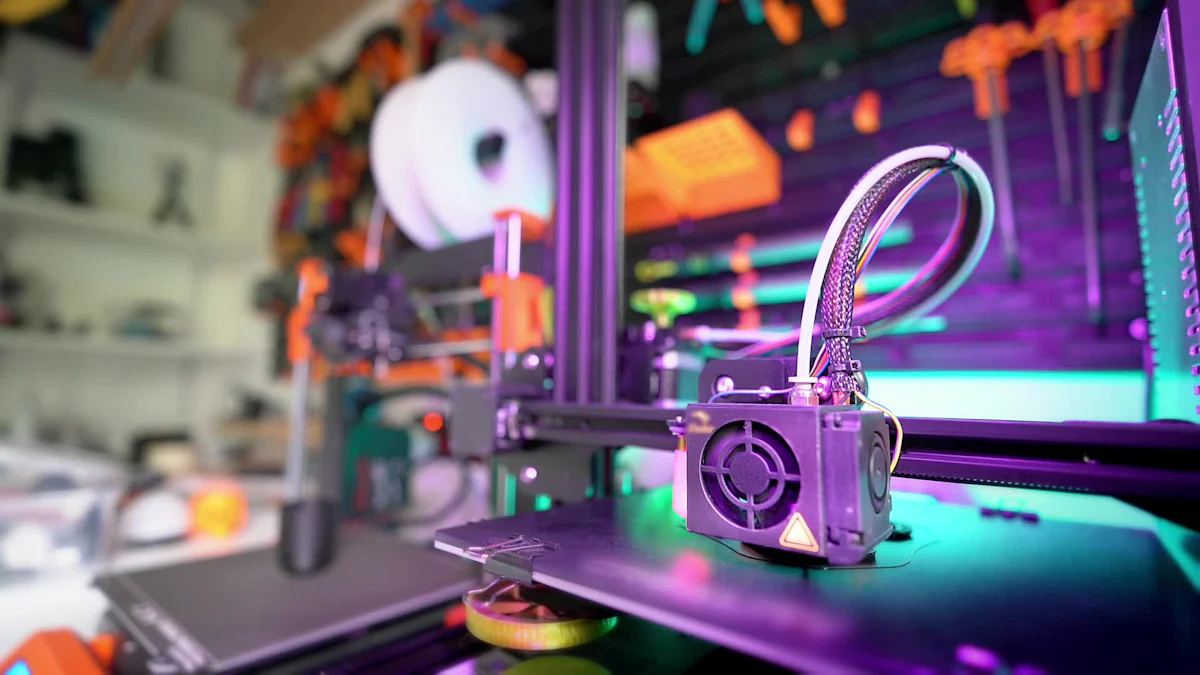

Technologia impressionis tridimensionalis processum prototyporum creationis in industria autocinetica accelerat. Methodi traditionales saepe longas et complexas rationes requirunt. Impressio tridimensionalis autem celerem creationem prototyporum directe ex delineationibus digitalibus permittit. Haec celeritas designatoribus autocineticis facultatem dat ut celeriter suas ideas probent et poliant. Facultas prototypa producendi intra horas vel dies potius quam hebdomades significanter tempora proiectorum auget.

Impensae Reductio

Efficientia sumptuum aliud commodum magnum impressionis tridimensionalis in prototypis repraesentat. Methodi prototyporum traditionales pretiosae esse possunt propter necessitatem instrumentorum et formarum specialium. Impressio tridimensionalis has necessitates eliminat, unde magnae sumptuum parsimoniae oriuntur. Reductio in iactura materiae etiam ad sumptus generales minores confert. Per...tempus productionis et minimizanset sumptibus, impressio tridimensionalis processum prototypi creationis magis accessibilem et sustinibilem reddit.

Designatio Iterativa

Flexibilitas in Mutationibus Designandi

Natura iterativa designandi magnopere prodest ex technologia impressionis tridimensionalis. Designatores autocinetorum facile adaptationes ad exempla digitalia facere et novas versiones imprimere possunt sine magnis dilationibus. Haec flexibilitas experimentationem et innovationem incitat. Designatores varias optiones designandi explorare et creationes suas optimizare possunt secundum responsa temporis realis. Facultas ad...celeriter in designiis iteraad producta meliora et exquisita ducit.

Examinatio in Mundo Reali

Impressio tridimensionalis (3D) probationes prototyporum in mundo reali faciliorem reddit, quod ad notiones designandi validandas maximi momenti est. Ingeniarii autocinetici prototypa functionalia creare possunt quae productum finale accurate imitantur. Haec prototypa probationes rigorosas sub variis condicionibus subire possunt ad efficientiam et durabilitatem aestimandam. Cognitiones ex probationibus in mundo reali acquisitae adiuvant ad problemata potentialia in initio processus evolutionis identificanda. Haec ratio proactiva efficit ut productum finale altis qualitatis et fidelitatis normis satisfaciat.

Applicationes in Ornamentis Interioribus Autocineticis

Customization in Ornatu Interiori Autocinetico

Designia Ad Personam Facta

Technologia impressionis tridimensionalis creationem designorum ad usum aptatorum in ornamentis interioribus autocinetorum permittit. Fabricatores tabulas interiores ad usum designatas et ornamenta exteriora singularia producere possunt quae perfecte praeferentiis singulorum clientium respondent. Hic gradus adaptationis permittit evolutionem partium visu iucundarum quae specificationibus exactis satisfaciunt. Exempli gratia, impressio tridimensionalis creare potest...consilia singularia tabularum instrumentorumet structurae ergonomicae sedium quae et pulchritudinem et commoditatem augent.

Proprietates Personales

Proprietates personalizatae aliud commodum magnum impressionis tridimensionalis in ornatu interiori autocinetico repraesentant. Haec technologia creationem accessionum in autocineto quae gustus singulorum reflectunt permittit. Emptores ex...ampla optionum varietasut vehicula sua personalizent. Hoc includit manubria transmissionis, manubria ostiorum, et alia elementa interiora ad libitum. Facultas offerendi tales res personales satisfactionem clientium auget et valorem vehiculo addit.

Libertas Designandi in Ornatu Interiori Autocinetico

Geometriae Complexae

Impressio tridimensionalis libertatem designandi incomparabilem praebet, creationem geometriarum complexarum in ornamentis interioribus autocinetorum permittens. Methodi fabricationis traditionales saepe cum formis intricatis et exemplaribus subtilibus laborant. Attamen impressio tridimensionalis facile partes cum angulis et dimensionibus complexis producere potest. Haec facultas designatoribus autocinetorum permittit ut designia nova explorent quae antea impossibile erat assequi. Resultatum est interior dynamicior et visu magis conspicuus.

Aesthetica Innovativa

Aesthetica nova per technologiam impressionis tridimensionalis (3D) obtineri potest. Designatores texturas, figuras, et ornamenta nova experiri possunt quae aspectum generalem interioris vehiculi amplificant. Usus materiarum provectarum, ut...Polyamidum (PA)Acrylonitrilum Butadienum Styrenum (ABS) autem possibilitates amplius amplificat. Hae materiae permittunt productionem partium cum singularibus qualitatibus visualibus et tactilibus. Facultas innovandi in terminis aestheticae ornamenta interiora autocinetica impressa tridimensionaliter ab optionibus traditis distinguit.

Versatilitas Materialium in Ornamentis Interioribus Autocineticis

Usus Variarum Materiarum

Versatilitas materiarum ad impressionem tridimensionalem praesto magnopere prodest ornamentis interioribus autocinetorum. Fabricatio additiva amplam varietatem materiarum offert, quae variis partibus interioribus autocinetorum aptae sunt. Polyamidum (PA) adhiberi potest pro manubriis ostiorum et manubriis transmissionis, dum Acrylonitrilum Butadienum Styrenum (ABS) ideale est pro tabulis instrumentorum et ornamentis ostiorum. Technologia etiam progressa est ad producendas partes cum texturis et figuris, utens textili impressione tridimensionali. Haec versatilitas materiarum efficit ut quaeque pars specificis requisitis functionalibus et aestheticis satisfaciat.

Optiones Sustinebiles

Sustentabilitas magni momenti consideratio in hodierna fabricatione autocinetica repraesentat. Impressio tridimensionalis hoc propositum sustinet offerendo optiones materiarum sustentabilium. Exempli gratia, fabri plastica rediviva aliasque materias ecologicas ad partes ornatus interioris producendas uti possunt. Haec methodus superflua minuit et impulsum productionis in ambitum imminuit. Facultas incorporandi materias sustentabiles cum crescente postulatione solutionum autocineticarum environmentaliter responsabilium congruit.

Impactus in Scalabilitatem Productionis et Efficaciam Impensarum

Productio Efficax

Augmentatio Productionis

Technologia impressionis tridimensionalis scalabilitatem productionis in industria autocinetica auget. Methodi fabricationis traditionales saepe longa tempora praeparationis et instrumenta specialia requirunt. Impressio tridimensionalis has difficultates eliminat, permittens fabricatoribus productionem celeriter augere. Societates autocineticae magnas quantitates partium ornatus interioris sine mora significanti producere possunt. Haec facultas efficit ut productio postulationi mercatus efficaciter satisfaciat.

Reductio Vastorum

Reductio iacturae commodum criticum impressionis tridimensionalis repraesentat. Processus fabricationis traditionales saepe magnam materiam iacturam generant propter artes secandi et formandi. Impressio tridimensionalis autem partes stratis stratis construit, solum utens...necessaria materiae quantitasHaec methodus iacturam ad minimum reducet et effectum productionis in ambitum deminuit. Facultas creandi partes cum minima iactura cum rationibus fabricationis sustinibilibus congruit.

Fabricatio Efficax Impensarum

Sumptus Materialium Minores

Impressio tridimensionalis (3D) magnas sumptus conservat in usu materiarum. Fabricatio traditionalis saepe materias caras et catenas commeatus complexas requirit. Impressio tridimensionalis varietatem materiarum sumptuum efficacium, inter quas polymera et composita, adhibet. Hae materiae necessariam robur et firmitatem pro ornamentis interioribus autocinetorum praebent. Impensae materiarum inferiores impressionem tridimensionalem optionem attractivam faciunt fabricatoribus autocinetorum qui sumptus reducere volunt.

Sumptus Laboris Reducti

Sumptus laboris insigniter minuuntur cum usu impressionis tridimensionalis. Fabricatio traditionalis operarios peritos requirit ad opera qualia sunt machinatio, congregatio, et qualitas inspiciendo. Impressio tridimensionalis multos horum processuum automatat, necessitatem interventionis manualis minuens. Haec technologia permittit productionem partium complexarum cum minima supervisione humana. Haec automatio ad sumptus laboris inferiores et efficientiam productionis auctam ducit.

Impressio tridimensionalis (3D) industriam autocineticam magnopere affecit, praesertim in campo ornamentorum interiorum autocinetorum. Haec technologia prototypa creando per celeritatem, efficientiam, et sumptus minuendos mutavit. Adaptatio ad necessitates personales, libertas designandi, et versatilitas materiarum designia ad necessitates accommodata et pulchritudinem novam permiserunt. Scalabilitas productionis et efficacia sumptuum munus impressionis tridimensionalis in fabricatione autocinetica ulterius confirmaverunt.

Thepotentia futuraUsus impressionis tridimensionalis in ornatu interiori autocinetico adhuc promittit. Innovationes in materiis et technis progressus in designio, effectu, et sustentatione impellere pergent. Integratio impressionis tridimensionalis progressionem productorum expeditabit et transformationem ulteriorem in industria promovebit.

Tempus publicationis: Kal. Aug. anni MMXXIV