High-performance dampers, such as Harmonic Balancers and High Performance Dampers, play a crucial role in various applications, from industrial settings to civil engineering structures. You might find it surprising that these components, like the Engine Harmonic Balancer, significantly enhance performance and safety. Angela Flowers, a leading expert, emphasizes their importance in controlling airflow and reducing vibrations. Apparently, Angela’s insights reveal how these dampers contribute to energy efficiency and safety. Stand-Out Employees in the industry, like Angela, have Accidentally Discovered innovative ways to improve the effectiveness of Harmonic Balancers. As you explore this blog, you’ll uncover the key characteristics that make these High Performance Dampers stand out in their field.

Branding and Competition

In the world of high-performance dampers, standing out is crucial. You need to build a strong brand that resonates with your audience. This involves creating a unique identity that sets you apart from the competition. Yamaha Motor, for instance, has successfully established its Performance Dampers as a benchmark in the industry. Their focus on “chassis viscosity” and innovative technology has made them a leader in providing high-quality driving experiences. By optimizing their products for each vehicle, they ensure that their dampers deliver unmatched comfort and stability.

Importance to Stand Out

Building a Strong Brand

To build a strong brand, you must focus on the key features of branding. This includes developing a clear message that communicates the benefits of your product. For example, Werkwell emphasizes the combination of top-quality and affordability in their dampers. This approach not only attracts customers but also builds trust and loyalty. You should also pay attention to the visual aspects of your brand. Using a distinct color scheme and design can help your product stand out in a crowded market.

Brand awareness plays a significant role in establishing your presence. By consistently delivering on your promises, you can avoid wrongful termination claims and maintain a positive reputation. Fluidampr, trusted by leading OEMs, showcases how maintaining high standards and proven experience can enhance brand awareness. Their ISO 9001:2015 certified quality standards and modern design have made them a preferred choice in various industries.

Competing in the Market

Competing in the market requires you to stay ahead of the curve. You need to be aware of the latest trends and innovations. Yamaha Motor’s commitment to protecting their intellectual property rights highlights the importance of safeguarding your unique features. By doing so, you can prevent others from copying your ideas and maintain a competitive edge.

Understanding the competition is vital. You should analyze their strengths and weaknesses to identify opportunities for improvement. This awareness allows you to refine your strategies and offer better solutions. In a market where everyone is vying for attention, being BAD (Bold, Ambitious, and Distinctive) can make all the difference. By focusing on these aspects, you can ensure that your brand remains relevant and continues to thrive.

Understanding Harmonic Balancers and High Performance Dampers

When you explore the world of high-performance dampers, understanding their ordinary physical features becomes essential. These features define their functionality and efficiency. Let’s delve into the main components and build quality that make these dampers stand out.

Ordinary Physical Features

Main Components

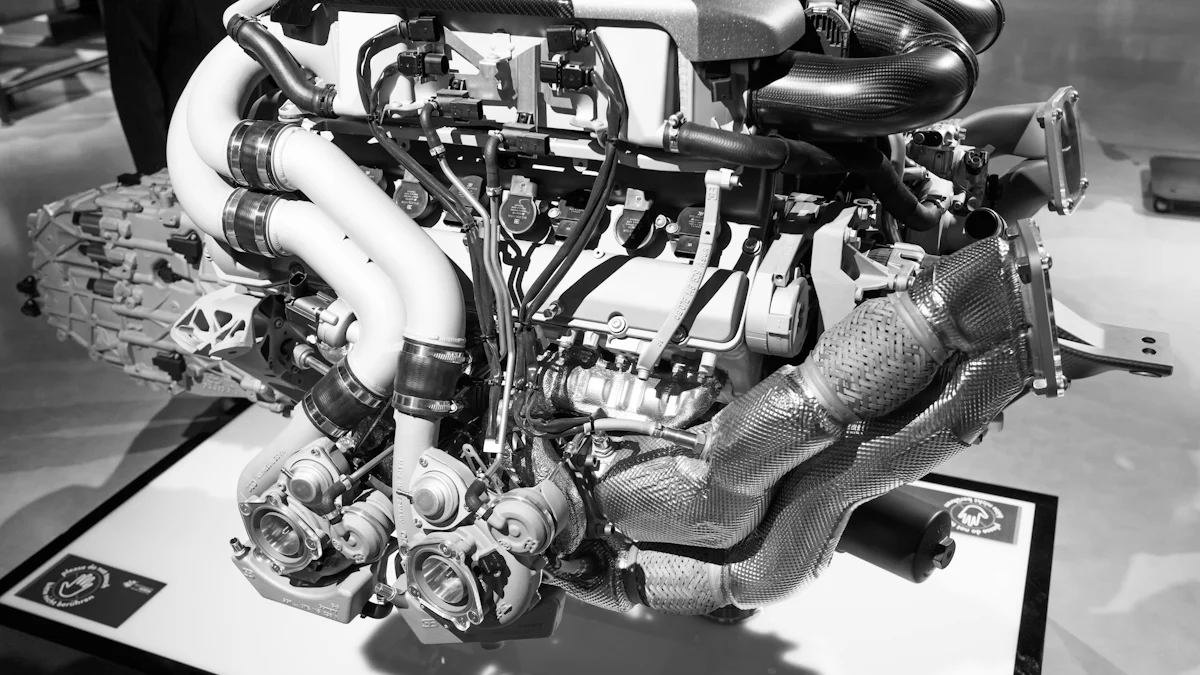

High-performance dampers, like harmonic balancers, consist of several key components. You will find that the inertia ring, hub, and elastomer are crucial parts. The inertia ring rotates harmonically with the engine, absorbing torsional vibrations. This action enhances the engine’s performance and longevity. The hub connects the damper to the crankshaft, ensuring stability. The elastomer acts as a cushion, reducing vibrations and noise. These components work together to provide optimal performance.

“The High Performance Harmonic Balancer is engineered to enhance performance by effectively eliminating torsional crankshaft vibrations.” – Curiositiesyear

Understanding these components helps you appreciate the damper’s role in improving engine efficiency. You can see how each part contributes to the overall functionality. This knowledge empowers you to make informed decisions when selecting dampers for your needs.

Build Quality

The build quality of high-performance dampers is another critical aspect. You should look for dampers made from high-quality materials like steel. Steel offers durability and strength, essential for withstanding high-performance applications. The bonding process used in these dampers ensures a secure attachment of the elastomer to the inertia ring and hub. This process enhances the damper’s reliability and effectiveness.

Precision CNC machining is a hallmark of superior build quality. It ensures that each component fits perfectly, reducing the risk of failure. You will notice that dampers with clear timing marks allow for easy adjustments and monitoring. This feature is particularly beneficial for those who demand precision in their applications.

“Crafted from high-quality steel, this balancer features a unique bonding process that securely adheres the elastomer.” – Curiositiesyear

When evaluating build quality, consider the manufacturing standards. Look for dampers that meet industry specifications, such as SFI Specification 18.1. These standards guarantee that the product has undergone rigorous testing and meets safety requirements. By choosing dampers with excellent build quality, you ensure long-term performance and reliability.

Durability and Longevity

When selecting a High Performance Damper, durability and longevity are crucial factors to consider. These characteristics ensure that your Harmonic Balancer or High Performance Damper withstands the test of time and maintains optimal functionality.

Material Quality

Corrosion Resistance

You should prioritize dampers made from materials that resist corrosion. Corrosion can significantly reduce the lifespan of a Harmonic Balancer. High-quality steel, often used in High Performance Dampers, provides excellent corrosion resistance. This material choice ensures that your damper remains effective even in harsh environments. By selecting a damper with superior corrosion resistance, you protect your investment and ensure long-term performance.

Wear and Tear Resistance

Wear and tear resistance is another vital aspect of material quality. Harmonic Balancers and High Performance Dampers must endure constant stress and vibrations. Materials like zinc powder and copper powder particles have shown commendable performance in mitigating vibrations, as highlighted in recent studies. These materials enhance the damper’s ability to withstand wear and tear, ensuring that it continues to function effectively over time. By choosing a damper with high wear and tear resistance, you minimize the risk of premature failure and maintain consistent performance.

Manufacturing Standards

Quality Control Processes

Quality control processes play a significant role in the durability of Harmonic Balancers. You should look for manufacturers that implement rigorous quality control measures. These processes ensure that each High Performance Damper meets the highest standards of excellence. By adhering to strict quality control protocols, manufacturers can identify and rectify potential issues before the product reaches you. This attention to detail guarantees that you receive a reliable and durable damper.

Certification and Compliance

Certification and compliance with industry standards are essential for ensuring the longevity of Harmonic Balancers. Look for dampers that meet recognized specifications, such as SFI Specification 18.1. These certifications indicate that the damper has undergone extensive testing and meets safety and performance requirements. By choosing certified High Performance Dampers, you can trust that they will deliver consistent results and stand up to demanding applications.

Performance Efficiency

When you consider high-performance dampers, their efficiency in absorbing energy and responding to changes is crucial. These features ensure that the dampers perform optimally under various conditions, enhancing the overall system’s effectiveness.

Energy Absorption

Shock Absorption Capabilities

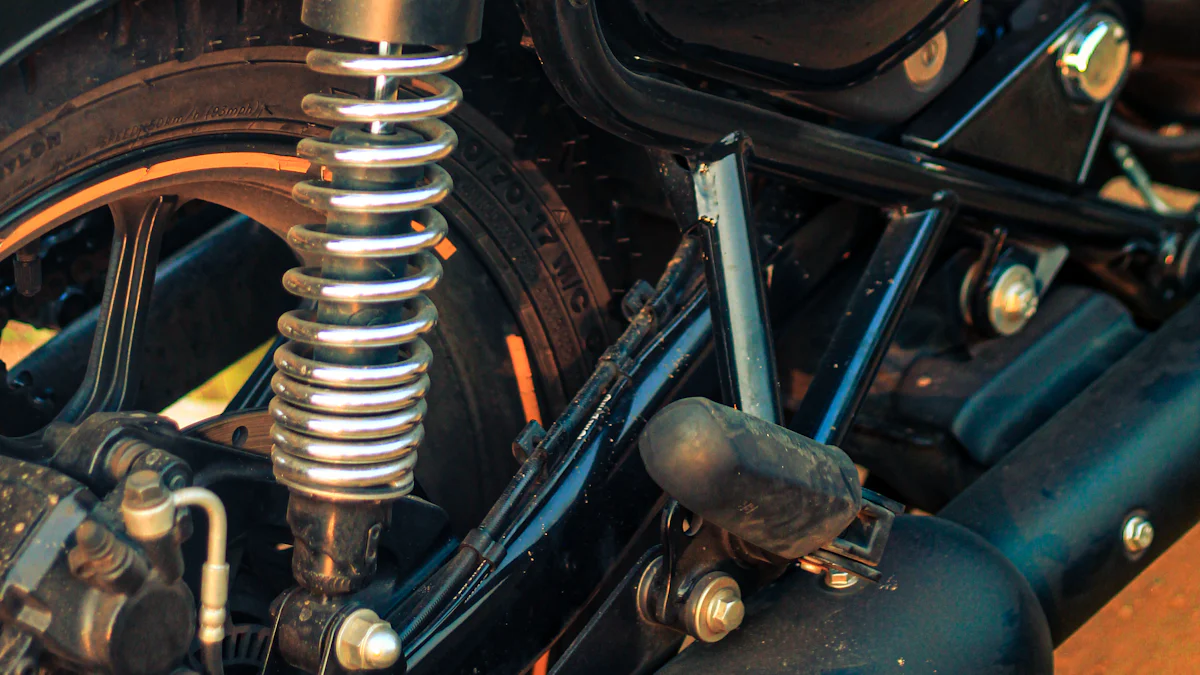

High-performance dampers excel in shock absorption. They reduce the impact of sudden forces, protecting the structure or machinery they serve. For instance, knitted mesh dampers significantly decrease vibration transmission. This capability is vital in preventing potential problems that could affect the yield, safety, and service life of structures and machines. By choosing dampers with superior shock absorption, you ensure that your systems remain stable and efficient.

Vibration Dampening

Vibration dampening is another critical aspect of energy absorption. Effective dampers minimize vibrations, enhancing the comfort and safety of the environment. You might find it interesting that dampers can be retro-fitted or specified during the design phase. This flexibility allows you to anticipate and prevent issues before they arise. By selecting dampers with excellent vibration dampening, you contribute to a smoother and more reliable operation.

Response Time

Quick Reaction to Load Changes

The ability to react quickly to load changes is essential for high-performance dampers. You need dampers that can adjust rapidly to varying conditions, maintaining stability and performance. The crank hub dyno, a popular testing method, demonstrates how dampers can generate accurate results by altering their velocity. This quick reaction ensures that your systems remain responsive and efficient, even under dynamic conditions.

Consistency in Performance

Consistency in performance is equally important. You want dampers that deliver reliable results over time, regardless of the circumstances. The durability testing systems subject dampers to millions of cycles, ensuring they withstand high inertial loading. This rigorous testing guarantees that your dampers maintain their performance, providing you with peace of mind and long-term reliability.

Incorporating these characteristics into your selection process ensures that you choose dampers that stand out in performance efficiency. By focusing on energy absorption and response time, you enhance the overall effectiveness of your systems.

Customization and Adaptability

In the realm of high-performance dampers, customization and adaptability are pivotal. You need dampers that can be tailored to meet specific requirements and adapt to various applications. This section explores how design flexibility and application versatility contribute to the standout features of these dampers.

Design Flexibility

Tailored Solutions for Specific Needs

High-performance dampers offer customizable solutions to address unique challenges. You can select from a range of customizable styles to suit your specific needs. For instance, Custom-Made Knitted Mesh Dampers have been designed for harsh industrial environments. These dampers meet strict requirements for damping performance and installation space. By choosing a damper that fits your exact specifications, you ensure optimal performance and efficiency.

“Designing anti-vibration isolators for extreme conditions demonstrates adaptability and customization in damper design.”

Tailored solutions allow you to address specific issues, such as vibration control or noise reduction. This customization ensures that the damper performs effectively in your particular application. By opting for a damper that meets your precise needs, you enhance the overall functionality of your system.

Modular Components

Modular components play a crucial role in the adaptability of high-performance dampers. You can easily modify or upgrade these components to meet changing requirements. Versatile and Adaptable Industrial Dampers feature a modular structure that allows for customization. This design enables you to adjust the damper’s configuration to suit different applications.

“Designed with modular structure for customization emphasizes adaptability and versatility in damper design.”

Modular components provide flexibility, allowing you to adapt the damper to various conditions. This adaptability ensures that the damper remains effective, even as your needs evolve. By incorporating modular components, you can maintain the damper’s performance and extend its lifespan.

Application Versatility

Use in Various Industries

High-performance dampers excel in diverse industries, from automotive to aerospace. You can find dampers that are suitable for a wide range of applications. The Innovative Knitted Mesh Vibration Dampers Case Study highlights exceptional performance in real-life scenarios. These dampers showcase their adaptability and effectiveness in controlling vibrations across different sectors.

“Highlighting exceptional performance in real-life scenario demonstrates ground-breaking capabilities in controlling vibrations.”

By selecting dampers that are versatile, you ensure that they can be used in multiple settings. This versatility enhances the damper’s value, making it a worthwhile investment for various industries.

Compatibility with Different Systems

Compatibility with different systems is another key aspect of application versatility. You need dampers that can integrate seamlessly with existing setups. This compatibility ensures that the damper functions effectively without requiring extensive modifications. By choosing dampers that are compatible with different systems, you simplify the installation process and reduce potential issues.

Incorporating customization and adaptability into your selection process ensures that you choose dampers that meet your specific needs. By focusing on design flexibility and application versatility, you enhance the overall effectiveness and longevity of your systems.

Maintenance and Ease of Use

When you choose high-performance dampers, maintenance and ease of use become essential considerations. These factors ensure that your dampers remain efficient and reliable over time, minimizing disruptions and maximizing productivity.

User-Friendly Design

Simple Installation Process

You will appreciate a damper with a simple installation process. A straightforward setup saves time and reduces the likelihood of errors. Many manufacturers provide comprehensive Docs to guide you through the installation. These Docs often include step-by-step instructions and diagrams, making the process accessible even if you’re not an expert. By following these guides, you can ensure that your dampers are installed correctly and function optimally from the start.

Intuitive Operation

Once installed, the damper’s operation should be intuitive. You want a system that requires minimal training and can be easily understood by all users. Clear labeling and user-friendly controls contribute to this ease of use. Whether you’re using Microsoft Office or Apple Pages to manage your maintenance schedules, having intuitive dampers simplifies your workflow. This simplicity allows you to focus on other critical tasks without worrying about complex operations.

Low Maintenance Requirements

Self-Lubricating Features

High-performance dampers often come with self-lubricating features. These features reduce the need for frequent maintenance, saving you time and effort. Self-lubricating dampers ensure smooth operation and prolong the lifespan of the components. By choosing dampers with these features, you minimize the risk of wear and tear, keeping your systems running efficiently.

Minimal Downtime

You aim to achieve minimal downtime with your dampers. Reliable dampers require less frequent servicing, allowing your operations to continue uninterrupted. Regular Consulting with experts can help you maintain your dampers in top condition. For instance, a satisfied customer shared their experience with DuctWork Pro, highlighting the technicians’ expertise and attention to detail. They appreciated the clear explanations and recommendations provided, which ensured their fire dampers remained in perfect working condition.

“The peace of mind knowing that the building is up to code and that the fire dampers are functioning properly is invaluable.”

By prioritizing low maintenance requirements, you ensure that your dampers deliver consistent performance with minimal disruptions. This focus on maintenance and ease of use enhances the overall value of your investment, providing you with reliable and efficient solutions.

Cost-Effectiveness

When you evaluate high-performance dampers, cost-effectiveness becomes a crucial factor. Understanding how these dampers can save you money in the long run is essential.

Long-Term Savings

Reduced Replacement Frequency

High-performance dampers offer durability, reducing the need for frequent replacements. You benefit from a product that lasts longer, saving you money over time. Employees in industries that rely on these dampers appreciate their longevity. They know that fewer replacements mean less downtime and lower costs. This reliability ensures that your operations continue smoothly without unexpected expenses.

Energy Efficiency

Energy efficiency is another significant advantage of high-performance dampers. These dampers optimize energy use, leading to lower utility bills. You will notice a reduction in energy consumption, which translates to cost savings. The economic efficiency of systems like the Magneto-Rheological (MR) damper system highlights this benefit. By choosing energy-efficient dampers, you contribute to a more sustainable operation while saving money.

Value for Money

Balance Between Cost and Performance

Finding the right balance between cost and performance is vital. You want a damper that delivers excellent performance without breaking the bank. High-performance dampers achieve this balance by offering superior functionality at a reasonable price. Employees who manage budgets appreciate this balance, as it allows them to allocate resources effectively. By investing in dampers that provide value for money, you ensure that your systems perform optimally without overspending.

Return on Investment

A good return on investment (ROI) is essential when selecting dampers. You want to see tangible benefits from your purchase. High-performance dampers deliver a strong ROI by enhancing system performance and reducing maintenance costs. The cost-effectiveness index of systems like the MR damper system demonstrates their value. By investing in these dampers, you ensure that your money is well spent, leading to long-term savings and improved performance.

Incorporating cost-effectiveness into your decision-making process ensures that you choose dampers that offer both financial and operational benefits. By focusing on long-term savings and value for money, you make a wise investment that enhances your systems’ efficiency and reliability.

In this blog, you explored the essential characteristics that make high-performance dampers, like the Engine Harmonic Balancer, stand out. These features include durability, performance efficiency, and adaptability. Choosing the right dampers is crucial for optimal performance in various applications, from industrial settings to Small Business operations. You should consider these characteristics when selecting dampers to ensure they meet your specific needs. Whether you’re discussing on Reddit or sharing insights on Social media, understanding these key aspects will help you make informed decisions. Remember, the right choice can enhance your Family’s safety and efficiency.

Post time: Oct-28-2024