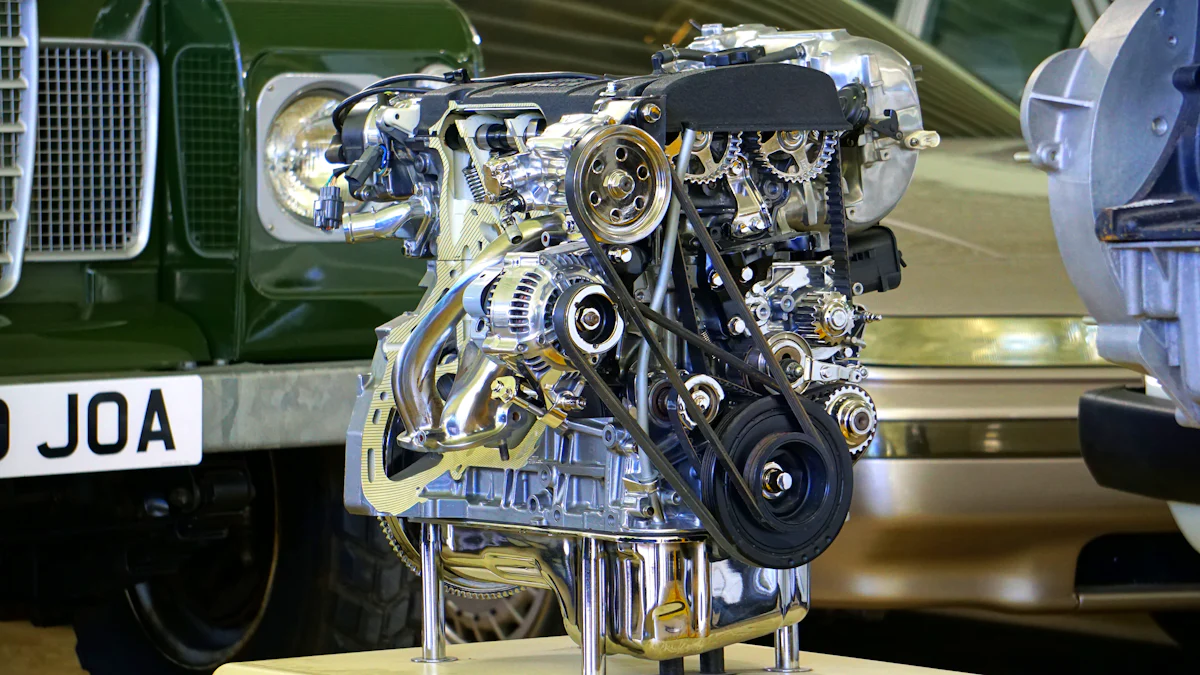

In the realm of car performance, the aluminum intake manifold stands as a pivotal component. Its lightweight nature, coupled with strength and corrosion resistance, makes it a top choice for racers seeking optimal efficiency. As vehicles evolve towards sustainability, the demand for aluminum intake manifolds continues to rise steadily. These manifolds play a crucial role in enhancing engine performance by optimizing airflow distribution. Amid debates on heat absorption and weight variances, the aluminum variant remains a frontrunner in discussions on power gains.

Benefits of Aluminum Intake Manifolds

Aluminum intake manifolds offer a significant advantage in terms of lightweight properties. The impact on vehicle weight and performance is undeniable, with aluminum being approximately one-third the weight of steel. This difference contributes to enhanced speed and agility on the road.

When compared with other materials like plastic, aluminum intake manifolds stand out for their added strength and modification ability. While aluminum may be heavier than plastic, its durability and adaptability make it the ideal choice for applications requiring a boost or nitrous injection. On the other hand, composite intakes excel in naturally aspirated (N/A) setups.

In addition to their lightweight nature, aluminum intake manifolds provide cost-effectiveness benefits that extend beyond manufacturing costs. Despite initial expenses, the long-term savings associated with aluminum manifolds are substantial. Their durability and minimal maintenance requirements translate to extended lifespan and reduced replacement costs over time.

The improved flow characteristics of aluminum intake manifolds play a crucial role in optimizing engine performance. By enhancing the air/fuel mixture within the manifold, these components contribute to increased power output and efficiency across various driving conditions. Whether cruising on highways or pushing limits on racetracks, the superior flow dynamics of aluminum manifolds ensure consistent performance gains.

Designs and Materials

Common Aluminum Alloys

356 Aluminum Alloy

- Lightweight and versatile, the 356 Aluminum Alloy stands out for its exceptional weldability and heat-treatable properties.

- Ideal for high-performance applications, this alloy offers a perfect balance of strength and formability.

Other popular alloys

- Among the array of aluminum alloys available, options like 3003, 2024, 6061, and 7075 are commonly utilized in racing components.

- Each alloy brings unique characteristics to the table, catering to specific requirements in terms of strength, fabricability, and corrosion resistance.

Advanced Manufacturing Techniques

3D-Printed Aluminum Manifolds

- Embracing innovation, the realm of automotive engineering has witnessed a surge in 3D-printed aluminum manifolds.

- This cutting-edge technique allows for intricate designs and precise customization, pushing the boundaries of performance optimization.

CNC Machining

- Precision meets efficiency with Computer Numerical Control (CNC) machining techniques applied to aluminum intake manifolds.

- Through meticulous programming and automated processes, CNC machining ensures unparalleled accuracy and consistency in manifold production.

Real-World Applications

High-Performance Vehicles

Ford Mustang GT

- Aluminum Intake Manifold technology has revolutionized the performance of iconic vehicles like the Ford Mustang GT.

- Racing enthusiasts have embraced the lightweight and durable Aluminum Intake Manifold to enhance engine efficiency and power output.

- The Ford Mustang GT’s precision-engineered Aluminum Intake Manifold ensures optimal airflow distribution for unmatched performance on the track.

Ken Block’s F-150 ‘Hoonitruck’

- Ken Block’s legendary F-150 ‘Hoonitruck’ showcases the cutting-edge innovation of Aluminum Intake Manifolds in high-performance trucks.

- The 3D-printed Aluminum Intake Manifold on the Hoonitruck exemplifies advanced engineering techniques for maximum power delivery.

- With an Aluminum Intake Manifold at its core, Ken Block’s F-150 dominates off-road challenges with unparalleled speed and agility.

Everyday Cars

Benefits for Daily Drivers

- Incorporating an Aluminum Intake Manifold in everyday cars elevates driving experiences by boosting fuel efficiency and engine responsiveness.

- Daily drivers benefit from the lightweight design of Aluminum Intake Manifolds, enhancing overall vehicle performance without compromising durability.

- The widespread adoption of Aluminum Intake Manifolds in standard vehicles underscores their reliability and efficiency for daily commuting needs.

Examples of Popular Models Using Aluminum Intake Manifolds

- Honda Civic: The Honda Civic integrates an Aluminum Intake Manifold to optimize engine combustion, delivering a perfect balance of power and fuel economy.

- Toyota Camry: Toyota’s renowned Camry features an advanced Aluminum Intake Manifold, ensuring smooth acceleration and consistent performance on city roads.

- Nissan Altima: Nissan’s Altima model benefits from an efficient Aluminum Intake Manifold, enhancing both horsepower output and long-term engine durability.

Explore Werkwell‘s exceptional product line featuring high-quality aluminum intake manifolds. Upgrade your car’s performance with our durable and efficient manifolds designed for optimal airflow distribution. Experience the benefits of lightweight components that enhance speed and agility on the road. Don’t miss out on the opportunity to elevate your driving experience with Werkwell’s innovative solutions. Take the first step towards improved engine efficiency and power output by considering aluminum intake manifolds for your vehicle today!

Post time: Jun-27-2024