In the realm of engine tuning, the RB25DET exhaust manifold holds significant importance. For enthusiasts delving into tuning Nissan engines, particularly the RB25DET, understanding the diverse Aftermarket Exhaust Manifold options is paramount. From stock to aftermarket choices, each variant offers unique advantages in enhancing engine performance. This guide aims to shed light on these options, providing a comprehensive overview to aid enthusiasts in making informed decisions for their tuning endeavors.

Types of RB25DET Exhaust Manifolds

When considering RB25DET exhaust manifolds, enthusiasts are often faced with the decision between Stock Manifolds and Aftermarket Manifolds. The distinction between these options lies in their design and performance capabilities.

Stock Manifolds

The stock manifold is the original equipment installed by the manufacturer. While it serves its basic function of expelling exhaust gases from the engine, it may lack the efficiency and performance enhancements that aftermarket alternatives offer. Stock manifolds are typically designed for general use, providing a standard level of functionality without specialized features tailored to maximize engine output.

Aftermarket Manifolds

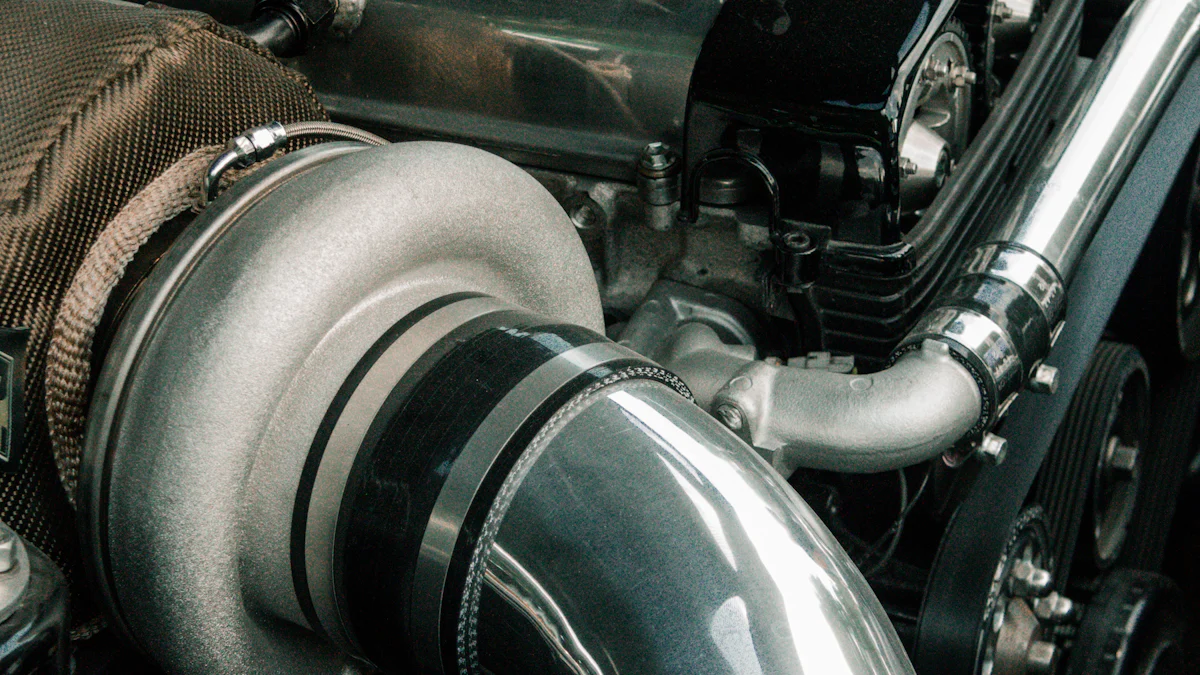

On the other hand, aftermarket manifolds cater to enthusiasts seeking to extract optimal performance from their RB25DET engines. These manifolds boast key differences compared to stock variants, such as increased flow capacity, optimized spool-up for quicker turbo response, and compatibility with larger turbines. Additionally, aftermarket manifolds often require heat-wrapping for thermal management and may feature thinner walls to reduce weight and improve airflow dynamics.

Top Mount vs. Bottom Mount

Within the realm of RB25DET exhaust manifold options, another crucial consideration is whether to opt for Top Mount Manifolds or Bottom Mount Manifolds. Each configuration offers distinct advantages depending on the desired engine setup and tuning goals.

Top Mount Manifolds

Top mount manifolds position the turbocharger above the engine block, allowing for efficient exhaust gas routing directly into the turbine housing. This setup promotes enhanced spool-up characteristics by minimizing exhaust travel distance and reducing lag between throttle input and turbo response. Enthusiasts looking to prioritize quick acceleration and high-end power delivery often opt for top mount configurations due to their favorable impact on overall engine performance.

Bottom Mount Manifolds

Conversely, bottom mount manifolds position the turbocharger below the engine block, requiring a different routing path for exhaust gases compared to top mount designs. While bottom mount setups may introduce slightly more turbo lag due to increased exhaust travel distance, they can offer benefits in terms of weight distribution and ease of maintenance access. Enthusiasts aiming for a balanced approach between power delivery and serviceability might find bottom mount manifolds more suitable for their RB25DET tuning endeavors.

Reverse Rotation Manifolds

Delving deeper into RB25DET exhaust manifold options unveils an intriguing category known as Reverse Rotation Manifolds. These specialized designs incorporate unique features that set them apart from traditional configurations, influencing both performance outcomes and installation considerations.

Design Features

Reverse rotation manifolds are characterized by innovative engineering elements aimed at optimizing turbo response and overall engine efficiency. With features like 33MM ID runners and reduced runner length, these manifolds promote faster spool-up times by minimizing air travel restrictions within the system. Additionally, reverse rotation designs may incorporate advanced materials or coatings to enhance durability under high-temperature operating conditions.

Performance Impact

The adoption of reverse rotation manifolds can have a profound impact on RB25DET engine performance metrics. By streamlining airflow dynamics and reducing internal resistance within the manifold assembly, these configurations contribute to improved turbo response times and enhanced power delivery across varying RPM ranges. Enthusiasts seeking a competitive edge in drag racing or track applications often gravitate towards reverse rotation manifolds for their proven ability to elevate overall engine output levels.

Materials and Construction

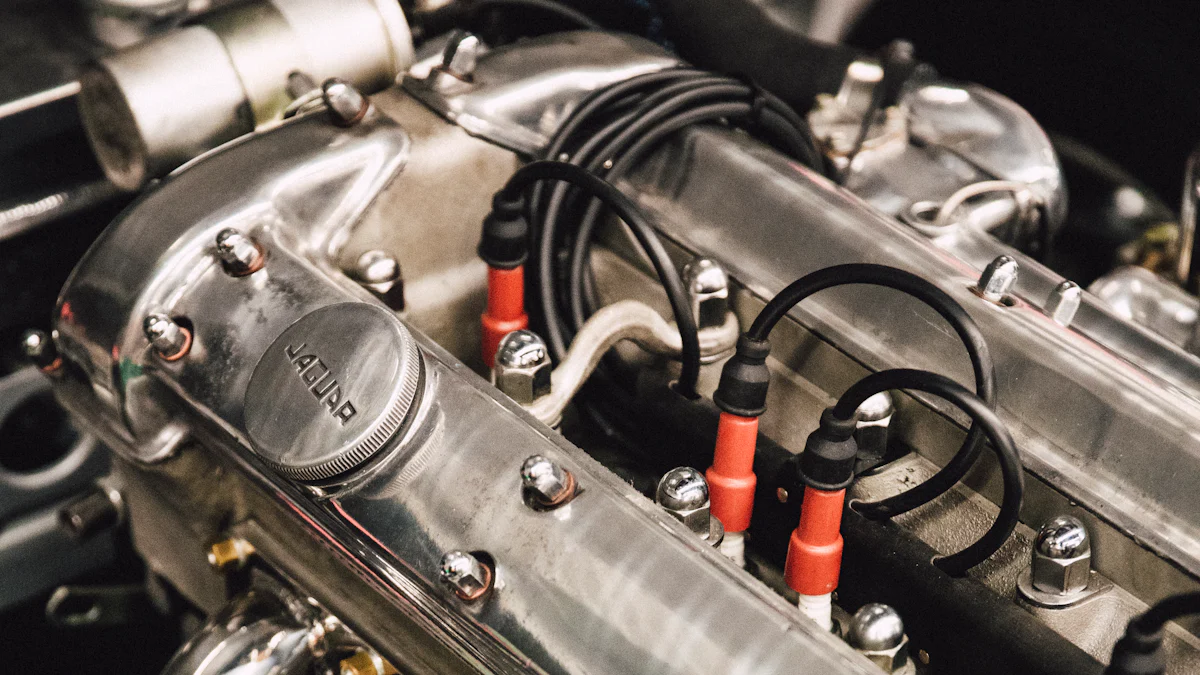

Stainless Steel

Stainless steel emerges as a popular choice for RB25DET exhaust manifolds due to its exceptional properties that benefit engine performance. The material’s corrosion resistance, durability, and heat tolerance make it an ideal option for enthusiasts seeking reliable and long-lasting modifications.

Benefits

- Enhanced Durability: Stainless steel’s robust nature ensures the manifold can withstand high temperatures and harsh operating conditions without succumbing to wear or deformation.

- Optimized Performance: The smooth internal surface of stainless steel manifolds promotes efficient exhaust flow, reducing back-pressure and enhancing overall engine efficiency.

- Improved Turbo Response: By minimizing heat dissipation, stainless steel manifolds aid in optimizing spool-up times, resulting in quicker turbo response for increased power delivery.

Drawbacks

- Cost Considerations: While offering superior performance benefits, stainless steel manifolds may come at a higher price point compared to other material options.

- Weight Impact: The density of stainless steel can add weight to the manifold assembly, potentially affecting the vehicle’s overall weight distribution and handling characteristics.

Titanium

Titanium represents a premium choice for enthusiasts seeking lightweight yet durable solutions for their RB25DET exhaust systems. Renowned for its strength-to-weight ratio and heat resistance, titanium manifolds offer a blend of performance and aesthetics.

Benefits

- Exceptional Strength: Titanium’s high tensile strength allows for the creation of lightweight yet sturdy exhaust manifolds that can withstand extreme temperatures and mechanical stress.

- Weight Reduction: The use of titanium results in a significant reduction in overall weight compared to traditional materials like stainless steel, contributing to improved vehicle agility and responsiveness.

- Corrosion Resistance: Titanium’s inherent corrosion resistance ensures longevity and reliability even under challenging environmental conditions.

Drawbacks

- Cost Constraints: The manufacturing process and raw material costs associated with titanium often translate into higher prices for these manifolds, making them less accessible to budget-conscious enthusiasts.

- Complex Fabrication: Working with titanium requires specialized equipment and expertise due to its unique properties, potentially leading to increased production complexities and costs.

Mild Steel

While not as commonly used as stainless steel or titanium, mild steel remains a viable option for RB25DET exhaust manifold construction, particularly for enthusiasts seeking cost-effective solutions without compromising on performance.

Benefits

- Affordability: Mild steel manifolds offer a budget-friendly alternative to pricier materials like stainless steel or titanium, making them accessible to a wider range of enthusiasts.

- Ease of Fabrication: The malleability of mild steel simplifies the manufacturing process, allowing for custom designs and modifications tailored to specific engine setups.

- Decent Performance: When properly designed and constructed, mild steel manifolds can deliver satisfactory performance gains by optimizing exhaust gas flow dynamics within the system.

Drawbacks

- Susceptibility to Corrosion: Unlike stainless steel or titanium, mild steel is more prone to corrosion over time if not adequately protected or maintained against environmental factors such as moisture or salt exposure.

- Limited Heat Resistance: Mild steel may exhibit lower heat tolerance compared to stainless steel or titanium alloys, potentially leading to thermal degradation under extreme operating conditions.

Installation Tips

Preparing the Engine

When preparing the engine for an exhaust manifold installation, it is crucial to have the necessary tools readily available. These tools typically include a socket wrench set, torque wrench, gasket scraper, penetrating oil, and safety gloves. Ensuring that all tools are in good condition and easily accessible can streamline the installation process and prevent any delays.

Safety Precautions

Prioritizing safety precautions during the installation of an RB25DET exhaust manifold is paramount to prevent accidents and ensure a smooth process. Enthusiasts should wear appropriate personal protective equipment such as safety goggles and gloves to shield against potential hazards. Additionally, disconnecting the battery before starting work can reduce the risk of electrical mishaps during the installation procedure.

Step-by-Step Installation

The step-by-step installation of an RB25DET exhaust manifold involves meticulous attention to detail to guarantee optimal performance outcomes. From removing the old manifold to installing the new manifold, each stage plays a critical role in enhancing engine efficiency and maximizing power output.

Removing the Old Manifold

Before embarking on installing a new exhaust manifold, enthusiasts must first focus on removing the old manifold effectively. This process entails loosening and removing the nuts securing the existing manifold to the cylinder head using a suitable wrench or socket set. Care should be taken not to damage surrounding components or threads during this disassembly phase.

Installing the New Manifold

Once the old manifold has been successfully removed, enthusiasts can proceed with installing the new manifold onto the RB25DET engine. Proper alignment of gaskets and studs is essential for ensuring a secure fitment that minimizes exhaust leaks and optimizes turbo response. Gradually tightening each nut in a crisscross pattern helps distribute pressure evenly across all connection points, promoting stability and longevity.

Post-Installation Checks

After completing the installation process, conducting thorough post-installation checks is vital to validate proper fitment and identify any potential issues that may affect performance down the line. By focusing on tasks such as ensuring proper fitment and testing for leaks, enthusiasts can confirm that their RB25DET engine is ready to deliver enhanced power and turbo responsiveness.

Ensuring Proper Fitment

Verifying proper fitment post-installation involves inspecting all connection points between the exhaust manifold and cylinder head for alignment accuracy. Any misalignments or gaps could lead to exhaust leaks or inefficient airflow distribution within the system. Adjustments may be necessary to achieve an optimal seal that promotes consistent engine performance.

Testing for Leaks

Conducting a comprehensive leak test following an exhaust manifold installation is essential for detecting any potential issues early on. Enthusiasts can utilize methods such as smoke testing or applying soapy water around connection points while running the engine to pinpoint areas where leaks may occur. Addressing leaks promptly ensures that engine power remains uncompromised and prevents long-term damage from occurring.

Performance Benefits

Improved Turbo Response

When considering the impact of Aftermarket Manifolds on turbo performance, enthusiasts can anticipate a notable enhancement in turbo response. By upgrading to an aftermarket manifold, individuals can experience reduced lag between throttle input and turbo spool-up. This reduction in lag translates to a more immediate and responsive acceleration, providing drivers with a thrilling boost in driving dynamics.

The transition from an OEM manifold to an aftermarket counterpart brings about a series of improvements that collectively contribute to increased power output. The optimized flow capacity of aftermarket manifolds allows for enhanced exhaust gas expulsion, reducing back-pressure within the system. As a result, the engine can operate more efficiently, generating higher power gains across various RPM ranges.

Enhanced Engine Efficiency

The design and material quality of an exhaust manifold play a pivotal role in influencing engine efficiency metrics. Factors such as shape, diameter, and production quality directly impact turbine performance, affecting overall engine responsiveness and power delivery. Enthusiasts seeking to maximize their RB25DET’s efficiency should carefully consider these aspects when selecting an exhaust manifold upgrade.

Stainless steel emerges as a top choice for enthusiasts prioritizing durability and quality in their exhaust manifold selection. The exceptional strength, corrosion resistance, and lifetime warranty associated with stainless steel manifolds underscore their reliability and longevity benefits. Investing in a high-quality stainless steel manifold ensures that the engine operates optimally under demanding conditions while maintaining peak performance levels.

Aesthetic Upgrades

Beyond the realm of performance enhancements, aftermarket exhaust manifolds offer opportunities for aesthetic upgrades that elevate the visual appeal of the engine bay. The sleek design and polished finish of premium manifolds add a touch of sophistication to the RB25DET setup, enhancing its overall aesthetic charm. Enthusiasts keen on showcasing their attention to detail through customization will find aftermarket options conducive to achieving a personalized look for their vehicle.

Customization options extend beyond visual enhancements to encompass functional modifications that cater to individual preferences and tuning goals. From specialized coatings for heat management to unique designs that optimize airflow dynamics, aftermarket manifolds present enthusiasts with a diverse array of choices for tailoring their RB25DET engines according to specific requirements.

Recapping the manifold options for RB25DET engines reveals a diverse landscape of choices. Stainless steel emerges as a durable and performance-enhancing material, while titanium offers lightweight strength for enthusiasts seeking agility. For those on a budget, mild steel provides a cost-effective alternative without sacrificing quality. Final recommendations urge enthusiasts to explore aftermarket options for enhanced turbo response and increased power, aligning with the quest for optimal engine efficiency and aesthetics. Embrace the opportunity to customize your RB25DET setup, unlocking its full potential.

Post time: Jun-24-2024