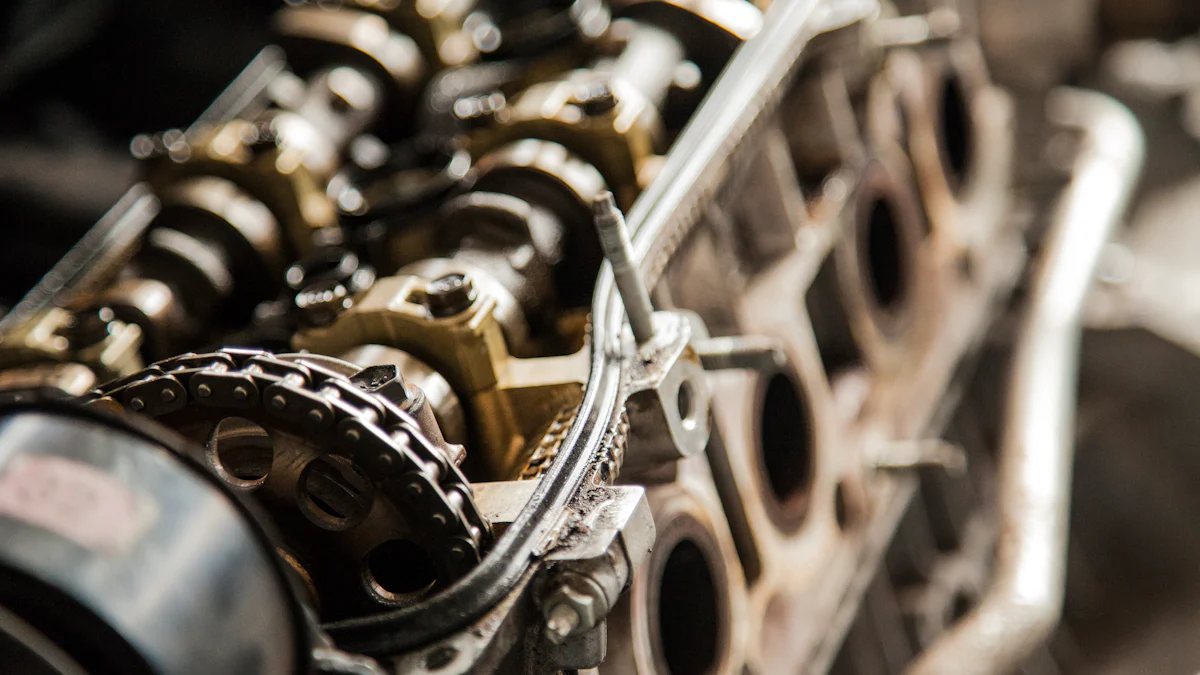

The timing marks on the harmonic balancer are a critical component that plays a pivotal role in maintaining engine performance. By dampening torsional distortion in the crankshaft, it prevents potential breakage and ensures smooth operation. This precision assembly, consisting of multiple parts like the outer ring and rubber isolator, acts as both a balancer and vibration damper. The timing marks on the harmonic balancer are essential indicators that help set the ignition timing correctly. This guide aims to simplify these concepts for beginners, providing valuable insights into engine functionality.

Understanding Harmonic Balancers

What is a Harmonic Balancer?

A Harmonic Balancer is an integral part of an engine, often overlooked but crucial for its smooth operation. It serves to absorb torsional vibrations in the crankshaft, preventing potential breakage and ensuring the engine’s stability at critical RPMs. This precision component plays a dual role as both a balancer and a vibration damper, essential for maintaining the engine’s overall performance.

Definition and function

The Harmonic Balancer acts as a safeguard against torsional distortion in the crankshaft, which can lead to severe issues if left unaddressed. By dampening twisting and spring-back effects during engine operation, it enhances the longevity and efficiency of the engine. Failure to address problems with the harmonic balancer can result in various complications, from annoying squeaking noises to catastrophic engine failure.

Importance in engine operation

In engines, especially those with traverse mounting configurations, the Harmonic Balancer plays a critical role in maintaining balance and stability. Its design, typically composed of two laminated pieces bonded together with rubber, effectively cancels out harmful harmonics generated by the crankshaft’s movements. This meticulous balancing act ensures that the engine operates smoothly without risking structural damage.

Components of a Harmonic Balancer

Understanding the components that make up a Harmonic Balancer provides insight into its functionality and significance within an engine system.

Outer ring

The outer ring of a Harmonic Balancer serves as the primary structure that houses crucial components responsible for balancing vibrations. Its robust construction ensures durability under high-stress conditions while effectively distributing forces throughout the assembly.

Rubber isolator

At the core of every Harmonic Balancer lies a rubber isolator that acts as a buffer against excessive vibrations. This component absorbs shocks and minimizes oscillations within the crankshaft, promoting smoother engine operation and reducing wear on internal parts.

Hub

The hub of a Harmonic Balancer connects directly to the crankshaft, transmitting rotational energy while maintaining precise alignment. Its secure attachment ensures that the balancer functions seamlessly with other engine components, contributing to overall performance optimization.

View Public Profile Find

Exploring Werkwell‘s Harmonic Balancer unveils advanced features designed to enhance engine performance and reliability.

Werkwell’s Harmonic Balancer

Werkwell’s Harmonic Balancers, crafted with precision engineering techniques, offer unparalleled quality and durability for various car models. Engineered to withstand rigorous conditions, these balancers ensure optimal performance by effectively dampening vibrations and harmonics within the crankshaft.

Key features and benefits

- Precision Engineering: Each Werkwell Harmonic Balancer undergoes meticulous manufacturing processes to guarantee superior quality.

- Enhanced Durability: The use of high-grade materials ensures long-lasting performance under demanding operating conditions.

- Improved Engine Stability: By reducing vibrations and harmonics, these balancers contribute to smoother engine operation and increased longevity.

- Compatibility: Designed for multiple car models including GM, Ford, Toyota, Honda, Chrysler, Hyundai, Nissan, Mitsubishi among others.

- Customization Options: Werkwell offers tailored solutions to meet specific customer requirements for enhanced performance outcomes.

Timing Marks Explained

What are Timing Marks?

Definition and purpose

Timing marks on a harmonic balancer are vital indicators that help mechanics set the ignition timing correctly. These marks, typically etched or painted on the balancer’s surface, align with a pointer to signify the Top Dead Center (TDC) position of the crankshaft. Ensuring these marks are aligned accurately is crucial for optimal engine performance.

Location on the harmonic balancer

The timing marks can be found at various positions on the harmonic balancer, depending on the engine model. Some balancers feature multiple sets of marks to accommodate different tuning requirements. Mechanics must locate these marks to determine the piston’s position in its stroke cycle accurately.

How to Read Timing Marks

Tools needed

To read timing marks effectively, mechanics require specific tools such as a timing light and a degree wheel. The timing light helps illuminate the marks during operation, while the degree wheel aids in measuring precise angles for ignition adjustments.

Step-by-step guide

- Start by locating the timing marks on your harmonic balancer.

- Connect a timing light to your engine according to manufacturer instructions.

- With the engine running, point the timing light at the marks to observe their alignment.

- Adjust the ignition timing as needed by turning the distributor until the marks align correctly.

- Use a degree wheel to verify that your ignition timing is set accurately.

Importance

Importance of correct timing

Ensuring that timing marks are set correctly is paramount for engine efficiency and longevity. Correct ignition timing allows fuel combustion to occur precisely when needed, optimizing power output and fuel efficiency.

Impact on engine performance

Incorrectly aligned timing marks can lead to poor engine performance, including reduced power, increased fuel consumption, and potential damage to internal components. Regularly checking and adjusting these marks can prevent costly repairs down the line.

Common Misconceptions

Misalignment issues

When the timing marks on the harmonic balancer are not aligned correctly, it can lead to a cascade of engine problems. One common misconception is that a slight misalignment won’t affect performance significantly. In reality, even a minor deviation can cause timing discrepancies, impacting combustion efficiency and overall engine operation. Mechanics should pay close attention to ensure precise alignment for optimal functionality.

Myths about timing marks

There are several myths surrounding timing marks that can mislead inexperienced enthusiasts. One prevalent myth suggests that all timing marks are universal across different engines, leading to incorrect adjustments. It’s essential to understand that each engine model has specific timing mark configurations tailored to its requirements. Another myth implies that visually estimating the alignment of timing marks is sufficient for accurate tuning. However, relying solely on visual cues without proper tools can result in inaccuracies and potential damage to the engine components.

By debunking these misconceptions and myths, beginners can grasp the importance of precise timing mark alignment for maintaining engine efficiency and longevity. Regular inspection and adjustment based on manufacturer guidelines are crucial steps in ensuring optimal performance and preventing costly repairs in the future.

Common Issues and Solutions

Difficulty Seeing Timing Marks

Causes

- Accumulated Dirt: Over time, road grime and dirt can obscure the timing marks on the harmonic balancer, making them challenging to identify accurately.

- Worn-Out Markings: Continuous use and exposure to engine heat may cause the timing marks to fade or wear off, further complicating their visibility during inspections.

Solutions

- Cleaning Routine: Regularly clean the harmonic balancer area to remove any accumulated dirt or grime that may be obstructing the timing marks.

- Mark Restoration: If the markings are faded, consider using a bright-colored paint or marker to redefine the timing marks for better visibility.

Incorrect Timing Alignment

Symptoms

- Engine Knocking: Misaligned timing marks can lead to engine knocking noises, indicating improper combustion timing within the cylinders.

- Reduced Power Output: When the ignition timing is off, the engine may experience reduced power output and overall performance issues.

Fixes

- Adjustment Check: Use a timing light tool to verify if the timing marks align correctly with the pointer. If misaligned, adjust the distributor accordingly for precise ignition timing.

- Professional Calibration: For complex tuning requirements or persistent issues, seek professional assistance from experienced mechanics to ensure accurate timing alignment.

Harmonic Balancer Slippage

Causes

- Loose Fasteners: Improper installation or worn-out fasteners can cause the harmonic balancer to slip out of alignment with the crankshaft over time.

- Excessive Vibrations: High levels of engine vibrations due to internal imbalances or component wear can contribute to harmonic balancer slippage issues.

Prevention

- Regular Inspection: Periodically check for any signs of slippage or misalignment in the harmonic balancer assembly during routine maintenance checks.

- Fastener Tightening: Ensure all fasteners securing the harmonic balancer are tightened to manufacturer specifications to prevent slippage and maintain proper alignment.

By addressing common issues related to visibility of timing marks, ensuring correct alignment, and preventing harmonic balancer slippage, enthusiasts can maintain optimal engine performance and longevity effectively.

Maintaining Your Harmonic Balancer

Regular Inspection

What to look for

Inspecting your harmonic balancer regularly is crucial to ensure optimal engine performance and prevent potential failures. Here are key aspects to focus on during your inspection:

- Outer Ring Condition: Check for any signs of wear, cracks, or separation in the outer ring. Any abnormalities could indicate potential issues with the balancer’s integrity.

- Rubber Isolator Health: Examine the rubber isolator for any deterioration or damage. The rubber plays a vital role in absorbing vibrations, so any compromise in its condition can impact overall performance.

- Hub Alignment: Verify that the hub is securely attached to the crankshaft without any looseness or misalignment. A stable hub connection is essential for proper balancer function.

Tools required

Performing a thorough inspection of your harmonic balancer requires specific tools to ensure accurate assessment and maintenance:

- Flashlight: Adequate lighting is essential to examine the balancer’s components effectively, especially in hard-to-reach areas.

- Torque Wrench: Use a torque wrench to check the tightness of fasteners securing the harmonic balancer in place. Proper torque ensures stability and prevents slippage.

- Rubber Mallet: In case adjustments are needed, a rubber mallet can help gently realign components without causing damage.

- Calipers: Precision measurements may be necessary during inspection, making calipers useful for assessing component dimensions accurately.

Replacement Guidelines

When to replace

Knowing when to replace your harmonic balancer is crucial in maintaining engine reliability and preventing catastrophic failures. Consider these factors when determining if replacement is necessary:

- Visible Damage: If you notice significant wear, cracks, or separation in any part of the harmonic balancer during inspection, immediate replacement is recommended.

- Excessive Vibrations: Unusual vibrations originating from the front of the engine could indicate issues with the harmonic balancer’s functionality, signaling a need for replacement.

- High Mileage: As part of regular maintenance, consider replacing the harmonic balancer after reaching a certain mileage threshold to preemptively address wear and tear.

Steps for replacement

When replacing your harmonic balancer, follow these steps to ensure a smooth and effective transition:

- Disconnect Battery: Prior to beginning any work on your engine, disconnect the battery to prevent electrical mishaps during replacement.

- Access Harmonic Balancer: Depending on your vehicle model, access the harmonic balancer by removing necessary components obstructing its view and access points.

- Secure Crankshaft Position: Utilize appropriate tools like an adjustable wrench or piston stop tool to secure the crankshaft position before removing the old harmonic balancer.

- Remove Old Balancer: Loosen fasteners securing the old harmonic balancer and carefully detach it from the crankshaft using proper removal techniques.

- Install New Balancer: Align and install the new harmonic balancer onto the crankshaft while ensuring proper fitment and alignment with timing marks as per manufacturer specifications.

- Secure Fasteners: Torque down fasteners according to manufacturer guidelines using a torque wrench to prevent over-tightening or under-tightening issues.

Professional Help

When to seek it

While DIY maintenance is feasible for some enthusiasts, certain situations warrant professional assistance with your harmonic balancer:

- Complex Issues: If you encounter intricate problems during inspection or replacement that require specialized knowledge or tools beyond your expertise, seeking professional help is advisable.

- Unfamiliarity with Procedures: For individuals unfamiliar with engine components or lacking experience in working on automotive systems, consulting a professional mechanic ensures correct handling of delicate parts like harmonic balancers.

Benefits of professional maintenance

Engaging professional services for maintaining your harmonic balancer offers various advantages:

- Expertise: Skilled mechanics possess extensive knowledge and experience in handling complex engine components like harmonic balancers efficiently.

- Precision Calibration: Professionals can accurately calibrate timing marks and ensure proper alignment during installation or replacement procedures.

- Enhanced Safety: By entrusting professionals with maintenance tasks, you reduce risks associated with incorrect installations or overlooked issues that could compromise engine safety.

By understanding when to conduct regular inspections, how to determine replacement needs, and when professional help is beneficial for maintaining your harmonic balancers effectively safeguards engine performance and longevity.

Highlighting the significance of timing marks and harmonic balancers is crucial for maintaining optimal engine performance. Regular inspection and maintenance of these components are key to preventing potential issues and ensuring smooth operation. By understanding the role of timing marks in ignition timing and the functionality of harmonic balancers, enthusiasts can enhance their engine’s longevity. Remember, a well-maintained harmonic balancer leads to a healthier engine overall.

Post time: May-30-2024