Harmonic balancers play a crucial role in vehicles, ensuring smooth engine operation by reducing vibrations. This blog aims to educate on Engine harmonic balancer bolt sizes, providing valuable insights for vehicle maintenance. Explore the world of automotive components with a focus on precision and quality. Werkwell stands out as an expert in delivering top-notch products for various vehicle models, guaranteeing reliability and performance.

Understanding Harmonic Balancers

What is a Harmonic Balancer?

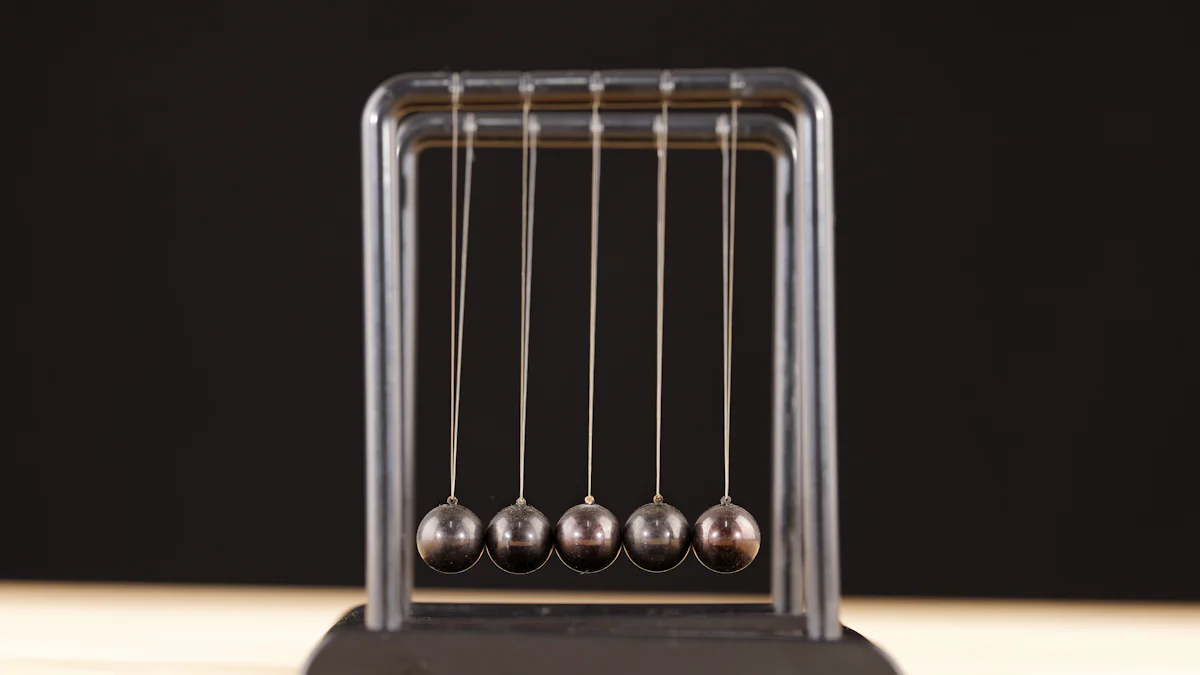

A Harmonic Balancer, also known as a crankshaft damper, is an essential component in the engine that plays a critical role in reducing vibrations. Its primary function is to absorb and minimize the harmonic vibrations produced by the engine, ensuring a smoother operation. By dampening these vibrations, the harmonic balancer helps protect the engine from potential damage and enhances its overall performance.

Components of a Harmonic Balancer

- Crankshaft: The crankshaft is a fundamental part of the engine responsible for converting the linear motion of the pistons into rotational motion. It connects to various components, including the harmonic balancer, to ensure synchronized movement within the engine.

- Bolt and Washer: The bolt and washer assembly secures the harmonic balancer in place on the crankshaft. This crucial connection ensures that the balancer remains fixed during engine operation, preventing any unwanted movements that could disrupt its functionality.

- Keyway: A keyway is a slot machined into both the crankshaft and harmonic balancer to prevent slippage. By aligning with each other, the keyway ensures that the balancer rotates in harmony with the crankshaft, maintaining proper timing and balance within the engine.

Common Issues with Harmonic Balancers

- Vibration Problems: One of the most common issues associated with harmonic balancers is vibration problems. If not properly installed or if damaged, the balancer may fail to effectively dampen vibrations, leading to increased engine noise and potential mechanical issues.

- Wear and Tear: Over time, harmonic balancers can experience wear and tear due to constant exposure to high levels of stress. This wear can manifest as cracks or separation between components, compromising the integrity of the balancer and its ability to function optimally.

Common Harmonic Balancer Bolt Sizes

When it comes to harmonic balancer bolt sizes, different vehicle models require specific measurements to ensure proper installation and functionality. Understanding the correct bolt size for your engine is crucial for maintaining the integrity of the harmonic balancer and preventing potential issues down the road.

Ford Engines

For Ford engines, two common harmonic balancer bolt sizes are prevalent:

M12 x 90mm

The M12 x 90mm bolt size is a standard measurement used in many Ford engines. This size ensures a secure fit for the harmonic balancer, providing stability during engine operation.

M12 x 70mm for 4.0L

In specific Ford engines like the 4.0L, a M12 x 70mm bolt is required. This slightly smaller size is tailored to fit the unique specifications of the 4.0L engine, ensuring optimal performance and reliability.

GM Engines

GM engines also have distinct requirements when it comes to harmonic balancer bolt sizes:

7/16 -20 UNF x 1 inch

The 7/16 -20 UNF x 1 inch bolt size is commonly found in GM engines. This precise measurement is essential for securing the harmonic balancer in place, preventing any unwanted movement or vibration.

5/8 inch for Chevy 350

For Chevy 350 engines, a 5/8 inch bolt is typically used. This larger size provides robust support for the harmonic balancer, ensuring that it remains firmly attached to the crankshaft.

Other Vehicle Models

Various other vehicle models have unique requirements for harmonic balancer bolt sizes:

3/8″-24 for 1990 4.3 engine

In 1990 models with a 4.3 engine, a 3/8″-24 bolt size is commonly utilized. This specific measurement caters to the needs of older engine models, offering a reliable solution for securing the harmonic balancer.

7/16-20 x 2.25 for 2000′s 4.3 L/W engine

For newer models like those from the early 2000s with a 4.3 L/W engine, a 7/16-20 x 2.25 bolt size is recommended. This slightly longer bolt provides added stability and support, ensuring optimal performance under various driving conditions.

Understanding these common harmonic balancer bolt sizes is essential for maintaining your vehicle’s engine health and performance over time.

How to Measure Bolt Sizes

Tools Needed

To accurately measure bolt sizes, you will require two essential tools: a Caliper and a Thread Gauge. These tools are indispensable for determining the precise dimensions of the bolts used in your vehicle’s harmonic balancer.

Step-by-Step Guide

When measuring bolt sizes, it is crucial to follow a systematic approach to ensure accuracy and reliability. Here is a step-by-step guide to help you determine the correct measurements:

Measuring Diameter

Begin by using the Caliper to measure the diameter of the bolt. Place the Caliper around the bolt shaft and tighten it gently to obtain an accurate reading. The diameter measurement is critical as it determines the compatibility of the bolt with your harmonic balancer.

Determining Thread Pitch

Next, utilize the Thread Gauge to determine the thread pitch of the bolt. Align the Thread Gauge with the threads on the bolt and identify the number of threads per inch. The thread pitch is essential for selecting bolts that fit securely into your harmonic balancer.

Measuring Length

Lastly, measure the length of the bolt using the Caliper. Position the Caliper from end to end, including the head if applicable, to ascertain the total length of the bolt. Ensuring that you have an accurate length measurement is vital for proper installation and secure mounting of your harmonic balancer.

Tips for Accurate Measurement

Achieving precise measurements when determining bolt sizes is key to maintaining your vehicle’s performance and safety. Here are some valuable tips to enhance accuracy during this process:

Double-Check Measurements

Always double-check your measurements to confirm their accuracy before selecting a replacement bolt for your harmonic balancer. Even minor discrepancies in size can lead to improper fitting and potential issues down the line.

Use Proper Tools

Utilizing high-quality tools such as a Caliper and Thread Gauge is essential for obtaining precise measurements. Investing in reliable equipment will not only streamline your measurement process but also ensure consistent and accurate results.

Tips for Choosing the Right Bolt

Compatibility with Vehicle Model

When selecting a bolt for your vehicle’s harmonic balancer, it is crucial to prioritize compatibility with the specific vehicle model. Each vehicle has unique requirements when it comes to bolt sizes, thread pitches, and lengths. To ensure a perfect fit, always refer to the manufacturer specifications provided for your vehicle. These specifications outline the exact measurements needed for the harmonic balancer bolt, guaranteeing optimal performance and safety.

Quality of the Bolt

The quality of the bolt you choose plays a significant role in the overall performance and longevity of your vehicle’s harmonic balancer. Opting for Grade 8 bolts is highly recommended due to their exceptional strength and durability. Grade 8 bolts are constructed from high-strength materials, making them resistant to wear, corrosion, and mechanical stress. By investing in high-quality bolts, you can enhance the stability and reliability of your harmonic balancer, ensuring smooth engine operation under various conditions.

Installation Tips

Proper installation of the harmonic balancer bolt is essential to maintain the integrity of your engine components and prevent potential issues down the road. Follow these essential installation tips to ensure a secure fit:

Proper Torque

When tightening the bolt that secures the harmonic balancer in place, it is crucial to apply the correct amount of torque. Using a torque wrench set to the manufacturer-recommended torque specification ensures that the bolt is tightened to the appropriate level without under or over-tightening. Proper torque application prevents loosening during engine operation and maintains consistent pressure on the harmonic balancer.

Ensuring Secure Fit

After installing the harmonic balancer bolt, perform a thorough inspection to ensure a secure fit. Check for any signs of misalignment or improper seating of components. Confirm that all connections are tight and properly aligned before starting your vehicle’s engine. A secure fit minimizes vibrations, reduces wear on engine components, and promotes overall stability during operation.

Harmonic balancer bolt sizes are a critical aspect of maintaining your vehicle’s engine health. Ensuring the correct thread size and length is essential for optimal performance. Remember to refer to manufacturer specifications for precise measurements. In summary, understanding the significance of these bolts, measuring accurately, and choosing high-quality components are key to a well-functioning harmonic balancer. For top-notch automotive components, consult Werkwell for reliable products tailored to your vehicle’s needs.

Post time: May-30-2024