Your vehicle’s engine relies on precision and balance to function smoothly. The GM Harmonic Balancer plays a critical role in maintaining this balance. It absorbs and reduces vibrations caused by the engine’s rotating components. Without it, these vibrations could lead to wear and tear or even severe engine damage. Positioned at the front of the engine, this component ensures stability during operation. By managing torsional vibrations, it helps your engine perform efficiently and last longer. Understanding its purpose highlights its importance in keeping your vehicle running reliably.

Key Takeaways

- The GM Harmonic Balancer is essential for absorbing engine vibrations, ensuring smooth operation and preventing damage to internal components.

- Regular maintenance and timely replacement of the harmonic balancer can significantly extend your engine’s lifespan and improve overall performance.

- Common signs of a failing harmonic balancer include unusual engine vibrations, a wobbling crankshaft pulley, and strange noises from the engine.

- Driving with a faulty harmonic balancer can lead to severe engine damage and increased repair costs, making prompt attention crucial.

- Replacing a harmonic balancer can be done as a DIY project if you have the right tools and knowledge, but professional installation ensures reliability and safety.Investing in a high-quality harmonic balancer is a proactive step to maintain your vehicle’s reliability and enhance your driving experience.

What Is a GM Harmonic Balancer and How Does It Work?

Definition and Purpose

A GM Harmonic Balancer is a crucial component in your vehicle’s engine system.

You can think of it as a stabilizer for your engine. It keeps the crankshaft balanced and minimizes stress on other parts. Without it, your engine would experience excessive vibrations, which could result in reduced efficiency and potential failure over time. This small yet powerful device plays a significant role in maintaining the overall health and stability of your engine.

Design and Components

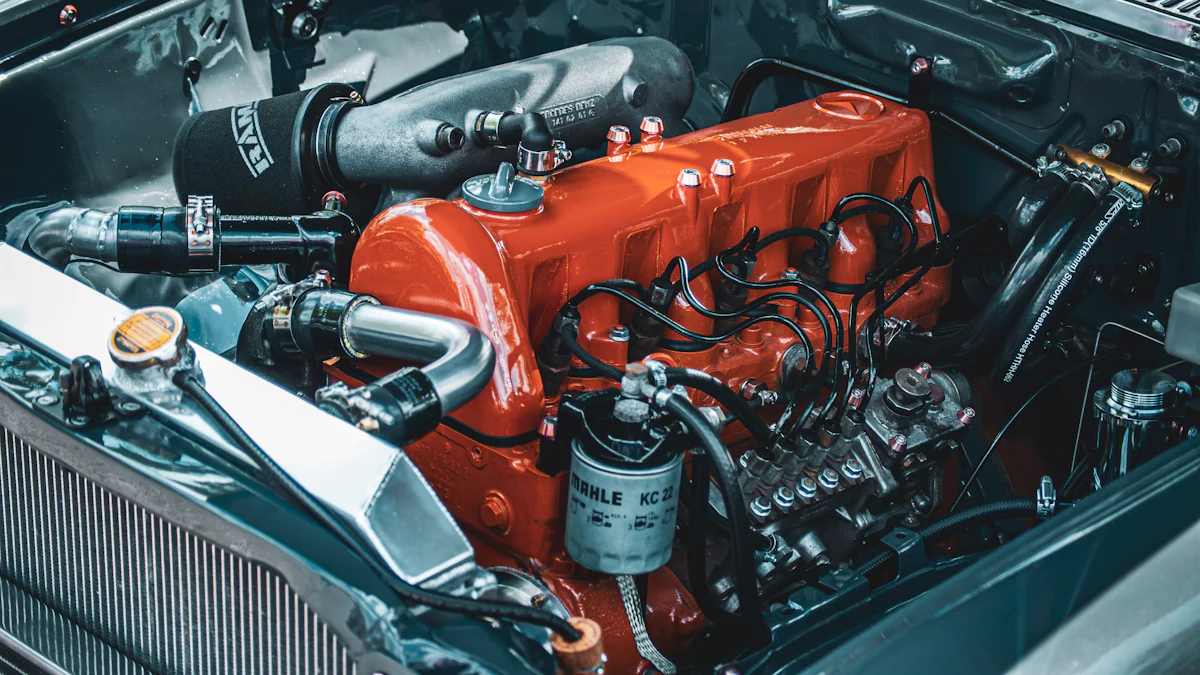

The design of a GM Harmonic Balancer combines simplicity with functionality. It typically consists of two main parts: a metal hub and a rubber ring. The metal hub connects directly to the crankshaft, while the rubber ring surrounds the hub. This combination allows the balancer to absorb vibrations effectively.

The rubber ring acts as a cushion. It dampens the vibrations generated by the crankshaft’s movement. The metal hub provides the necessary weight to counterbalance the rotational forces. Together, these components work in harmony to reduce stress on the engine and ensure smooth operation.

The construction materials and design ensure durability, allowing the harmonic balancer replacement to withstand the harsh conditions of engine operation.

Understanding how this component works helps you appreciate its importance. It is not just a simple part; it is a key player in keeping your engine running efficiently and reliably.

The Role of a GM Harmonic Balancer in Engine Stability

Reducing Engine Vibrations

Your engine generates vibrations as it operates. These vibrations come from the rapid movement of internal components, especially the crankshaft. Without proper control, these vibrations can disrupt the engine’s balance and reduce its efficiency. The GM Harmonic Balancer plays a critical role in managing this issue. It absorbs and dampens the vibrations, ensuring that your engine runs smoothly.

The rubber ring within the balancer acts as a cushion. It absorbs the energy from the vibrations and prevents them from spreading to other parts of the engine. This process reduces the strain on the crankshaft and other components. By minimizing vibrations, the balancer helps your engine maintain stability, even during high-speed operation. This ensures a quieter and more comfortable driving experience for you.

A well-functioning GM Harmonic Balancer not only improves engine performance but also extends the lifespan of your vehicle.

Preventing Engine Damage

Uncontrolled vibrations can cause significant damage to your engine over time. They create stress on the crankshaft, which may lead to cracks or even complete failure. The GM Harmonic Balancer prevents this by counteracting the torsional forces generated during engine operation. It ensures that the crankshaft remains balanced and protected from excessive stress.

When the balancer absorbs vibrations, it reduces the risk of damage to other engine components. Parts like bearings, pistons, and connecting rods rely on a stable crankshaft to function properly. Without the balancer, these components could wear out prematurely, leading to costly repairs or replacements.

By ensuring that this component is in good condition, you protect your engine from unnecessary harm and keep your vehicle running reliably, maintaining engine stability.

Symptoms of a Failing GM Harmonic Balancer

Common Warning Signs

A failing GM Harmonic Balancer often shows clear warning signs. Paying attention to these symptoms can help you address the issue before it causes severe engine damage. One of the most noticeable signs is unusual engine vibrations. If you feel excessive shaking while driving, the harmonic balancer may no longer be absorbing vibrations effectively.

Another common symptom is a misaligned or wobbling crankshaft pulley. The harmonic balancer connects to the crankshaft, so any damage to it can cause the pulley to move unevenly. You might also hear strange noises, such as rattling or knocking, coming from the front of the engine. These sounds often indicate that the rubber ring inside the balancer has deteriorated or separated from the metal hub.

In some cases, you may notice a decrease in engine performance. A failing harmonic balancer can disrupt the engine’s balance, leading to reduced efficiency and power. If you experience any of these issues, inspect the harmonic balancer immediately. Ignoring these warning signs can lead to more costly repairs down the line.

Risks of Driving with a Faulty Harmonic Balancer

Driving with a faulty GM Harmonic Balancer poses serious risks to your engine. The balancer plays a critical role in reducing vibrations and maintaining engine stability.

A damaged harmonic balancer can also affect other engine components. Bearings, pistons, and connecting rods rely on a stable crankshaft to function properly. When the balancer fails, these parts endure additional strain, increasing the likelihood of premature wear and tear. Over time, this can result in significant engine damage.

Ignoring a faulty harmonic balancer can also compromise your safety. Excessive vibrations can make driving uncomfortable and reduce your control over the vehicle. Addressing the issue promptly ensures your engine remains stable and reliable. Regular inspections and timely replacements protect your vehicle and keep you safe on the road.

Replacing a GM Harmonic Balancer: Costs and Feasibility

Replacement Costs

Replacing a GM Harmonic Balancer involves costs that vary based on your vehicle model and the type of balancer required. On average, you can expect to spend between 150 and 500 for the part itself. High-performance or specialized balancers may cost more. Labor charges also add to the total expense. Professional installation typically ranges from 200 to 400, depending on the mechanic’s rates and the complexity of the job.

You should also consider additional expenses, such as tools or accessories, if other components need adjustment during the replacement process. While the upfront cost may seem significant, replacing a failing harmonic balancer prevents more expensive engine repairs in the future. Investing in a quality balancer ensures your engine remains stable and reliable.

DIY vs. Professional Installation

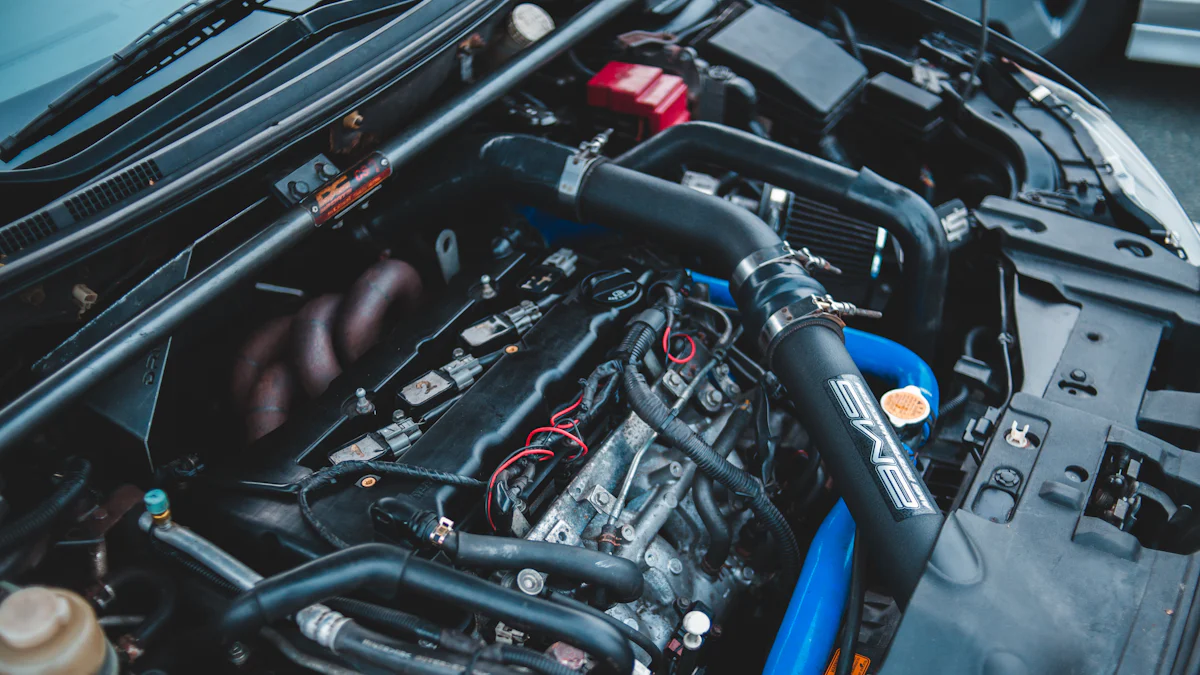

Replacing a GM Harmonic Balancer yourself can save money, but it requires mechanical knowledge and the right tools. The process involves removing the old balancer and installing the new one onto the crankshaft. You will need a harmonic balancer puller, a torque wrench, and other basic tools. Following the manufacturer’s instructions is crucial to avoid damaging the engine.

If you lack experience or confidence, professional installation is the safer option. Mechanics have the expertise and equipment to complete the job efficiently. They can also inspect other engine components for potential issues during the replacement. While professional installation costs more, it provides peace of mind and ensures the job is done correctly.

Choosing between DIY and professional installation depends on your skill level, available tools, and budget. If you decide to replace the balancer yourself, take your time and follow each step carefully. For those who prefer a hassle-free solution, hiring a professional guarantees a smooth and reliable outcome.

A GM Harmonic Balancer plays a vital role in keeping your engine stable and efficient. It reduces harmful vibrations, ensuring smooth performance and protecting critical engine components. Regular maintenance helps you catch potential issues early, preventing costly damage and enhancing safety. Replacing a failing balancer on time safeguards your vehicle’s reliability and extends its lifespan. By investing in a high-quality harmonic balancer, you ensure your GM vehicle remains dependable for years. Prioritize this essential component to maintain optimal engine health and enjoy a better driving experience.

FAQ

What is the primary function of a GM Harmonic Balancer?

The GM Harmonic Balancer primarily absorbs and reduces torsional vibrations in your engine. It ensures the crankshaft remains stable during operation, preventing damage to internal components and maintaining smooth engine performance.

How can I tell if my GM Harmonic Balancer is failing?

You might notice unusual engine vibrations, a wobbling crankshaft pulley, or strange noises like rattling or knocking from the front of the engine. Reduced engine performance can also indicate a failing harmonic balancer. Address these signs promptly to avoid further damage.

Can I drive with a faulty GM Harmonic Balancer?

Driving with a faulty harmonic balancer is risky. It increases stress on the crankshaft and other engine components, leading to potential damage or failure. Excessive vibrations can also make driving uncomfortable and unsafe. Replacing the balancer immediately is essential.

How often should I replace my GM Harmonic Balancer?

The lifespan of a harmonic balancer varies depending on your vehicle and driving conditions. Regular inspections during routine maintenance help identify wear or damage. Replacing it at the first sign of failure ensures your engine remains stable and reliable.

Is replacing a GM Harmonic Balancer expensive?

The cost of replacing a harmonic balancer depends on your vehicle model and whether you choose professional installation. The part itself typically costs 150 and 500, while labor charges range from 200 to 400. Investing in a quality balancer prevents more costly engine repairs.

Can I replace a GM Harmonic Balancer myself?

You can replace it yourself if you have mechanical knowledge and the right tools, such as a harmonic balancer puller and a torque wrench. Follow the manufacturer’s instructions carefully. If you lack experience, professional installation is a safer and more reliable option.

What happens if I ignore a failing GM Harmonic Balancer?

Ignoring a failing harmonic balancer can lead to severe engine damage. The crankshaft may crack or fail due to excessive stress. Other components, like bearings and pistons, can also wear out prematurely. Timely replacement prevents costly repairs and ensures safety.

Does a GM Harmonic Balancer affect engine performance?

Yes, it directly impacts engine performance. By reducing vibrations, it helps the engine run smoothly and efficiently. A failing balancer disrupts this balance, leading to reduced power, efficiency, and overall performance.

Are all GM Harmonic Balancers the same?

No, they vary based on vehicle models and engine specifications. Some balancers include additional features, like timing marks, for precise engine adjustments. Always choose a balancer compatible with your vehicle to ensure proper functionality.

How can I maintain my GM Harmonic Balancer?

Regular inspections during routine maintenance help identify wear or damage early. Keep an eye out for warning signs like vibrations or unusual noises. Replacing the balancer when necessary ensures your engine stays stable and performs reliably.

Post time: Dec-09-2024