The GM Harmonic Balancer GM 3.8L is a critical component of your engine. It minimizes vibrations caused by the crankshaft’s movement. Without it, your engine could experience severe wear and tear. This balancer ensures smoother operation and protects vital parts, helping your GM 3.8L engine perform efficiently and last longer.

What Is the GM Harmonic Balancer GM 3.8L?

Definition and purpose

The GM Harmonic Balancer GM 3.8L is a vital part of your engine. It connects to the crankshaft and helps reduce the vibrations caused by the engine’s operation. Every time the crankshaft rotates, it creates energy pulses. These pulses can lead to harmful vibrations if left unchecked. The harmonic balancer absorbs these vibrations, ensuring the engine runs smoothly.

This component also protects other engine parts. Without it, the vibrations could damage the crankshaft, bearings, and other critical components. By minimizing stress on these parts, the harmonic balancer extends the life of your GM 3.8L engine. Its purpose is not just to reduce vibrations but also to maintain the engine’s overall health.

Tip: Think of the harmonic balancer as a shock absorber for your engine. It keeps everything running smoothly and prevents long-term damage.

How it works in the GM 3.8L engine

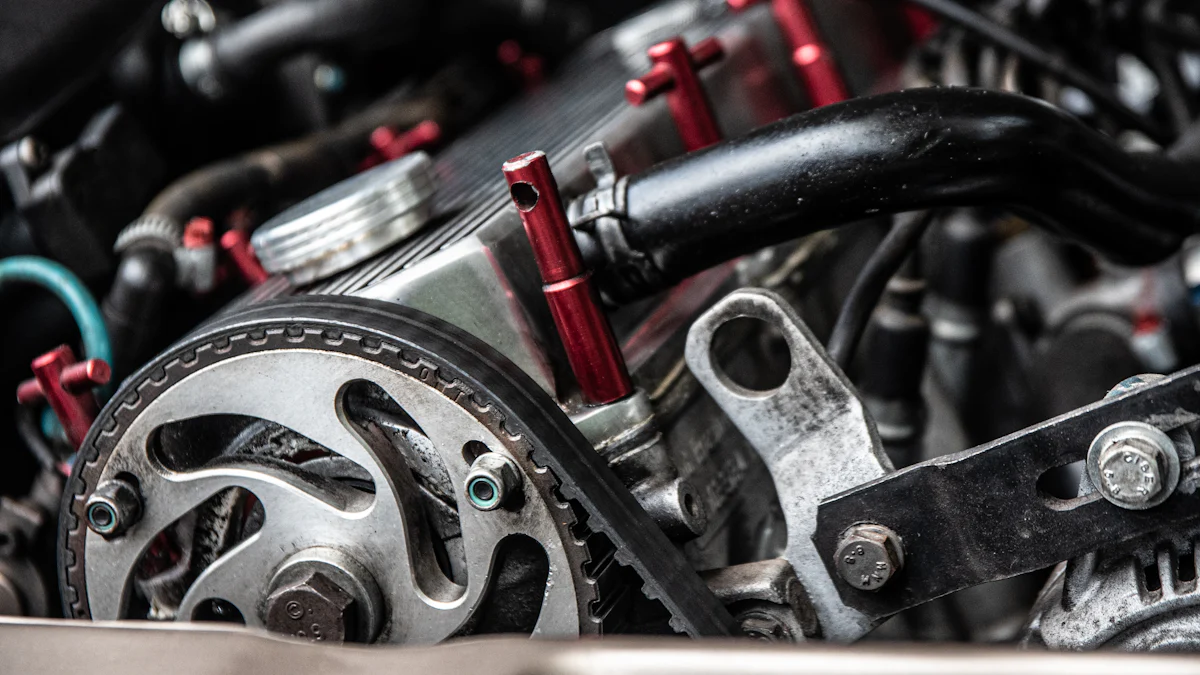

The GM Harmonic Balancer GM 3.8L works by using a combination of rubber and metal. The rubber layer sits between the inner hub and the outer ring. When the crankshaft generates vibrations, the rubber absorbs the energy. This prevents the vibrations from spreading to other parts of the engine.

In the GM 3.8L engine, the harmonic balancer also plays a role in timing. It ensures the crankshaft and other components stay in sync. This synchronization is crucial for efficient engine performance. Without it, your engine could misfire or lose power.

Note: A properly functioning harmonic balancer is essential for keeping your GM 3.8L engine running at its best.

Why Is the GM Harmonic Balancer GM 3.8L Important?

Reducing engine vibrations

The GM Harmonic Balancer GM 3.8L plays a key role in keeping your engine smooth and stable. Every time the crankshaft rotates, it generates vibrations. These vibrations can build up and cause your engine to shake or even rattle. The harmonic balancer absorbs these vibrations before they spread to other parts of the engine. This keeps your driving experience comfortable and prevents unnecessary wear on the engine.

Without this component, you might notice your engine running rough or making unusual noises. Over time, these vibrations could lead to serious damage. By reducing these vibrations, the harmonic balancer ensures your engine operates efficiently and stays in good condition.

Tip: If you feel unusual vibrations while driving, it might be time to inspect the harmonic balancer.

Protecting the crankshaft and engine components

The harmonic balancer doesn’t just reduce vibrations. It also protects the crankshaft and other engine parts from damage. Vibrations can put stress on the crankshaft, which is a critical part of your engine. If the crankshaft gets damaged, it can lead to costly repairs or even engine failure.

The GM Harmonic Balancer GM 3.8L absorbs the energy from these vibrations, preventing them from reaching the crankshaft. This protection extends to other components like bearings and belts. By keeping these parts safe, the harmonic balancer helps your engine last longer and perform better.

Note: Regular maintenance of the harmonic balancer can save you from expensive repairs down the road.

Signs of a Failing GM Harmonic Balancer GM 3.8L

Unusual engine vibrations

One of the first signs of a failing harmonic balancer is unusual vibrations coming from your engine. You might feel these vibrations through the steering wheel, floor, or even the seat. This happens because the balancer can no longer absorb the crankshaft’s energy pulses effectively. Over time, these vibrations can worsen, making your driving experience uncomfortable. Ignoring this issue could lead to more severe engine damage.

Tip: Pay attention to any new or unusual vibrations while driving. Early detection can save you from costly repairs.

Visible wear or cracks

Inspecting the harmonic balancer can reveal visible signs of wear or damage. Look for cracks, splits, or a worn-out rubber layer between the metal parts. These issues indicate that the balancer is no longer functioning as it should. A damaged balancer cannot properly absorb vibrations, which puts extra stress on your engine. If you notice any of these signs, replacing the balancer becomes essential.

Note: Regular visual inspections can help you catch these problems before they escalate.

Decreased engine performance

A failing GM Harmonic Balancer GM 3.8L can also affect your engine’s performance. You might notice a drop in power, rough idling, or even misfires. This happens because the balancer helps keep the crankshaft and other components in sync. When it fails, the engine’s timing can become inconsistent, leading to performance issues. Addressing this problem quickly can prevent further damage to your engine.

Alert: If your engine feels sluggish or struggles to perform, check the harmonic balancer as part of your troubleshooting process.

How to Inspect the GM Harmonic Balancer GM 3.8L

Tools required for inspection

To inspect the GM Harmonic Balancer GM 3.8L, you need a few essential tools. These tools help you identify any visible damage or performance issues. Here’s what you’ll need:

- Flashlight: To check for cracks, wear, or damage on the balancer.

- Socket wrench set: To remove any components blocking access to the balancer.

- Inspection mirror: To view hard-to-see areas of the balancer.

- Torque wrench: To ensure bolts are tightened correctly after inspection.

- Protective gloves: To keep your hands safe during the process.

Tip: Having all tools ready before starting makes the inspection process smoother and faster.

Step-by-step inspection process

Follow these steps to inspect the GM Harmonic Balancer GM 3.8L:

- Turn off the engine: Ensure the engine is completely off and cool to avoid injury.

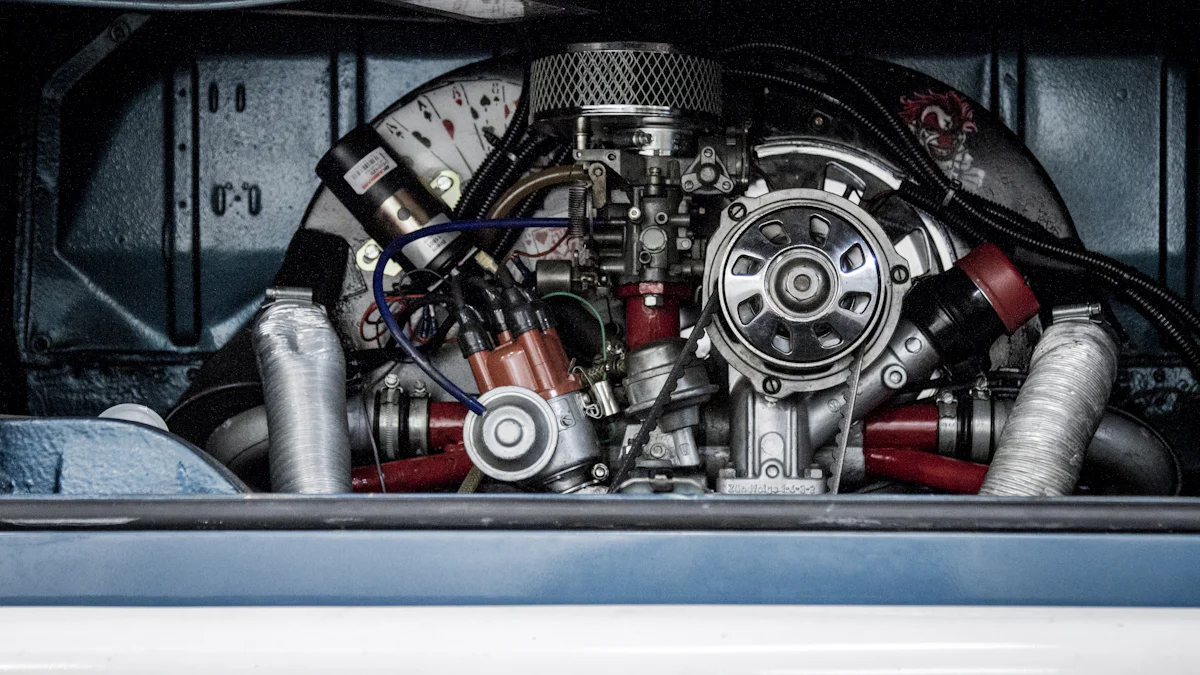

- Locate the harmonic balancer: Find it at the front of the engine, connected to the crankshaft.

- Inspect the rubber layer: Use the flashlight to check for cracks, splits, or signs of wear in the rubber section.

- Check for misalignment: Look for any wobbling or uneven positioning of the balancer. Use the inspection mirror for a better view.

- Examine the metal parts: Look for rust, dents, or other damage on the metal components.

- Spin the balancer manually: If possible, rotate it by hand to check for smooth movement. Any resistance or grinding could indicate a problem.

Alert: If you notice significant damage or misalignment, replace the harmonic balancer immediately to prevent further engine issues.

Regular inspections help you catch problems early, saving you from costly repairs later.

Replacing the GM Harmonic Balancer GM 3.8L

Tools and parts needed

To replace the GM Harmonic Balancer GM 3.8L, gather the following tools and parts:

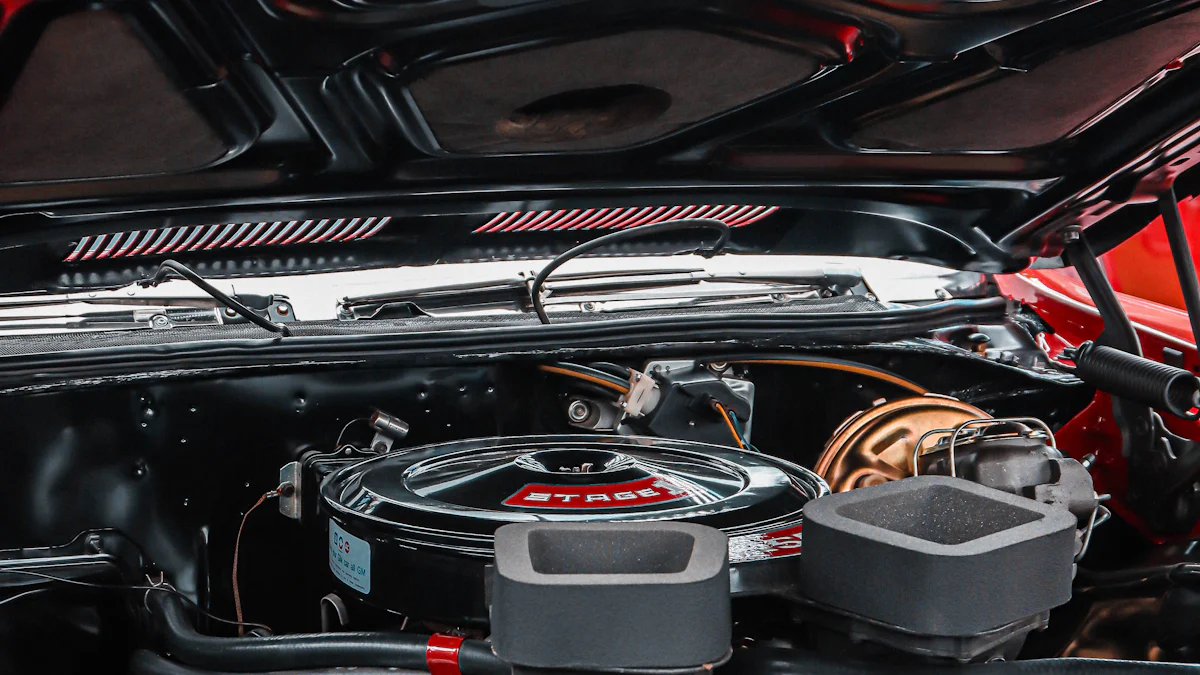

- New harmonic balancer: Ensure it matches your GM 3.8L engine specifications.

- Harmonic balancer puller tool: This helps you remove the old balancer without damaging the crankshaft.

- Socket wrench set: Use this to loosen and tighten bolts.

- Torque wrench: Ensures bolts are tightened to the correct specifications.

- Breaker bar: Provides extra leverage for stubborn bolts.

- Protective gloves: Keeps your hands safe during the process.

- Thread locker: Secures bolts and prevents them from loosening over time.

Tip: Double-check that you have all the tools before starting to avoid interruptions.

Step-by-step replacement guide

- Turn off the engine: Ensure the engine is cool and the battery is disconnected.

- Locate the harmonic balancer: Find it at the front of the engine, attached to the crankshaft.

- Remove the serpentine belt: Use the socket wrench to release tension and slide the belt off.

- Loosen the balancer bolt: Use the breaker bar to loosen the central bolt holding the balancer.

- Attach the puller tool: Secure the puller to the balancer and carefully remove it from the crankshaft.

- Inspect the crankshaft: Check for damage or debris before installing the new balancer.

- Install the new balancer: Align it with the crankshaft and slide it into place.

- Tighten the bolt: Use the torque wrench to tighten the bolt to the manufacturer’s specifications.

- Reinstall the serpentine belt: Ensure it is properly aligned with all pulleys.

- Reconnect the battery: Start the engine and check for smooth operation.

Alert: If you encounter resistance during installation, stop and recheck the alignment.

Safety precautions during replacement

Safety should always come first when replacing the GM Harmonic Balancer GM 3.8L. Wear protective gloves to avoid injuries. Disconnect the battery to prevent accidental starts. Use the correct tools to avoid damaging the crankshaft or other components. Always follow the torque specifications to ensure the balancer is securely installed. Work on a cool engine to prevent burns. If you feel unsure about any step, consult a professional mechanic.

Note: Taking safety precautions reduces the risk of injury and ensures a successful replacement.

Maintenance Tips for the GM Harmonic Balancer GM 3.8L

Regular inspection schedule

Regular inspections keep your GM Harmonic Balancer GM 3.8L in top condition. Check it every 12,000 to 15,000 miles or during routine maintenance. Look for cracks, worn rubber, or misalignment. Use a flashlight and inspection mirror to examine hard-to-see areas. Early detection of damage prevents costly repairs. If you notice unusual vibrations or visible wear, inspect the balancer immediately. Consistent checks ensure your engine stays healthy and performs efficiently.

Tip: Pair harmonic balancer inspections with oil changes to make it part of your routine.

Preventing premature wear

Preventing premature wear extends the life of your harmonic balancer. Avoid overloading your engine by driving smoothly and avoiding sudden acceleration. Keep the serpentine belt properly tensioned. A loose or overly tight belt can strain the balancer. Replace worn belts promptly to reduce stress on the component. Use high-quality replacement parts when necessary. Poor-quality balancers wear out faster and may not perform as effectively.

Note: Maintaining proper engine alignment also reduces unnecessary strain on the balancer.

Troubleshooting common issues

Troubleshooting common issues helps you address problems early. If you feel unusual vibrations, check the balancer for damage. Listen for rattling or knocking sounds near the crankshaft. These noises often indicate a failing balancer. Inspect the rubber layer for cracks or separation. Misalignment or wobbling suggests the balancer needs replacement. If you notice decreased engine performance, include the balancer in your diagnostic process.

Alert: Ignoring these signs can lead to severe engine damage. Act quickly to avoid expensive repairs.

The GM Harmonic Balancer GM 3.8L is essential for your engine’s performance and durability. Regular inspections and timely replacements prevent costly repairs. Proactive maintenance ensures smooth operation and extends engine life.

Post time: Jan-13-2025