Understanding how hot an engine exhaust manifold can get is crucial for vehicle owners. This blog delves into the significance of comprehending exhaust manifold temperatures, providing valuable insights into the extreme heat levels involved. From typical temperature ranges to peak temperatures exceeding 1200 degrees Fahrenheit, readers will gain a comprehensive understanding of this essential aspect of engine operation.

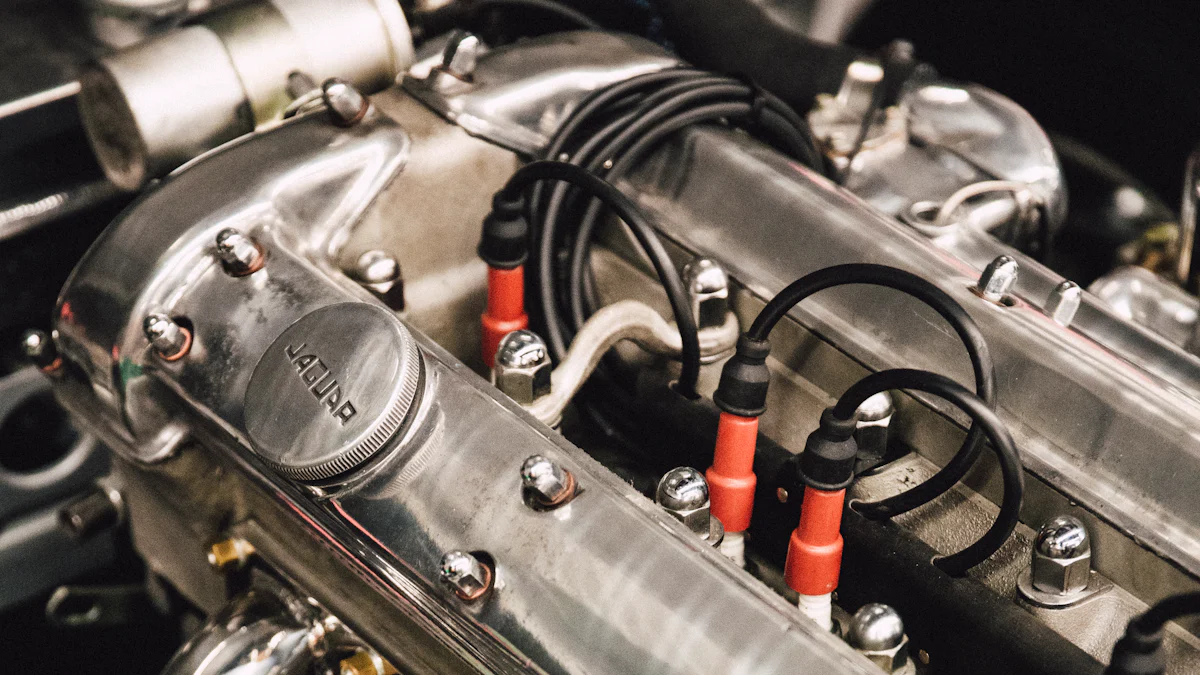

Understanding Exhaust Manifolds

When considering the engine exhaust manifold of a vehicle, it’s essential to grasp its intricate details and functions. An exhaust manifold serves as a crucial component in an engine’s exhaust system, responsible for collecting exhaust gases from multiple cylinders and channeling them towards the exhaust pipe. This process plays a significant role in maintaining the engine’s overall performance and efficiency.

What is an Exhaust Manifold?

Definition and Function

The exhaust manifold can be described as a vital link between the engine cylinders and the exhaust pipe. Its primary function involves gathering the hot, toxic gases produced during combustion within each cylinder and directing them towards the catalytic converter or muffler for emission control. By efficiently collecting these gases, the exhaust manifold contributes to optimizing the engine’s operation and reducing harmful emissions.

Types of Exhaust Manifolds

There are various types of exhaust manifolds, each designed to cater to specific engine configurations and performance requirements. Common variants include cast iron manifolds, stainless steel manifolds, and tubular headers. Cast iron manifolds are known for their durability and cost-effectiveness, while stainless steel manifolds offer superior corrosion resistance. Tubular headers, on the other hand, enhance exhaust flow efficiency by providing individual headpipes for each cylinder.

How Hot Does an Exhaust Manifold Get?

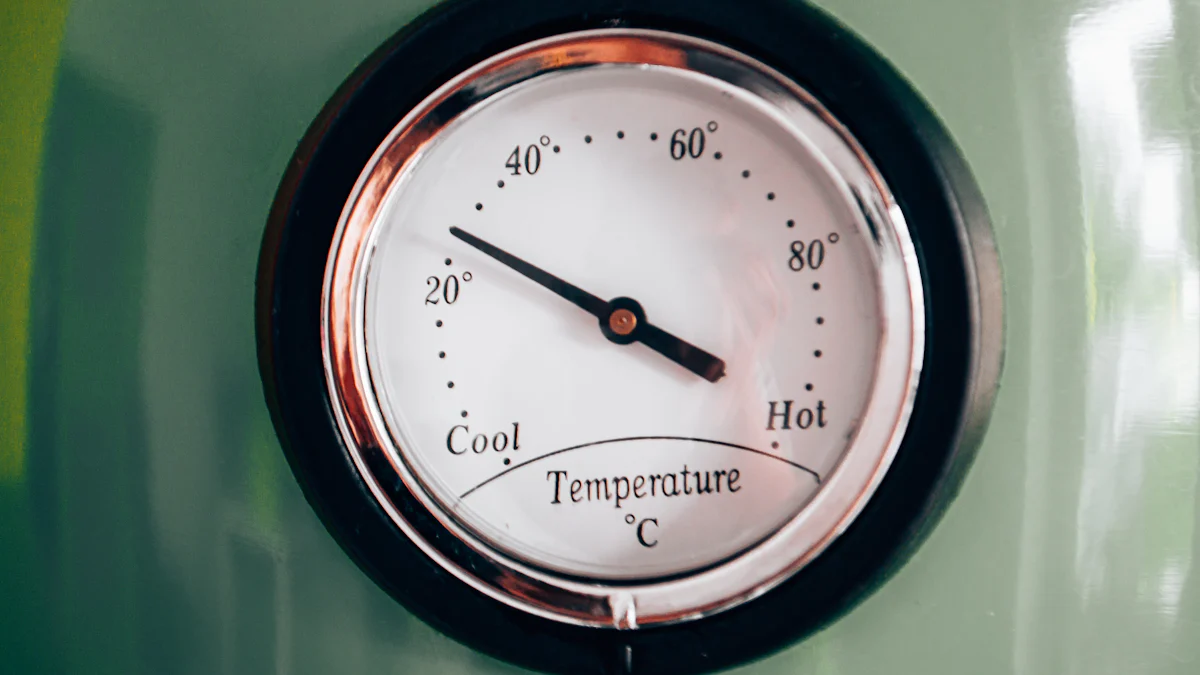

Typical Temperature Ranges

The exhaust manifold temperature can vary significantly depending on driving conditions and engine load. Under normal operating conditions, most stock engines exhibit temperatures ranging from 275 to 300 degrees Fahrenheit at idle. However, during high-performance scenarios such as racing or heavy-duty applications, these temperatures can escalate rapidly.

Peak Temperatures

In extreme cases, such as in high-performance vehicles or heavy-duty machinery, exhaust manifolds can reach temperatures exceeding 1200 degrees Fahrenheit. These extreme heat levels pose challenges in terms of material durability and thermal management within the engine compartment.

Manifold of Car Withstand

Material Composition

Given the demanding environment they operate in, exhaust manifolds are constructed using materials with high heat resistance properties. Common materials include cast iron, stainless steel, and mild steel. Each material offers a unique set of advantages concerning heat tolerance and longevity.

Design Considerations

The design of an exhaust manifold plays a crucial role in optimizing engine performance and torque characteristics. Factors such as pipe length, diameter, joints, welds, and interior smoothness significantly impact gas flow efficiency. Additionally, proper sizing of the manifold branches is essential to ensure timely reflection of counter-pulses in the collector.

As manufacturers strive to enhance vehicle performance while meeting stringent emission standards, continuous advancements in engine exhaust manifold design are witnessed across various automotive segments.

Factors Affecting Manifold Temperatures

When examining the temperature of an exhaust manifold, it’s essential to consider various factors that can influence these extreme heat levels. Understanding how engine load and speed, fuel type and quality, as well as exhaust system design, play a pivotal role in determining the overall thermal performance of the manifold is crucial for vehicle owners.

Engine Load and Speed

Impact of Driving Conditions

Driving conditions have a significant impact on the temperature of an exhaust manifold. During high-speed highway driving, the increased airflow through the engine compartment can help dissipate heat more efficiently. Conversely, in stop-and-go city traffic, where the engine operates at lower speeds for extended periods, heat buildup within the manifold can be more pronounced.

Performance Situations

In performance situations such as racing or towing heavy loads, engines operate under higher loads and speeds, leading to increased combustion temperatures. This elevated thermal stress results in higher exhaust gas temperatures exiting the cylinders and flowing into the manifold. As a consequence, the manifold must withstand these extreme conditions without compromising its structural integrity.

Fuel Type and Quality

Gasoline vs. Diesel

The type of fuel used in an engine can also impact exhaust manifold temperatures. Diesel engines typically operate at higher combustion temperatures than gasoline engines due to their compression ignition process. As a result, diesel-powered vehicles may experience greater heat generation within the exhaust system, including the manifold.

Influence of Fuel Additives

The quality of fuel additives utilized can further affect exhaust temperatures. Certain additives are designed to enhance combustion efficiency or clean engine components, potentially altering the thermal characteristics of exhaust gases. By modifying combustion properties, these additives may indirectly influence the temperature profile within the exhaust manifold.

Exhaust System Design

Role of Catalytic Converters

Catalytic converters play a crucial role in reducing harmful emissions by converting toxic gases into less harmful byproducts. However, catalytic converters also introduce additional heat into the exhaust system due to exothermic reactions occurring within them. This added thermal load impacts not only converter temperatures but also influences overall heat dissipation along the entire length of the exhaust system.

Influence of Headers and Pipes

The design and material composition of headers and pipes directly impact how efficiently exhaust gases flow through the system. Headers with equal-length primary tubes promote balanced gas flow from each cylinder into a single collector, minimizing backpressure and reducing temperature differentials between cylinders. Additionally, using mandrel-bent tubing ensures smooth transitions for exhaust gases without creating unnecessary restrictions that could elevate temperatures locally.

By considering these critical factors affecting manifold temperatures, vehicle owners can gain valuable insights into optimizing engine performance while ensuring longevity and reliability under varying operating conditions.

Real-World Temperature Measurements

Idle and Normal Driving Conditions

When exhaust gases flow through the exhaust manifold, they carry with them the remnants of combustion, releasing heat in the process. During idle or normal driving conditions, these temperatures provide valuable insights into the engine’s efficiency and performance.

- The exhaust port during idle showcases temperatures that can range from 275 to 300 degrees Fahrenheit on most stock engines. This indicates a stable operating temperature for the manifold under minimal load.

- In contrast, performance engines exhibit slightly higher temperatures, reaching up to 325 degrees Fahrenheit during idle. This increase is attributed to the enhanced combustion processes within these high-performance setups.

High-Performance Scenarios

In high-performance scenarios such as racing conditions or heavy-duty applications, the demands placed on the engine result in elevated temperatures within the exhaust system. These extreme conditions push the exhaust manifold to its limits, testing its durability and thermal resilience.

- Racing conditions push exhaust temperatures to new heights, with readings surpassing 1200 degrees Fahrenheit in some instances. The intense heat generated during high-speed races challenges even the most robust materials used in manifold construction.

- Heavy-duty applications, like towing heavy loads or powering industrial machinery, subject exhaust manifolds to prolonged exposure to high temperatures. Temperatures exceeding 1000 degrees Fahrenheit are not uncommon in these demanding environments.

Temperature Variations

The distribution of heat across different cylinders and vehicle models highlights the intricate nature of exhaust system dynamics. Understanding these variations is crucial for optimizing engine performance and ensuring consistent reliability.

- Between cylinders, variations in exhaust gas temperatures can be observed due to factors like fuel injection patterns and cylinder-specific combustion characteristics. These differences can lead to temperature differentials of up to 100 degrees Fahrenheit between adjacent cylinders.

- Across different vehicle models, variations in exhaust manifold design and engine specifications contribute to diverse temperature profiles. For instance, vehicles with turbocharged engines may exhibit higher exhaust temperatures compared to naturally aspirated counterparts due to increased boost pressures.

By examining real-world temperature measurements under various operating conditions, vehicle owners can gain a deeper appreciation for the thermal challenges faced by exhaust manifolds. Monitoring these temperatures provides valuable insights into engine health and performance optimization strategies.

Implications of High Temperatures

Engine Performance

Efficiency and Power Output

High temperatures in the exhaust manifold can significantly impact the engine’s performance by influencing its efficiency and power output. When the exhaust gases reach extreme heat levels, they can affect the combustion process within the cylinders, leading to suboptimal engine operation.

- The efficiency of an engine is closely tied to the temperature management of critical components like the exhaust manifold. Excessive heat can disrupt the ideal conditions for combustion, resulting in incomplete fuel burning and reduced energy conversion from fuel to mechanical work.

- In terms of power output, elevated temperatures in the exhaust system can hinder the engine’s ability to generate sufficient force for vehicle propulsion. The thermal stress on internal components caused by high temperatures may compromise overall power delivery, affecting acceleration and towing capabilities.

- To maintain optimal engine performance, it is essential to monitor exhaust manifold temperatures regularly and address any issues that may arise due to excessive heat buildup. By ensuring proper cooling and insulation measures are in place, vehicle owners can safeguard their engine’s efficiency and power output.

Longevity and Durability

The longevity and durability of an engine are closely linked to how well it withstands high temperatures in critical areas such as the exhaust manifold. Prolonged exposure to extreme heat levels can accelerate wear and tear on components, potentially leading to premature failure of vital engine parts.

- Over time, continuous exposure to elevated temperatures can degrade the structural integrity of materials used in exhaust manifolds. This degradation may manifest as cracks, warping, or corrosion, compromising the manifold’s ability to contain and direct exhaust gases effectively.

- The durability of an engine under high-temperature conditions is a testament to its resilience against thermal stress. Components subjected to intense heat must exhibit robustness and resistance to deformation or material fatigue to ensure long-term reliability.

- By prioritizing maintenance practices that mitigate excessive heat buildup in the exhaust system, vehicle owners can enhance their engine’s longevity and durability. Regular inspections, timely repairs, and adequate cooling mechanisms play a crucial role in preserving engine components from premature deterioration.

Maintenance Considerations

Preventive Measures

Implementing proactive maintenance strategies is essential for mitigating the adverse effects of high temperatures on exhaust manifolds and overall engine performance. By adopting preventive measures aimed at temperature control and component protection, vehicle owners can prolong their engine’s lifespan and optimize its operational efficiency.

- Regular Inspections: Conduct routine visual inspections of the exhaust manifold for signs of discoloration, rust, or physical damage that may indicate overheating issues.

- Cooling System Maintenance: Ensure proper functioning of the vehicle’s cooling system, including radiator flushes, coolant level checks, and thermostat inspections.

- Heat Shield Installation: Consider installing heat shields around vulnerable areas near the exhaust manifold to reduce radiant heat transfer and protect surrounding components.

- Exhaust System Upgrades: Upgrade exhaust components with higher heat tolerance materials or improved designs that enhance thermal dissipation capabilities.

- Monitoring Tools: Invest in temperature monitoring tools or sensors that provide real-time data on exhaust manifold temperatures during various driving conditions.

- Professional Servicing: Schedule regular maintenance appointments with qualified technicians who specialize in diagnosing and addressing issues related to high-temperature environments.

Signs of Overheating

Recognizing early indicators of overheating in an engine’s exhaust system is crucial for preventing potential damage or malfunctions caused by excessive temperatures. By being vigilant about common warning signs associated with overheating components like the exhaust manifold, vehicle owners can take prompt action to avoid costly repairs or replacements.

- Unusual Smells: Pay attention to any abnormal odors emanating from the engine compartment that could indicate overheated materials or leaking fluids.

- Increased Exhaust Smoke: Monitor changes in exhaust smoke color or density as darker emissions may signal burning oil or coolant due to overheating.

- Engine Misfires: Be alert for irregular engine misfires or rough idling patterns that could result from compromised combustion processes linked to high manifold temperatures.

- Reduced Fuel Efficiency: Track variations in fuel consumption rates as increased fuel usage without corresponding performance gains may suggest inefficient combustion caused by overheating.

- Dashboard Warnings: Heed warning lights on the dashboard related to coolant temperature or engine malfunctions that could point towards elevated operating temperatures within critical systems.

By staying attuned to these signs of overheating within the exhaust system, vehicle owners can proactively address underlying issues before they escalate into more severe mechanical problems. Prioritizing preventive maintenance measures ensures optimal performance while safeguarding against potential risks associated with high temperatures affecting key engine components like the exhaust manifold.

- To summarize, understanding the intricate details of exhaust manifold temperatures is crucial for optimal engine performance and longevity. By monitoring these temperatures, vehicle owners can proactively address potential issues and ensure the efficient operation of their engines. Regular inspections, proper cooling system maintenance, and the installation of heat shields are essential preventive measures to safeguard against overheating. For further insights on maintaining exhaust manifold health and maximizing engine efficiency, exploring additional resources on temperature management in vehicle systems is highly recommended. Stay informed to keep your engine running smoothly!

Post time: Jun-05-2024