A clean intake manifold cleaner is vital for optimal engine performance. Neglecting maintenance can lead to a host of issues, including reduced efficiency and potential damage. Cleaning without removal offers a solution that enhances engine longevity and efficiency. Understanding the process is key to ensuring a well-functioning vehicle. As expert Tsukasa Azuma notes, “Carbon build-up within the Exhaust Intake Manifold can significantly impact your engine’s performance.” Regular maintenance is crucial to prevent costly repairs down the line.

Understanding the Intake Manifold

What is an Intake Manifold?

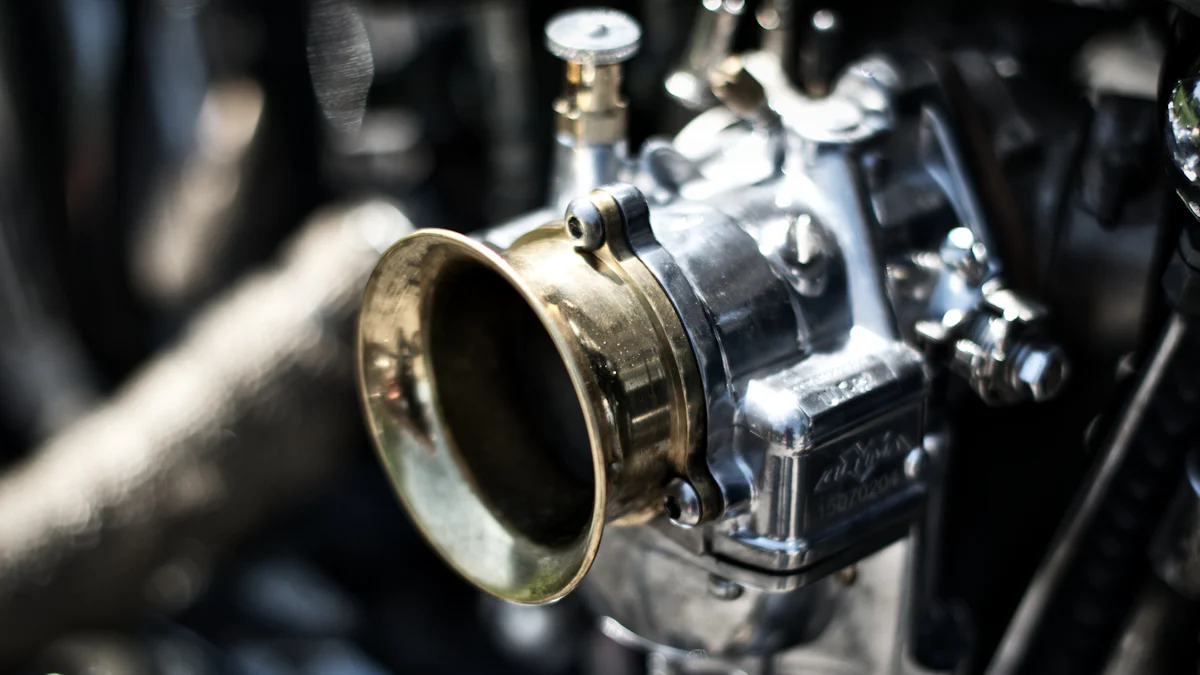

The intake manifold plays a crucial role in ensuring optimal engine performance. It serves as a pathway that directs air into the engine cylinders for combustion. Without a clean intake manifold, the airflow can be obstructed, leading to inefficiencies in the combustion process.

Function and Importance

- The primary function of the intake manifold is to distribute air evenly to all cylinders.

- A clean intake manifold ensures that the right amount of air reaches each cylinder for efficient combustion.

- Contaminants like carbon deposits can accumulate in the intake manifold, disrupting airflow and fuel mixture balance.

Common Contaminants

- Carbon build-up is a common issue that affects the performance of the intake manifold.

- Other contaminants such as oil sludge and dirt particles can also accumulate over time.

- These contaminants restrict airflow, leading to decreased power output and reduced acceleration.

Symptoms of a Dirty Intake Manifold

When the intake manifold is dirty or clogged with contaminants, several symptoms may manifest, indicating potential issues with engine performance.

Reduced Engine Performance

- A dirty intake manifold can impede airflow, resulting in decreased power output.

- Reduced engine performance may lead to sluggish acceleration and overall inefficiency.

Increased Fuel Consumption

- Contaminants in the intake manifold can disrupt the air-fuel ratio, causing the engine to consume more fuel than necessary.

- Increased fuel consumption is often a sign of inefficient combustion due to a dirty intake manifold.

Engine Misfires

- Contaminated intake manifolds can cause irregular fuel distribution to cylinders, leading to engine misfires.

- Engine misfires result in rough idling, poor acceleration, and potential damage to engine components.

Preparing for the Cleaning Process

Tools and Materials Needed

Cleaning Solutions

- Choose a suitable cleaning solution that is compatible with your intake manifold material.

- Opt for products like Seafoam spray or Amsoil power foam for effective cleaning.

- Ensure the solution is safe for your engine components to avoid any damage.

Brushes and Scrapers

- Select appropriate brushes and scrapers to remove stubborn deposits from the intake manifold.

- Use tools like brass hand wire brushes or nylon/brass rifle type brushes for efficient cleaning.

- Ensure the brushes are gentle enough not to damage the manifold surface.

Safety Gear

- Wear protective gear such as gloves, goggles, and a mask to safeguard yourself from harmful chemicals.

- Use safety equipment to prevent skin contact with cleaning solutions and debris.

- Prioritize safety throughout the cleaning process to avoid any accidents.

Safety Precautions

Working in a Well-Ventilated Area

- Perform the cleaning process in a well-ventilated area to minimize exposure to fumes.

- Ensure there is proper airflow to dissipate any chemical odors during cleaning.

- Protect yourself by working in a ventilated space to maintain good air quality.

Wearing Protective Gear

- Put on gloves, goggles, and a mask before starting the cleaning procedure.

- Avoid direct contact with cleaning solutions or debris by wearing appropriate protective gear.

- Prioritize your safety by using protective equipment throughout the process.

Disconnecting the Battery

- Disconnect the car battery before initiating the intake manifold cleaning process.

- Prevent electrical mishaps by disconnecting the battery terminals carefully.

- Ensure safety by cutting off power sources before starting any maintenance work.

Step-by-Step Cleaning Procedure

Accessing the Intake Manifold

To begin the cleaning process, locate the intake manifold within your vehicle’s engine. Identify its position to ensure efficient access for maintenance. Once located, proceed by removing any necessary components that obstruct direct access to the manifold.

Locating the Intake Manifold

- Identify the intake manifold’s position near the engine block.

- Ensure clear visibility to facilitate easy access for cleaning.

Removing Necessary Components

- Detach any surrounding components that hinder direct reach to the intake manifold.

- Clear the area around the manifold for a thorough cleaning process.

Applying the Cleaning Solution

After accessing the intake manifold, it is essential to select an appropriate cleaner for effective removal of contaminants. The choice of cleaner and proper application techniques are crucial for optimal results.

Choosing the Right Cleaner

- Select a suitable cleaning solution compatible with your intake manifold material.

- Ensure that the cleaner effectively targets and eliminates built-up residues.

Application Techniques

- Apply the chosen cleaner generously over the surface of the intake manifold.

- Allow sufficient time for the solution to penetrate and break down stubborn deposits.

Scrubbing and Removing Deposits

Once the cleaning solution has had ample time to work its magic, proceed with scrubbing off accumulated deposits from the intake manifold surface using appropriate tools.

Using Brushes and Scrapers

- Utilize brushes or scrapers designed for removing tough residues without damaging the manifold.

- Scrub gently but firmly to dislodge contaminants effectively.

Ensuring Thorough Cleaning

- Inspect all areas of the intake manifold to guarantee complete removal of contaminants.

- Verify that no deposits remain before proceeding to flush and finalize the cleaning process.

Flushing and Final Checks

Flushing with Water or Air

- Begin the final phase by flushing the intake manifold with either water or air.

- Ensure a thorough cleanse by directing the flow through all passages.

- Eliminate any remaining debris to optimize engine performance.

Inspecting for Residual Deposits

- Conduct a meticulous inspection post-flushing to detect any lingering deposits.

- Verify that all contaminants have been effectively removed from the manifold.

- Address any remnants promptly to prevent future issues.

Reassembling Components

- Commence reassembly of components once the intake manifold is clean and dry.

- Carefully place each part back in its original position to ensure proper alignment.

- Double-check connections and fittings before completing the process.

Post-Cleaning Maintenance Tips

Regular Inspection and Cleaning

Frequency of Cleaning

- Inspect the intake manifold regularly to ensure it remains free from contaminants.

- Clean the manifold every 30,000 to 40,000 miles to maintain optimal engine performance.

- Monitor for any signs of carbon build-up or debris accumulation within the intake manifold.

Signs to Look For

- Watch out for symptoms like reduced engine power or rough idling, indicating a dirty intake manifold.

- Check for increased fuel consumption as a potential sign of contamination in the intake system.

- Be aware of engine misfires or poor acceleration, which could signal a clogged intake manifold.

Using Fuel Additives

Types of Additives

- Consider using products like Sea Foam or Amsoil power foam as effective additives for intake manifold maintenance.

- Explore non-aerosol liquid cleaners that can efficiently remove deposits without disassembling the manifold.

- Opt for STP® Pro-Series Intake Valve Cleaner for professional-grade results without extensive teardown.

Benefits and Usage

- Experience improved engine performance and fuel efficiency with regular use of fuel additives.

- Enhance combustion quality by eliminating carbon deposits and maintaining clean intake components.

- Maximize the lifespan of your engine by incorporating fuel additives into your maintenance routine.

Maintaining Overall Engine Health

Regular Oil Changes

- Schedule routine oil changes to keep your engine running smoothly and prevent internal damage.

- Follow manufacturer recommendations for oil type and change intervals to optimize engine health.

- Ensure proper lubrication of engine components by adhering to a consistent oil change schedule.

Using Quality Fuel

- Invest in high-quality fuel to promote cleaner combustion and reduce harmful emissions.

- Avoid low-grade fuels that may contain impurities leading to carbon buildup in the intake system.

- Prioritize premium fuel options for enhanced engine performance and longevity.

Recapping the meticulous cleaning process ensures a well-maintained intake manifold. The benefits of a spotless intake manifold are evident in improved engine performance and fuel efficiency. Encouraging regular maintenance guarantees longevity for your vehicle’s heart. In conclusion, prioritize engine care for optimal performance on the road.

Post time: Jun-26-2024