Crankshaft Pulley And Harmonic Balancer components are vital for your vehicle’s performance, as they work to minimize engine vibrations and ensure a smooth driving experience. A malfunctioning GM Harmonic Balancer or crankshaft pulley can lead to significant issues, such as irregular noises like squealing or chirping from worn-out belts. Increased engine vibrations might suggest a problem with the dampening material. The GM Harmonic Balancer, specifically engineered for GM vehicles, plays a key role in maintaining engine integrity. Recognizing these signs early can prevent more severe engine problems in the future. Investing in a quality Engine Harmonic Balancer, such as the LS Harmonic Balancer, is crucial for the health of your vehicle.

Understanding Crankshaft Pulley And Harmonic Balancer

Function and Importance

Role in Engine Performance

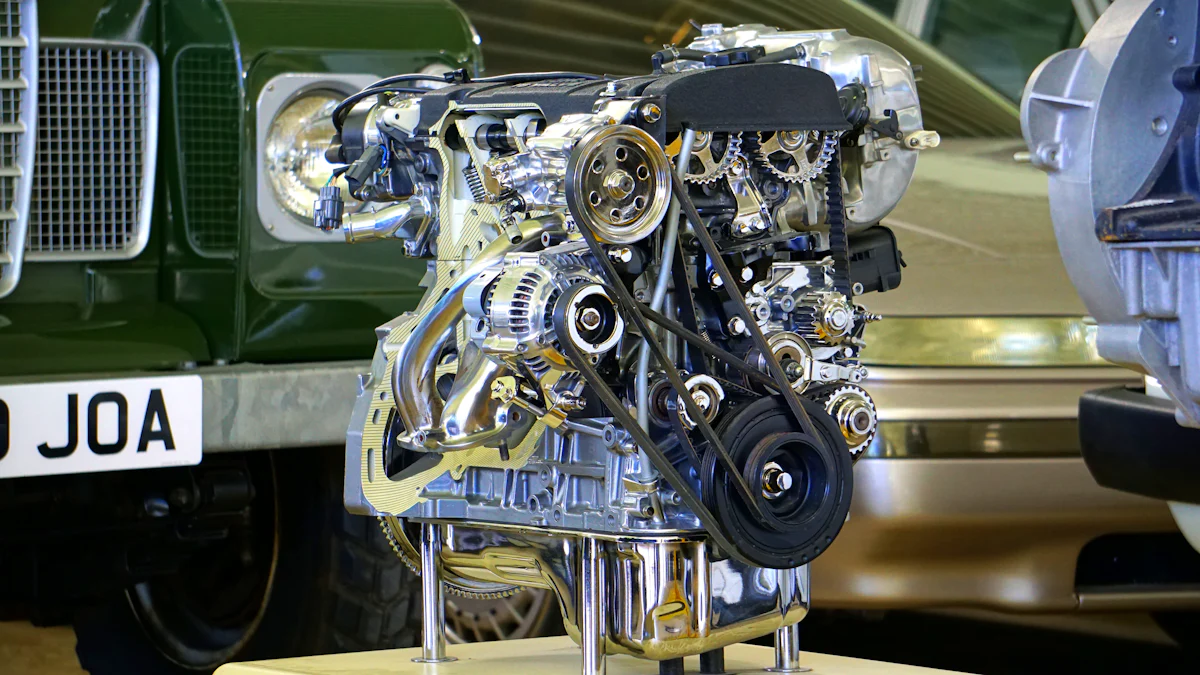

You might wonder why the crankshaft pulley and harmonic balancer are so crucial for your vehicle. These components play a pivotal role in enhancing engine performance. The crankshaft pulley, often made from materials like steel or aluminum, helps optimize your vehicle’s performance by reducing weight and absorbing vibrations. This reduction in vibration is essential because it prevents unnecessary wear and tear on your engine. The GM Harmonic Balancer, specifically designed for GM vehicles, further aids in minimizing engine vibrations. By doing so, it ensures that your engine runs smoothly and efficiently, contributing to a better driving experience.

Impact on Vehicle Longevity

The longevity of your vehicle heavily depends on the health of its engine components. A well-functioning Engine Harmonic Balancer can significantly extend the life of your vehicle. By dampening vibrations, it protects other engine parts from damage. This protection is vital because excessive vibrations can lead to rough idling and potential damage to engine accessories. Investing in a quality harmonic balancer not only enhances performance but also safeguards your vehicle against costly repairs in the future.

Signs a Crankshaft Pulley is Bad

Engine Vibration

One of the most noticeable signs of a faulty crankshaft pulley is increased engine vibration. You might feel these vibrations more prominently when your vehicle is idling. The rubber ring within the pulley acts as a vibration dampener. If this ring wears out or fails, vibrations can transfer to the accessory driving belt, causing discomfort and potential damage. It’s crucial to address these vibrations promptly to avoid further complications.

Unusual Noises

Unusual noises, such as squealing or chirping, often indicate a problem with the crankshaft pulley. These sounds usually result from worn-out belts or misalignment caused by a faulty pulley. If you hear these noises, it’s essential to inspect the pulley for any visible damage or misalignment. Ignoring these signs can lead to more severe engine issues over time. Regular inspection and maintenance can help you catch these problems early, ensuring your vehicle remains in top condition.

Recognizing Symptoms of a Faulty Crankshaft Pulley or Harmonic Balancer

Spotting the signs of a faulty crankshaft pulley or harmonic balancer early can save you from costly repairs. Let’s dive into the common symptoms and visual indicators that might suggest something’s amiss.

Common Symptoms

Unusual Engine Noises

You might notice strange noises coming from your engine. These noises often sound like rattling or banging, especially when accelerating. One driver shared their experience of hearing an odd rattle behind the glovebox, which turned out to be related to the crankshaft pulley. If you hear such noises, it’s crucial to investigate further. The noise could stem from a bad bearing within the pulley or harmonic balancer. Ignoring these sounds might lead to more severe issues down the road.

Increased engine vibration is another telltale sign. You might feel these vibrations more when your vehicle is idling. A bad harmonic balancer or crankshaft pulley can cause these vibrations. The rubber component within the harmonic balancer helps dampen vibrations. When this part wears out, vibrations can transfer to the belt, causing discomfort and potential damage. Addressing these vibrations promptly can prevent further complications.

Increased engine vibration is another telltale sign. You might feel these vibrations more when your vehicle is idling. A bad harmonic balancer or crankshaft pulley can cause these vibrations. The rubber component within the harmonic balancer helps dampen vibrations. When this part wears out, vibrations can transfer to the belt, causing discomfort and potential damage. Addressing these vibrations promptly can prevent further complications.

Visual Indicators

Visible Wear and Tear

A quick visual inspection can reveal a lot. Look for visible wear and tear on the pulley or harmonic balancer. Cracks, dings, or missing chunks indicate damage. The rubberized material between the inner and outer rings of the harmonic balancer might separate, leading to wobbling. This separation can cause the belt to chirp, signaling a problem. Regular checks can help you catch these issues early.

Misalignment

Misalignment is another visual clue. If the zero mark on the outer ring of the harmonic balancer doesn’t align with the timing belt cover, it might indicate a problem. Misalignment can cause the belt to slip, leading to increased noise and vibration. Ensuring proper alignment can help maintain your vehicle’s performance.

By keeping an eye out for these symptoms and indicators, you can ensure your vehicle runs smoothly. If you suspect your crankshaft pulley is bad, consider consulting a professional. They can provide a thorough inspection and recommend the best course of action. Remember, investing in a quality LS Harmonic Balancer can enhance your vehicle’s performance and longevity.

Diagnostic Techniques

Physical Inspection

Checking for Cracks or Damage

You can start diagnosing a faulty crankshaft pulley or harmonic balancer by conducting a physical inspection. Look closely at the pulley for any visible cracks or damage. These imperfections often indicate wear and tear. If you spot any dings or missing chunks, it might be time to consider a replacement. Regular inspections help you catch these issues early, preventing more severe engine problems.

Assessing Pulley Alignment

Next, assess the alignment of the pulley. Misalignment can cause the belt to slip, leading to increased noise and vibration. Check if the zero mark on the outer ring of the harmonic balancer aligns with the timing belt cover. If it doesn’t, you might have an alignment issue. Ensuring proper alignment keeps your vehicle running smoothly and efficiently.

Performance Testing

Engine Performance Analysis

Performance testing provides valuable insights into the health of your crankshaft pulley and harmonic balancer. Start by analyzing your engine’s performance. Pay attention to any unusual noises or vibrations. These symptoms often suggest a problem with the pulley or balancer. A smooth-running engine indicates that these components are functioning correctly.

Vibration Testing

Vibration testing is another effective diagnostic technique. Use a vibration analyzer to measure the levels of vibration in your engine. Excessive vibrations can signal a faulty harmonic balancer or crankshaft pulley. By identifying these vibrations early, you can address the issue before it leads to more significant engine damage. Regular vibration testing helps maintain your vehicle’s performance and longevity.

By following these diagnostic techniques, you can ensure your vehicle remains in top condition. If you suspect any issues, consider consulting a professional for a thorough inspection. They can provide expert advice and recommend the best course of action. Remember, investing in a quality harmonic balancer enhances your vehicle’s performance and extends its lifespan.

Suggested Methods for Identification

Identifying a faulty harmonic balancer or crankshaft pulley can be tricky, but with the right tools and expertise, you can get to the bottom of the issue. Here are some methods to help you pinpoint the problem.

Using Diagnostic Tools

OBD-II Scanner

An OBD-II scanner is a handy tool for diagnosing vehicle issues. You can plug it into your car’s diagnostic port to read error codes. These codes can give you clues about what’s wrong with your crankshaft pulley or harmonic balancer. If you see codes related to engine misfires or timing issues, it might be time to take a closer look at these components. The scanner helps you catch problems early, saving you from costly repairs down the line.

Vibration Analyzer

A vibration analyzer measures the vibrations in your engine. Excessive vibrations often indicate a problem with the harmonic balancer or crankshaft pulley. By using this tool, you can detect abnormal vibrations that might not be noticeable otherwise. Regular checks with a vibration analyzer can help you maintain your vehicle’s performance and prevent further damage.

Professional Inspection

Consulting a Mechanic

Sometimes, it’s best to leave it to the pros. Consulting a mechanic can provide you with a thorough inspection of your vehicle. Mechanics have the experience and tools to diagnose issues accurately. They can spot problems that you might miss and offer solutions to fix them. If you’re unsure about your crankshaft pulley’s condition, a mechanic’s expertise can be invaluable.

Seeking a Second Opinion

If you’re still uncertain, seeking a second opinion can be a wise move. Another mechanic might offer a different perspective or catch something the first one missed. This approach ensures that you get a comprehensive understanding of your vehicle’s condition. Remember, it’s better to be safe than sorry when it comes to your car’s health.

BG Automotive Experts emphasize the importance of addressing crankshaft pulley issues promptly. They warn that a broken vibration dampener can lead to severe engine damage, which is costly to repair. By using these diagnostic methods, you can catch problems early and keep your vehicle running smoothly.

By following these suggested methods, you can effectively identify issues with your crankshaft pulley or harmonic balancer. Whether you use diagnostic tools or seek professional help, taking action early can save you from more significant problems in the future.

Community Insights and Real-World Experiences

When it comes to crankshaft pulleys and harmonic balancers, real-world experiences from vehicle owners can be incredibly insightful. You can learn a lot from those who have faced similar issues and found solutions that work.

Common Issues Reported by Vehicle Owners

Frequent Problems with Specific Models

Many vehicle owners have shared their experiences with crankshaft pulley problems on various forums. In January, several Members reported issues with specific GM models. They noticed increased engine vibrations and unusual noises. These problems often appeared in older models, particularly those with high mileage. If you drive a Buick, Oldsmobile, Pontiac, or Chevrolet, you might want to pay extra attention to these symptoms.

User-Reported Solutions

Owners have also shared solutions that worked for them. One common fix involves replacing the worn-out harmonic balancer with a new GM Harmonic Balancer. This replacement often resolves the vibration and noise issues. Some users recommend checking the alignment of the pulley as well. Misalignment can cause the belt to slip, leading to further problems. By addressing these issues early, you can prevent more severe engine damage.

Tips from Automotive Experts

Preventive Maintenance Advice

Automotive experts emphasize the importance of regular maintenance. They suggest scheduling routine inspections to catch potential problems early. During these checks, you should look for visible wear and tear on the crankshaft pulley and harmonic balancer. Experts also recommend listening for unusual noises, as they can indicate underlying issues. By staying proactive, you can keep your vehicle running smoothly.

Recommended Tools and Techniques

Experts often recommend using specific tools to diagnose crankshaft pulley issues. A vibration analyzer can help you detect abnormal vibrations in your engine. An OBD-II scanner is another useful tool. It reads error codes that might indicate problems with the pulley or harmonic balancer. By using these tools, you can identify issues before they escalate.

BG Automotive Experts highlight the importance of addressing crankshaft pulley problems promptly. They warn that ignoring these issues can lead to costly engine repairs. By following expert advice and learning from other vehicle owners, you can ensure your vehicle remains in top condition.

If you’re experiencing issues with your crankshaft pulley or harmonic balancer, consider sharing your experience online. Many forums offer sharing options where you can post your story and get feedback from other Members. You can also find a Link to comment on specific threads, allowing you to engage with others facing similar problems. Sharing your experience not only helps you find solutions but also assists others in the community.

Preventive Measures and Maintenance Tips

Keeping your vehicle in top shape involves regular checks and timely replacements. Let’s explore some preventive measures and maintenance tips to help you spot and address issues with your crankshaft pulley or harmonic balancer.

Regular Inspection Routines

Scheduled Maintenance Checks

Regular maintenance checks are crucial for your vehicle’s health. You should schedule these checks according to your vehicle’s manual. During these inspections, focus on the crankshaft pulley and harmonic balancer. Look for signs of wear and tear, such as cracks or misalignment. These checks can help you catch problems early, preventing more severe damage.

DIY Inspection Tips

You can perform some inspections yourself. Start by visually examining the pulley for any visible damage. Check for wobbling or misalignment, which might indicate a problem. Listen for unusual noises like squealing or chirping. These sounds often suggest issues with the pulley or belts. By staying vigilant, you can address minor issues before they escalate.

Replacement and Repair Guidelines

When to Replace a Crankshaft Pulley

Knowing when to replace your crankshaft pulley is essential. If you notice excessive vibrations or hear unusual noises, it might be time for a replacement. A user from the maxima.org forum shared that their crank pulley failed at 365k miles, causing belt issues. Replacing the pulley promptly can prevent further damage to your engine.

Choosing the Right Replacement Parts

Choosing the right replacement parts ensures your vehicle runs smoothly. Opt for high-quality components like the GM Harmonic Balancer, designed specifically for GM vehicles. This balancer reduces engine vibrations and enhances performance. When selecting parts, ensure they meet or exceed OEM specifications. This choice guarantees compatibility and reliability.

BG Automotive Experts stress the importance of addressing crankshaft pulley issues promptly. Ignoring these problems can lead to costly engine repairs. By following these preventive measures and maintenance tips, you can keep your vehicle in excellent condition and avoid unexpected breakdowns.

Spotting a faulty crankshaft pulley or harmonic balancer early can save you from costly repairs. Remember these key diagnostic steps: look for unusual noises, check for engine vibrations, and inspect for visible wear. Timely identification and repair are crucial. Excessive vibrations can lead to engine wear, affecting performance and durability. Failures can occur at any time, so staying vigilant is essential. If you’re unsure, don’t hesitate to seek professional help. A mechanic can provide expert advice and ensure your vehicle runs smoothly. Keep your engine healthy and enjoy a better driving experience.

Post time: Oct-21-2024