The Pontiac 400 engine, renowned for its robust performance in the muscle car era, stands out as a favorite V-8 powerplant. Generating up to 360 horsepower, it outshines competitors like the Chevy 400 with its impressive output. This high-performance engine, featured in iconic Pontiac models, embodies reliability and power. The Pontiac 400 exhaust manifold is a crucial component that optimizes engine efficiency and enhances overall performance. Proper installation of the Cast Exhaust Manifold is essential to maintain peak performance levels.

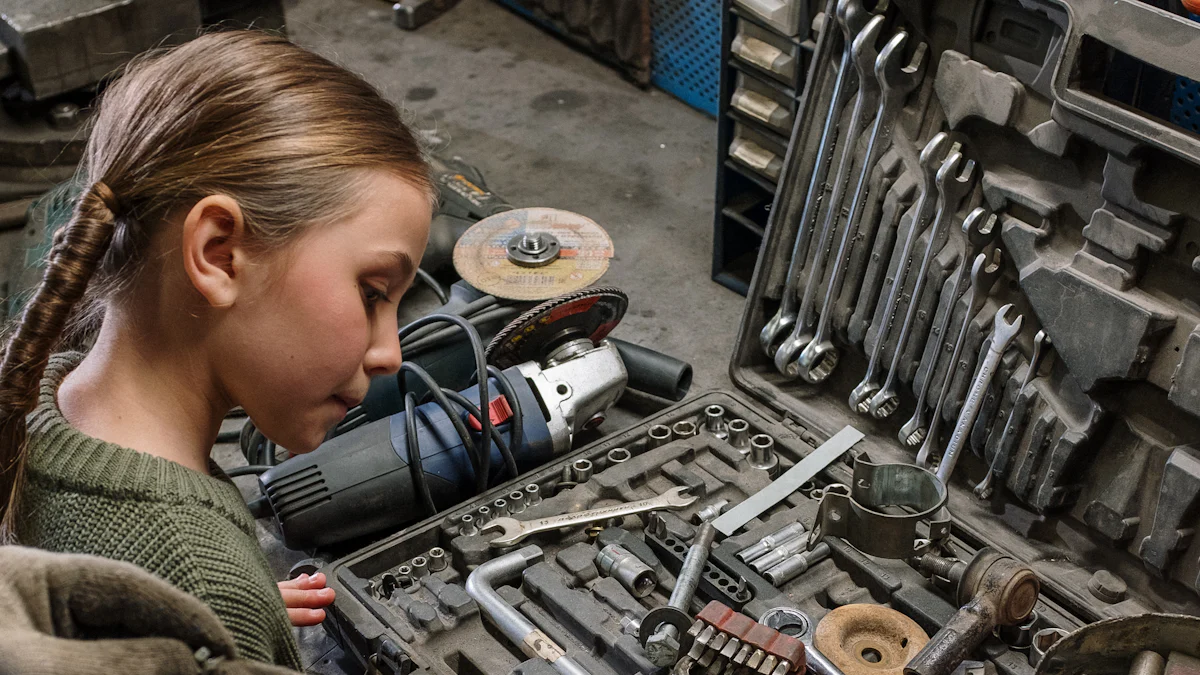

Tools and Materials Needed

Essential Tools

Wrenches and Sockets

- Socket Set: Offers a range of socket sizes for various nuts and bolts, ensuring a smooth installation process.

- Safety Gear: Includes gloves and safety glasses to protect against potential hazards during the installation.

Torque Wrench

- Torque Wrench: A crucial tool for precise tightening of bolts to manufacturer specifications.

Screwdrivers

- Screwdrivers: Essential for removing and installing screws with accuracy.

Required Materials

Exhaust Manifold

- Cast Exhaust Manifold: The heart of the installation process, ensuring optimal performance.

Gaskets

- Remflex Exhaust Gaskets: Designed to withstand clamping force and incredible heat, enhancing durability.

Bolts and Nuts

- Standard Length Bolts: Suitable for securing the exhaust manifold without the need for longer bolts.

Anti-seize Compound

- Anti-seize Compound: Facilitates future disassembly by preventing corrosion between metal parts.

Preparation Steps

Safety Precautions

When preparing for the exhaust manifold installation, disconnecting the battery is a critical initial step to ensure safety and prevent electrical mishaps. By disconnecting the battery, potential short circuits or electrical accidents can be avoided.

Prior to beginning the installation process, it is essential to prioritize wearing safety gear. Equipping oneself with proper safety attire such as gloves and safety glasses safeguards against any unforeseen accidents during the installation procedure.

Vehicle Preparation

To commence the vehicle preparation phase, lifting the vehicle is necessary to gain adequate access to the underside where the exhaust manifold will be installed. Elevating the vehicle provides a clear workspace and facilitates a smoother installation process.

Following this, removing the old exhaust manifold becomes imperative to make way for the new component. Carefully detaching the existing exhaust manifold ensures a clean slate for installing the new one without any obstructions.

Installation Process

Positioning the Exhaust Manifold

Aligning the Manifold with the Engine

To ensure optimal performance, align the Exhaust Manifold meticulously with the engine. This precise alignment guarantees efficient exhaust flow, enhancing overall engine operation and power delivery.

Ensuring Proper Gasket Placement

Properly positioning the Gaskets is crucial for a seamless installation process. By ensuring correct gasket placement, you prevent potential leaks and maintain the integrity of the exhaust system. The intricate design elements work harmoniously to enhance overall engine performance, delivering a driving experience that is both exhilarating and efficient.

Securing the Manifold

Inserting and Tightening Bolts

Secure the Exhaust Manifold firmly by inserting and tightening bolts meticulously. Each bolt plays a vital role in maintaining structural integrity and preventing any unwanted movement during engine operation. The empirical evidence speaks volumes about the undeniable impact of these exhaust manifolds on overall engine performance.

Using a Torque Wrench for Final Tightening

For precise tightening of bolts to manufacturer specifications, utilize a torque wrench. This tool ensures that each bolt is tightened to the required torque setting, guaranteeing a secure fit that withstands engine vibrations and thermal stress. Enthusiasts can rest assured knowing that their vehicles are equipped with exhaust manifolds that prioritize both power and durability.

Connecting the Exhaust System

Attaching the Downpipe

Connect the downpipe seamlessly to complete the exhaust system assembly. The downpipe integration is crucial for directing exhaust gases away from the engine efficiently, contributing to improved performance and reduced backpressure within the system.

Securing with Clamps and Bolts

Secure all components using clamps and bolts to create a robust connection within the exhaust system. Proper securing prevents any potential leaks or dislodgment while driving, ensuring a smooth and uninterrupted flow of exhaust gases for optimal engine function.

Post-Installation Checks

Inspecting for Leaks

Visual Inspection

Upon completing the exhaust manifold installation, a thorough visual inspection is imperative to detect any potential leaks or irregularities. Inspecting the entire assembly meticulously ensures that all components are securely fastened and aligned, guaranteeing optimal performance and preventing any issues that may arise from leaks.

Listening for Unusual Noises

In addition to visual inspection, listening for unusual noises during engine operation can provide valuable insights into the integrity of the exhaust system. Any abnormal sounds, such as hissing or rattling, may indicate leaks or loose connections within the exhaust manifold assembly. By actively listening for these cues, enthusiasts can address any anomalies promptly, safeguarding their vehicle’s performance and longevity.

Test Driving the Vehicle

Monitoring Engine Performance

After completing the installation and initial checks, monitoring engine performance through a test drive is essential to evaluate the functionality of the newly installed exhaust manifold. Observing factors like acceleration smoothness and power delivery can indicate whether the installation was successful and if any adjustments are necessary to optimize engine performance further.

Checking for Exhaust Leaks

During the test drive, checking for exhaust leaks by inspecting visible areas around the exhaust manifold can reveal potential issues that may not have been apparent during installation. Any signs of escaping exhaust gases or soot accumulation near connection points signify leaks that require immediate attention to prevent performance degradation and ensure safe operation on the road.

Recapping the meticulous installation process underscores the dedication required for optimal performance. Regular maintenance is key to preserving the engine’s efficiency and longevity. Seeking professional assistance ensures precision in intricate procedures. Readers are encouraged to share their insights or queries, fostering a community of enthusiasts eager to learn and grow together. Your commitment to excellence in automotive care will undoubtedly elevate your driving experience.

Post time: Jun-19-2024