Balancing the crankshaft is essential for optimal engine performance and longevity. Utilizing a high-quality Engine harmonic balancer ensures precision in weight distribution, reducing vibrations and enhancing overall efficiency. This blog delves into the top 5 machines available, each offering unique features and benefits tailored to meet varying needs. From the ProBal 500 Deluxe to Werkwell Harmonic Balancer, readers will discover a range of options to elevate their engine building endeavors.

Balancing

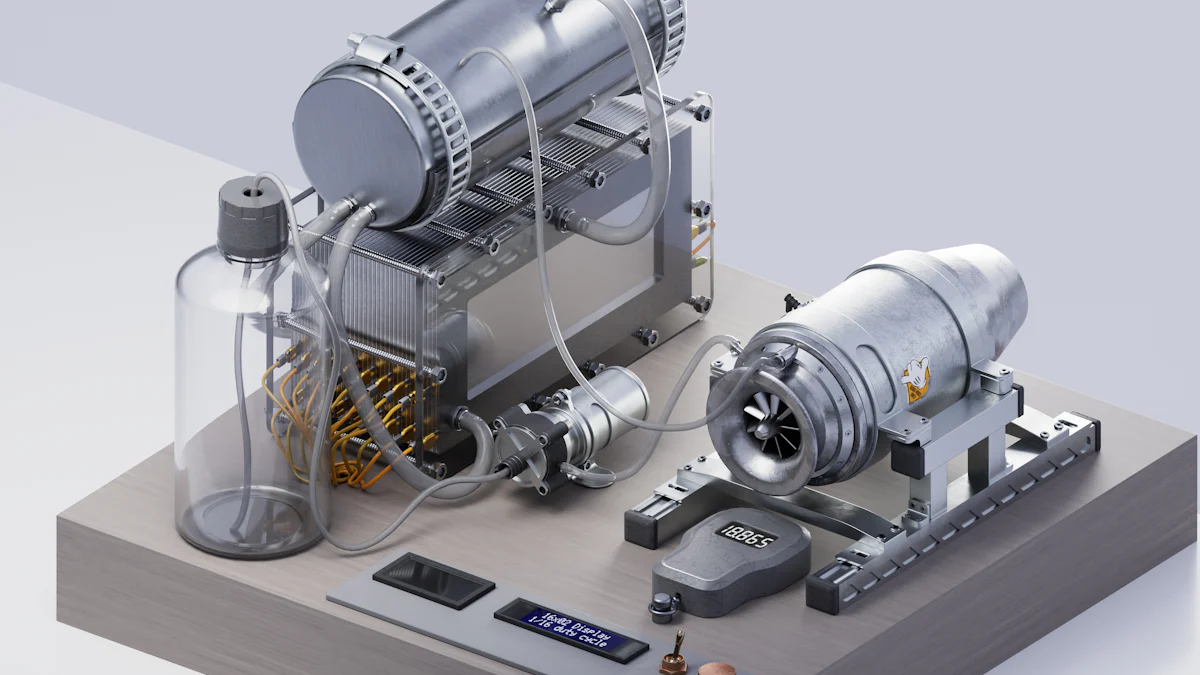

When considering crankshaft balancing machines, precision and efficiency are paramount. The ProBal 500 Deluxe stands out as a state-of-the-art balancer that offers third plane analysis, heavy metal vector analysis, and precision drill qualifying for fast and accurate balancing. With its heavy-duty work cabinet and user-friendly touch screen controls, this machine ensures optimal performance. Weighing over 4000 pounds, the ProBal 500 Deluxe features a special resin-filled base that eliminates vibrations, making it a reliable choice for balancing cranks up to 1200 pounds. This machine opens up new markets for industrial balancing applications.

On the other hand, Ascential Technologies Machines offer an advanced solution for crankshaft balancing with the ProBal Dynamic Balancing PB-L500 model. This machine is designed to ensure peak performance by precisely measuring and correcting imbalances. Its adaptable modular design and comprehensive features evolve with your workshop’s requirements, providing flexibility and efficiency in your balancing processes. Opting for ProBal Dynamic Balancing signifies more than just selecting a machine; it represents a dedication to superior quality, continuous innovation, and progress in the industry.

CRANKSHAFT BALANCING MACHINE PACKAGE

Multi-Bal 5000

Features

The Multi-Bal 5000 by CWT is a top-tier balancing machine that sets the standard in precision and efficiency. Equipped with ‘Third Plane Analysis’ capabilities, this balancer ensures accurate weight distribution for optimal engine performance. The touch screen controls offer a user-friendly experience, allowing for seamless operation and quick adjustments. With ‘HMV’ Heavy Metal Analysis and ‘PDQ’ Precision Drill Qualifying features, the Multi-Bal 5000 guarantees precise balancing results every time.

Benefits

- Achieve unparalleled accuracy in crankshaft balancing.

- Reduce vibrations and enhance overall engine efficiency.

- Streamline your workflow with intuitive touch screen controls.

- Ensure peak performance with advanced Heavy Metal Analysis.

- Experience faster and more efficient balancing processes.

Why Choose Multi-Bal 5000

When it comes to choosing a crankshaft balancing machine, the Multi-Bal 5000 stands out for its unmatched features and benefits. By selecting this cutting-edge balancer, you are investing in precision, efficiency, and reliability for your engine building endeavors. Elevate your workshop’s capabilities with the industry-leading technology of the Multi-Bal 5000.

Fentech Equipment

Features

Fentech Equipment offers a revolutionary solution in crankshaft balancing equipment with their innovative technology and high-quality craftsmanship. The Fentech Equipment is designed to provide customers with a seamless balancing experience, combining precision engineering with user-friendly features. With its durable construction and advanced components, this machine ensures consistent and accurate results for all your balancing needs.

Benefits

- Enhance engine performance with perfectly balanced crankshafts.

- Increase productivity in your workshop with efficient balancing processes.

- Enjoy long-lasting durability and reliability for years to come.

- Simplify complex balancing tasks with intuitive controls and features.

- Stay ahead of the competition by investing in state-of-the-art equipment.

Why Choose Fentech

Choosing Fentech Equipment means choosing excellence in crankshaft balancing technology. With a focus on quality, innovation, and customer satisfaction, Fentech Equipment delivers superior products that meet the highest standards of performance. Take your engine building to new heights by partnering with Fentech Equipment for all your balancing needs.

Practical Engine Building

Werkwell Harmonic Balancer

Crafted with precision engineering techniques, the Werkwell Harmonic Balancer offers unparalleled quality and durability for various car models. Engineered to withstand rigorous conditions, this balancer ensures optimal performance by effectively dampening vibrations and harmonics within the crankshaft.

Features

- Precision engineering for durability and reliability

- Custom design modifications available for personalization

- Specifically engineered for compatibility with 7.3 engines

Benefits

- Enhances engine performance by reducing vibrations

- Ensures optimal operation under various driving conditions

- Personalized design options cater to unique preferences

Why Choose Werkwell Harmonic Balancer

Investing in the Werkwell Harmonic Balancer means choosing a product that prioritizes quality, reliability, and customization. With its precision engineering and compatibility with 7.3 engines, this balancer offers unmatched performance benefits for your engine building needs.

Millennium Technologies Service

Meticulously crafted using high-quality materials, the Millennium Technologies Service provides exceptional solutions for engine enthusiasts. With a focus on precision and innovation, this service guarantees top-notch results that enhance engine longevity and performance.

Features

- High-quality materials ensure durability and reliability

- Precision techniques for optimal engine performance

- Customizable solutions tailored to specific requirements

Benefits

- Extended engine lifespan through superior service quality

- Enhanced engine efficiency and power output

- Personalized options for a tailored experience

Why Choose Millennium Technologies

Opting for the Millennium Technologies Service signifies a commitment to excellence in engine maintenance and enhancement. By choosing this service, you are ensuring that your engine receives the best care possible, leading to improved performance, longevity, and overall satisfaction.

crankshaft balancing machine for sale

Engine Builder Magazine Recommendations

When considering options for Balancing Machines that are currently available for sale, turning to reputable sources like Engine Builder Magazine can provide valuable insights. The magazine’s recommendations are based on thorough research and expert opinions, ensuring that you make an informed decision for your engine building needs.

Features

- Detailed reviews of the latest Crankshaft Balancing Machines

- Comparison charts highlighting key specifications and performance metrics

- Expert commentary on the benefits and drawbacks of each machine

Benefits

- Access to unbiased information from industry professionals

- Guidance on selecting a machine that aligns with your specific requirements

- Stay updated on the newest advancements in crankshaft balancing technology

Why Follow Engine Builder Magazine

By following Engine Builder Magazine, you gain access to a wealth of knowledge and expertise in the field of engine building. Their recommendations can help you navigate the market with confidence, ensuring that you invest in a Balancing Machine that meets your expectations and delivers exceptional results.

Sampson Racing Engines

For those seeking top-tier performance and reliability in their engine components, Sampson Racing Engines stands out as a trusted name in the industry. Specializing in high-quality products designed to enhance engine efficiency, Sampson Racing Engines offers a range of solutions tailored to meet the demands of professional builders and enthusiasts alike.

Features

- Precision-engineered components for optimal performance

- Extensive product line catering to various engine types and configurations

- Reputation for excellence in craftsmanship and durability

Benefits

- Improved engine functionality and longevity with Sampson Racing Engines’ products

- Customizable options to suit individual preferences and requirements

- Access to expert guidance and support from a renowned engine specialist

Why Choose Sampson Racing Engines

Selecting Sampson Racing Engines means choosing reliability, performance, and innovation for your engine building endeavors. With a commitment to quality and customer satisfaction, Sampson Racing Engines sets the standard for excellence in the industry. Experience unparalleled results and elevate your engines to new heights with Sampson Racing Engines.

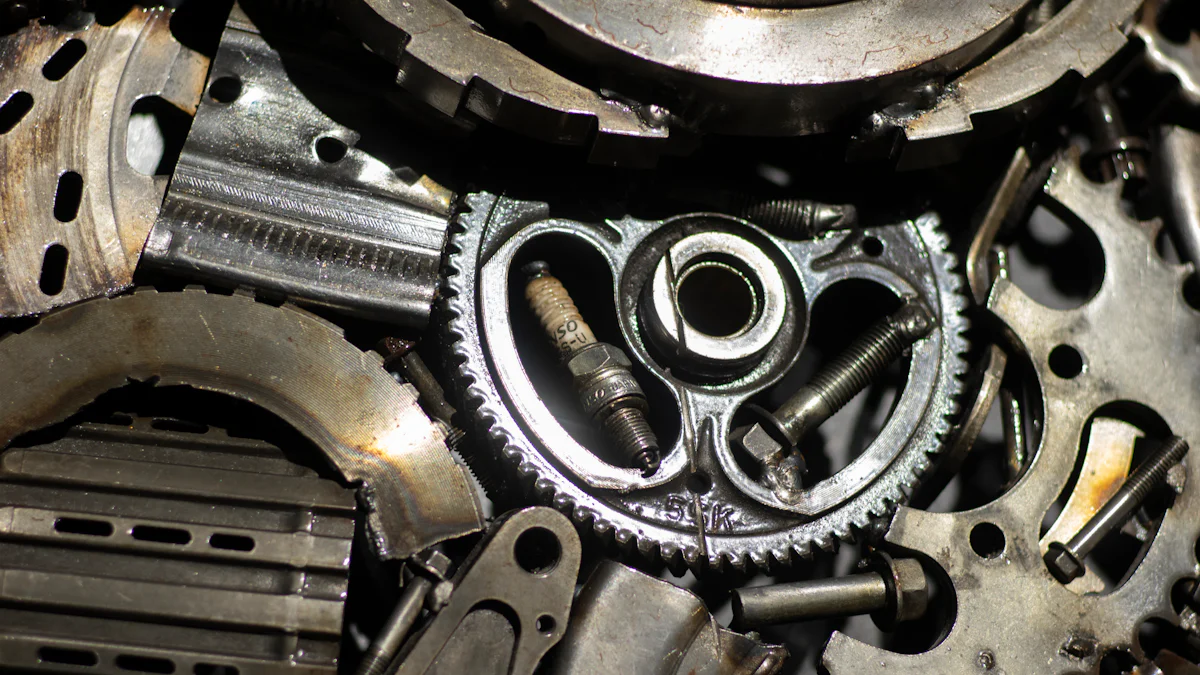

BALANCING A CRANKSHAFT

Importance of Precision

Precision in balancing a crankshaft is paramount to ensure optimal engine performance and longevity. Balancing techniques play a crucial role in reducing vibrations, enhancing efficiency, and prolonging the lifespan of engine components. The first source emphasizes the significance of precision balancing in engine design, highlighting the meticulous process required for achieving peak performance. On the other hand, the second source delves into static and dynamic balancing methods for inline-four cylinder crankshafts, showcasing the impact of counterweight reduction on overall balance.

Features

- Accurate Measurement: Ensuring precise weight distribution for optimal performance.

- Advanced Technology: Utilizing cutting-edge tools and techniques for efficient balancing.

- Customizable Options: Tailoring balancing processes to specific engine requirements.

Benefits

- Enhanced Performance: Achieving smoother operation and reduced vibrations.

- Extended Lifespan: Prolonging the durability of engine components through proper balancing.

- Improved Efficiency: Enhancing overall engine efficiency and power output.

Why Precision Matters

Precision in crankshaft balancing directly correlates to engine reliability and performance. By prioritizing accuracy in weight distribution and balance, engine builders can mitigate potential issues such as excessive vibration or premature wear. Properly balanced crankshafts contribute to smoother operation, increased efficiency, and prolonged engine lifespan. Investing time and effort into precision balancing techniques ensures that engines operate at their full potential, delivering consistent performance under various driving conditions.

Techniques and Tools

When it comes to balancing a crankshaft effectively, utilizing the right techniques and tools is essential for achieving optimal results. Engine builders rely on a combination of innovative methods and specialized equipment to ensure that each component works harmoniously within the system. The importance of dynamic balancing is underscored by its ability to address imbalances during operation, leading to improved overall performance.

Features

- Dynamic Balancing Machines: Automatic systems that analyze unbalance levels dynamically.

- High-Torque Drills: Precision drills designed for accurate weight adjustments.

- Exclusive Drive Systems: Advanced drive mechanisms ensuring consistent rotation speeds.

Benefits

- Enhanced Accuracy: Achieving precise weight distribution with dynamic balancing machines.

- Efficient Drilling Process: Streamlining weight adjustments with high-torque drills.

- Consistent Rotation Speeds: Maintaining uniformity in balance correction with exclusive drive systems.

Why Use Proper Techniques

Utilizing proper techniques in crankshaft balancing is crucial for maintaining engine integrity and functionality. Dynamic balancing machines offer real-time analysis of unbalance levels, allowing for immediate corrections to be made during the process. High-torque drills enable precise weight adjustments without compromising component integrity. Exclusive drive systems ensure consistent rotation speeds, contributing to uniform balance correction across all components. By employing these advanced techniques and tools, engine builders can guarantee optimal performance, reduced vibrations, and prolonged engine lifespan.

In the realm of engine manufacturing and rebuilding, crankshaft balancing emerges as a pivotal process. Ensuring the optimal balance of this crucial engine component minimizes vibrations and guarantees seamless operation. The top-tier machines highlighted in this blog, such as the ProBal 500 Deluxe and Werkwell Harmonic Balancer, offer unparalleled benefits for engine builders. It’s time to take action and choose the right machine to elevate your engine building endeavors.

Post time: Jun-04-2024