Harmonic balancer installation is a critical step in ensuring the smooth operation of engines, particularly in Small Block Chevy (SBC) engines. These balancers play a vital role in reducing engine vibration and maintaining overall stability. Understanding the nuances of installing a harmonic balancer SBC is essential for optimal engine performance. With the right knowledge and tools, this process can be seamless and efficient. This blog aims to provide valuable insights into the significance of proper Automotive harmonic balancer installation on SBC engines.

Preparing for Installation

When embarking on the journey of harmonic balancer installation on your Small Block Chevy (SBC) engine, proper preparation is key to a successful outcome. This section will guide you through the essential steps to ensure a seamless installation process.

Gather Necessary Tools

To commence the installation process smoothly, it is imperative to have the right tools at your disposal. Here are the tools you will need:

Harmonic Balancer Installation Tool

The Harmonic Balancer Installation Tool is a specialized instrument designed specifically for installing harmonic balancers with precision and ease. This tool ensures that the balancer is mounted correctly onto the crankshaft, preventing any potential damage during installation.

Torque Wrench

A Torque Wrench is an essential tool for tightening the balancer bolt to the manufacturer’s recommended specifications. Proper torque application is crucial to secure the balancer in place and maintain optimal engine performance.

Safety Gear

Prioritize safety during the installation process by wearing appropriate safety gear such as gloves and protective eyewear. Safety gear protects you from any unforeseen accidents and ensures a secure working environment.

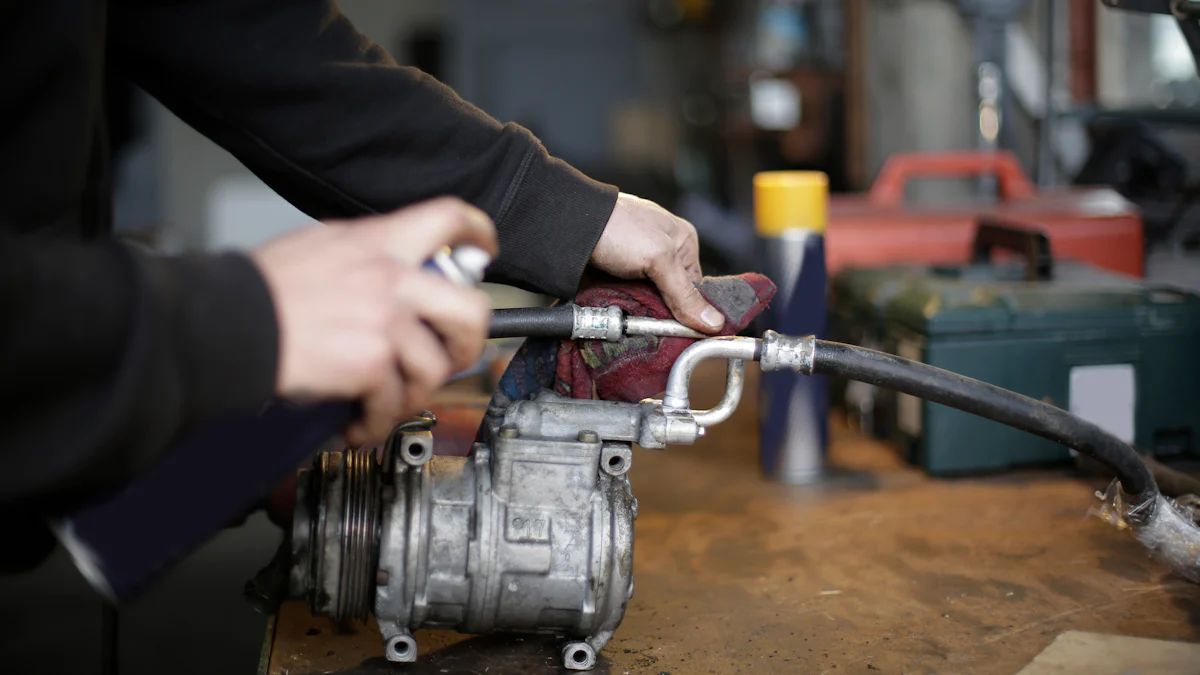

Inspect the Harmonic Balancer

Before proceeding with the installation, it is vital to inspect the harmonic balancer thoroughly to guarantee its integrity and compatibility with your engine.

Check for Damage

Carefully examine the harmonic balancer for any signs of damage, such as cracks or deformities. Installing a damaged balancer can lead to severe engine issues, making it crucial to replace it if any defects are detected.

Verify Size Compatibility

Ensure that the harmonic balancer size matches your engine specifications. Using an incompatible size can disrupt engine balance and performance, emphasizing the importance of selecting the right size for optimal functionality.

Supreme Member Join Date

As you delve into harmonic balancer installation, understanding timing and distributor alignment plays a significant role in ensuring smooth engine operation.

Importance of Timing

Timing synchronization is critical for harmonious engine function. Aligning the timing precisely guarantees that all components work together seamlessly, enhancing overall performance and efficiency.

Aligning the Distributor

Properly aligning the distributor with precise timing settings optimizes ignition sequences within your SBC engine. This alignment ensures that fuel combustion occurs at the right moment, maximizing power output and fuel efficiency.

Step-by-Step Installation Process

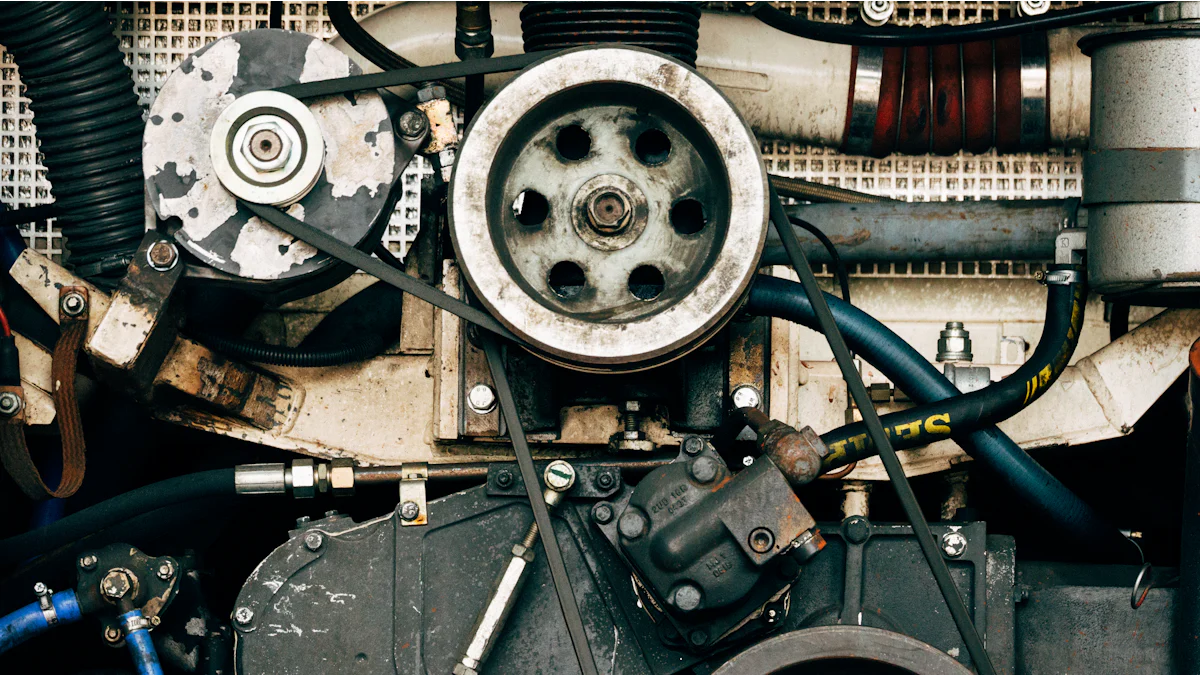

Removing the Old Balancer

To initiate the Harmonic balancer install process effectively, start by disconnecting the battery to ensure safety during the procedure. This precaution prevents any electrical mishaps that may occur while working on your engine. Following this, proceed to remove the belts and pulleys connected to the old balancer. By detaching these components, you create a clear pathway for accessing and replacing the harmonic balancer without any obstructions.

Disconnect battery

- Turn off the engine and locate the vehicle’s battery.

- Carefully disconnect the negative terminal first to prevent electrical accidents.

- Remove the positive terminal next to fully isolate the battery from the engine.

Remove belts and pulleys

- Loosen the tension on each belt by adjusting their respective tensioner pulleys.

- Slide off each belt from its corresponding pulley carefully.

- Once all belts are removed, detach any additional pulleys connected to the harmonic balancer.

Installing a Harmonic Balancer SBC

With the old balancer successfully removed, it’s time to proceed with installing a new Harmonic Balancer tailored for your Small Block Chevy (SBC) engine. Follow these steps meticulously to ensure a seamless installation process that enhances your engine’s performance and longevity.

Position the new balancer

- Identify the keyway slot on your crankshaft where the harmonic balancer fits.

- Align the keyway of your new balancer with that of the crankshaft for proper positioning.

- Gently slide the harmonic balancer onto the crankshaft, ensuring it sits flush against its designated placement.

Use an installation tool

- Utilize a specialized Harmonic Balancer Installation Tool designed for precise and secure installations.

- Place the installation tool over the harmonic balancer hub and tighten it securely.

- Slowly rotate or tap on the installation tool as needed until you achieve a snug fit between the balancer and crankshaft.

Torquing The Balancer Bolt

Once you have positioned and secured your new harmonic balancer in place, it is crucial to torque down its bolt accurately to prevent any slippage or misalignment that could affect your engine’s operation negatively.

Proper torque specifications

- Refer to your manufacturer’s guidelines or service manual for specific torque values applicable to your SBC engine model.

- Set your torque wrench accordingly and gradually tighten down on the bolt in incremental turns until reaching optimal torque levels.

- Double-check all connections post-torquing to confirm that everything is securely fastened in place.

Ensuring correct seating

- Inspect visually or use a mirror to verify that no gaps exist between your harmonic balancer and crankshaft surface.

- Ensure that there is uniform contact around both components without any protrusions or misalignments present.

- Confirm that all parts are aligned correctly before proceeding with further assembly steps.

Post-Installation Checks

Inspect for Wobbling

Signs of a bent crankshaft

Inspecting the harmonic balancer post-installation is crucial to identify any signs of wobbling, which could indicate underlying issues with the engine components. One common indication of wobbling is an irregular movement pattern exhibited by the balancer during engine operation. This irregularity can stem from a bent crankshaft, causing imbalances that affect the overall performance and longevity of the engine.

To detect potential issues with a bent crankshaft, observe the harmonic balancer closely while the engine is running. Look for abnormal movements or vibrations that deviate from the typical rotational motion. Additionally, pay attention to any unusual noises emanating from the engine bay, as these auditory cues can also signal problems related to a misaligned or damaged crankshaft.

Corrective measures

Addressing wobbling concerns promptly is essential to prevent further damage to your SBC engine and ensure its continued smooth operation. If you suspect a bent crankshaft based on the observed wobbling patterns, consider taking the following corrective measures:

- Professional Inspection: Consult with an experienced mechanic or automotive specialist to conduct a thorough inspection of your engine components. Their expertise can help pinpoint the exact cause of the wobbling and recommend appropriate solutions.

- Crankshaft Replacement: In severe cases where a bent crankshaft is confirmed, replacing the component may be necessary to restore optimal engine functionality. A new crankshaft installation should be performed meticulously to avoid future wobbling issues.

- Balancer Realignment: If minor misalignments are detected during inspection, realigning the harmonic balancer with precision tools can rectify these issues. Proper alignment ensures that the balancer functions harmoniously with other engine parts, reducing vibrations and enhancing performance.

- Regular Maintenance: Implement a routine maintenance schedule for your SBC engine to monitor its condition and address any emerging issues promptly. Regular inspections and upkeep practices can prevent wobbling problems before they escalate into more significant concerns.

Final Adjustments

Aligning the timing

After completing the harmonic balancer installation process and conducting post-installation checks, it is essential to focus on aligning the timing of your Small Block Chevy (SBC) engine accurately. Timing alignment plays a pivotal role in synchronizing various internal combustion processes within your engine, ensuring optimal performance and efficiency.

To align timing effectively:

- Timing Adjustment: Use timing marks on your SBC engine components to adjust ignition timing precisely according to manufacturer specifications.

- Distributor Calibration: Calibrate your distributor settings in coordination with timing adjustments for seamless ignition sequences.

- Testing Procedures: Conduct thorough testing procedures post-timing alignment to verify that all components function cohesively without any discrepancies.

- Fine-Tuning: Fine-tune timing adjustments as needed based on performance evaluations and operational feedback from your SBC engine.

Checking Engine Performance

Once you have aligned the timing accurately on your Small Block Chevy (SBC) engine, it is imperative to assess its overall performance post-harmonic balancer installation thoroughly. Monitoring key performance indicators allows you to gauge the effectiveness of your installation process and identify any potential areas for improvement.

When checking engine performance:

- Idle Stability: Observe idle stability levels after installation completion to ensure consistent and smooth idling without fluctuations.

- Acceleration Response: Test acceleration response times under varying driving conditions to evaluate how well your SBC engine responds post-installation.

- Vibration Analysis: Monitor vibration levels during operation to detect any irregularities that may indicate unresolved issues with harmonic balancer installation or other components.

- Power Output Verification: Verify power output levels by assessing acceleration capabilities and overall horsepower generated by your SBC engine after installing a new harmonic balancer.

By conducting comprehensive checks on both idle behavior and operational performance, you can fine-tune adjustments as needed for optimal functionality and longevity of your Small Block Chevy (SBC) engine equipped with a newly installed harmonic balancer from Werkwell products.

- To summarize, ensuring a seamless harmonic balancer installation on your SBC engine involves meticulous preparation and precise execution.

- The significance of proper installation cannot be overstated, as it directly impacts engine performance and longevity.

- For any uncertainties or complexities during the installation process, seeking guidance from experts is highly recommended.

- For high-quality harmonic balancers and automotive products, contact Werkwell to experience top-notch reliability and performance.

Post time: Jun-03-2024