The exhaust manifold plays a crucial role in engine performance. This component collects exhaust gases from multiple cylinders and directs them to the exhaust pipe. Regular maintenance of the exhaust manifold ensures optimal engine efficiency and longevity. Well-maintained manifolds help improve engine output, fuel efficiency, and overall vehicle performance.

Understanding the Exhaust Manifold

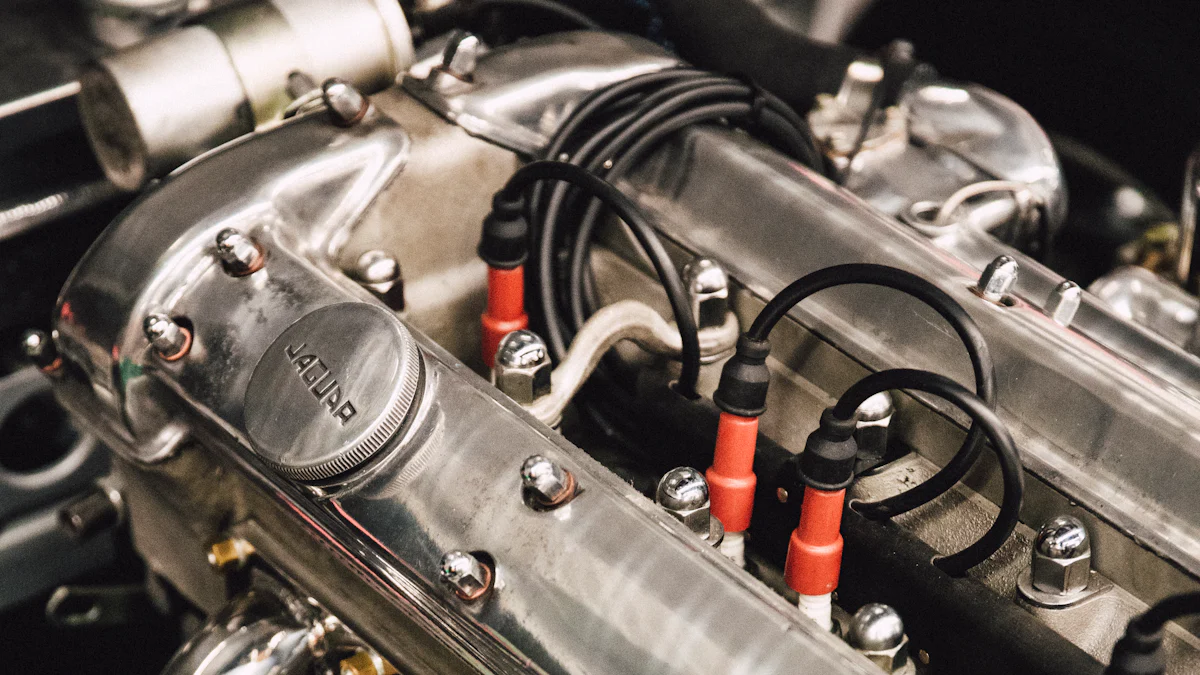

Components of an Exhaust Manifold

Primary Tubes

Primary tubes in an exhaust manifold connect each cylinder to the collector. These tubes handle high temperatures and direct exhaust gases efficiently. The material of the primary tubes ensures durability and resistance to corrosion.

Collector

The collector merges gases from the primary tubes into a single pipe. This design optimizes the flow of exhaust gases. The collector reduces backpressure, which improves engine performance and fuel efficiency.

Flanges

Flanges secure the exhaust manifold to the engine block. These components ensure a tight seal to prevent leaks. Properly installed flanges maintain the integrity of the exhaust system.

Functions of the Exhaust Manifold

Collecting Exhaust Gases

The exhaust manifold collects gases from multiple cylinders. This collection process channels the gases into a single exhaust pipe. Efficient gas collection reduces the risk of backpressure.

Reducing Emissions

The exhaust manifold plays a role in reducing emissions. By directing gases through the catalytic converter, the manifold helps lower harmful pollutants. This function contributes to environmental protection.

Improving Engine Efficiency

The exhaust manifold improves engine efficiency by optimizing exhaust flow. Proper exhaust flow enhances combustion and reduces engine strain. Improved efficiency leads to better fuel economy and overall vehicle performance.

Preventive Maintenance Tips

Regular Inspections

Visual Checks for Cracks and Leaks

Regular visual inspections help identify potential issues early. Examine the exhaust manifold for visible cracks. Look for any signs of leaks around the flanges and gaskets. Cracks and leaks can lead to engine performance problems. Addressing these issues promptly prevents further damage.

Listening for Unusual Noises

Unusual noises often indicate problems with the exhaust manifold. Listen for ticking or hissing sounds while the engine runs. These noises may suggest a leak or crack in the manifold. Early detection allows for timely repairs, maintaining optimal engine performance.

Cleaning the Exhaust Manifold

Removing Carbon Deposits

Carbon deposits accumulate on the exhaust manifold over time. These deposits can hinder the flow of exhaust gases. Use a wire brush to remove carbon buildup. Ensure the engine has cooled completely before cleaning. Proper cleaning enhances the efficiency of the exhaust system.

Using Appropriate Cleaning Agents

Select appropriate cleaning agents for the exhaust manifold. Avoid harsh chemicals that can damage the manifold’s surface. Use products designed specifically for automotive exhaust systems. Following the manufacturer’s recommendations ensures safe and effective cleaning.

Ensuring Proper Installation

Checking Bolts and Gaskets

Proper installation of the exhaust manifold is crucial. Check bolts and gaskets regularly to ensure they remain secure. Loose bolts can cause leaks and reduce engine efficiency. Tighten bolts to the manufacturer’s specifications to maintain a proper seal.

Aligning the Manifold Correctly

Correct alignment of the exhaust manifold is essential. Misalignment can lead to leaks and uneven stress on the manifold. Ensure the manifold aligns correctly with the engine block during installation. Proper alignment extends the lifespan of the exhaust manifold and improves overall performance.

Expert Testimony:

Qualified Technician, an expert in automotive exhaust systems, emphasizes the importance of regular inspections and proper maintenance. “Consider having the exhaust system serviced by a qualified technician who specializes in automotive exhaust systems. They can provide expert advice, conduct thorough inspections, and perform necessary repairs or replacements.”

Expert Manufacturer, known for custom exhaust manifold fabrication, highlights the role of passivation in maintaining the manifold. “Passivation is a chemical process that helps rid surface contaminants and blemishes, enhancing corrosion resistance. Generally, exhaust manifolds are exposed to high temperatures and corrosive gases, consequently requiring passivation. The process helps create a protective film on the surface of the manifold, shielding it from the corrosive gases, thereby enhancing its lifespan.”

Signs of Exhaust Manifold Failure

Common Symptoms

Engine Misfires

Engine misfires often indicate issues with the exhaust manifold. Faulty manifolds can disrupt the air-fuel mixture. This disruption causes incomplete combustion, leading to misfires. Regular checks help identify and address these problems early.

Decreased Fuel Efficiency

Decreased fuel efficiency serves as another sign of exhaust manifold failure. Leaks in the manifold allow unmetered air into the engine. This extra air affects the engine’s performance and fuel consumption. Monitoring fuel efficiency helps detect manifold issues.

Unusual Noises

Unusual noises may signal a failing exhaust manifold. Ticking or hissing sounds often come from cracks or leaks. These noises usually become more noticeable during acceleration. Identifying these sounds early allows for timely repairs.

Diagnosing Issues

Using Diagnostic Tools

Diagnostic tools assist in identifying exhaust manifold problems. A smoke test can reveal leaks in the manifold. Measuring exhaust pressure helps detect blockages. Using these tools ensures accurate diagnosis and effective repairs.

Consulting a Professional Mechanic

Consulting a professional mechanic provides expert insights into exhaust manifold issues. Mechanics have specialized equipment for thorough inspections. They can recommend the best course of action for repairs or replacements. Trusting a professional ensures the longevity and efficiency of the exhaust system.

Specific Inspection Steps

Visual Inspection

Checking for Cracks and Rust

Inspect the exhaust manifold for visible cracks and rust. Cracks can develop due to high temperatures and stress. Rust forms when moisture interacts with the metal surface. Use a flashlight to examine hard-to-see areas. Pay close attention to the primary tubes and flanges. Address any signs of damage immediately to prevent further issues.

Inspecting Gaskets and Seals

Gaskets and seals play a crucial role in maintaining the integrity of the exhaust manifold. Inspect these components for wear and tear. Look for signs of leakage around the gaskets. A damaged gasket can cause exhaust gases to escape, leading to engine performance problems. Replace worn-out gaskets to ensure a proper seal.

Performance Testing

Conducting a Smoke Test

A smoke test helps identify leaks in the exhaust manifold. Introduce smoke into the exhaust system and observe where it escapes. Leaks will become visible as smoke exits through cracks or gaps. This test provides a clear indication of where repairs are needed. Conduct the smoke test in a well-ventilated area for safety.

Measuring Exhaust Pressure

Measuring exhaust pressure helps detect blockages in the exhaust manifold. Use a pressure gauge to measure the exhaust pressure at different points. Compare the readings to the manufacturer’s specifications. High pressure indicates a blockage, while low pressure suggests a leak. Accurate measurements ensure effective diagnosis and repair.

Qualified Technician emphasizes the importance of thorough inspections. “Expert advice and necessary repairs or replacements can extend the life of the exhaust manifold.”

Regular inspections and performance testing maintain the efficiency and longevity of the exhaust manifold. Proper maintenance prevents costly repairs and ensures optimal engine performance.

Maintaining the exhaust manifold ensures optimal engine performance and longevity. Regular inspections and proper maintenance prevent costly repairs. Following the tips provided will help identify issues early. A well-maintained exhaust manifold improves fuel efficiency and reduces emissions. Consistent care enhances overall vehicle performance. Prioritize exhaust manifold upkeep for a reliable and efficient engine.

Post time: Jul-25-2024