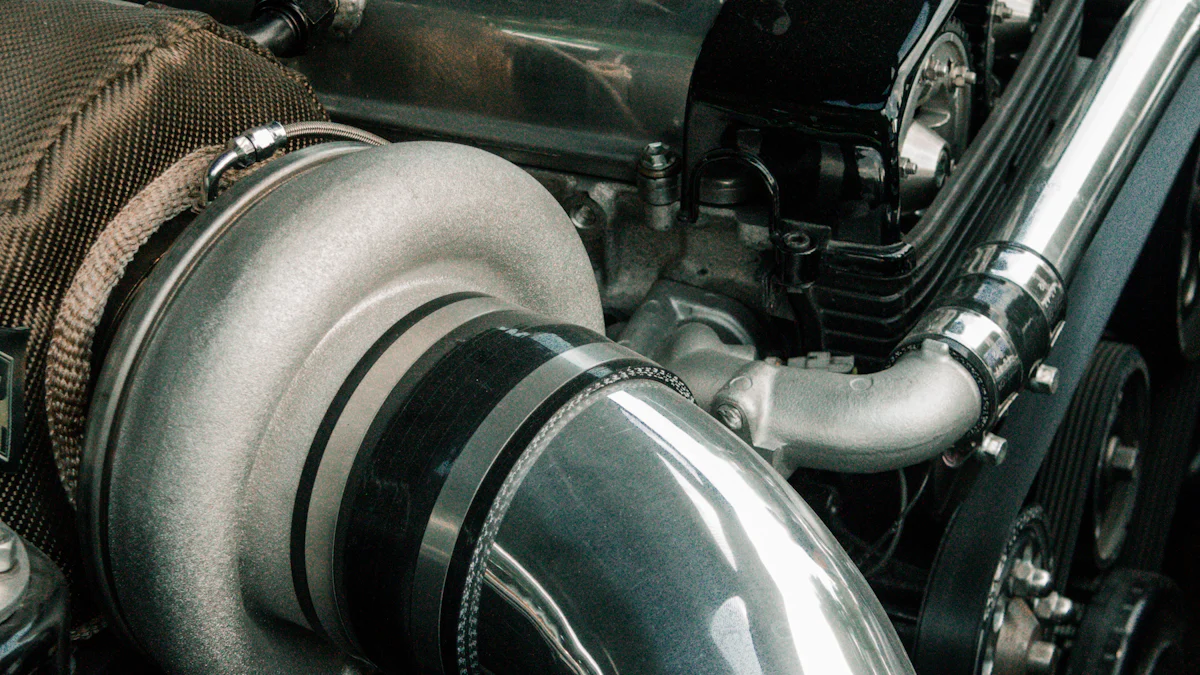

Exhaust Manifold Pipe, a crucial component of a vehicle’s exhaust system, plays a vital role in collecting exhaust gases from the engine’s cylinders and channeling them into a single pipe. This component is essential for optimizing exhaust flow and reducing backpressure, ultimately enhancing vehicle performance. In this article, we will delve into the details of exhaust manifold pipes, discussing their types, key components, functionality, advantages, and disadvantages. By gaining insights into these aspects, automotive enthusiasts can make informed choices to improve their vehicle’s efficiency.

Basics of Manifold Exhaust Pipes

When considering Exhaust Manifold Pipes, it’s vital to understand the various elements that contribute to their functionality and impact on vehicle performance. Let’s delve into the specifics of these components without overlooking their historical significance.

What is a Manifold Exhaust Pipe?

Definition and function

- The primary purpose of a Manifold Exhaust Pipe is to efficiently collect exhaust gases from the engine cylinders and direct them towards a single exit point.

- By optimizing the flow of exhaust gases, these pipes play a crucial role in enhancing engine performance and overall efficiency.

Historical development

- Over time, advancements in automotive engineering have led to significant improvements in manifold exhaust pipe design.

- The evolution of these pipes has been driven by the need for better engine performance, reduced emissions, and improved fuel economy.

Types of Manifold Exhaust Pipes

Cast iron manifolds

- Cast iron manifolds are known for their durability and heat resistance, making them a popular choice in traditional vehicle designs.

- While they may be heavier than other materials, cast iron manifolds offer robust performance capabilities.

Stainless steel manifolds

- Stainless steel manifolds are favored for their corrosion resistance and longevity, ensuring reliable operation over an extended period.

- These manifolds are ideal for modern vehicles seeking high-performance solutions with minimal maintenance requirements.

Performance headers

- Performance headers, also referred to as aftermarket exhaust manifolds, are designed to enhance engine efficiency by improving exhaust gas flow.

- Engineered from premium materials, such as stainless steel or aluminized steel, performance headers offer superior performance benefits.

Key Components

Primary tubes

- The primary tubes within manifold exhaust pipes are strategically designed to optimize exhaust gas flow from the engine cylinders.

- By carefully shaping these tubes, manufacturers can improve scavenging effects and boost overall engine performance.

Collector

- The collector serves as a critical junction point where exhaust gases from individual cylinders merge before exiting through the pipe.

- Proper design of the collector ensures efficient gas mixing and contributes to enhanced engine output.

Flanges

- Flanges play a key role in securing manifold components together while maintaining airtight connections.

- Quality flanges prevent leaks and ensure that exhaust gases flow smoothly through the system without any obstructions.

How Manifold Exhaust Pipes Work

Exhaust Gas Flow

When Exhaust Manifold Pipes are in operation, the journey of exhaust gases begins within the engine cylinders. Each cylinder expels these gases, which then travel through the manifold pipes towards a unified exit point. This streamlined flow is crucial for maintaining optimal engine performance and efficiency.

To understand the significance of exhaust gas flow, consider the impact of backpressure on the system. Backpressure, a natural result of exhaust gas flow resistance, can hinder engine performance if not managed effectively. By ensuring a smooth path for exhaust gases to exit, manifold pipes help reduce backpressure, enabling the engine to operate more efficiently.

Heat Management

Efficient heat dissipation is another essential function of Exhaust Manifold Pipes. As exhaust gases pass through these pipes, they carry significant amounts of heat generated during combustion. Proper heat management within the manifold pipes is vital for preventing overheating and potential damage to surrounding components.

The effective dissipation of heat plays a critical role in maintaining engine performance at optimal levels. By efficiently managing heat within the exhaust system, manifold pipes contribute to overall engine efficiency and longevity.

Emission Control

In addition to optimizing exhaust gas flow and managing heat, Exhaust Manifold Pipes also play a role in emission control within vehicles. Two key components involved in this process are catalytic converters and oxygen sensors.

Catalytic converters are responsible for converting harmful pollutants in exhaust gases into less harmful emissions before releasing them into the environment. By incorporating catalytic converters into the exhaust system, vehicles can minimize their environmental impact and comply with emission regulations.

Oxygen sensors, on the other hand, monitor oxygen levels in exhaust gases to ensure efficient fuel combustion. These sensors provide real-time feedback to the vehicle’s engine control unit (ECU), allowing for adjustments that optimize fuel efficiency while reducing emissions.

Benefits and Drawbacks

Advantages

Improved Engine Performance

- Tubular Exhaust Manifolds: Enhance engine performance by optimizing exhaust flow from individual cylinders.

- Selecting the Right Exhaust Manifold: Ensures efficient exhaust scavenging, improving overall power output.

- Performance-Oriented Exhaust Manifolds: Increase engine power by maximizing the exhaust scavenging effect.

Enhanced Fuel Efficiency

- Upgrading to performance-oriented exhaust manifolds can lead to improved fuel efficiency.

- Aftermarket options offer enhanced fuel economy through optimized exhaust gas flow.

- Choosing the right manifold design can contribute to better combustion efficiency.

Disadvantages

Potential for Increased Noise

- Some aftermarket exhaust manifolds may result in louder engine noise due to enhanced performance.

- Certain designs that prioritize power gains might produce a more aggressive exhaust note.

- Upgraded manifolds could amplify engine sound levels during acceleration.

Cost Considerations

- Investing in high-performance manifold exhaust pipes may involve higher initial costs.

- Maintenance and repairs for specialized manifold types could incur additional expenses.

- Balancing performance benefits with budget constraints is crucial for cost-effective upgrades.

Practical Advice for Vehicle Owners

Maintenance Tips

Regular inspections

- Expert manufacturer suggests that regular inspections of your exhaust manifold pipes are crucial to ensure optimal performance and identify any potential issues early on.

- Inspect the manifold pipes for signs of wear, corrosion, or leaks that could impact their efficiency.

- Schedule routine maintenance checks to address any concerns promptly and prevent more significant problems down the line.

Cleaning and repairs

- When it comes to maintaining your Exhaust Manifold Pipes, cleaning plays a vital role in preserving their functionality.

- Use appropriate cleaning solutions recommended by experts to remove carbon buildup and debris from the pipes.

- If you notice any damage during inspections, seek professional assistance for timely repairs to avoid further complications.

Upgrading Manifold Exhaust Pipes

Choosing the right type

- Selecting an appropriate Exhaust Manifold Pipe is a critical decision that can significantly impact your vehicle’s performance.

- Consider factors such as material quality, design compatibility, and performance enhancements when choosing a new manifold pipe.

- Consult with experts in custom exhaust manifold fabrication to tailor the pipe specifications to meet your specific requirements effectively.

Installation considerations

- Expert manufacturer emphasizes the importance of proper installation procedures when upgrading your exhaust manifold pipes.

- Ensure that all components are securely fitted and aligned correctly to prevent leaks or inefficiencies in the system.

- Follow detailed instructions provided by manufacturers or seek professional assistance for a seamless installation process.

In summarizing the intricate details of Exhaust Manifold Pipes, it becomes evident that these components are pivotal for optimizing engine performance and efficiency. The comprehensive exploration of manifold types, key components, and operational functions underscores their significance in enhancing vehicle capabilities. Recognizing the critical role of Exhaust Manifold Pipes in exhaust gas flow management and emission control is essential for informed decision-making by automotive enthusiasts. Embracing regular maintenance practices and considering upgrades tailored to specific needs can further elevate overall vehicle functionality.

Post time: Jun-25-2024