Racing engines demand precision, where every component must work seamlessly to achieve peak performance. The High Performance Intake Manifold is a crucial element in this process, ensuring air is evenly distributed to the cylinders for optimal combustion and power output. In the dynamic relationship between the Intake Manifold And Exhaust Manifold, the intake manifold breathes life into the engine, while the exhaust manifold expels gases. Werkwell’s High Performance Intake Manifold elevates this process with cutting-edge techniques like Computational Fluid Dynamics (CFD) and flow bench testing, delivering unmatched airflow and efficiency. Paired with components like the Crankshaft Harmonic Balancer and High Performance Transmission, racers can experience enhanced throttle response and acceleration, securing a competitive edge on the track.

The Role of High Performance Intake Manifolds

How Intake Manifolds Work

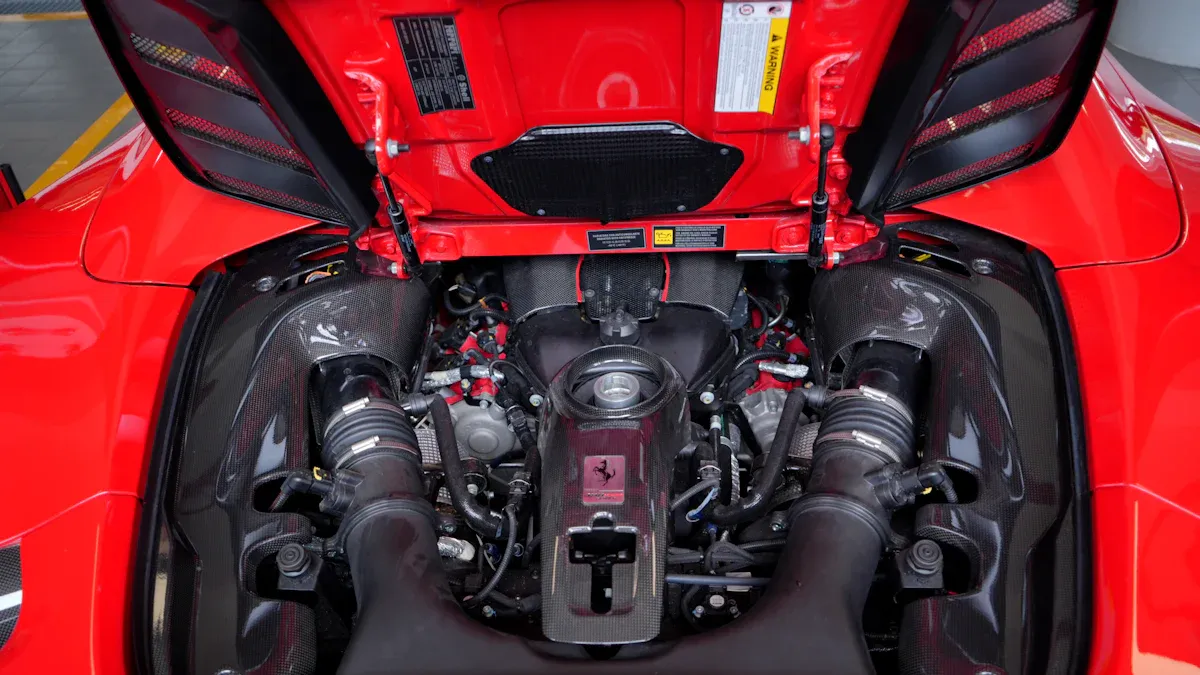

An intake manifold plays a vital role in an engine’s performance by managing airflow. It ensures that air, or the air-fuel mixture in some engines, is evenly distributed to all cylinders. This even distribution is critical for smooth combustion and consistent power delivery. The manifold, made up of a series of tubes, directs air into the engine during the intake stroke. This airflow is essential for the combustion process, which powers the vehicle.

Modern engineering techniques, like Computational Fluid Dynamics (CFD) and flow bench testing, have revolutionized intake manifold design. Engineers use CFD simulations to study airflow patterns and identify areas of turbulence. Flow bench testing validates these designs by measuring real-world airflow. Together, these methods ensure that a High Performance Intake Manifold delivers optimal airflow, reducing resistance and improving engine efficiency.

| Evidence Type | Description |

|---|---|

| CFD Analysis | Simulates airflow to optimize design and reduce turbulence. |

| Flow Bench Testing | Measures actual airflow to validate performance in real-world conditions. |

Impact on Engine Efficiency and Power

A well-designed intake manifold directly impacts engine efficiency and power. By optimizing airflow, it allows the engine to “breathe” better, leading to improved combustion. This results in higher horsepower, better throttle response, and enhanced fuel efficiency. For example, studies show that a High Performance Intake Manifold can increase horsepower by up to 15% in racing engines like the Small Block Chevy V8.

The material and design of the manifold also play a role. Lightweight materials, such as aluminum or composites, reduce weight while maintaining strength. Variable intake designs, which adjust runner length based on engine speed, further enhance performance across different RPM ranges. These innovations make high-performance manifolds indispensable for racers aiming to maximize their engine’s potential.

| Design Type | Key Features | Performance Impact |

|---|---|---|

| Single Plane | High-RPM performance | Boosts power at high speeds. |

| Dual Plane | Balances low-end torque and high-RPM power | Ideal for versatile performance. |

| Variable Intake | Adjusts runner length based on RPM | Optimizes performance across ranges. |

Why High Performance Intake Manifolds Matter

Limitations of Standard Manifolds

Standard intake manifolds often fall short when it comes to racing performance. They are typically designed for everyday driving, not the high demands of competitive racing. These manifolds can create turbulence in the airflow, which reduces engine efficiency. Post-test diagnostics frequently reveal areas where airflow speed and distribution need improvement. For example:

- Turbulence in the airflow disrupts combustion.

- Uneven air distribution leads to inconsistent cylinder performance.

- Limited design optimization results in lower horsepower and torque.

Without advanced engineering, standard manifolds struggle to meet the airflow needs of high-speed engines. Computational Fluid Dynamics (CFD) testing has shown that traditional designs lack the precision required to minimize turbulence. This makes them unsuitable for racers who need every ounce of power from their engines.

| Brand | Performance Features | Price Range |

|---|---|---|

| Dorman | Limited performance enhancements | Extremely affordable |

| Flowmaster | Noticeable gains in horsepower and torque | Higher side |

Advantages of High-Performance Designs

High-performance intake manifolds are engineered to overcome these limitations. They use advanced techniques like CFD simulations to optimize airflow and reduce resistance. This ensures that air reaches each cylinder evenly, improving combustion and boosting power. For instance, the Werkwell Engine Intake Manifold supports engine speeds up to 7500 RPM, enhancing airflow dynamics and combustion efficiency. This results in better fuel economy and increased power output.

| Metric | Improvement |

|---|---|

| Fuel Efficiency | 10% increase |

| Horsepower | 15% increase |

| Emissions | 20% reduction |

These designs also use lightweight materials like aluminum, which reduce engine weight without compromising strength. Variable intake designs further enhance performance by adjusting airflow based on engine speed. Racers using high-performance manifolds experience smoother throttle response, higher RPM capabilities, and better overall engine efficiency.

The Werkwell Advantage

Engineering Precision and Material Quality

Werkwell Intake Manifolds stand out because of their unmatched engineering precision. Every manifold is designed using advanced tools like Computational Fluid Dynamics (CFD). This ensures that airflow is smooth and turbulence is minimized. Engineers carefully analyze every curve and angle to maximize performance. The result? A High Performance Intake Manifold that delivers consistent power to every cylinder.

Material quality is another area where Werkwell excels. These manifolds are crafted from lightweight yet durable materials like aluminum. This reduces the overall weight of the engine while maintaining strength. Aluminum also resists corrosion, which means the manifold lasts longer even under extreme conditions. Racers can trust Werkwell manifolds to perform reliably, lap after lap.

Tip: Lightweight materials not only improve speed but also enhance fuel efficiency. That’s a win-win for racers!

Proven Performance Results

Werkwell Intake Manifolds have been tested on the track and in the lab. Racers using these manifolds report noticeable improvements in throttle response and acceleration. In fact, dyno tests show up to a 15% increase in horsepower when compared to standard manifolds. That’s the kind of edge every racer dreams of.

Success stories from professional racers highlight the real-world benefits. Many have shared how Werkwell manifolds helped them shave seconds off their lap times. These results aren’t just numbers—they’re proof of Werkwell’s commitment to excellence. Whether it’s a local race or a national championship, Werkwell manifolds deliver the performance racers need to win.

Real-World Benefits for Racers

Enhanced Track Performance

Racers know that every second counts on the track. A well-designed intake manifold can make all the difference. Werkwell’s High Performance Intake Manifold ensures engines breathe better, delivering smoother throttle response and faster acceleration. This means racers can push their vehicles harder without worrying about airflow limitations.

The lightweight materials used in Werkwell manifolds also reduce engine weight. This improves handling and speed, giving racers an edge in tight corners and straightaways. With optimized airflow, engines run cooler and more efficiently, reducing the risk of overheating during intense races. These benefits translate directly into better lap times and more consistent performance.

Pro Tip: Pairing a Werkwell manifold with other performance upgrades, like a high-performance exhaust system, can unlock even greater potential on the track.

Success Stories with Werkwell Manifolds

Many racers have shared how Werkwell manifolds transformed their performance. One professional driver shaved nearly two seconds off their lap time after upgrading to a Werkwell manifold. Another racer reported a noticeable boost in horsepower, helping them secure a podium finish in a regional championship.

Even amateur racers have seen impressive results. A weekend enthusiast described how their car felt more responsive and powerful after installing a Werkwell manifold. These stories highlight the real-world impact of Werkwell’s engineering. Whether it’s a local race or a national competition, Werkwell manifolds consistently deliver results that racers can rely on.

High-performance intake manifolds play a key role in racing. They boost engine power and efficiency, giving racers the edge they need. Werkwell Intake Manifolds shine with their precision design and durable materials.

Why choose Werkwell?

Proven results, unmatched quality, and track-tested performance.

For racers chasing victory, Werkwell is the ultimate choice.

Post time: Mar-24-2025