Harmonic balancers play a vital role in engine performance by absorbing and reducing torsional vibrations, ensuring smooth operation. Understanding the nuances of ls harmonic balancer differences is key to optimizing engine efficiency. This guide offers an insightful overview of the variations in design and their impact on engine performance. By delving into the intricacies of Engine harmonic balancers, enthusiasts can make informed decisions to enhance their vehicle’s capabilities.

Understanding Harmonic Balancers

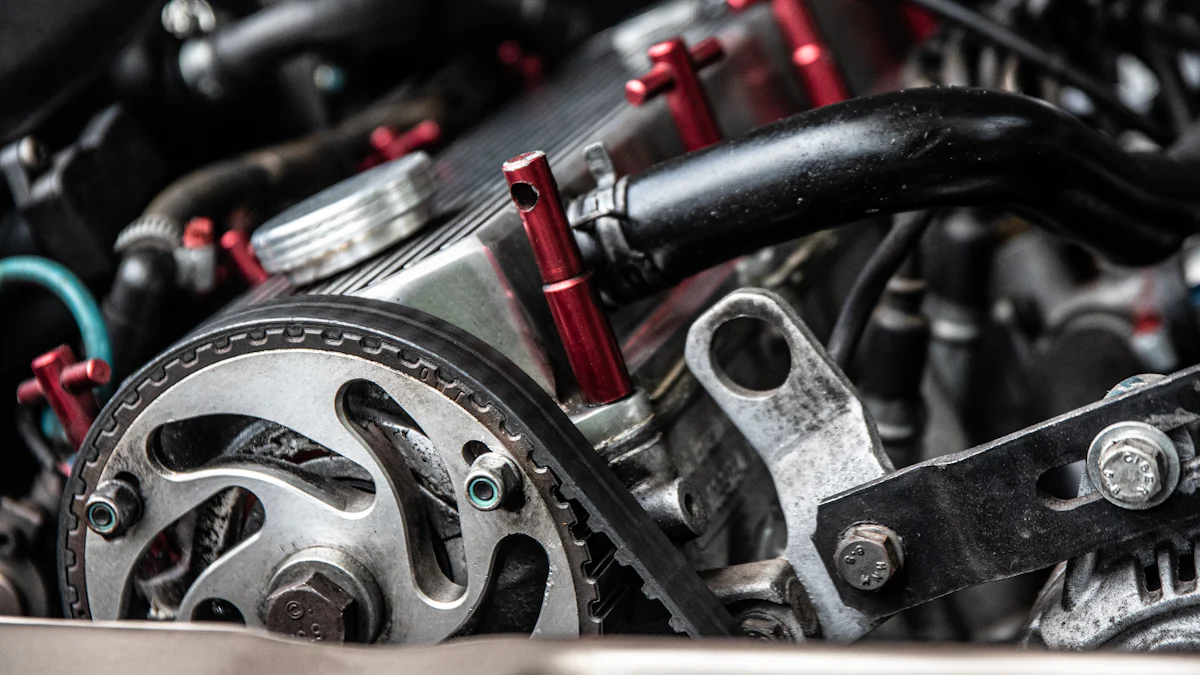

In the realm of engine mechanics, the Engine harmonic balancer stands as a crucial component that orchestrates a delicate dance between power and precision. This section will delve into the intricate details surrounding this mechanical marvel, shedding light on its evolution and impact on engine performance.

What is a Harmonic Balancer?

Definition and Function

At its core, the harmonic Balancer serves as a silent guardian, protecting the engine from the relentless onslaught of vibrations that threaten to disrupt its harmonious operation. Crafted with meticulous engineering precision, this device acts as a shield, absorbing torsional forces and ensuring smooth rotation within the heart of the engine.

Importance in Engine Performance

The significance of the Engine harmonic balancer cannot be overstated. By mitigating vibrations that stem from combustion cycles and rotational movements, it safeguards critical engine components from potential damage. This preservation not only extends the lifespan of the engine but also enhances its overall performance, allowing for optimal power output.

TECH Resident Join Date

Historical Context

Embark on a journey through time to explore the origins of this ingenious invention. From its humble beginnings to its modern-day adaptations, witness how the TECH Resident Join Date has shaped the landscape of automotive engineering. Each iteration reflects a commitment to innovation and an unwavering dedication to improving engine efficiency.

Evolution Over Time

As generations have passed, so too has the technology behind Engine harmonic balancers evolved. With each new model comes enhanced capabilities and refined designs aimed at addressing emerging challenges in engine dynamics. The continuous pursuit of perfection drives engineers to push boundaries and redefine what is possible in harmonizing engine performance.

ls harmonic balancer differences

Variations in Design

Dive into the intricate world of ls harmonic balancer differences, where subtle nuances can yield significant impacts on overall engine function. From pulley offset variations to material composition choices, every design element plays a pivotal role in shaping how these balancers interact with their respective engines.

Impact on Engine Performance

The ripple effect of choosing one type of harmonic Balancer over another reverberates throughout an entire vehicle’s operation. Whether it’s optimizing power delivery or fine-tuning vibration dampening capabilities, understanding these differences empowers enthusiasts to tailor their engines for peak performance.

Types of LS Harmonic Balancers

In the realm of LS engines, Elastomer Harmonic Balancers stand out as a prevalent choice among enthusiasts seeking to strike a balance between performance and durability. Understanding the intricate mechanisms behind these balancers unveils a world of possibilities for engine optimization.

Elastomer Harmonic Balancers

Mechanism

- The Elastomer Harmonic Balancer operates on a simple yet effective principle. It consists of a rubber insulator sandwiched between two metal components. This design allows the balancer to absorb torsional vibrations generated by the engine, thereby reducing stress on critical components.

- By utilizing the elasticity of rubber, Elastomer Harmonic Balancers dampen vibrations that could otherwise compromise engine performance. The flexibility of the material enables it to adapt to varying engine speeds and conditions, ensuring smooth operation under all circumstances.

Pros and Cons

- Pros:

- Enhanced Vibration Dampening: The inherent properties of elastomer materials make these balancers highly effective at reducing engine vibrations.

- Cost-Effective Solution: Compared to other types of harmonic balancers, elastomer variants offer a budget-friendly option without compromising on performance.

- Wide Compatibility: Elastomer Harmonic Balancers are compatible with a wide range of LS engine models, making them a versatile choice for enthusiasts.

- Cons:

- Limited Longevity: Over time, the rubber component in elastomer balancers may degrade due to exposure to heat and mechanical stress.

- Performance Restrictions: While effective for most applications, elastomer balancers may not provide the same level of precision tuning as other types in high-performance scenarios.

Moving beyond traditional designs, Fluid Harmonic Balancers introduce a dynamic element into the equation, offering unique advantages in terms of vibration control and adaptability.

Fluid Harmonic Balancers

Mechanism

- At the core of Fluid Harmonic Balancers lies a specialized fluid chamber designed to counteract torsional vibrations within the engine. As the crankshaft rotates, the fluid inside the chamber shifts dynamically, absorbing and dissipating vibrations before they can propagate through the system.

- By harnessing fluid dynamics principles, these balancers excel at fine-tuning vibration control across a broad spectrum of engine speeds. The ability to adjust damping characteristics on-the-fly makes fluid variants ideal for applications where precise tuning is paramount.

Pros and Cons

- Pros:

- Dynamic Vibration Control: The fluid medium inside these balancers offers unparalleled flexibility in adjusting vibration damping properties based on real-time engine conditions.

- High Precision Tuning: Enthusiasts seeking optimal performance can benefit from the precise tuning capabilities afforded by Fluid Harmonic Balancers, allowing for customized setups tailored to specific requirements.

- Longevity and Reliability: With fewer moving parts than traditional designs, fluid balancers often boast extended lifespans and enhanced reliability under demanding operating conditions.

- Cons:

- Complexity in Maintenance: The intricate design of fluid harmonic balancers may require specialized maintenance procedures compared to simpler variants like elastomer balancers.

- Higher Initial Cost: While offering advanced features, fluid harmonic balancers typically come at a higher price point than traditional options due to their sophisticated construction.

Stepping into uncharted territory, Friction Harmonic Balancers push boundaries with innovative mechanisms that redefine conventional notions of vibration control in LS engines.

Friction Harmonic Balancers

Mechanism

- Unlike their counterparts, which rely on passive elements like rubber or fluids for vibration dampening, **Friction Harmonic Bal…

Choosing the Right Harmonic Balancer

When it comes to selecting the ideal Balancer for your engine, several crucial factors demand consideration. From the size of your engine to its performance requirements, each element plays a pivotal role in determining the optimal Balancer choice. By understanding these key aspects and exploring the benefits of upgrading, enthusiasts can unlock a world of possibilities to enhance their vehicle’s longevity and maximize horsepower output.

Factors to Consider

Engine Size

- Begin by assessing the specific dimensions of your engine.

- Evaluate the cubic capacity and power output to determine the appropriate Balancer size.

- Matching the Balancer size to your engine’s specifications is essential for seamless integration and optimal performance.

Performance Requirements

- Define your performance goals and expectations from the Balancer.

- Consider factors such as torque delivery, acceleration capabilities, and overall engine responsiveness.

- Tailoring your Balancer choice to meet these performance demands can significantly impact your vehicle’s overall driving experience.

Benefits of Upgrading

Longevity

- Upgrading to a high-quality Balancer can substantially enhance your engine’s lifespan.

- By reducing vibrations and stress on critical components, a premium Balancer ensures long-term durability.

- Investing in longevity through an upgraded Balancer translates to fewer maintenance issues and increased reliability over time.

Maximizing Horsepower

- One of the most significant advantages of upgrading your Balancer is the potential for maximizing horsepower output.

- A well-suited Balancer can optimize power transfer efficiency within the engine, resulting in enhanced performance.

- Whether you’re seeking improved acceleration or increased top speed, choosing the right Balancer is key to unlocking your engine’s full horsepower potential.

Aftermarket Options

Werkwell Harmonic Balancers

- Explore aftermarket solutions such as Werkwell Harmonic Balancers for premium quality and performance.

- Werkwell offers a range of customizable options tailored to meet diverse customer needs.

- With a focus on innovation and precision engineering, Werkwell Harmonic Balancers are designed to elevate your engine’s capabilities.

Customization and Quality

- Embrace customization options offered by Werkwell Harmonic Balancers for a personalized touch.

- Tailor your Balancer selection based on specific requirements, from design preferences to functional enhancements.

- Prioritize quality craftsmanship and attention to detail when choosing a harmonic balancer upgrade for lasting satisfaction.

- In summary, understanding the nuances of LS harmonic balancer differences is crucial for optimizing engine performance and longevity.

- Selecting the right harmonic balancer tailored to your engine’s specifications can significantly enhance power output and reduce maintenance issues.

- Looking ahead, enthusiasts should consider aftermarket options like Werkwell Harmonic Balancers for customized solutions that elevate their vehicle’s capabilities to new heights.

Post time: Jun-04-2024