Automotive harmonic balancers are essential components in a vehicle’s engine system. Understanding the significance of Harmonic Balancer wobble is crucial for maintaining engine health. In this blog, Werkwell delves into the complexities of harmonic balancers, shedding light on their functions and potential issues. By exploring the causes and solutions related to harmonic balancer wobble, readers will gain valuable insights into preserving their vehicle’s performance and longevity.

Harmonic Balancer Wobble

What is Harmonic Balancer Wobble?

The Harmonic Balancer is a critical component in an engine system that helps reduce vibrations. When the Balancer experiences Wobble, it can lead to severe issues. The Definition of this phenomenon involves the irregular movement of the balancer, deviating from its intended rotation. This deviation can cause detrimental effects on the engine’s performance and longevity. Recognizing the Symptoms of harmonic balancer wobble is essential for early detection and prevention of further damage.

Definition

The Harmonic Balancer Wobble refers to the irregular movement of this crucial engine part, disrupting its smooth operation and potentially causing significant harm.

Symptoms

- Unusual engine noises

- Vibrations felt while driving

- Misaligned belts

Importance of Addressing Wobble

Addressing Wobble in the Harmonic Balancer is paramount due to its direct impact on vehicle health. Neglecting this issue can result in severe consequences that affect both the engine’s functionality and overall performance.

Potential Engine Damage

Failure to address harmonic balancer wobble can lead to catastrophic outcomes such as:

- Crankshaft fractures

- Timing belt misalignment

- Increased wear on engine components

Impact on Performance

The presence of harmonic balancer wobble can significantly diminish a vehicle’s performance by:

- Reducing fuel efficiency

- Compromising engine stability

- Accelerating wear and tear on internal parts

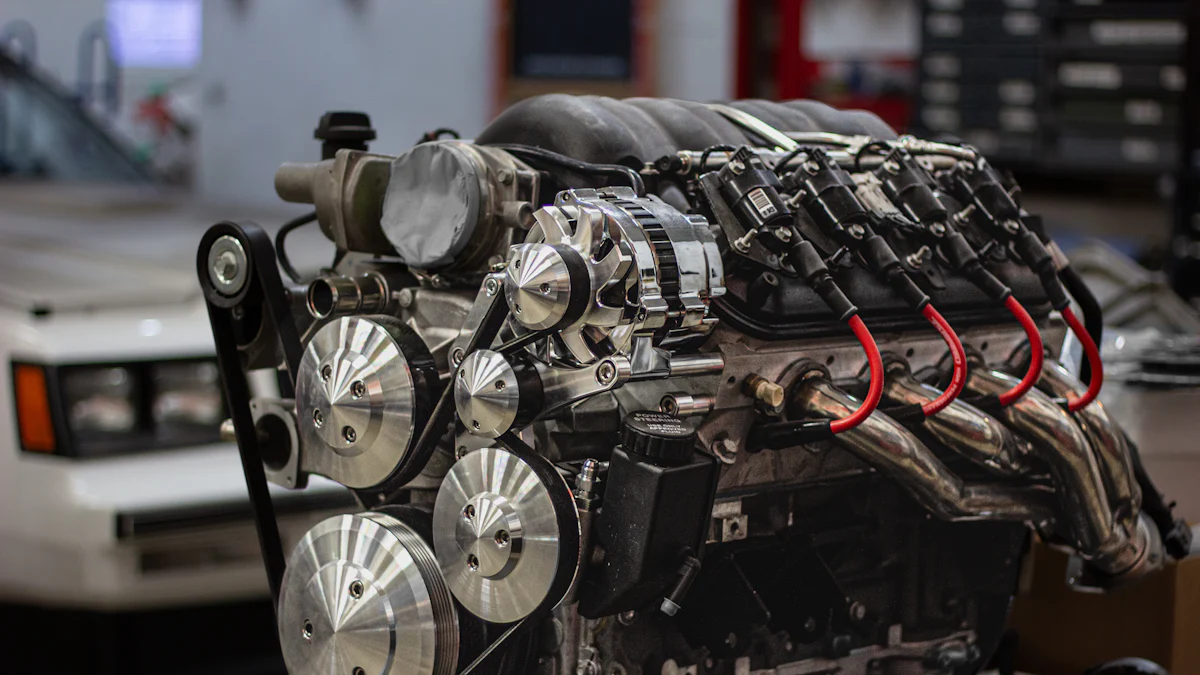

Case Study: Corvette

Exploring a real-world example like the Corvette provides valuable insights into common issues related to harmonic balancer wobble and potential solutions discussed within automotive communities.

Common Issues

- Belt slippage due to wobbling balancers

- Engine misfires caused by timing discrepancies

- Excessive wear on pulleys and belts

Solutions Discussed in Forums

Enthusiasts often share practical solutions for addressing harmonic balancer wobble in forums, including:

- Upgrading to high-quality OEM belts like Goodyear Gatorback

- Regularly inspecting and maintaining the harmonic balancer

- Considering a Goodyear Gatorback belt replacement for improved durability

Causes of Harmonic Balancer Wobble

Internal Construction Issues

Rubber Deterioration

Rubber deterioration in the crankshaft balancer assembly can lead to Wobble. The degradation of the rubber component within the Balancer affects its ability to absorb vibrations effectively. As the rubber weakens over time, it fails to maintain the necessary stability required for smooth engine operation. This deterioration often results from prolonged exposure to heat and stress, common in high-performance vehicles.

Metal Fatigue

Metal fatigue is another significant factor contributing to Harmonic Balancer Wobble. The constant stress and strain experienced by the metal components of the crankshaft balancer can lead to structural weaknesses over time. This weakening of the metal parts compromises the overall integrity of the Balancer, causing it to wobble during engine operation. Metal fatigue is a gradual process that worsens with extended use and can eventually result in complete failure if left unaddressed.

External Factors

Excessive Belt Tension

Excessive belt tension plays a crucial role in inducing Wobbling Crankshaft Balancer issues. When belts are overly tightened, they exert excessive pressure on the crankshaft balancer assembly, leading to misalignment and imbalance. This misalignment causes the Balancer to wobble erratically, disrupting its primary function of dampening vibrations. Proper belt tensioning is essential for maintaining optimal performance and preventing unnecessary stress on engine components.

Crankshaft Snout Runout

Crankshaft snout runout is a common external factor that contributes to Harmonic Balancer Wobble. When the crankshaft’s snout, which interfaces with the harmonic balancer, experiences runout or deviation from its true axis, it results in imbalanced rotation. This misalignment directly impacts the harmonious movement of the Balancer, causing it to wobble during engine operation. Addressing crankshaft snout runout through proper alignment procedures is crucial for mitigating potential wobbling issues.

Supporting Components

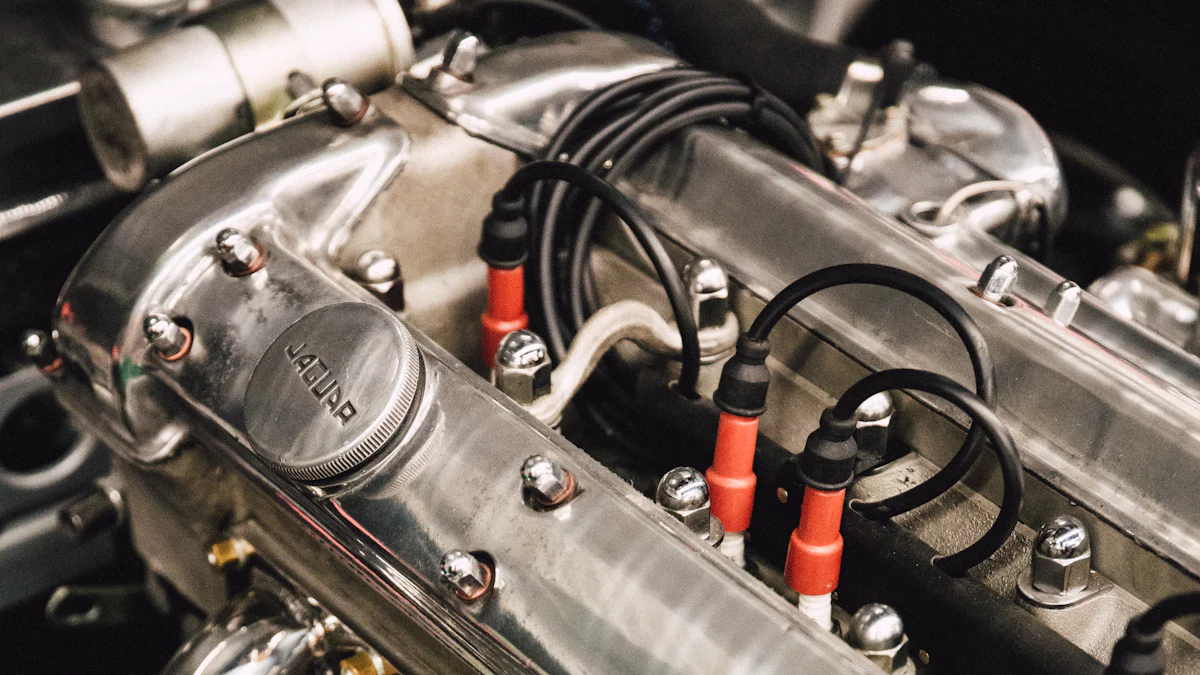

Role of Belts

Belts play a vital role in supporting the functionality of the harmonic crankshaft balancer assembly. Properly tensioned belts ensure that power is efficiently transferred from the engine to various components, including the balancer itself. When belts are correctly aligned and tensioned, they help stabilize the rotational movement of the crankshaft balancer, reducing the likelihood of wobbling issues. Regular inspection and maintenance of belts are essential for preserving their integrity and preventing disruptions in engine performance.

Role of Pulleys

Pulleys serve as integral components that interact with both belts and the harmonic balancer within an engine system. These rotating wheels support belt movement and facilitate power transmission throughout different engine parts. Properly functioning pulleys contribute to maintaining consistent belt tension and alignment, which directly impact the stability of the Balancer. Any irregularities or damage in pulleys can lead to imbalances that exacerbate harmonic balancer wobbling problems.

Solutions and Maintenance

Identifying Wobble Early

Regular Inspections

To identify potential wobble in the Harmonic Balancer, conducting regular inspections is crucial. These inspections involve visually examining the balancer for any signs of irregular movement or misalignment. By closely monitoring the balancer’s rotation during engine operation, early detection of wobbling issues can prevent further damage. Inspecting the harmonic balancer as part of routine maintenance ensures that any deviations from its intended function are promptly addressed.

Listening for Symptoms

Another effective method for identifying wobble early is by listening for symptoms while the engine is running. Unusual noises such as rattling or knocking sounds may indicate underlying issues with the harmonic balancer. By paying attention to these auditory cues, drivers can detect potential wobbling problems before they escalate. Being attuned to these distinct sounds enables proactive measures to be taken, safeguarding the engine from more severe repercussions.

Repair and Replacement

When to Replace

Determining the optimal time for repair or replacement of a wobbling harmonic balancer is essential for maintaining engine performance. If visual inspections or symptom listening reveal significant wobble in the balancer, it may be time to consider a replacement. Timely action when detecting abnormal movements can prevent further complications and ensure uninterrupted engine operation. Replacing a faulty harmonic balancer promptly mitigates risks associated with prolonged use of a deteriorating component.

Choosing the Right Product

When selecting a replacement product for a wobbling harmonic balancer, opting for high-quality components like Harmonic Balancer Sleeve can enhance long-term reliability. The Harmonic Balancer Sleeve offers durability and precision engineering tailored to address wobbling issues effectively. Its design focuses on restoring balance and stability to the crankshaft assembly, promoting smoother engine performance. Choosing this reliable product ensures that harmonics are properly managed, reducing the risk of future wobbling incidents.

Preventative Measures

Proper Installation

Ensuring proper installation of a new harmonic balancer or sleeve is paramount in preventing future wobbling concerns. Following manufacturer guidelines and torque specifications guarantees secure attachment and alignment within the engine system. Properly installed components maintain structural integrity and reduce the likelihood of imbalance during operation. By adhering to correct installation procedures, drivers can proactively safeguard their engines against potential wobble-related complications.

Regular Maintenance

Implementing a regimen of regular maintenance routines significantly contributes to prolonging the lifespan of harmonic balancing components. Scheduled checks on belt tension, pulley alignment, and overall balancer condition help detect early signs of wear or deterioration. By incorporating maintenance tasks into routine service schedules, drivers can address minor issues before they escalate into major malfunctions. Consistent upkeep promotes optimal engine health and minimizes risks associated with harmonic balancer wobble.

In conclusion, understanding the implications of Harmonic Balancer Wobble is paramount for maintaining a healthy engine. By addressing issues related to wobbling balancers promptly, drivers can prevent severe consequences like crankshaft fractures and timing belt misalignment. Regular inspections and timely repairs are essential to safeguard engine performance. Choosing high-quality replacement components such as Harmonic Balancer Sleeve can enhance long-term reliability. To ensure optimal engine health, drivers should prioritize proper installation and regular maintenance routines. By taking proactive measures, individuals can prolong their vehicle’s lifespan and prevent potential wobbling complications.

Post time: May-29-2024