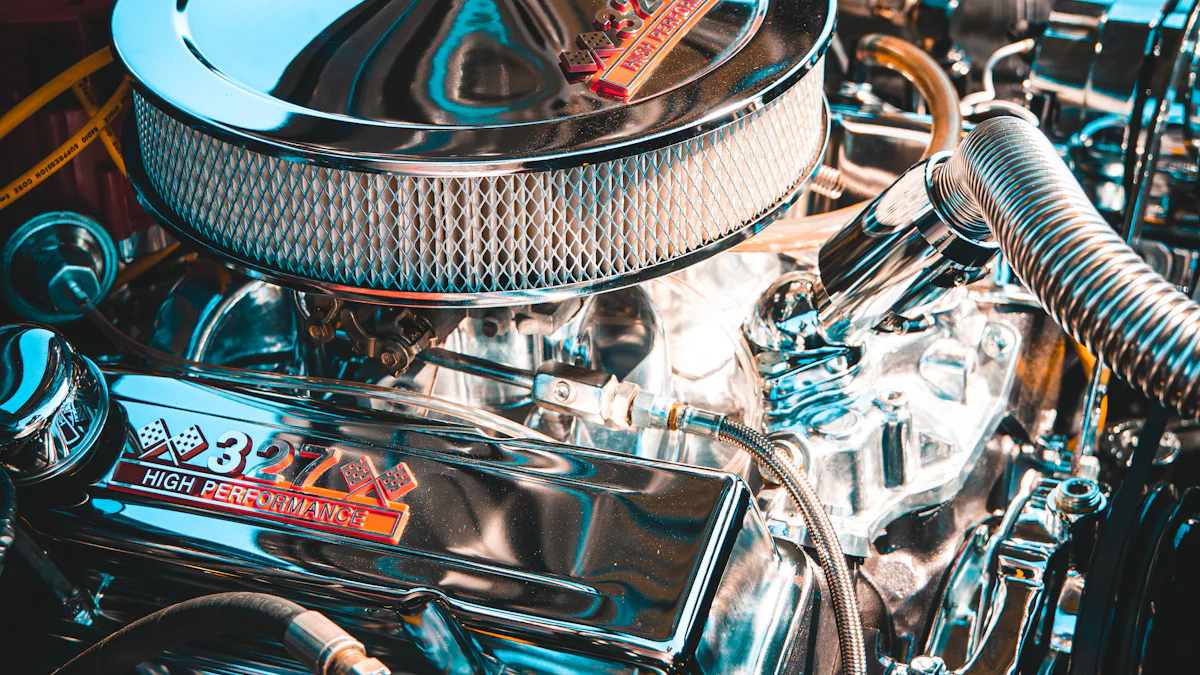

In the realm of small block Chevy engines, the Automotive harmonic balancer stands as a silent hero, crucial for engine longevity and performance. This blog aims to dissect the nuances of these vital components, shedding light on their significance in the automotive world. By exploring the intricacies of small block chevy harmonic balancer differences, readers will gain a deeper understanding of how these seemingly simple parts play a pivotal role in engine dynamics.

Differences by Size

When delving into the realm of small block Chevy engines, the Automotive harmonic balancer reveals its critical role in maintaining engine balance and longevity. Understanding the distinctions between various sizes of harmonic balancers is paramount for optimizing engine performance and durability.

6-Inch Harmonic Balancers

The 6-inch Harmonic Balancers, such as the 6 3/4″ variant, are renowned for their compact size and precise engineering. These balancers are specifically tailored to fit engines with a smaller build, offering a seamless integration that enhances overall performance. Their characteristics include a lightweight design, efficient vibration dampening capabilities, and compatibility with a wide range of small block Chevy engines.

In terms of applications, the 6-inch harmonic balancers are commonly favored in engine rebuilds that necessitate a more streamlined approach. Their versatility allows them to adapt to different configurations seamlessly, making them an ideal choice for enthusiasts seeking enhanced engine balance without compromising on space or weight.

8-Inch Harmonic Balancers

Contrasting the smaller counterparts, 8-inch Harmonic Balancers exude robustness and resilience, catering to high-performance demands with ease. Engine re-builders often opt for these larger balancers due to their superior capacity to handle increased RPMs and crankshaft harmonics effectively. The 8-inch balancers boast a sturdy construction, advanced vibration absorption properties, and compatibility with specific engine setups requiring additional support.

In practical applications, the 8-inch harmonic balancers shine in scenarios where power output and performance enhancements take precedence. Their ability to withstand higher stress levels while maintaining optimal engine balance makes them a popular choice among automotive enthusiasts seeking peak efficiency.

User InfoSend Private TopicView

Recognizing the Importance of Size in Performance is crucial when selecting the appropriate harmonic balancer for your small block Chevy engine. The size of the balancer directly influences its ability to counteract vibrations and ensure smooth operation under varying conditions. By choosing a harmonious balance between size and performance requirements, enthusiasts can elevate their driving experience while safeguarding their engine’s longevity.

Differences by Type

Internally Balanced Harmonic Balancers

In the realm of small block Chevy engines, the distinction between Internally Balanced Harmonic Balancers and their externally balanced counterparts holds significant importance. Understanding the unique characteristics and applications of internally balanced balancers is essential for engine optimization and longevity.

Characteristics

- Internal balance in harmonic balancers ensures a precise distribution of weight within the engine assembly, minimizing vibrations and enhancing overall performance.

- The absence of offset weights distinguishes internally balanced balancers, offering a more streamlined design that promotes smoother engine operation.

- Internally balanced harmonic balancers are meticulously engineered to align with specific engine configurations, providing tailored solutions for varying performance requirements.

Applications

- High-Performance Engines:

- Internally balanced harmonic balancers are favored in high-performance engines where precision and efficiency are paramount.

- The seamless integration of these balancers contributes to maximizing power output while maintaining optimal engine balance under high-stress conditions.

- Engine builders often opt for internally balanced harmonic balancers in racing applications to ensure peak performance and durability.

- Daily Driving Engines:

- For everyday vehicles, internally balanced harmonic balancers offer a reliable solution to minimize wear and tear on the engine components.

- The smooth operation facilitated by these balancers enhances driving comfort and fuel efficiency, making them an ideal choice for daily commuting needs.

- Internally balanced harmonic balancers play a crucial role in extending the lifespan of engines subjected to regular use, promoting longevity and reliability.

Externally Balanced Harmonic Balancers

Contrasting their internal counterparts, Externally Balanced Harmonic Balancers present a distinct approach to addressing engine balance requirements. The key differences between internally and externally balanced balancers lie in their construction and compatibility with specific engine setups.

Characteristics

- Externally balanced harmonic balancers feature offset weights that counteract the inherent imbalances within certain rotating assemblies, ensuring smoother operation at varying RPMs.

- The presence of additional balance weights on both the harmonic balancer and the flywheel/flexplate distinguishes externally balanced configurations from internal balancing methods.

- Engine builders rely on externally balanced harmonic balancers to address specific performance demands that necessitate fine-tuning of rotational dynamics for optimal functionality.

Applications

- Performance-Oriented Builds:

- Externally balanced harmonic balancers excel in performance-oriented builds where precise tuning of crankshaft harmonics is essential for achieving maximum power output.

- These balancers are commonly utilized in high-performance racing engines that require meticulous attention to detail in balancing rotating components for enhanced durability and efficiency.

- Custom Engine Configurations:

- For custom-built engines with unique specifications, externally balanced harmonic balancers offer a versatile solution to fine-tune balance factors according to individual requirements.

- The flexibility provided by these balancers allows engine enthusiasts to tailor their setups for specific applications, whether it be drag racing or off-road performance.

Small Block Chevy Harmonic Balancer Differences

Exploring the nuances of small block chevy harmonic balancer differences unveils critical insights into their impact on engine longevity and operational efficiency. Selecting the right type of harmonic balancer is paramount for ensuring optimal performance and durability in small block Chevy engines.

Impact on Engine Longevity

- Choosing between internally or externally balanced harmonics can significantly influence the lifespan of your engine by minimizing vibrations that lead to premature wear.

- Properly matched harmonics contribute to smoother operation, reducing stress on internal components and preserving critical parts over extended periods.

- The selection of an appropriate small block Chevy harmonic balancer based on your engine’s requirements can enhance overall reliability while safeguarding against potential issues related to imbalance.

Application-Specific Differences

High-Performance Engines

In the realm of high-performance engines, the quest for optimal functionality and durability reigns supreme. When delving into the intricacies of Harmonic Balancers, enthusiasts are met with a myriad of considerations tailored to meet the demands of these power-driven machines.

Required Features

- SFI-Approved Balancers: Ensuring that harmonic balancers meet SFI standards is paramount in high-performance applications, where precision and safety go hand in hand.

- Enhanced Vibration Dampening: The ability of balancers to effectively absorb torsional vibrations is crucial in maintaining engine stability under extreme conditions.

- Increased Durability: Opting for durable harmonic balancers guarantees longevity and reliability, essential for engines operating at peak performance levels.

Recommended Sizes and Types

- 8-Inch Harmonic Balancers:

- The robust nature of 8-inch harmonic balancers makes them ideal for high-performance engines requiring superior vibration control.

- Their larger size enables them to handle increased RPMs and crankshaft harmonics effectively, ensuring consistent performance.

- Internally Balanced Harmonic Balancers:

- Internally balanced balancers offer precise weight distribution within the engine assembly, minimizing vibrations and enhancing overall efficiency.

- Their streamlined design promotes smoother engine operation, making them a preferred choice for high-performance applications.

Daily Driving Engines

For individuals navigating daily commutes and routine drives, the reliability and efficiency of their vehicles are paramount. Understanding how harmonic balancers cater to the needs of daily driving engines sheds light on optimizing everyday performance.

Required Features

- Balanced Operation: Harmonic balancers that promote balanced engine operation reduce wear and tear on internal components, enhancing overall longevity.

- Smooth Performance: The seamless integration of harmonic balancers ensures smooth engine operation, translating to enhanced driving comfort and fuel efficiency.

- Consistent Reliability: Opting for reliable harmonic balancers safeguards daily driving engines against potential issues related to imbalance or excessive vibrations.

Recommended Sizes and Types

- 6-Inch Harmonic Balancers:

- The compact size and efficient design of 6-inch harmonic balancers make them an excellent choice for daily driving engines seeking optimized balance.

- Their lightweight construction and compatibility with various small block Chevy configurations cater to the diverse needs of everyday vehicles.

- Externally Balanced Harmonic Balancers:

- Externally balanced balancers excel in custom engine setups by offering versatile solutions tailored to specific requirements.

- Their ability to fine-tune balance factors according to individual specifications makes them a valuable asset in enhancing daily driving engine performance.

User InfoSend Private TopicView

When faced with the task of selecting the right harmonic balancer for your vehicle, meticulous consideration is key. By understanding the nuances of different sizes, types, and applications specific to your engine’s needs, you pave the way for an optimized driving experience.

Choosing the Right Harmonic Balancer

The failure of factory oil pump gears due to a lack of a harmonic damper illustrates the seriousness of harmonic vibrations in high-performance engines.

In high-performance scenarios like drag racing, where power adders alter engine harmonics significantly, opting for quality aftermarket harmonic balancers becomes imperative. These specialized components play a pivotal role in safeguarding engine integrity under extreme conditions by countering harmful vibrations effectively.

By prioritizing SFI-approved options that align with stringent safety standards and investing in durable solutions designed for enhanced vibration dampening capabilities, enthusiasts can elevate their driving experiences while ensuring long-term reliability. Selecting the appropriate size and type based on individual requirements not only optimizes performance but also safeguards against potential issues associated with imbalanced operations.

In the intricate world of small block Chevy engines, the selection of the right Harmonic Balancer emerges as a critical decision with far-reaching implications. By delving into the nuances of size and type variations, enthusiasts gain valuable insights into optimizing engine performance and longevity. The journey through 6-inch and 8-inch balancers, internally versus externally balanced options, and application-specific considerations underscores the pivotal role these components play in engine dynamics. As enthusiasts navigate the realm of harmonic balancers, prioritizing precision, durability, and compatibility ensures a smooth ride towards enhanced engine efficiency and reliability.

Post time: Jun-04-2024