The GM Harmonic Balancer plays a critical role in keeping an engine running smoothly. It absorbs vibrations caused by the crankshaft’s twisting motion. These vibrations often result from several factors: cyclic combustion forces, piston movement, or even resonance. Without this harmonic balancer, the crankshaft could suffer damage over time. Many confuse the harmonic balancer with the crankshaft pulley, but their functions differ. While the pulley drives accessories, the balancer reduces harmful vibrations. This distinction ensures the engine stays stable and performs efficiently, extending its lifespan. For those working with the Ford Harmonic Balancer FORD 4.0L, 245, understanding these differences is equally important for maintaining engine performance.

Key Takeaways

- The GM Harmonic Balancer is crucial for absorbing engine vibrations, protecting the crankshaft from damage, and ensuring smooth engine operation.

- Regular inspection and maintenance of the harmonic balancer can prevent costly repairs and extend the engine’s lifespan; look for signs like unusual vibrations or visible damage.

- Choosing between OEM and aftermarket harmonic balancers depends on your performance needs; OEM offers factory quality, while aftermarket options cater to high-performance applications.

How Does a GM Harmonic Balancer Work?

The science behind torsional vibrations

Engines generate power through a series of rapid explosions in the cylinders. These explosions create rotational force, but they also cause the crankshaft to twist slightly with each cycle. This twisting motion, known as torsional vibration, can lead to serious problems if left unchecked. Over time, these vibrations can weaken the crankshaft, causing cracks or even complete failure. The GM Harmonic Balancer steps in to absorb these vibrations, ensuring the crankshaft stays stable and the engine runs smoothly.

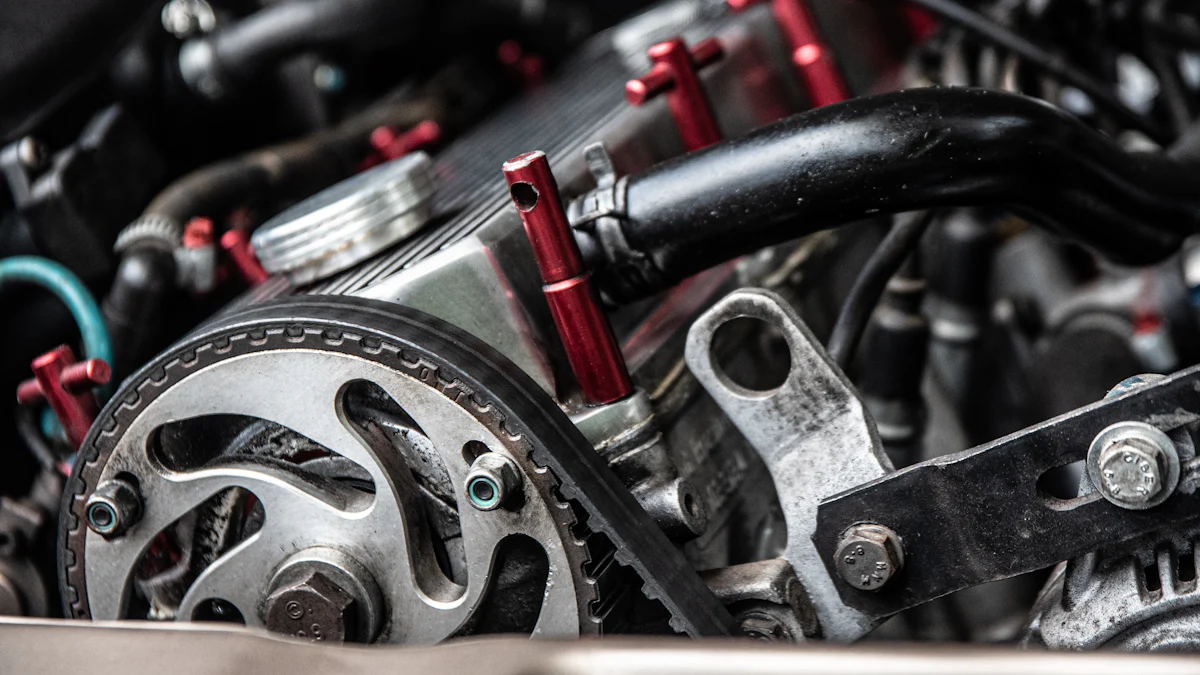

Key components of a GM harmonic balancer

The GM Harmonic Balancer is a carefully engineered device made up of several key parts:

- Metal Hub: This connects directly to the crankshaft, forming the foundation of the balancer.

- Rubber or Elastomer Ring: Positioned between the hub and the outer ring, this flexible material absorbs vibrations.

- Outer Metal Ring: This adds mass to counteract the torsional forces effectively.

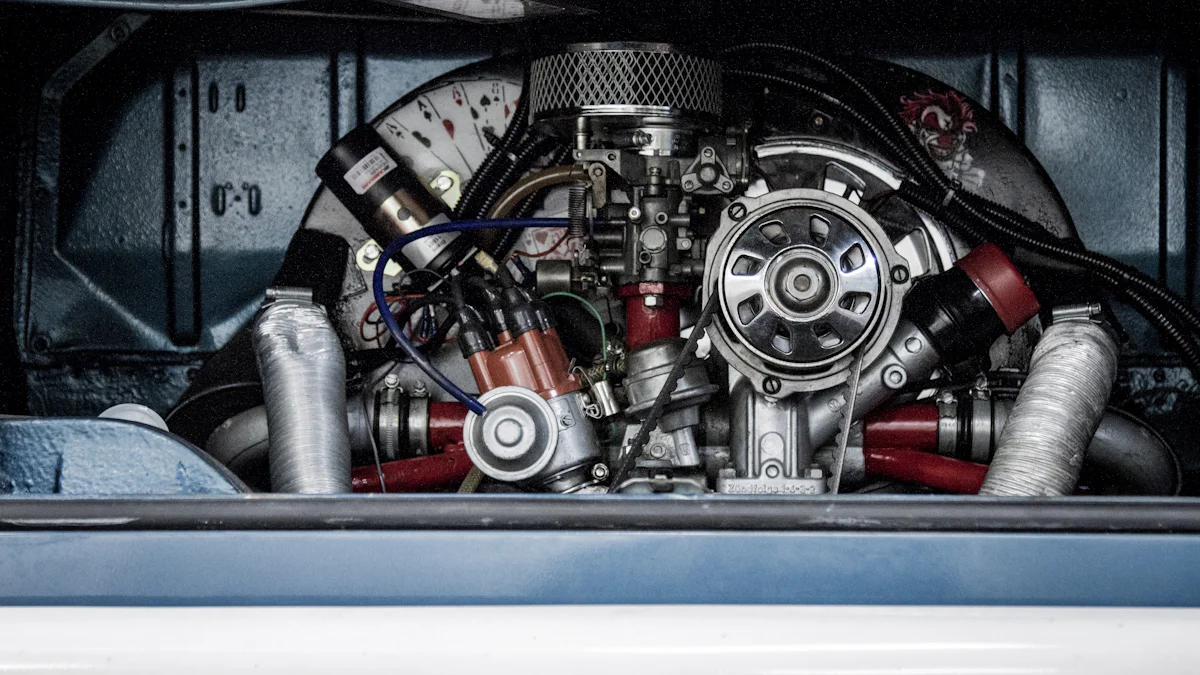

Different materials are used depending on the application:

- Steel balancers are strong and cost-effective, ideal for standard engines.

- Aluminum balancers are lightweight, perfect for high-performance engines.

- Fluid or viscous balancers use advanced materials like silicone for superior vibration absorption at high RPMs.

How it dampens vibrations and protects the crankshaft

The design of the GM Harmonic Balancer allows it to neutralize harmful vibrations. When the crankshaft twists, the rubber ring compresses and absorbs the energy. The outer metal ring, acting as an inertia mass, counterbalances the vibrations. This process reduces stress on the crankshaft and other engine components, preventing wear and tear. Over the years, advancements in balancer design, especially in LS engines, have improved their precision and efficiency, ensuring modern engines perform at their best.

Why Is the GM Harmonic Balancer Essential for Engine Health?

Preventing crankshaft damage and mechanical failure

The GM Harmonic Balancer plays a vital role in protecting the crankshaft from excessive stress. Without it, vibrations from the engine can cause serious damage over time. These vibrations weaken the crankshaft, leading to cracks or even complete failure. Other components, like bearings and timing belts, also face increased strain when the balancer isn’t functioning properly. Misalignment of drive belts and damage to the timing system are common issues that arise when the harmonic balancer fails. Prolonged use without a working balancer can even result in catastrophic engine failure, creating dangerous driving conditions. By absorbing vibrations, the balancer ensures the crankshaft and other parts stay in good shape.

Enhancing engine performance and stability

A properly functioning GM Harmonic Balancer doesn’t just protect the engine—it also improves its performance. By reducing vibrations, it allows the engine to run more smoothly. This smoother operation minimizes wear and tear on critical components, extending the engine’s lifespan. The balancer also helps the engine perform more efficiently by dissipating rotational forces. Drivers often notice improved stability and quieter operation when the balancer is in good condition. Whether it’s a daily driver or a high-performance vehicle, the harmonic balancer is key to keeping the engine running at its best.

Recognizing signs of a failing harmonic balancer

Spotting a failing GM Harmonic Balancer early can save you from costly repairs. Common symptoms include significant engine vibrations and unusual noises like knocking or rattling. A wobbling harmonic balancer is another red flag, often caused by a deteriorating rubber isolator. Drivers may also see the check engine light turn on due to abnormal signals from the crankshaft position sensor. Visible damage, such as cracks or separation between the hub and outer ring, is another clear sign. Addressing these issues promptly can prevent further damage and keep your engine running smoothly.

Practical Tips for Maintenance and Replacement

When and how to inspect or replace a GM harmonic balancer

Regular inspection of the GM harmonic balancer can save you from unexpected engine troubles. During routine maintenance, take a moment to check for any visible signs of wear. Look for cracks, warping, or separation in the rubber ring. If the engine starts vibrating unusually or makes knocking noises, it’s time to investigate further. These symptoms often point to a failing balancer.

Replacement becomes necessary when the balancer shows significant wear or damage. Common reasons include natural wear and tear, improper installation, or excessive stress from high-performance engines. Addressing these issues promptly ensures the engine stays in top shape and avoids costly repairs.

Proper alignment and installation techniques

Installing a harmonic balancer requires precision. Misalignment can lead to vibrations and damage other engine components. To get it right, use the proper tools:

- Harmonic balancer installation tool for even pressing.

- Torque wrench to tighten the bolt to the manufacturer’s specifications.

- Anti-seize lubricant for smoother installation.

- A heat gun or oven to gently expand the balancer if needed.

- Flashlight and magnifying glass to inspect for damage or debris.

Incorrect bolt torque is a common mistake. Over-tightening can strip threads or harm the crankshaft. Taking the time to align and install the balancer correctly prevents these risks and ensures reliable engine performance.

Comparing aftermarket vs. OEM harmonic balancers

Choosing between aftermarket and OEM harmonic balancers depends on your needs. Here’s a quick comparison:

| Feature | OEM Harmonic Balancers | Aftermarket Harmonic Balancers |

|---|---|---|

| Durability | Exceptional durability due to high-quality materials. | Remarkable durability with premium materials. |

| Performance | Consistent performance over extended periods. | Consistent performance even in high-stress environments. |

| Efficiency | Effectively reduces engine vibrations, improving fuel economy. | Significantly reduces engine vibrations, enhancing fuel economy. |

OEM balancers are ideal for those seeking factory-quality parts, while aftermarket options cater to high-performance needs. Both choices offer excellent durability and performance, so pick one that suits your driving style and engine requirements.

The GM Harmonic Balancer is essential for reducing engine vibrations and protecting critical components. Regular maintenance prevents premature wear, keeps the crankshaft stable, and avoids costly repairs. Inspecting for cracks, cleaning debris, and ensuring proper bolt torque are simple steps that go a long way. Prioritizing its health ensures smoother performance and a longer engine life. Don’t wait—keep your engine running at its best!

FAQ

What happens if the GM harmonic balancer fails?

A failing harmonic balancer causes excessive engine vibrations, crankshaft damage, and misaligned belts. Ignoring it can lead to costly repairs or complete engine failure.

How often should a GM harmonic balancer be replaced?

Replace it every 80,000 to 100,000 miles or when visible wear appears. Regular inspections during maintenance help catch issues early.

Can you drive with a damaged harmonic balancer?

Post time: Jan-06-2025