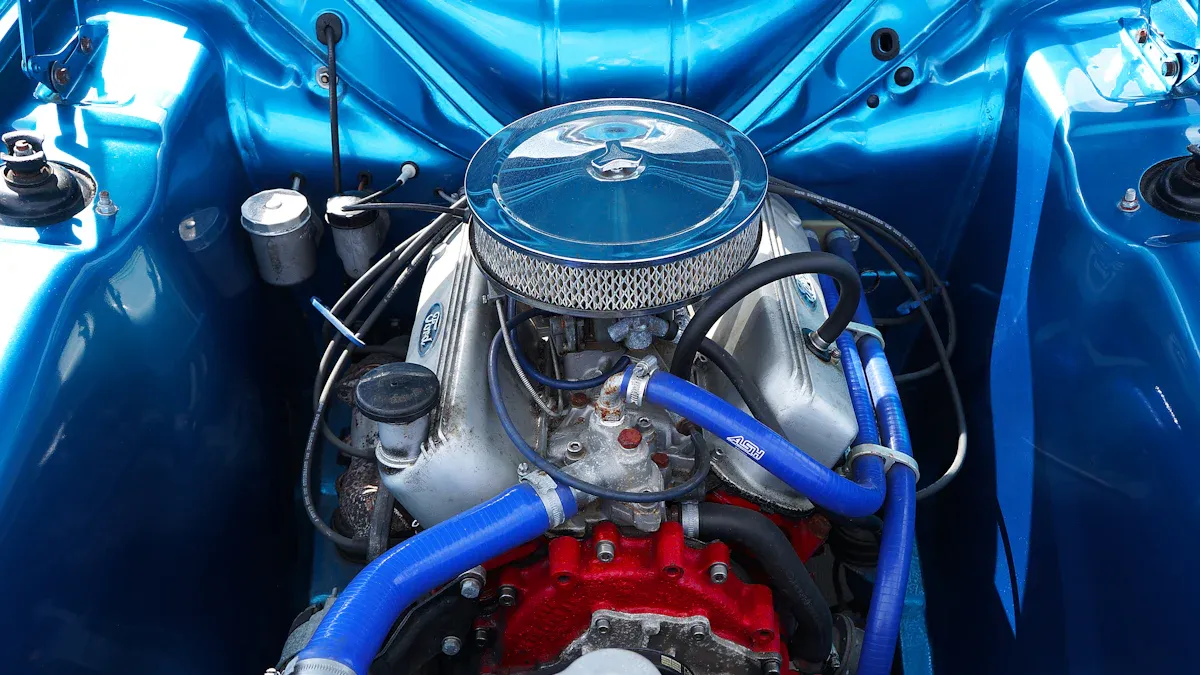

Engines generate intense vibrations during operation. A harmonic balancer, such as the engine harmonic balancer, plays a vital role in reducing these vibrations, ensuring smoother performance and longer engine life. For example, a GM harmonic balancer minimizes wear and tear, preventing premature failures. This not only extends engine longevity but also reduces repair costs, making it a smart investment. Additionally, the LS truck harmonic balancer is specifically designed to enhance the performance of LS engines, further contributing to the overall efficiency and durability of the vehicle.

What Is a Harmonic Balancer and Why Is It Essential?

Definition and Primary Functions

A harmonic balancer is a critical engine component designed to reduce vibrations caused by the crankshaft during operation. It ensures the engine runs smoothly by absorbing harmful harmonics that could otherwise damage internal parts. Without this device, the crankshaft would experience excessive stress, leading to wear and tear on vital components.

By minimizing vibrations, the harmonic balancer helps maintain the engine’s integrity and extends its lifespan. It also plays a role in improving timing efficiency, ensuring the engine operates at peak performance.

Dual Role as a Vibration Damper and Pulley

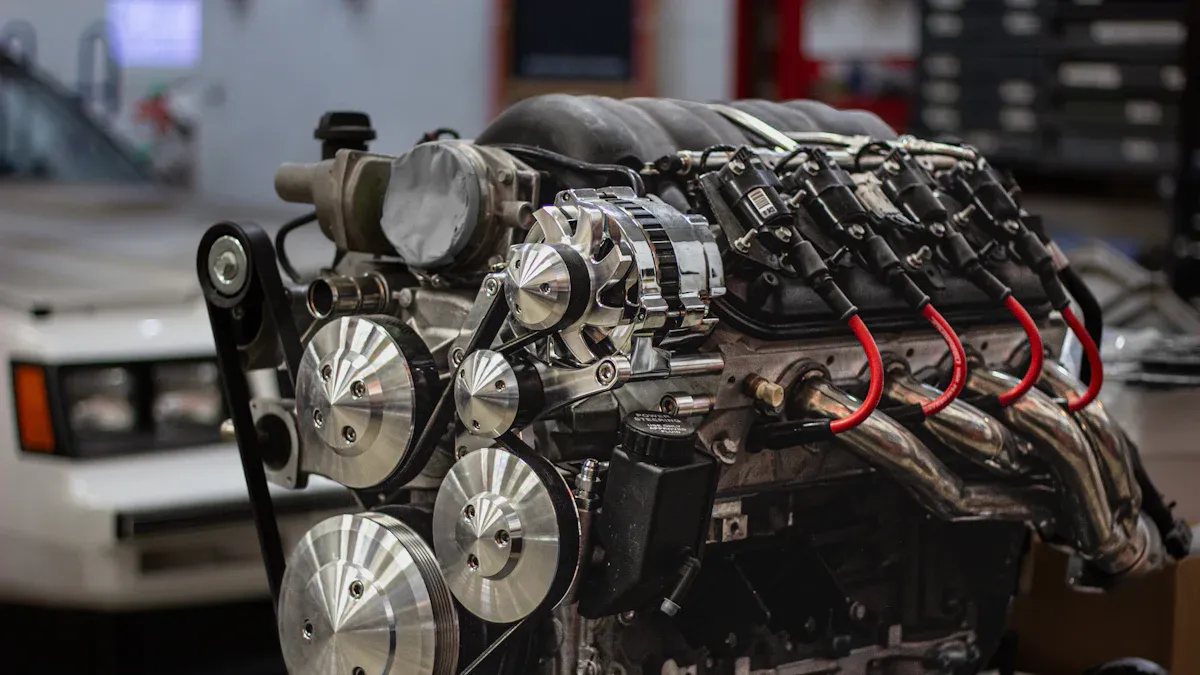

The harmonic balancer serves two essential purposes. First, it acts as a vibration damper, reducing destructive torsional vibrations generated by the crankshaft. These vibrations, if left unchecked, can harm the engine’s valve train and timing mechanisms. Second, it functions as a pulley, driving accessories like the alternator and air conditioning system.

This dual functionality makes the harmonic balancer indispensable for modern engines. It not only protects the engine but also contributes to its overall efficiency.

- Key benefits of the harmonic balancer:

- Reduces crankshaft torsional vibration.

- Drives engine accessories.

- Enhances valve train and timing efficiency.

- Prevents wear on critical components.

Importance in Engine Synchronization and Longevity

Engine synchronization relies heavily on the harmonic balancer. By dampening vibrations, it ensures the crankshaft rotates smoothly, keeping all engine components in sync. This synchronization prevents misalignment and reduces the risk of severe damage to parts like the crankshaft and pistons.

A reliable harmonic balancer also plays a vital role in extending engine life. It minimizes stress on internal components, allowing the engine to perform efficiently over time. Investing in a high-quality harmonic balancer is a smart choice for anyone looking to protect their engine and avoid costly repairs.

Benefits of a Reliable Harmonic Balancer

Enhanced Engine Performance and Efficiency

A reliable harmonic balancer plays a key role in boosting engine performance. By reducing vibrations, it ensures the crankshaft operates smoothly, which improves timing and synchronization. This leads to better fuel efficiency and overall engine output. Drivers often notice smoother acceleration and quieter operation when their harmonic balancer is functioning properly.

Modern harmonic balancers also handle increased engine power effectively. Aftermarket options, for instance, are designed to manage higher RPMs without compromising performance. This makes them a great choice for those seeking enhanced efficiency and durability in their engines.

Prevention of Severe Engine Damage

A failing harmonic balancer can cause serious harm to an engine. Excessive vibrations can damage the crankshaft, misalign components, and even lead to catastrophic failures. A high-quality balancer prevents these issues by absorbing harmful vibrations and maintaining engine stability.

The impact of a reliable harmonic balancer is evident in studies. For example:

| Study Source | Findings | Impact on Engine Damage |

|---|---|---|

| WERKWELL | Significantly reduced engine vibrations at all RPMs | Improved engine life |

| JEGS | Reported smoother engine operation and fewer maintenance issues | Reduced risk of severe damage |

These findings highlight how a dependable harmonic balancer protects critical engine components and extends their lifespan.

Cost-Effectiveness and Long-Term Savings

Investing in a reliable harmonic balancer saves money in the long run. High-quality aftermarket balancers, made with advanced materials, last longer and require fewer replacements. This reduces maintenance costs over time.

- Benefits of a durable harmonic balancer:

- Fewer replacements and lower maintenance costs.

- Enhanced efficiency and longevity, reducing repair expenses.

- Savings on fuel due to improved engine performance.

Choosing a dependable harmonic balancer is a smart financial decision. It not only protects the engine but also minimizes long-term expenses.

Recognizing the Signs of a Failing Harmonic Balancer

Common Symptoms to Watch For

A failing harmonic balancer often gives clear warning signs. Drivers may notice rough idling, especially at specific RPM ranges like 600 or 1700. The car might shake noticeably during these moments. Vibrations can also become more intense around 1400 RPM and persist up to 2000 RPM. These vibrations make the engine feel unstable and can disrupt the driving experience.

Another common symptom is visible damage to the harmonic balancer itself. Cracks, slipping, or misalignment can affect engine timing and performance. Drivers should also listen for unusual noises, such as rattling or knocking, which often indicate internal issues. Paying attention to these signs can help catch problems early.

Risks of Ignoring Warning Signs

Ignoring these symptoms can lead to severe consequences. Excessive vibrations can damage the crankshaft, misalign components, and even cause the harmonic balancer to detach. This could result in costly repairs or complete engine failure.

When the harmonic balancer fails, it disrupts the engine’s synchronization. This misalignment puts extra stress on internal parts, increasing wear and tear. Over time, the engine’s performance declines, and the risk of catastrophic failure rises.

Importance of Timely Maintenance and Professional Assistance

Timely maintenance is crucial for preventing these issues. Regular inspections can identify early signs of wear or damage. Replacing a failing harmonic balancer before it causes further harm saves money and extends engine life.

Professional assistance ensures the job is done right. Mechanics have the tools and expertise to diagnose and fix problems accurately. They can also recommend high-quality replacements that match the engine’s specifications. Taking action early keeps the engine running smoothly and avoids unnecessary expenses.

Werkwell’s Contribution to Harmonic Balancer Innovation

Advanced Manufacturing Processes and Materials

Werkwell has revolutionized the production of harmonic balancers by adopting cutting-edge manufacturing techniques and premium materials. The company uses steel or cast iron for strength and durability, while rubber or elastomer components effectively absorb vibrations. This combination ensures the balancers withstand the intense forces generated by engines.

Precision engineering plays a key role in Werkwell’s process. Every harmonic balancer is designed to meet exact specifications, ensuring compatibility and optimal performance. Rigorous testing further guarantees that each product adheres to original equipment standards.

| Material Type | Benefits |

|---|---|

| Steel or Cast Iron | Provides strength to withstand engine vibrations |

| Rubber or Elastomer | Effectively absorbs and reduces vibrations |

| Design Aspect | Importance |

|---|---|

| Precision Engineering | Ensures optimal performance and compatibility |

| Rigorous Testing | Guarantees adherence to original specifications |

OEM/ODM Services and Customization Options

Werkwell stands out as a leader in offering OEM and ODM services. Their advanced R&D and QC departments are equipped with state-of-the-art laboratories and testing facilities. This allows them to meet unique customer requirements with precision and expertise.

The company also integrates 3D printing technology into its design process. This innovation accelerates workflows, simplifies design for manufacturing (DFM), and reduces costs. Customers benefit from faster project completion and fewer design changes, making Werkwell a trusted partner for customized solutions.

Certifications and Quality Assurance

Quality assurance is at the heart of Werkwell’s operations. The company holds the prestigious IATF 16949 certification, which reflects its commitment to excellence. This certification enables Werkwell to build detailed FMEA and Control Plans for projects, ensuring every product meets the highest standards.

Werkwell also issues 8D reports promptly to address any issues that arise. Their dedication to quality and reliability ensures that customers receive products they can trust. By combining advanced processes, customization options, and rigorous quality checks, Werkwell continues to lead the way in harmonic balancer innovation.

A reliable harmonic balancer offers more than just smoother engine performance. It’s a small investment with big returns. Drivers save money on repairs and fuel while avoiding frequent replacements.

- Key benefits include:

- Cost-effectiveness over time.

- Enhanced efficiency and longevity.

- Reduced need for costly repairs.

Proactive maintenance ensures your engine stays healthy and your drives remain smooth.

FAQ

What happens if I ignore a failing harmonic balancer?

Ignoring it can lead to crankshaft damage, misaligned components, or even engine failure. Repairs become expensive, and the engine’s lifespan shortens significantly.

How often should I replace my harmonic balancer?

Most harmonic balancers last 100,000 miles. Check for wear during routine maintenance. Replace it immediately if you notice cracks, slipping, or unusual vibrations.

Can I install a harmonic balancer myself?

Post time: Mar-17-2025