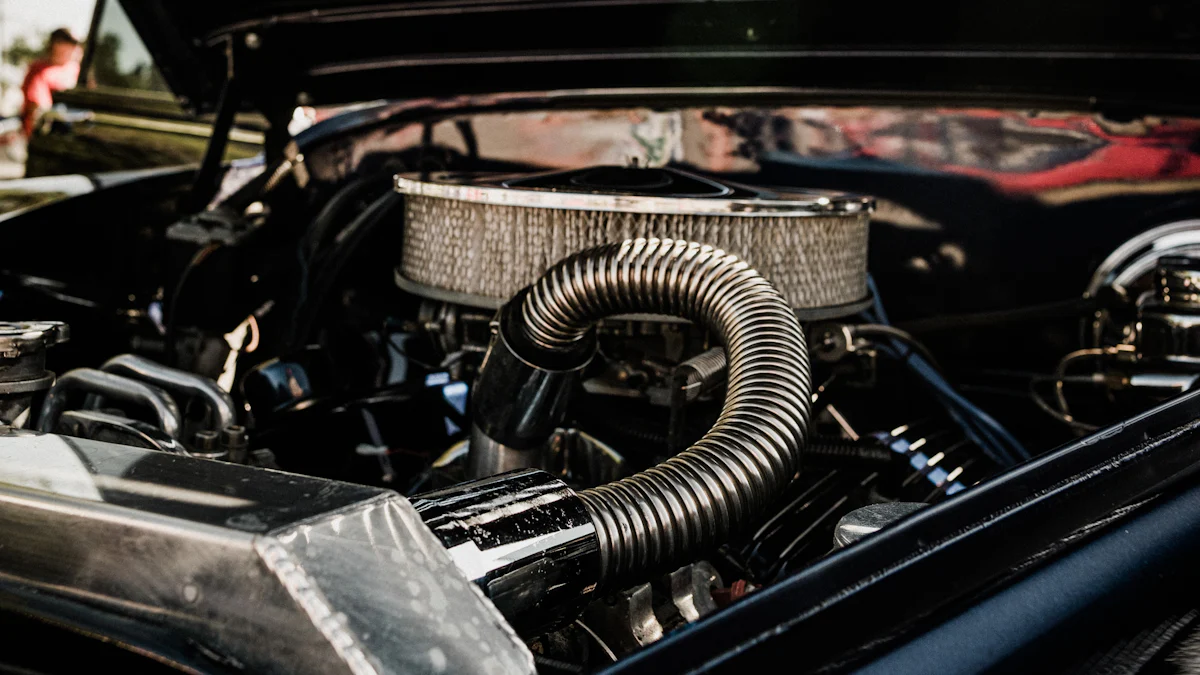

Pontiac 400 exhaust manifolds are a vital component in enhancing automotive performance. These manifolds play a significant role in optimizing engine efficiency and power output. This blog will delve into the importance of these engine exhaust manifolds, highlighting their historical significance, engineering excellence, and impact on overall engine performance. By exploring the benefits and practical tips associated with Pontiac 400 exhaust manifolds, enthusiasts can gain valuable insights into why upgrading to these manifolds is a must for maximizing their vehicle’s potential.

The Importance of Pontiac 400 Exhaust Manifolds

Historical Significance

Evolution of Pontiac 400

Pontiac Motor Division spearheaded high-performance engine programs, leading to the development of the iconic Pontiac 400. This engine marked a significant advancement in automotive engineering, showcasing Pontiac’s commitment to power and performance. Introduced in 1967, the Pontiac 400 quickly gained recognition for its exceptional capabilities and became a cornerstone in the realm of muscle cars.

Role in Muscle Car Era

During the golden age of muscle cars, the Pontiac 400 stood out as one of the most formidable powerhouses on the road. Its presence in vehicles like the GTO and Firebird solidified its reputation as a force to be reckoned with. Enthusiasts marveled at the raw power and exhilarating performance delivered by this legendary engine, making it a symbol of American automotive excellence.

Engineering Excellence

Design Features

The Pontiac 400 exhaust manifolds exemplify engineering brilliance with their precision-crafted design. Each manifold is meticulously engineered to optimize exhaust flow, ensuring maximum efficiency and power output. The intricate design elements work harmoniously to enhance overall engine performance, delivering a driving experience that is both exhilarating and efficient.

Material Quality

Crafted from high-quality materials, such as durable cast iron or premium alloys, these exhaust manifolds are built to withstand the rigors of intense driving conditions. The superior material quality ensures longevity and reliability, allowing enthusiasts to push their vehicles to the limit without compromising on performance. With a focus on durability and resilience, Pontiac has set a standard for excellence in exhaust manifold construction.

Impact on Engine Performance

Vibration Reduction

One notable benefit of Pontiac 400 exhaust manifolds is their ability to minimize engine vibrations during operation. By effectively reducing unwanted vibrations, these manifolds contribute to a smoother and more stable driving experience. Enthusiasts can enjoy enhanced comfort behind the wheel while also prolonging the lifespan of critical engine components.

Enhanced Durability

The robust construction of Pontiac 400 exhaust manifolds ensures unparalleled durability under demanding conditions. Whether navigating city streets or conquering challenging terrains, these manifolds remain resilient and reliable throughout every journey. Their ability to withstand high temperatures and intense pressure underscores their exceptional quality and craftsmanship.

Performance Benefits

Improved Horsepower

When considering the advantages of Pontiac 400 exhaust manifolds over stock alternatives, the focus inevitably shifts to the substantial enhancement in horsepower that these manifolds deliver. The comparison between Stock Pontiac 400 CID exhaust manifolds and Long tube headers reveals a remarkable difference in performance. Long tube headers, known for their ability to increase mid-range and top-end power, outshine stock exhaust manifolds in optimizing engine output.

To illustrate this point further, let’s delve into real-world scenarios where enthusiasts have experienced tangible gains by upgrading to Pontiac 400 exhaust manifolds. The transition from conventional stock manifolds to these high-performance counterparts has resulted in significant boosts in horsepower, transforming driving experiences into thrilling adventures on the road. The empirical evidence speaks volumes about the undeniable impact of these exhaust manifolds on overall engine performance.

Enhanced Torque

Beyond the realm of horsepower lies another critical aspect of engine performance: torque. Pontiac 400 exhaust manifolds not only excel in enhancing horsepower but also offer substantial benefits in terms of torque delivery. Whether for daily commuting or competitive racing, the advantages of upgraded torque cannot be overstated.

For daily driving enthusiasts, the increased torque provided by these exhaust manifolds translates into improved acceleration and responsiveness on city streets and highways alike. The seamless power delivery ensures a dynamic driving experience that is both efficient and exhilarating. On the racing front, the enhanced torque becomes a game-changer, propelling vehicles towards victory with unmatched speed and agility.

Better Exhaust Flow

One of the key features that set Pontiac 400 exhaust manifolds apart is their superior design efficiency when it comes to optimizing exhaust flow. Compared to streamlined exhaust manifolds for GTO or other models, these Pontiac-manufactured components exhibit unparalleled engineering finesse that directly impacts engine health and performance.

The design efficiency of Pontiac 400 exhaust manifolds plays a pivotal role in maintaining optimal engine conditions by ensuring smooth airflow throughout the system. This seamless flow not only enhances overall performance but also contributes to prolonged engine longevity and reliability. Enthusiasts can rest assured knowing that their vehicles are equipped with exhaust manifolds that prioritize both power and durability.

Comparison with Other Manifolds

Stock vs. Aftermarket

Cost Analysis

- When comparing stock exhaust manifolds to aftermarket options, cost plays a crucial role in decision-making.

- Stock manifolds are typically more budget-friendly initially, making them an attractive choice for enthusiasts looking to upgrade without breaking the bank.

- In contrast, aftermarket exhaust manifolds may come with a higher price tag due to their advanced engineering and performance enhancements.

- Despite the initial investment, aftermarket manifolds offer long-term value through improved engine efficiency and power output.

- Enthusiasts seeking optimal performance upgrades often find that the benefits of aftermarket manifolds outweigh the higher upfront costs.

Performance Differences

- The performance disparities between stock and aftermarket exhaust manifolds are significant, influencing overall engine capabilities.

- Stock manifolds, while reliable, may lack the design features and material quality found in their aftermarket counterparts.

- Aftermarket manifolds are engineered for maximum performance, utilizing innovative designs to enhance exhaust flow and minimize restrictions.

- The superior construction of aftermarket options results in improved horsepower and torque gains, transforming driving experiences into exhilarating adventures on the road.

- Enthusiasts looking to unleash the full potential of their vehicles often turn to aftermarket exhaust manifolds for unparalleled performance enhancements.

Headers vs. Manifolds

Installation Ease

- When considering headers versus traditional exhaust manifolds, installation ease is a key factor for enthusiasts seeking upgrades.

- Headers typically require more intricate installation procedures compared to direct-fit manifolds due to their design complexity.

- While headers offer superior performance benefits, the installation process may be more time-consuming and labor-intensive.

- On the other hand, exhaust manifolds provide a straightforward replacement option that requires minimal modifications for installation.

- Enthusiasts looking for a balance between ease of installation and enhanced performance often opt for high-quality exhaust manifolds as a practical solution.

Maintenance Considerations

- Maintenance considerations differ between headers and exhaust manifolds, impacting long-term upkeep and reliability.

- Headers may require more frequent inspections and adjustments due to their intricate design and individual tube configuration.

- Regular maintenance tasks such as checking for leaks or ensuring proper alignment are essential for preserving header integrity and performance.

- In comparison, exhaust manifolds offer simplified maintenance requirements with fewer components that need monitoring over time.

- Enthusiasts prioritizing ease of maintenance without compromising on performance often choose exhaust manifolds as a hassle-free solution for their vehicles.

Long-branch vs Ram Air

Performance Metrics

1.Pontiac 400 D-Port Turbo Headers have been recognized for their compact design allowing use in small engine bays while maintaining heavy wall construction for cooler engine bay temperatures.*

2.Long tube headers increase mid-range and top-end performance compared to stock exhaust manifolds.

3.Pontiac Ram Air Engines experienced improvements in intake efficiency leading to boosted power.

User Preferences

1.Enthusiasts appreciate the versatility of long-branch manifold designs that offer enhanced power delivery without sacrificing durability.

2.The user-friendly nature of Ram Air intake systems appeals to enthusiasts seeking increased horsepower gains coupled with easy installation.

3.Pontiac 400 owners often gravitate towards long tube headers for their proven track record in optimizing engine output across various driving conditions.

Practical Tips for Enthusiasts

Installation Tips

Tools Needed

- Harmonic Balancer Puller: Essential for removing the harmonic balancer without causing damage to the engine components.

- Torque Wrench: Ensures precise tightening of bolts to manufacturer specifications, preventing over-tightening or under-tightening.

- Socket Set: Provides a range of socket sizes for various nuts and bolts, facilitating smooth installation and assembly.

- Gasket Sealant: Helps create a tight seal between components, preventing leaks and ensuring optimal performance.

- Safety Gear: Includes gloves and safety glasses to protect against potential hazards during the installation process.

Step-by-step Guide

- Begin by disconnecting the negative battery cable to prevent electrical mishaps during installation.

- Remove any components obstructing access to the exhaust manifolds, such as heat shields or brackets.

- Unbolt the old exhaust manifolds carefully, ensuring all connections are detached before removal.

- Clean the mounting surface thoroughly to remove any debris or residue that could affect the new manifold’s fit.

- Apply gasket sealant to both sides of the new exhaust manifold gaskets before placing them in position.

- Install the new Pontiac 400 exhaust manifolds by aligning them with the cylinder head ports and securing them with bolts.

- Tighten the bolts gradually and evenly using a torque wrench to avoid uneven pressure distribution.

- Reattach any removed components and reconnect the negative battery cable once installation is complete.

Maintenance Advice

Regular Checks

- Inspect the exhaust manifolds periodically for signs of corrosion, cracks, or leaks that could impact performance.

- Check for loose bolts or gaskets that may cause exhaust leaks, affecting engine efficiency and sound quality.

- Monitor exhaust temperatures during operation to detect any irregularities that could indicate manifold issues.

Common Issues and Fixes

- Issue: Exhaust Leaks

- Fix: Tighten loose bolts or replace damaged gaskets to restore a proper seal and prevent leaks.

- Issue: Corrosion

- Fix: Remove rust buildup using a wire brush and apply heat-resistant paint to protect against further corrosion.

- Issue: Cracks

- Fix: Depending on severity, weld minor cracks or replace severely damaged sections for optimal performance.

Upgrading Options

Best Brands

- Werkwell: Renowned for offering high-quality aftermarket Pontiac 400 exhaust manifolds designed for superior performance and durability.

- Flowtech: Known for its innovative designs that optimize exhaust flow efficiency, enhancing overall engine power output.

Cost-effective Upgrades

- Consider upgrading to Ram Air manifolds from Werkwell for improved performance without breaking your budget.

- Opt for cast iron manifolds from reputable brands like Flowtech as a cost-effective solution with reliable performance benefits.

By following these practical tips on installation, maintenance advice, and upgrading options provided above enthusiasts can ensure their Pontiac 400 exhaust manifolds operate at peak efficiency while maximizing their vehicle’s overall performance potential in an economical manner.

Recap of the importance of Pontiac 400 exhaust manifolds:

- Enhancing engine efficiency and power output.

- Historical significance in the muscle car era.

- Precision-crafted design for optimal performance.

Summary of performance benefits:

- Significant horsepower and torque gains.

- Improved acceleration and responsiveness.

- Enhanced engine health and longevity.

Final thoughts on why enthusiasts should consider upgrading:

- Unleash the full potential of your vehicle.

- Transform driving experiences into thrilling adventures.

- Experience unparalleled performance enhancements.

Call to action for readers to explore options and make informed decisions:

Upgrade to Pontiac 400 exhaust manifolds today for a driving experience that surpasses expectations. Explore Werkwell’s Harmonic Balancer for additional engine optimization, ensuring smooth operation and maximum performance. Make the choice that elevates your vehicle to new heights!

Post time: Jun-12-2024