Kunzwisisa Exhaust Manifolds

Mhando dzeExhaust Manifolds

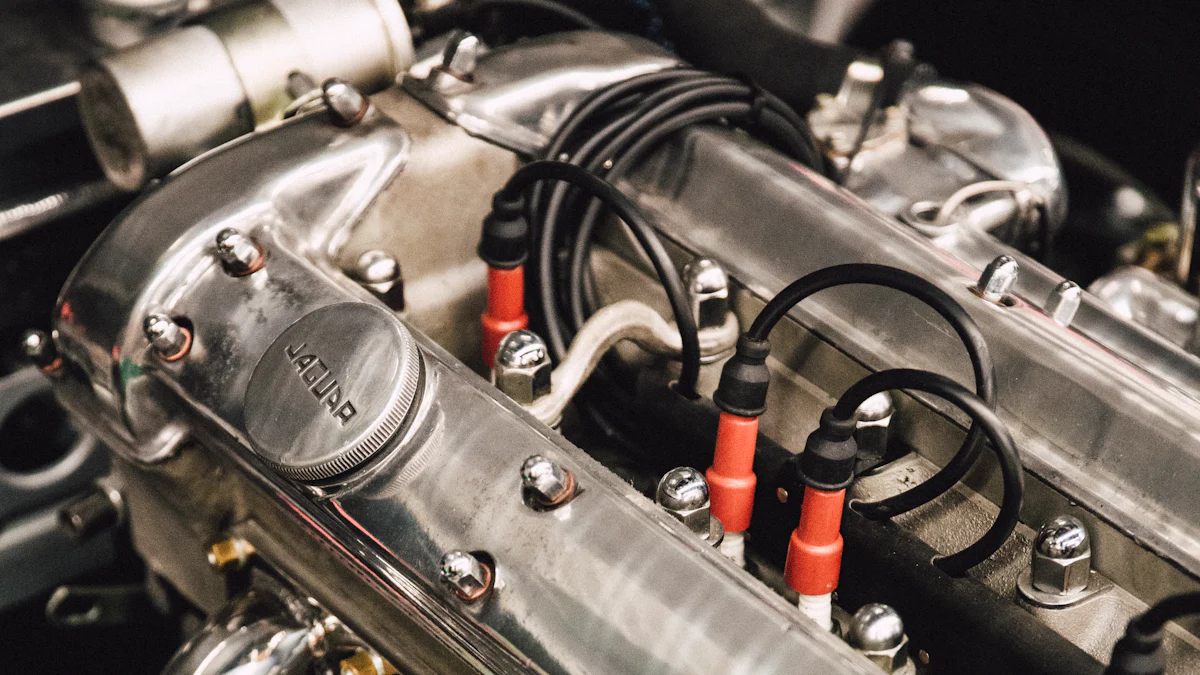

Kanda Iron Manifolds

Cast iron manifolds inopa kusimba uye kudhura-kushanda. Aya manifolds anoshingirira tembiricha yakakwira uye anoramba kutsemuka. Nekudaro, huremu hwavo hunorema hunogona kukanganisa kuita kwemotokari. Masimbi ekukandira anowanzo kuoneka mumhando dzemotokari dzekare kana bhajeti.

Stainless Simbi Manifolds

Stainless simbi manifolds inopa chiyero pakati pesimba nehuremu. Aya manifolds anodzivirira corrosion uye anochengetedza chimiro chekuvimbika pasi pemamiriro akanyanya. Huremu huremu hwesimbi isina tsvina hunovandudza huwandu hwemotokari. Mota zhinji dzemazuvano dzinoshandisa simbi isina simbi manifolds kuti iwedzere kuita.

Tubular Manifolds

Tubular manifolds, anozivikanwawo semisoro, anosanganisira mapaipi ega ega silinda. Mapombi aya anobatana kuita muunganidzi mumwe. Tubular manifolds inogonesakupera kwegasi kuyererauye kuderedza backpressure. Performance vanofarira vanowanzofarira tubular manifolds nekuda kwekugona kwavo kuwedzera simba kubuda.

Basa uye Dhizaini

Basa muInjini Kubudirira

Iyo exhaust manifold inoita basa rakakosha mukubudirira kweinjini. Dhizaini yakakodzera inogonesa kupera kwegasi kuyerera kubva kumasilinda ejini kuenda kune exhaust system. Kuyerera kwegasi kunoshanda kunoderedza kudzoka shure, izvo zvinowedzera kushanda kweinjini uye hupfumi hwemafuta. Iyo manifold exhaust inobatsirawo kubata tembiricha yeinjini nekutungamira magasi anopisa kure nejini block.

Kufunga Kwekugadzira

Kugadzira exhaust manifold kunosanganisira akati wandei mafungiro. Mainjiniya anofanirwa kuverengera chimiro uye kureba kwemapombi akawanda. Kureba kwepombi uye dhayamita kwakaringana kunogonesa kuyerera kwegasi uye kuderedza mhirizhonga. Iyo manifold inofanirawo kukwana mukati mejini bay pasina kukanganisa zvimwe zvikamu. Pamusoro pezvo, dhizaini inofanirwa kufambisa nyore kuisa uye kugadzirisa.

Kusarudzwa kwezvinhu

Kusarudzwa kwezvinhu kunokanganisa zvakanyanya kushanda kweanopotera akawanda. Zvigadzirwa zvemhando yepamusoro zvinoshingirira kupisa uye mechanical stress. Cast iron, Stainless simbi, uye tubular dhizaini imwe neimwe inopa yakasarudzika mabhenefiti. Cast iron inopa kusimba, nepo simbi isina tsvina ichipa chiyero chesimba uye uremu. Tubular manifolds inosimudzira mashandiro kuburikidza neyakagadziriswa gasi kuyerera. Mainjiniya anofanirwa kusarudza zvinhu zvakakodzera zvichienderana nezvinodiwa zvemotokari.

Emissions Analysis

Mhando dzeEmissions

Carbon Monoxide (CO)

Carbon monoxide inoumba panguva yekupisa kusina kukwana kwemafuta. Iri gasi rinounza njodzi huru dzehutano, kusanganisira kutemwa nemusoro uye dzungu. Iyo manifold epositi inofanirwa kunyatso fambisa gasi rekupedza simba kuti rideredze kuburitswa kweCO. Dhizaini chaiyo uye kusarudzwa kwezvinhu zvinoita basa rakakosha mukudzikisa CO mazinga.

Hydrocarbons (HC)

MaHydrocarbons anokonzerwa nemafuta asina kupiswa ari kubuda mukamuri rinopisa. Mishonga iyi inobatsira kune smog uye nyaya dzekufema. Iyo exhaust manifold dhizaini inokanganisa kugona kweinjini kupisa mafuta zvachose. Madhizaini akakwenenzverwa anobatsira kudzikisira kuburitswa kweHC nekuona kuti gasi rinobuda zvakanaka.

Nitrogen Oxides (NOx)

Nitrogen oxides inoumba pakupisa kwakanyanya. Aya magasi anokonzera matambudziko ezvakatipoteredza uye ehutano, kusanganisira mvura ine acid uye zvirwere zvekufema. Iyo exhaust manifold inokanganisa NOx emissions kuburikidza netembiricha manejimendi. Madhizaini anoshanda anobatsira kuchengetedza yakaderera kupisa tembiricha, nekudaro kuderedza NOx kuumbwa.

Mhedzisiro yeExhaust Manifold pane Emissions

Kufurira Kwekugadzira

Dhizaini ye exhaust manifold inokanganisa zvakananga kubuda. Iyo yakanyatsogadzirwa manifold inogonesa kupera kwegasi kuyerera, kuderedza backpressure uye kunatsiridza kupisa kwekuita. Zvidzidzo zvinoratidza izvozvotapered magadzirirwo anowedzera mashandiro by kuderedza backpressure. Kufambiswa kwegasi kwakavandudzwa kunotungamira kuburitsa kwakaderera kweCO, HC, uye NOx.

Pesvedzero Yezvinhu

Kusarudzwa kwezvinhu kunokanganisa zvakanyanya kushanda kwe exhaust manifold.Kanda simbi nesimbi isina tsvinazvinhu zvakajairika zvinoshandiswa mukuvaka akawanda. Cast iron inopa kusimba asi inogona kuwedzera uremu. Simbi isina tsvina inopa chiyero pakati pesimba uye uremu, ichiwedzera kugona kwese. Zvese zviri zviviri zvinhu zvinofanirwa kumirisana nekupisa uye kwemakanika kushushikana kuchengetedza kuita kwakanyanya uye kuderedza kuburitsa.

Temperature Management

Kutonga kwematembiricha kunoita basa rakakosha mukudzora kuburitswa. Iyo manifold epositi inofanira kunyatso bvisa kupisa kudzivirira zvakanyanya kupisa tembiricha. Kupisa kwakanyanya kunotungamira mukuwedzera NOx kuumbwa. Kushanda tembiricha manejimendi inobatsira kuchengetedza yakaderera kupisa tembiricha, nekudaro kuderedza NOx emissions. Zvishandiso zvepamberi uye mabhanhire anogona kuwedzera hunyanzvi hwekugona kutonga kupisa.

Power Output Analysis

Zvinhu Zvinokanganisa Kubuda Kwesimba

Exhaust Flow Dynamics

Exhaust flow dynamics inoita basa rakakosha mukuita kweinjini. Dhizaini yekuburitsa manifold inopesvedzera zvakananga mabudiro anoita gasi rekuburitsa mujini. Yakanyatsogadzirwa manifold inovimbisa yakatsetseka uye nekukurumidza gasi kuyerera, kuderedza mhirizhonga. Izvi zvinoguma nekuvandudzwa kweinjini kufema uye kuwedzera simba kubuda. Mainjiniya anowanzo kukwidziridza chimiro uye kureba kwemapombi akawanda kuti awane yakanakira kuyerera maitiro.

Backpressure

Kudzokera shure (backpressure) zvinoreva kushorwa kunosangana nemagasi anopedza simba paanobuda muinjini. High backpressure inogona kutadzisa injini kuita nekudzora kuyerera kwemhepo. Performance exhaust misoro inovavarirakuderedza kuyerera kwekudzivirira, zvichiita kuti injini iwedzere kushanda zvakanaka. Lower backpressure inobvumira injini kudzinga gasi rinopedza simba zvakanyanya, zvichiita kuti iwane simba rekubuda. Theichangobva kugadzirwa exhaust akawandamadhizaini anowanzo tarisa pakudzikisira backpressure kuti uwedzere kuita kweinjini.

Kuchengetedza Kupisa

Kuchengetedza kupisa mukati meiyo manifold yekuburitsa kunokanganisa kushanda kweinjini uye kubuda kwesimba. Kupisa kwakanyanya kunogona kukonzera kupisa kwakanyanya, izvo zvinogona kuderedza kushanda kweinjini. Kushanda kwekushisa kunobatsira kuchengetedza zvakakwana tembiricha yekushanda. Zvishandiso zvepamberi uye machira mukuvakwa kwakawanda zvinogona kuwedzera kupisa kupisa. Kuchengetedza kwakaringana kupisa kunovimbisa kuti injini inoshanda mukati meiyo tembiricha yemhando, kuwedzera simba rekubuda.

Performance Testing

Dyno Testing

Kuongorora kweDyno kunopa nharaunda inodzorwa kuyera kuita kweanopotera manifold. Mainjiniya anoshandisa dynamometer kutevedzera mamiriro ekutyaira chaiwo. Iyi nzira yekuyedza inoongorora maitiro ezvakawanda pakubuda kwemagetsi, torque, uye kushanda kwemafuta. Kuedza kweDyno kunopa data chairo, zvichiita kuti mainjiniya aite sarudzo dzine ruzivo nezve manifold dhizaini uye kusarudzwa kwezvinhu.

Real-world Testing

Yechokwadi-yepasirese kuyedzwa kunozadzisa dyno kuyedzwa nekuongorora manifold ekunze pasi pemamiriro chaiwo ekutyaira. Mainjiniya anoongorora kuti manifold anoita sei munzvimbo dzakasiyana siyana, sekutyaira muguta, kufambisa migwagwa mikuru, uye kukurumidza kukurumidza. Kuyedzwa kwepasirese kunobatsira kuona chero zvingangoitika zvingave zvisingaoneke munzvimbo inodzorwa. Iyi nzira yakazara inovimbisa kuti exhaust manifold inopa kushanda kwakafanana mumamiriro akasiyana ekutyaira.

Kuenzanisa Kuongorora

Kuenzanisa ongororo kunosanganisira kuongorora akasiyana exhaust akawanda madhizaini kuti aone maitiro azvo pakubuda kwemagetsi. Mainjiniya anofananidza zvinhu zvakaita senge exhaust flow dynamics, backpressure, uye kuchengetedza kupisa. Ongororo iyi inobatsira kuona madhizaini akanyanya kushanda ekusimudzira kuita kweinjini. Nekuenzanisa akasiyana manifolds, mainjiniya anogona kuona kusimba uye kusasimba kwega yega dhizaini. Iyi nzira inotungamira mukuenderera mberi nekuvandudza uye hunyanzvi mukupedza manifold tekinoroji.

Zvitsva uye Mafambiro Emangwana

Advanced Materials

Ceramic Coatings

Ceramic coatings yakabuda sekufambira mberi kwakakosha mukupedza manifold tekinoroji. Aya mabhanhire anopa zvakanakisa kupisa kwemafuta, kuderedza kupisa kuchinjika kune zvakatenderedza injini zvikamu. Iyi insulation inobatsira kuchengetedza yakaringana tembiricha yeinjini, inosimudzira kuita uye hupenyu hurefu. Ceramic coatings inopawo kukwirira kwekupokana nekuora uye kupfeka, kuve nechokwadi kusimba kweiyo manifold echaust. Mainjiniya emotokari anowedzera kutora machira eceramic kuvandudza kushanda uye kuvimbika kweanopotera masisitimu.

Composite Materials

Composite zvinhu zvinomiririra imwe nzira yekuvandudza mukupedza manifold dhizaini. Zvishandiso izvi zvinosanganisa zvinhu zvakasiyana kuti zviwane kuenzana kwesimba, huremu, uye kupisa kwekupisa. Semuyenzaniso, kabhoni faibha macomposites anopa yakakwira simba-kune-uremu reshiyo, zvichiita kuti ive yakanakira maapplication ekuita. Iko kushandiswa kwezvinhu zvinosanganiswa kunogona kuderedza zvakanyanya huremu hwemanifold ekunze, zvichitungamira mukuvandudza kugona kwemotokari uye kubata. TheFluidForming Yakareruka Stainless SimbiExhaust Manifold Case Studyyakaratidza kutsiva kwakabudirira kweanorema cast iron manifolds neakareruka Stainless simbi, ichiratidza mabhenefiti ezvigadzirwa zvepamberi muinjiniya yemotokari.

Design Innovations

Variable Geometry Manifolds

Variable geometry manifolds (VGM) inomiririra yekucheka-kumucheto hunyanzvi mukupedza manifold dhizaini. VGMs inogadzirisa chimiro uye kureba kwepombi dzakawanda zvichienderana nemamiriro ekushanda kweinjini. Uku kuchinjika kunokwirisa kupera kwegasi kuyerera, kudzikisa backpressure uye kuwedzera injini kuita. VGMs inogona kuvandudza kushanda kwemafuta uye kuderedza kuburitswa nekuchengetedza yakakwana exhaust dynamics munzvimbo dzakasiyana siyana dzekutyaira. Vagadziri vemotokari vanowedzera kuongorora maVGM kuti asangane nemirairo yakaomesesa yekuburitsa uye kuita zvinodiwa.

Yakabatanidzwa Catalytic Converters

Kubatanidza catalytic converters zvakananga mune exhaust manifold inopa akati wandei mabhenefiti. Iyi dhizaini inoderedza chinhambwe chinofambiswa nemagasi asati asvika kune catalytic converter, achivandudza kugona kwe emission control. Akabatanidzwa catalytic converters anobatsira kuwana nekukurumidza-kudzima nguva, kuderedza kutonhora kwekutanga kuburitsa. Uku kusanganisa zvakare kunorerutsa iyo exhaust system marongero, kuderedza huremu uye kuoma. Mota zhinji dzemazuvano zvino dzine macontectors akabatanidzwa anoshandura kuti asangane nemamiriro ekunze uku uchichengetedza kuita kwepamusoro.

Ongororo iyi inoratidzira basa rakakosha rekupedza manifold dhizaini uye kusarudzwa kwezvinhu mukugadzirisa mashandiro einjini uye kuderedza kuburitsa. Zvakawanikwa zvakakosha zvinoratidza kuti zvinhu zvemberi zvakaita sesimbi isina tsvina uye machira eceramic anowedzera kusimba uye kushanda nesimba. Dhizaini magadzirirwo akadai akasiyana geometry manifolds uye akabatanidzwa catalytic converters anovandudza kushanda kwemafuta uye emission control.

Tekinoroji kufambira mberi uyekuchinja zvinodiwa nevatengifambisa zvakakosha kuindasitiri yemotokari.Magadzirirwo emagetsi anoshandauye maitiro ekutyaira anogona kuderedza kuburitswa kwemotokari, zvichibatsira mukuchengetedzeka kwezvakatipoteredza. Tsvagiridzo yeramangwana inofanirwa kutarisisa kugadzira zvinhu zvireruke uye dhizaini dhizaini kuti isangane nekubuda kwemitemo uye kuita zvinodiwa.

Nguva yekutumira: Jul-31-2024