Thematšoao a nakohoharmonic balancerke karolo ea bohlokoa e bapalang karolo ea bohlokoa ho boloka tšebetso ea enjine. Kaho kokobetsa ho sotha ha torsionalhocrankshaft, e thibela ho senyeha ho ka 'nang ha e-ba teng' me e tiisa hore ho sebetsa hantle. Kopano ena e nepahetseng, e nang le likarolo tse ngata tse kang lesale la ka ntle lemotho ea arolang rabara, e sebetsa joalo ka e leka-lekaneng ledamper ea ho sisinyeha. Thematšoao a nako ho sekala sa harmonicke matšoao a bohlokoa a thusang ho behanako ea ho hotetsaka nepo. Tataiso ena e ikemiselitse ho nolofatsa mehopolo ena bakeng sa ba qalang, ho fana ka lintlha tsa bohlokoa mabapi le ts'ebetso ea enjine.

Ho utloisisa Harmonic Balancers

Harmonic Balancer ke eng?

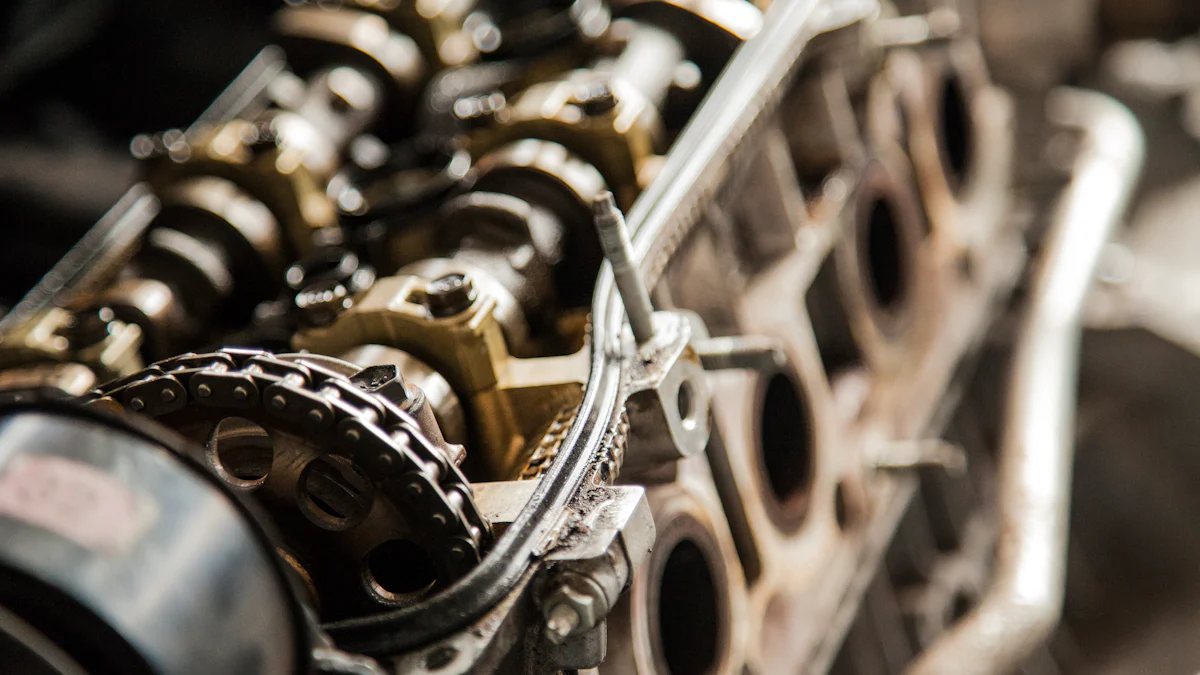

A Harmonic Balancerke karolo ea bohlokoa ea enjene, eo hangata e hlokomolohuoang empa e le ea bohlokoa bakeng sa ho sebetsa ha eona hantle. E thusa ho monya ho thothomela ha mokokotlo ka har'a crankshaft, ho thibela ho robeha ho ka bang teng le ho netefatsa botsitso ba enjene ho li-RPM tse bohlokoa. Karolo ena e nepahetseng e bapala karolo e 'meli e le se leka-lekaneng le se thothomelang, se bohlokoa bakeng sa ho boloka tšebetso ea enjene ka kakaretso.

Tlhaloso le mosebetsi

TheHarmonic Balancere sebetsa joalo ka tšireletso khahlanong lekhopamiso ea ho sothaka crankshaft, e ka lebisang mathateng a tebileng haeba a sa rarolloe. Ka ho fokotsa litlamorao tsa ho sotha le ho khutlela morao nakong ea ts'ebetso ea enjene, e ntlafatsa bophelo bo bolelele le katleho ea enjene. Ho hloleha ho sebetsana le mathata le harmonic balancer ho ka fella ka mathata a sa tšoaneng, ho tloha ho lerata le hlabang le khopisang ho ea.ho hloleha ha enjene ya tlokotsi.

Bohlokoa ts'ebetsong ea enjene

Ka lienjineri, haholo-holo tse nang le litlhophiso tse ntseng li eketseha tsa marang-rang, theHarmonic Balancere bapala karolo ea bohlokoa ho boloka botsitso le botsitso. Moralo oa eona, hangata o entsoe kalikotoana tse peli tsa laminatede kopantsoeng le rabara, ka katleho e hlakola li-harmonics tse kotsi tse hlahisoang ke metsamao ea crankshaft. Ketso ena e hlokolosi ea ho leka-lekanya e netefatsa hore enjene e sebetsa hantle ntle le ho beha kotsi ea ho senyeha ha sebopeho.

Likarolo tsa Harmonic Balancer

Ho utloisisa likarolo tse etsang aHarmonic Balancere fana ka temohisiso mabapi le ts'ebetso le bohlokoa ba eona ka har'a sistimi ea enjene.

selikalikoe sa kantle

Lesale le kantle la aHarmonic Balancere sebetsa e le sebopeho sa mantlha se bolokang likarolo tsa bohlokoa tse ikarabellang bakeng sa ho leka-lekanya ho thothomela. Kaho ea eona e matla e tiisa ho tšoarella tlas'a maemo a khatello e phahameng ha ho ntse ho ajoa matla ho pholletsa le kopano.

Rabara e itšehla thajana

Bohareng ba ntho e 'ngoe le e 'ngoeHarmonic Balancerho na le rabara e itšehlang thajana e sebetsang joalo ka tšireletso khahlanong le ho thothomela ho feteletseng. Karolo ena e monya litšisinyeho 'me e fokotsa ho sisinyeha ka har'a crankshaft, e khothalletsa ts'ebetso ea enjene e bonolo le ho fokotsa ho senyeha ha likarolo tse ka hare.

Hub

Setsi sa aHarmonic Balancere hokahana ka kotloloho le crankshaft, e fetisa matla a ho potoloha ha e ntse e boloka tlhophiso e nepahetseng. Sephutheloana sa eona se sireletsehileng se tiisa hore balancer e sebetsa ka mokhoa o tsitsitseng le likarolo tse ling tsa enjene, e leng se tlatsetsang ntlafatsong ea tshebetso ka kakaretso.

Sheba Profile ea Sechaba Fumana

Ho hlahlobaWerkwell's Harmonic Balancere senola likarolo tse tsoetseng pele tse etselitsoeng ho ntlafatsa ts'ebetso ea enjine le ho ts'epahala.

Harmonic Balancer ea Werkwell

Harmonic Balancers ea Werkwell, e entsoeng kaboenjiniere bo nepahetsengmekhoa, e fana ka boleng bo ke keng ba lekanngoa le ho tšoarella ho mefuta e fapaneng ea likoloi. E etselitsoe ho mamella maemo a thata, li-balancers tsena li netefatsa ts'ebetso e nepahetseng ka ho fokotsa ho thothomela le li-harmonics ka har'a crankshaft.

Likarolo tsa bohlokoa le melemo

- Precision Engineering: E mong le e mongWerkwell Harmonic Balancere sebetsa ka mokhoa o hlokolosi oa tlhahiso ho netefatsa boleng bo holimo.

- Ntlafatso ea ho tšoarella: Tšebeliso ea lisebelisoa tsa boemo bo phahameng e tiisa ts'ebetso ea nako e telele tlas'a maemo a thata a ho sebetsa.

- Ntlafatso ea Engine Stability: Ka ho fokotsa ho sisinyeha le li-harmonics, li-balancers tsena li kenya letsoho ho sebetsa ha enjene ka mokhoa o bonolo le ho eketsa nako e telele ea bophelo.

- Ho lumellana: E etselitsoe mefuta e mengata ea likoloi tse kenyelletsang GM, Ford, Toyota, Honda, Chrysler, Hyundai, Nissan, Mitsubishi har'a tse ling.

- Dikgetho tsa ho itlhophisa: Werkwell e fana ka litharollo tse hlophisitsoeng ho fihlela litlhoko tse khethehileng tsa bareki bakeng sa liphetho tse ntlafalitsoeng tsa ts'ebetso.

Matshwao a Nako a Hlalositswe

Li-Timing Marks ke life?

Tlhaloso le morero

Matšoao a nakoka har'a harmonic balancer ke matšoao a bohlokoa a thusang mak'henike ho setanako ea ho hotetsaka nepo. Matšoao ana, a atisang ho beoa kapa a pentiloe holim'a sekala, a ikamahanya le pointer ho bontšaTop Dead Center (TDC)boemo ba mokokotlo. Ho netefatsa hore matshwao ana a tsamaiswa ka nepo ho bohlokwa bakeng sa tshebetso e nepahetseng ya enjene.

Sebaka ho balancer ea harmonic

Thematšoao a nakoe ka fumanoa maemong a sa tšoaneng ho balancer ea harmonic, ho itšetlehile ka mohlala oa enjene. Li-balancers tse ling li na le lihlopha tse ngata tsa matšoao ho lumellana le litlhoko tse fapaneng tsa tokiso. Bo-machane ba tlameha ho fumana matšoao ana ho fumana hore na piston e lutse hokae potolohong ea eona ea stroke ka nepo.

Mokhoa oa ho Bala Lits'oants'o Tsa Nako

Lisebelisoa tse hlokahalang

Ho balamatšoao a nakoka nepo, mechini e hloka lisebelisoa tse ikhethileng joalo ka lebone la nako le lebili la degree. Leseli la nako le thusa ho khantša matšoao nakong ea ts'ebetso, ha lebili la degree le thusa ho metha li-angles tse nepahetseng bakeng sa liphetoho tsa ho tima.

Tataiso ea mohato ka mohato

- Qala ka ho fumana sebaka samatšoao a nakoho balancer ea hau ea harmonic.

- Hokela lebone la nako ho enjene ea hau ho latela litaelo tsa moetsi.

- Ha enjene e sebetsa, supa lebone la nako homatšoaoho hlokomela tlhophiso ea tsona.

- Fetola nako ea ho khantša ha ho hlokahala ka ho fetola distributor ho fihlelamatšoaoikamahanya hantle.

- Sebelisa lebili la degree ho netefatsa hore nako ea ho tima e behiloe ka nepo.

Bohlokoa

Bohlokoa ba nako e nepahetseng

Ho netefatsa seomatšoao a nakoli behiloe ka nepo ke tsa bohlokoa bakeng sa katleho ea enjene le bophelo bo bolelele. Nako e nepahetseng ea ho tima e lumella ho chesa mafura hore ho etsahale ka nepo ha ho hlokahala, ho ntlafatsa matla a tsoang le ho sebetsa hantle ha mafura.

Tšusumetso mosebetsing oa enjene

E hlophisitsoe ka phosomatšoao a nakoe ka lebisa ts'ebetsong e mpe ea enjene, ho kenyelletsa matla a fokotsehileng, tšebeliso e eketsehileng ea mafura, le tšenyo e ka bang teng ho likarolo tsa kahare. Kamehla hlahloba le ho lokisa tsenamatšoaoe ka thibela litokiso tse bitsang chelete e ngata.

Maikutlo a Tloaelehileng a Fosahetseng

Litaba tsa ho se tsamaisane hantle

Ha thematšoao a nakoka har'a harmonic balancer ha li tsamaisane hantle, ho ka lebisa ho cascade ea mathata a enjene. Khopolo e 'ngoe e fosahetseng ke hore ho se nepahale hanyenyane ho ke ke ha ama ts'ebetso haholo. Ha e le hantle, esita le ho kheloha ho honyenyane ho ka baka ho se lumellane ha nako, ho ama ts'ebetso ea mollo le ts'ebetso ea enjene ka kakaretso. Mechanics e lokela ho ela hloko haholo ho netefatsa ho lokisoa ho nepahetseng bakeng sa ts'ebetso e nepahetseng.

Litšōmo mabapi le matšoao a nako

Ho na le litšōmo tse 'maloa tse potolohilengmatšoao a nakoseo se ka kgelosang batjhesehi ba se nang boiphihlelo. Tšōmo e 'ngoe e atileng e fana ka maikutlo a hore matšoao ohle a nako a teng hohle ho lienjineri tse fapaneng, e leng se lebisang liphetohong tse fosahetseng. Ho bohlokoa ho utloisisa hore mofuta o mong le o mong oa enjine o na le tlhophiso ea matšoao a nako e tsamaellanang le litlhoko tsa ona. Tšōmo e 'ngoe e fana ka maikutlo a hore ho hakanya ka mahlo ho lokisoa ha matšoao a nako ho lekane bakeng sa tokiso e nepahetseng. Leha ho le joalo, ho itšetleha feela ka litšoantšo tse bonahalang ntle le lisebelisoa tse nepahetseng ho ka fella ka ho se nepahale le tšenyo e ka bang teng likarolong tsa enjene.

Ka ho hlakisa menahano ena e fosahetseng le litšōmo, ba qalang ba ka utloisisa bohlokoa ba ho nepahalaletshwao la nakoalignment bakeng sa ho boloka katleho ea enjene le bophelo bo bolelele. Tlhahlobo ea khafetsa le litokiso tse ipapisitseng le litataiso tsa moetsi ke mehato ea bohlokoa ho netefatsa ts'ebetso e nepahetseng le ho thibela litokiso tse bitsang chelete e ngata nakong e tlang.

Mathata a Tloaelehileng le Litharollo

Bothata ba ho Bona Matšoao a Nako

Lisosa

- Litšila tse Bokeletseng: Ha nako e ntse e ea, litšila tsa litsela le litšila li ka patamatšoao a nakoka har'a harmonic balancer, ho etsa hore ho be thata ho khetholla ka nepo.

- Matšoao a Khathetseng: Tšebeliso e tsoelang pele le ho pepesehela mocheso oa enjine ho ka etsa hore matšoao a nako a nyamele kapa a fokole, 'me a thatafalletsa ponahalo ea ona nakong ea tlhahlobo.

Litharollo

- Mokhoa oa ho Hloekisa: Hloekisa sebaka sa ho leka-lekanya ha harmonic khafetsa ho tlosa litšila leha e le life tse bokeletsoeng tse ka 'nang tsa sitisa matšoao a nako.

- Tšoaea Tsosoloso: Haeba matshwao a fifetse, nahana ka ho sebedisa pente e mebala e kganyang kapa lesupa ho hlakisa matshwao a nako hore a bonahale hantle.

Tobakanyo ya Nako e Fosahetseng

Matšoao

- Ho Kota Enjene: Matšoao a nako a sa lumellaneng a ka lebisa ho lerata la ho kokota enjene, e leng se bontšang nako e sa lokelang ea ho tuka ka har'a li-cylinders.

- Motlakase o Fokotsoeng: Ha nako ea ho tima e tingoe, enjene e ka ba le tlhahiso e fokotsehileng ea matla le mathata a ts'ebetso ka kakaretso.

Litokiso

- Tlhahlobo ea Phetoho: Sebelisa sesebelisoa sa lebone la nako ho netefatsa hore na matšoao a nako a tsamaisana hantle le sesupa. Haeba e sa tsamaellane hantle, fetola seboholi ho latela nako e nepahetseng ea ho tima.

- Tekanyetso ea Setsebi: Bakeng sa litlhoko tse rarahaneng tsa tokiso kapa litaba tse ntseng li tsoela pele, batla thuso ea litsebi ho tsoa ho bo-machane ba nang le boiphihlelo ho netefatsa tlhophiso e nepahetseng ea nako.

Harmonic Balancer Slippage

Lisosa

- Li-Fasteners tse hlephileng: Ho kenya li-fasteners tse sa nepahalang kapa li-fasteners tse tsofetseng ho ka etsa hore balancer ea harmonic e tsoe tseleng e tsamaisanang le crankshaft ha nako e ntse e ea.

- Ho sisinyeha ho Feteletseng: Maemo a phahameng a ho thothomela ha enjine ka lebaka la ho se leka-lekane ha ka hare kapa ho aparoa ha likaroloana ho ka kenya letsoho litabeng tse thellang tsa haronic balancer.

Thibelo

- Tlhahlobo ea Kamehla: Nako le nako hlahloba matšoao leha e le afe a ho thella kapa ho se tsamaisane hantle kopanong ea harmonic balancer nakong ea licheke tsa tlhokomelo ea kamehla.

- Fastener Tightening: Etsa bonnete ba hore li-fasteners tsohle tse bolokang balancer ea harmonic li tiisitsoe ho litlhaloso tsa moetsi ho thibela ho thella le ho boloka ho lumellana hantle.

Ka ho sebetsana le litaba tse tloaelehileng tse amanang leponahalo ya matshwao a nako, ho netefatsa ho lumellana ho nepahetseng, le ho thibela ho thella ha harmonic balancer, ba chesehang ba ka boloka ts'ebetso e nepahetseng ea enjene le bophelo bo bolelele ka katleho.

Ho boloka Harmonic Balancer ea Hao

Tlhahlobo ea Kamehla

Seo u ka se batlang

Ho hlahloba balancer ea hau ea harmonickamehla ho bohlokoa ho netefatsatshebetso e nepahetseng ea enjine le ho thibela ho hloleha ho ka bang teng. Mona ke lintlha tsa bohlokoa tseo u lokelang ho tsepamisa maikutlo ho tsona nakong ea tlhahlobo ea hau:

- Kantle Ring Boemo: Sheba hore na ho na le matšoao afe kapa afe a ho khathala, mapetsong, kapa karohano ka har'a reng e ka ntle. Maemo afe kapa afe a sa tloaelehang a ka bonts'a mathata a ka bang teng mabapi le botšepehi ba motho ea lekanyang.

- Rabara Isolator Bophelo bo Botle: Hlahloba rabara e itšehla thajana bakeng sa ho senyeha kapa tšenyo leha e le efe. Rabara e bapala karolo ea bohlokoa ho monyeng ho thothomela, kahoo ho sekisetsa leha e le efe boemong ba eona ho ka ama ts'ebetso ka kakaretso.

- Ho tsamaisana ha Hub: Netefatsa hore hub e khomaretsoe ka mokhoa o sireletsehileng ho crankshaft ntle le ho hlephisa kapa ho se tsamaisane hantle. Khokahano e tsitsitseng ea hub e bohlokoa bakeng sa ts'ebetso e nepahetseng ea ho leka-lekanya.

Lisebelisoa tse hlokahalang

Ho etsa tlhahlobo e phethahetseng ea balancer ea hau ea harmonic ho hloka lisebelisoa tse khethehileng ho netefatsa tlhahlobo e nepahetseng le tlhokomelo:

- Lesedi: Mabone a lekaneng a bohlokoa ho hlahloba likarolo tsa balancer ka katleho, haholo-holo libakeng tseo ho leng thata ho fihla ho tsona.

- Wrench ea Torque: Sebelisa wrench ea torque ho lekola ho tiea ha li-fasteners tse tiisang hore sekala sa harmonic se teng. Torque e nepahetseng e tiisa botsitso mme e thibela ho thella.

- Rubber Mallet: Haeba ho hlokahala liphetoho, rabara mallet e ka thusa ho lokisa likarolo ka bonolo ntle le ho baka tšenyo.

- Li-calipers: Litekanyo tse nepahetseng li ka 'na tsa hlokahala nakong ea tlhahlobo, ho etsa hore li-caliper li be molemo bakeng sa ho hlahloba likarolo tsa likarolo ka nepo.

Phapanyetsano ea Tataiso

Nako ea ho nkela sebaka

Ho tseba nako ea ho nka sebaka sa "haronic balancer" ho bohlokoa ho boloka ts'epo ea enjine le ho thibela ho hloleha ho hoholo. Nahana ka lintlha tsena ha u etsa qeto ea hore na ho hlokahala phetoho:

- Tšenyo e Bonahalang: Haeba u hlokomela ho senyeha ho hoholo, mapetsong, kapa ho arohana karolong efe kapa efe ea harmonic balancer nakong ea tlhahlobo, ho khothalletsoa ho nkela sebaka hang-hang.

- Ho sisinyeha ho Feteletseng: Ho thothomela ho sa tloaelehang ho tsoang ka pele ho enjene ho ka bontša litaba tse amanang le ts'ebetso ea "haronic balancer", e leng se bontšang hore ho hlokahala hore ho nkeloe sebaka.

- Mileage e Phahameng: E le karolo ea tlhokomelo ea kamehla, nahana ka ho fetola balancer ea harmonic ka mor'a ho fihla moeling o itseng oa lik'hilomithara ho rarolla bothata ba ho senyeha.

Mehato ea ho fetola

Ha u fetola balancer ea hau ea harmonic, latela mehato ena ho etsa bonnete ba phetoho e bonolo le e sebetsang:

- Hakolla Battery: Pele o qala mosebetsi ofe kapa ofe enjeneng ea hau, tlosa betri ho thibela mathata a motlakase nakong ea ho e nchafatsa.

- Fumana Harmonic Balancer: Ho ipapisitse le mofuta oa koloi ea hau, fihlella ho balancer ka ho tlosa likarolo tse hlokahalang tse sitisang pono ea eona le libaka tsa phihlello.

- Sebaka se sireletsehileng sa Crankshaft: Sebelisa lisebelisoa tse nepahetseng joalo ka wrench e fetolehang kapa sesebelisoa sa ho emisa piston ho boloka boemo ba crankshaft pele o tlosa sekala sa khale sa harmonic.

- Tlosa Old Balancer: Lokolla li-fasteners tse bolokang balancer ea khale ea harmonic 'me u e tlose ka hloko ho tloha crankshaft u sebelisa mekhoa e nepahetseng ea ho tlosa.

- Kenya Balancer e Ncha: Lulahanya 'me u kenye sekala se secha sa harmonic holim'a crankshaft ha u ntse u etsa bonnete ba hore e lekana hantle le ho ikamahanya le matšoao a nako ho latela litlhaloso tsa moetsi.

- Li-Fasteners tse sireletsehileng: Torque fasteners ho ea ka litataiso tsa moetsi ho sebelisa wrench ea torque ho thibela mathata a ho tiea ho feta tekano kapa ka tlase.

Thuso ea Setsebi

Nako ea ho e batla

Le ha tlhokomelo ea DIY e ka khonahala bakeng sa batho ba chesehang, maemo a mang a hloka thuso ea litsebi ka sekala sa hau sa harmonic:

- Mathata a Mathata: Haeba u kopana le mathata a rarahaneng nakong ea tlhahlobo kapa ho nkela sebaka se hlokang tsebo e khethehileng kapa lisebelisoa tse fetang tsebo ea hau, ho batla thuso ea litsebi ho bohlokoa.

- Ho se tloaelane le Mekhoa: Bakeng sa batho ba sa tloaelanang le likarolo tsa enjene kapa ba se nang boiphihlelo ba ho sebetsa lits'ebetsong tsa makoloi, ho buisana le setsebi sa mak'henike ho netefatsa ho tšoaroa ka nepo ha likarolo tse bonojoana joalo ka li-balancers tsa harmonic.

Melemo ea tlhokomelo ea litsebi

Ho kenyelletsa lits'ebeletso tsa profeshenale bakeng sa ho boloka balancer ea hau ea harmonic ho fana ka melemo e fapaneng:

- Tsebo: Mechini e nang le litsebo e na le tsebo e batsi le boiphihlelo ba ho sebetsana le likarolo tse rarahaneng tsa enjine joalo ka li-balancers tsa harmonic ka nepo.

- Phatlalatso e nepahetseng: Litsebi li ka khona ho lekanya matšoao a nako ka nepo le ho etsa bonnete ba tlhophiso e nepahetseng nakong ea ts'ebetso ea ho kenya kapa ea ho nchafatsa.

- Tšireletseho e Matlafalitsoeng: Ka ho fa litsebi mesebetsi ea ho lokisa, o fokotsa likotsi tse amanang le ho kenya lisebelisoa tse fosahetseng kapa litaba tse hlokomolohuoang tse ka behang polokeho ea enjine kotsing.

Ka ho utloisisa nako ea ho etsa litlhahlobo khafetsa, mokhoa oa ho tseba litlhoko tse ncha, le ha thuso ea litsebi e le molemo bakeng sa ho boloka li-balancers tsa hau tsa harmonic ka katleho li sireletsa ts'ebetso ea enjine le bophelo bo bolelele.

Ho totobatsa bohlokoa bamatšoao a nako'me li-balancers tsa harmonic li bohlokoa bakeng sa ho boloka ts'ebetso e nepahetseng ea enjene. Tlhahlobo ea kamehla letlhokomeloea likarolo tsena ke senotlolo sa ho thibela mathata a ka bang teng le ho netefatsa ts'ebetso e bonolo. Ka ho utloisisa karolo eamatšoao a nakoka nako ea ho khantša le ho sebetsa ha li-balancers tsa harmonic, ba chesehang ba ka ntlafatsa bophelo ba enjene ea bona. Hopola, "haronic balancer" e hlokometsoeng hantle e lebisa ho enjene e phetseng hantle ka kakaretso.

Nako ea poso: May-30-2024