Ho utloisisa mefuta e mengata ea Exhaust

Mefuta e mengata ea Exhaust Manifolds

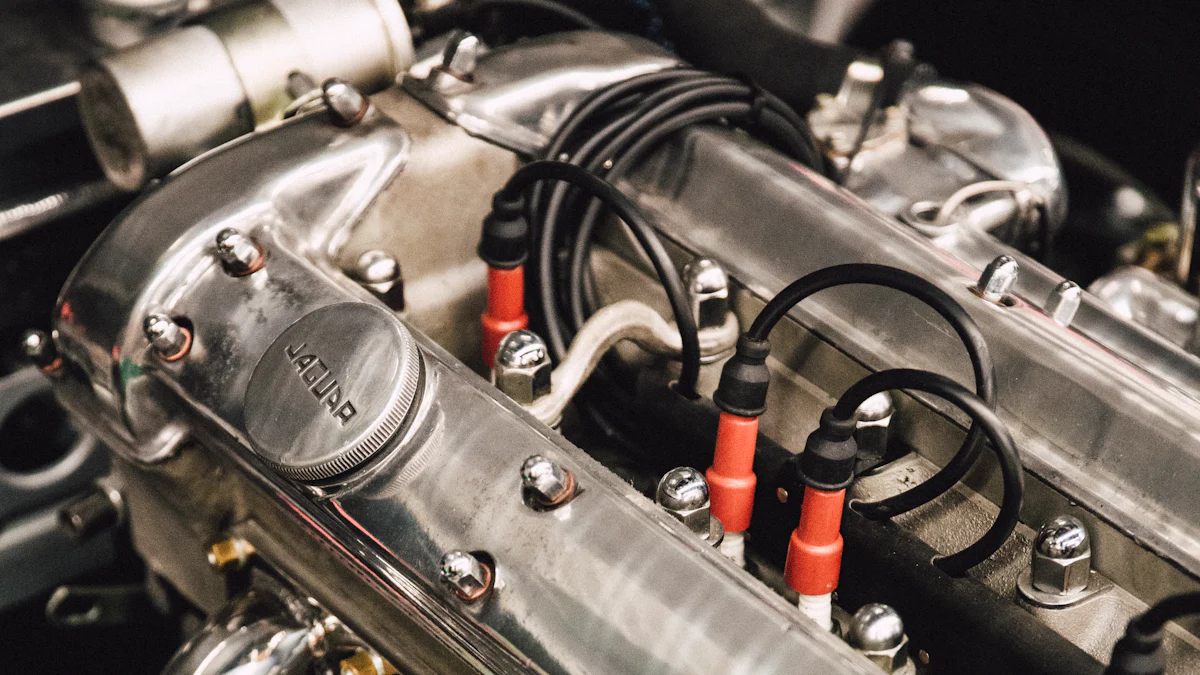

Lahlela Litšepe Tse Ngata

Mehaho e mengata ea tšepe ea cast e fana ka nako e telele le ho boloka litšenyehelo. Mefuta ena e mengata e mamella mocheso o phahameng 'me e hanela ho peperana. Leha ho le joalo, boima ba bona bo boima bo ka ama ts'ebetso ea koloi hampe. Hangata li-cast iron manifolds li hlaha mefuteng ea likoloi tsa khale kapa tse hlokomelang tekanyetso.

Mefuta e mengata ea tšepe e se nang tšepe

Mefuta e mengata ea tšepe e sa hloekang e fana ka tekanyo pakeng tsa matla le boima ba 'mele. Mefuta ena e mengata e hanana le kutu 'me e boloka botšepehi ba sebopeho tlas'a maemo a feteletseng. Boima bo bobebe ba tšepe e sa hloekang bo ntlafatsa katleho ea koloi ka kakaretso. Likoloi tse ngata tsa sejoale-joale li sebelisa mefuta e mengata ea tšepe e sa hloekang bakeng sa ts'ebetso e ntlafalitsoeng.

Li-Tubular Manifolds

Li-tubular manifolds, tse tsejoang hape e le lihlooho, li na le liphaephe tse ikemetseng bakeng sa silindara ka 'ngoe. Liphaephe tsena li kopana ho ba mokelli a le mong. Li-tubular manifolds lia ntlafalaho phalla ha khasele ho fokotsa khatello ea maikutlo. Batho ba chesehelang ts'ebetso hangata ba khetha mefuta e mengata ea li-tubular bakeng sa bokhoni ba bona ba ho matlafatsa tlhahiso ea matla.

Mosebetsi le Moralo

Seabo ho Bokhoni ba Enjene

Manifold exhaust e bapala karolo ea bohlokoa molemong oa ho sebetsa hantle ha enjine. Moralo o nepahetseng o netefatsa phallo e boreleli ea khase e tsoang ho li-cylinders tsa enjene ho ea ho sistimi ea ho tima. Phallo e sebetsang hantle ea khase e fokotsa khatello ea maikutlo, e ntlafatsang ts'ebetso ea enjene le moruo oa mafura. Exhaust manifold e boetse e thusa ho laola mocheso oa enjene ka ho tsamaisa likhase tse chesang hole le sebaka sa enjine.

Mehopolo ea Moralo

Ho theha manifold exhaust ho kenyelletsa lintlha tse 'maloa tsa bohlokoa. Baenjiniere ba tlameha ho ikarabella bakeng sa sebōpeho le bolelele ba lipeipi tse ngata. Bolelele le bophara bo nepahetseng ba liphaephe li netefatsa phallo e nepahetseng ea khase le ho fokotsa moferefere. Manifold a boetse a tlameha ho lekana ka har'a kou ea enjene ntle le ho kena-kenana le likarolo tse ling. Ho feta moo, moralo o lokela ho thusa ho kenya le ho hlokomela habonolo.

Khetho ea Lintho

Khetho ea thepa e ama haholo ts'ebetso ea mochini o tsoang ka bongata. Lisebelisoa tsa boleng bo phahameng li mamella khatello ea mocheso le mechine. Meetso ea tšepe, tšepe e sa hloekang le meralo e 'ngoe le e' ngoe e fana ka melemo e ikhethang. Cast iron e fana ka nako e telele, ha tšepe e sa hloekang e fana ka tekanyo ea matla le boima ba 'mele. Li-tubular manifolds li ntlafatsa ts'ebetso ka phallo e ntlafalitsoeng ea khase. Baenjiniere ba tlameha ho khetha thepa e nepahetseng ho latela litlhoko tse khethehileng tsa koloi.

Tlhahlobo ea Mesi

Mefuta ea Metsi

Carbon monoxide (CO)

Carbon monoxide e etsoa nakong ea mollo o sa fellang oa mafura. Khase ena e baka likotsi tse kholo tsa bophelo bo botle, ho kopanyelletsa le ho opa ha hlooho le ho tsekela. Mohaho o mongata oa ho ntša metsi o tlameha ho tsamaisa likhase tsa mouoane hantle ho fokotsa likhase tsa CO. Moralo o nepahetseng le khetho ea thepa e bapala karolo ea bohlokoa ho fokotsa maemo a CO.

Hydrocarbons (HC)

Li-hydrocarbons li bakoa ke mafura a sa chesoang a phonyohang phaposing e tukang. Metsoako ena e kenya letsoho litabeng tsa mosi le ho hema. Moralo oa exhaust manifold o ama bokhoni ba enjene ba ho chesa mafura ka botlalo. Meralo e ntlafalitsoeng e thusa ho fokotsa tlhahiso ea HC ka ho netefatsa phallo e ntle ea khase ea ho tsoa.

Nitrogen oxides (NOx)

Nitrogen oxides e theha mocheso o phahameng oa ho tuka. Likhase tsena li baka mathata a tikoloho le bophelo bo botle, ho kopanyelletsa le pula ea asiti le mafu a ho hema. Mohaho o mongata o susumetsa tlhahiso ea NOx ka taolo ea mocheso. Meralo e sebetsang hantle e thusa ho boloka mocheso o tlase oa mollo, ka hona o fokotsa sebopeho sa NOx.

Kameho ea Exhaust Manifold on Emissions

Tšusumetso ea Moralo

Moralo oa manifold oa ho ntša metsi o ama ka kotloloho mesi. Manifold e entsoeng hantle e tiisa hore ho phalla ha khase e boreleli, ho fokotsa khatello ea morao le ho ntlafatsa ts'ebetso ea mollo. Liphuputso li bontša seoliqapi tse tapered li ntlafatsa ts'ebetso by ho fokotsa khatello ea maikutlo. Phallo e ntlafetseng ea khase e lebisa ho fokotseng ho tsoa ha CO, HC, le NOx.

Tšusumetso ea Lintho

Khetho ea thepa e ama haholo ts'ebetso ea exhaust.Lahlela tšepe le tšepe e sa hloekangke lisebelisoa tse tloaelehileng tse sebelisoang kahong e mengata. Cast iron e fana ka nako e telele empa e ka eketsa boima ba 'mele. Tšepe e sa hloekang e fana ka ho leka-lekana pakeng tsa matla le boima ba 'mele, ho ntlafatsa katleho ka kakaretso. Lisebelisoa ka bobeli li tlameha ho mamella khatello ea mocheso le mochini ho boloka ts'ebetso e nepahetseng le ho fokotsa mesi.

Taolo ea Mocheso

Taolo ea mocheso e bapala karolo ea bohlokoa taolong ea mesi. Mohaho o mongata o tlameha ho qhala mocheso ka nepo ho thibela mocheso o tukang o feteletseng. Lithempereichara tse phahameng li lebisa ho eketseha ha sebopeho sa NOx. Taolo e nepahetseng ea mocheso e thusa ho boloka mocheso o tlase oa ho tuka, ka hona ho fokotsa tlhahiso ea NOx. Lisebelisoa tse tsoetseng pele le lirafshoa li ka ntlafatsa bokhoni ba mefuta e mengata ea ho laola mocheso.

Tlhahlobo ea Phallo ea Matla

Lintlha tse Amang Phallo ea Matla

Exhaust Flow Dynamics

Matla a phallo ea motlakase a bapala karolo ea bohlokoa ts'ebetsong ea enjene. Moralo oa manifold exhaust ka ho toba o susumetsa tsela eo likhase tse tsoang ka ntle ho enjene li tsoa ka eona. Mefuta e mengata e entsoeng hantle e tiisa ho phalla ha khase e boreleli le ka potlako, ho fokotsa moferefere. Sena se fella ka phefumoloho e ntlafalitsoeng ea enjine le matla a ntlafatsoang. Hangata lienjineri li ntlafatsa sebopeho le bolelele ba liphaephe tse ngata-ngata ho fumana litšobotsi tse ntle tsa phallo.

Kgatello ya mokokotlo

Backpressure e bolela khanyetso eo likhase tse senyang li kopanang le tsona ha li tsoa enjene. Khatello e phahameng ea mokokotlo e ka sitisa ts'ebetso ea enjine ka ho thibela phallo ea mosi. Lihlooho tsa ho qeta tšebetso li ikemiselitse hofokotsa ho hanyetsa ho phalla, ka tsela eo e eketsa bokhoni ba enjene ea bophahamo ba modumo. Motlakase o ka tlaase o lumella enjene ho leleka likhase tsa ho qeta ka mokhoa o atlehileng haholoanyane, e leng se lebisang ho phaello ea matla a matla. Thee sa tsoa etsoa exhaust e ngatameralo hangata e shebana le ho fokotsa khatello ea maikutlo ho matlafatsa ts'ebetso ea enjene.

Ho Boloka Mocheso

Ho boloka mocheso ka har'a mefuta e mengata ea ho tima ho ama ts'ebetso ea enjene le tlhahiso ea matla. Mocheso o feteletseng o ka lebisa ho mocheso o phahameng oa ho tuka, o ka fokotsang ts'ebetso ea enjene. Taolo e nepahetseng ea mocheso e thusa ho boloka mocheso o nepahetseng oa ts'ebetso. Lisebelisoa tse tsoetseng pele le lirafshoa mohahong o mongata li ka ntlafatsa ho qhala ha mocheso. Ho boloka mocheso o nepahetseng ho tiisa hore enjene e sebetsa ka har'a mocheso o nepahetseng oa mocheso, ho eketsa tlhahiso ea matla.

Teko ea Ts'ebetso

Tlhahlobo ea Dyno

Teko ea Dyno e fana ka tikoloho e laoloang ho lekanya ts'ebetso ea mefuta e mengata ea ho tima. Baenjiniere ba sebelisa dynamometer ho etsisa maemo a sebele a ho khanna. Mokhoa ona oa tlhahlobo o lekola tšusumetso ea mefuta e mengata ho phallo ea matla, torque le ts'ebetso ea mafura. Teko ea Dyno e fana ka lintlha tse nepahetseng, tse nolofalletsang baenjiniere ho etsa liqeto tse nang le tsebo mabapi le moralo o mongata le khetho ea thepa.

Teko ea 'Nete ea Lefatše

Teko ea 'nete ea lefats'e e tlatselletsa tlhahlobo ea dyno ka ho lekola mefuta e mengata ea ho ntša metsi tlas'a maemo a sebele a ho khanna. Baenjineri ba lekola hore na mefuta e mengata e sebetsa joang maemong a fapaneng, joalo ka ho khanna teropong, ho tsamaea ka maoto litseleng tse kholo le ho potlakisa lebelo le matla. Teko ea 'nete ea lefats'e e thusa ho tseba mathata afe kapa afe a ka bang teng a sa hlahelle tikolohong e laoloang. Mokhoa ona o pharaletseng o tiisa hore mefuta e mengata ea exhaust e fana ka ts'ebetso e ts'oanang maemong a fapaneng a ho khanna.

Tlhahlobo ea Papiso

Tlhahlobo ea papiso e kenyelletsa ho lekola meralo e mengata e fapaneng ea ho ntša motlakase ho fumana hore na e ama phello ea eona ho phallo ea matla. Baenjineri ba bapisa lintho tse kang matla a phallo ea mosi, khatello e ka morao, le ho boloka mocheso. Tlhahlobo ena e thusa ho tseba meralo e sebetsang ka ho fetesisa ea ho ntlafatsa ts'ebetso ea enjine. Ka ho bapisa mefuta e mengata e fapaneng, baenjiniere ba ka supa matla le bofokoli ba moralo o mong le o mong. Ts'ebetso ena e lebisa ntlafatsong e tsoelang pele le boqapi ba theknoloji e mengata e fapaneng.

Litlhahiso le Mekhoa ea Bokamoso

Lisebelisoa tse tsoetseng pele

Liaparo tsa Ceramic

Liaparo tsa ceramic li hlahile e le tsoelo-pele e kholo ho theknoloji e mengata ea motlakase. Liaparo tsena li fana ka tšireletso e ntle haholo ea mocheso, ho fokotsa ho fetisoa ha mocheso likarolong tse potolohileng tsa enjene. Insulation ena e thusa ho boloka mocheso o nepahetseng oa enjine, ho ntlafatsa ts'ebetso le bophelo bo bolelele. Liaparo tsa Ceramic li boetse li fana ka khanyetso e phahameng ea ho senya le ho roala, ho netefatsa ho tšoarella ha mefuta e mengata ea ho qeta. Baenjineri ba likoloi ba ntse ba amohela liphahlo tsa ceramic ho ntlafatsa ts'ebetso le ts'epahalo ea litsamaiso tsa mosi.

Lisebelisoa tse Kopantsoeng

Lisebelisoa tse kopantsoeng li emela mokhoa o mong o mocha oa moralo o mongata oa ho ntša metsi. Lisebelisoa tsena li kopanya lintho tse fapaneng ho finyella tekanyo ea matla, boima le ho hanyetsa mocheso. Ka mohlala, metsoako ea carbon fiber e fana ka litekanyetso tse phahameng tsa matla-to-weight, e leng se etsang hore e be tse loketseng bakeng sa lits'ebetso tsa ts'ebetso. Tšebeliso ea lisebelisoa tse kopantsoeng e ka fokotsa boima ba mefuta e mengata ea ho qeta, e leng se lebisang ho ntlafatseng bokhoni ba koloi le ho sebetsana le eona. TheFluidForming Lightweight Stainless SteelExhaust Manifold Case Studye bonts'itse phetoho e atlehileng ea litšepe tse boima tse entsoeng ka tšepe e bobebe e bobebe, e totobatsang melemo ea thepa e tsoetseng pele ea boenjiniere ba likoloi.

Lintlafatso tsa Moralo

Mefuta e sa tšoaneng ea Geometry Manifolds

Li-geometry manifolds (VGM) tse feto-fetohang li emela boqapi bo tsoetseng pele molemong oa ho sebelisa mefuta e mengata. Li-VGM li fetola sebopeho le bolelele ba liphaephe tse ngata ho latela maemo a ts'ebetso ea enjene. Ho ikamahanya le maemo ho ntlafatsa phallo ea khase e tsoang, ho fokotsa khatello ea maikutlo le ho ntlafatsa ts'ebetso ea enjine. Li-VGM li ka ntlafatsa ts'ebetso ea mafura le ho fokotsa mesi ka ho boloka matla a ho felloa ke matla maemong a fapaneng a ho khanna. Baetsi ba likoloi ba ntse ba tsoela pele ho hlahloba li-VGM ho fihlela melao e thata ea tlhahiso le litlhoko tsa ts'ebetso.

Li-converter tse kopantsoeng tsa Catalytic

Ho kopanya li-converter tsa catalytic ka kotloloho ho manifold a mangata ho fana ka melemo e mengata. Moralo ona o fokotsa sebaka seo khase e tsamaeang ka sona pele e fihla ho catalytic converter, e ntlafatsa ts'ebetso ea taolo ea mosi. Li-converter tse kopantsoeng tsa catalytic li thusa ho fihlella linako tse potlakileng tsa ho tima khanya, ho fokotsa likhase tse batang. Ho kopanya hona ho boetse ho nolofatsa mokhoa oa tsamaiso ea ho qeta, ho fokotsa boima le ho rarahana. Likoloi tse ngata tsa sejoale-joale li na le li-converter tse kopaneng tsa catalytic ho fihlela maemo a tikoloho ha li ntse li boloka ts'ebetso e phahameng.

Tlhahlobo e totobatsa karolo ea bohlokoa ea moralo o mongata oa ho ntša metsi le khetho ea thepa ho ntlafatsa ts'ebetso ea enjine le ho fokotsa tlhahiso. Liphuputso tsa bohlokoa li bonts'a hore lisebelisoa tse tsoetseng pele joalo ka tšepe e sa hloekang le lirafshoa tsa ceramic li matlafatsa ho tšoarella le ho sebetsa hantle. Lintlafatso tsa moralo tse joalo ka mefuta e fapaneng ea li-geometry le li-converter tse kopaneng tsa catalytic li ntlafatsa ts'ebetso ea mafura le taolo ea mosi.

Likhatelopele tsa theknoloji leho fetola likhetho tsa barekiho tsamaisa litlamorao tse kholo indastering ea likoloi.Litsamaiso tse sebetsang hantle tsa ho ntša metsile mekhoa ea ho khanna e ka fokotsa ho tsoa ha likoloi, ho kenya letsoho ho boloka tikoloho. Patlisiso ea nako e tlang e lokela ho tsepamisa maikutlo ho nts'etsopele ea lisebelisoa tse bobebe le meralo e ncha ho fihlela litlhoko tse tsoelang pele tsa taolo le ts'ebetso.

Nako ea poso: Jul-31-2024