Kutloisisoho chesa ha kae ha enjene e tsoa ka bongataka fumanae bohlokoa ho beng ba likoloi. Blog ena e shebisisa bohlokoa ba ho utloisisaho felloa ke matlamocheso, ho fana ka lintlha tsa bohlokoa homocheso o feteletseng o amehang. Ho tloha maemong a tloaelehileng a mocheso ho ea ho mocheso o phahameng o fetang1200 likhato tsa Fahrenheit, babali ba tla fumana kutloisiso e pharaletseng ea karolo ena ea bohlokoa ea ts'ebetso ea enjene.

Ho utloisisa mefuta e mengata ea Exhaust

Ha ho nahanoa kaenjene ho felloa ke matlaea koloi, ho bohlokoa ho utloisisa lintlha le mesebetsi ea eona e rarahaneng. Anho felloa ke matlae sebetsa e le karolo ea bohlokoa tsamaisong ea mosi oa enjene, e ikarabellang bakeng sa ho bokella likhase tsa mosi ho lisilindara tse ngata le ho li tsamaisa ho lebile phala ea ho tsoa. Ts'ebetso ena e phetha karolo ea bohlokoa ho boloka tšebetso ea enjene ka kakaretso le ho sebetsa hantle.

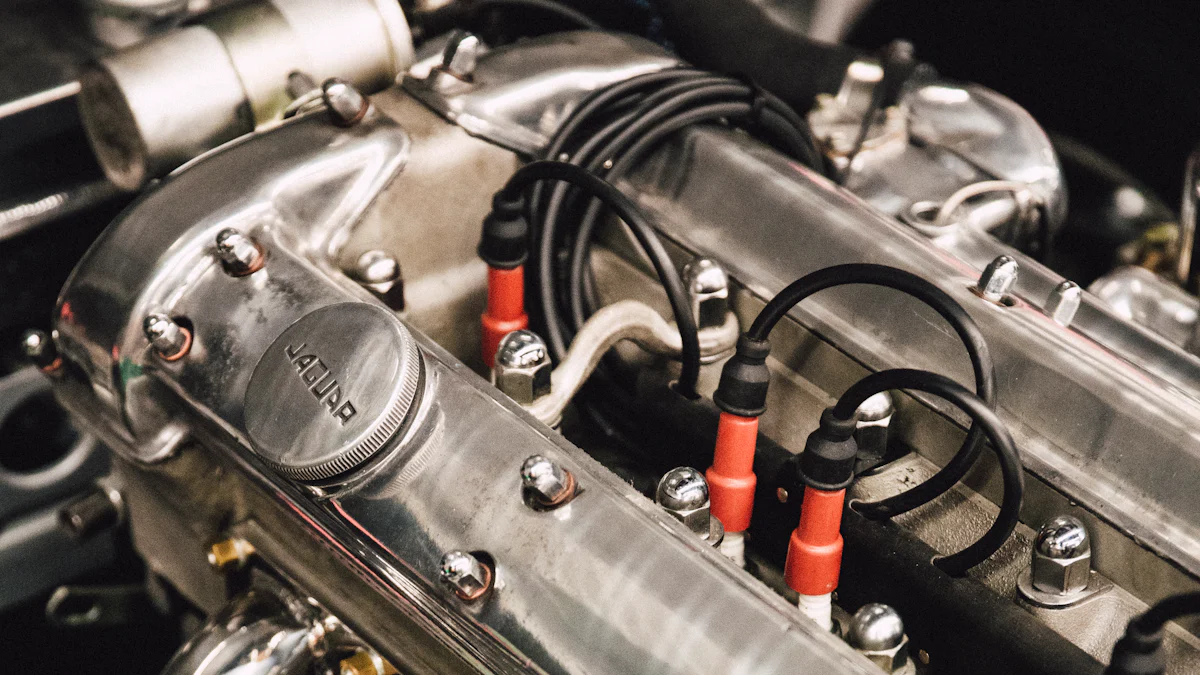

Exhaust Manifold ke eng?

Tlhaloso le Mosebetsi

Theho felloa ke matlae ka hlalosoa e le sehokelo sa bohlokoa lipakeng tsa lisilindara tsa enjene le phala ea mosi. Mosebetsi oa eona oa mantlha o kenyelletsa ho bokella likhase tse chesang, tse chefo tse hlahisoang nakong ea ho tuka ka har'a silindara ka 'ngoe le ho li lebisa ho converter ea catalytic kapa muffler bakeng sa taolo ea tlhahiso. Ka ho bokella likhase tsena ka bokhabane, hoho felloa ke matlae thusa ho ntlafatsa ts'ebetso ea enjene le ho fokotsa mesi e kotsi.

Mefuta e mengata ea Exhaust Manifolds

Ho na le mefuta e fapaneng eaho felloa ke matla, e 'ngoe le e' ngoe e etselitsoe ho sebetsana le tlhophiso e khethehileng ea enjene le litlhoko tsa ts'ebetso. Mefuta e tloaelehileng e kenyelletsa mefuta e mengata ea tšepe e entsoeng ka tšepe, mefuta e mengata ea tšepe e sa hloekang, lelihlooho tsa tubular. Mefuta e mengata ea tšepe ea cast e tsebahala ka ho tšoarella ha eona le ho baballa litšenyehelo, athe mefuta e mengata ea tšepe e sa tsitsang e fana ka khanyetso e phahameng ea kutu. Ka lehlakoreng le leng, lihlooho tsa li-tubula li ntlafatsa bokhoni ba ho phalla ha metsi ka ho fana ka li-headpipe bakeng sa silinda e 'ngoe le e' ngoe.

Exhaust Manifold e Chesa Hakae?

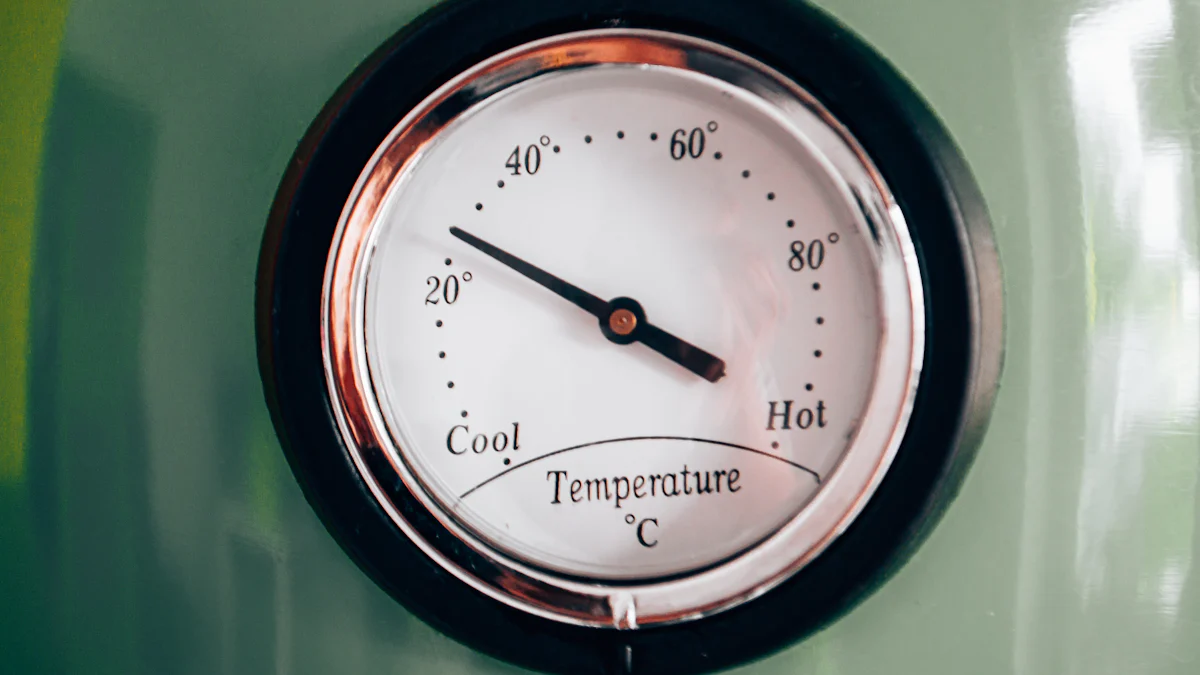

Mefuta e Tloaelehileng ea Mocheso

Theho ntša mocheso o mongatae ka fapana haholo ho latela maemo a ho khanna lemojaro oa enjene. Tlas'a maemo a tloaelehileng a ts'ebetso, lienjineri tse ngata tsa stock li bonts'a mocheso ho tloha ho 275 ho isa ho 300 degrees Fahrenheit li sa sebetse. Leha ho le joalo, nakong eamaemo a tshebetso e phahamengjoalo ka mabelo kapa lits'ebetso tse boima, mocheso ona o ka nyoloha ka potlako.

Lithempereichara tse Hloahloa

Maemong a feteletseng, joalo ka likoloi tse sebetsang hantle haholo kapa mochini o boima,ho felloa ke matlae ka fihla mocheso o fetang likhato tse 1200 tsa Fahrenheit. Maemo ana a mocheso a feteletseng a baka mathata mabapi le ho tšoarella ha thepa le taolo ea mocheso ka har'a phaposi ea enjene.

Manifold of Car Withstand

Sebopeho sa Lintho

Ka lebaka la tikoloho e boima eo ba sebetsang ho eona,ho felloa ke matlali hahoa ho sebelisoa thepa kathepa e phahameng ea ho hanyetsa mocheso. Lisebelisoa tse tloaelehileng li kenyelletsa tšepe e entsoeng ka tšepe, tšepe e sa hloekang le tšepe e bonolo. Boitsebiso bo bong le bo bong bo fana ka melemo e ikhethang mabapi le ho mamella mocheso le ho phela nako e telele.

Mehopolo ea Moralo

Moralo oaho felloa ke matlae bapala karolo ea bohlokoa ho ntlafatseng ts'ebetso ea enjine le litšobotsi tsa torque. Lintho tse kang bolelele ba liphaephe, bophara, manonyeletso, li-welds, leboreledi ka haree ama haholo katleho ea phallo ea khase. Ho feta moo, boholo bo nepahetseng ba makala a mangata bo bohlokoa ho etsa bonnete ba hore ponahatso e nakong ea li-pulse ho mokelli.

Ha bahlahisi ba ntse ba leka ho ntlafatsa ts'ebetso ea koloi ha ba ntse ba kopana le litekanyetso tse thata tsa tlhahiso, tsoelo-pele e tsoelang peleho felloa ke matla ha enjenemoralo li pakoa ho pholletsa le likarolo tse fapaneng tsa likoloi.

Lintlha tse Amang Lithempereichara Tse Ngata

Ha u hlahlobamochesoka bongata ba mosi, ho bohlokoa ho nahana ka lintlha tse fapaneng tse ka susumetsang maemo ana a mocheso a feteletseng. Ho utloisisa hore na joangmojaro oa enjenele lebelo,mofuta oa mafurale boleng, hammoho lemoralo oa sistimi ea exhaust, e phetha karolo ea bohlokoa ho lekanyetsa ts'ebetso e akaretsang ea mocheso oa mefuta e mengata e bohlokoa bakeng sa beng ba likoloi.

Mojaro oa Enjene le Lebelo

Tšusumetso ea Maemo a ho Khanna

Maemo a ho khanna a na le tšusumetso e kholo ho mocheso oa mefuta e mengata ea ho ntša metsi. Nakong ea ho khanna ka lebelo le phahameng, phallo e ntseng e eketseha ea moea ka phaposing ea enjene e ka thusa ho qhala mocheso ka mokhoa o atlehileng haholoanyane. Ka lehlakoreng le leng, sephethephetheng sa litoropo, moo enjene e sebetsang ka lebelo le tlase ka nako e telele, ho eketseha ha mocheso ka har'a mefuta e mengata ho ka bonahala haholoanyane.

Maemo a Tshebetso

Maemong a ts'ebetso joalo ka ho matha kapa ho hula meroalo e boima, lienjineri li sebetsa tlas'a meroalo le lebelo le holimo, e leng se lebisang keketsehong.mocheso o tukang. Khatello ena e phahameng ea mocheso e fella ka holimoho felloa ke mocheso oa khaseho tsoa ka lisilindara le ho phalla ka har'a bongata. Ka lebaka leo, mefuta e mengata e tlameha ho mamella maemo ana a feteletseng ntle le ho senya botšepehi ba eona ba sebopeho.

Mofuta oa Mafura le Boleng

Peterole vs. Dizeli

Mofuta oa mafura o sebelisoang enjeneng o ka boela oa ama mocheso o mongata oa mocheso. Hangata lienjineri tsa diesel li sebetsa maemong a mocheso a phahameng a tukang ho feta lienjine tsa peterole ka lebaka la ts'ebetso ea tsona ea ho hotetsa. Ka lebaka leo, likoloi tse tsamaeang ka diesel li ka 'na tsa e-ba le mocheso o moholo oa mocheso ka har'a tsamaiso ea ho ntša metsi, ho kenyeletsa le mefuta e mengata.

Tšusumetso eaLisebelisoa tsa Mafura

Boleng ba lisebelisoa tsa peterole tse sebelisoang li ka ama mocheso oa mosi. Li-additives tse ling li etselitsoe ho ntlafatsa ts'ebetso ea ho tuka kapa likarolo tse hloekileng tsa enjene, tse ka fetolang litšobotsi tsa mocheso oa likhase tsa mosi. Ka ho fetola thepa ea mollo, li-additives tsena li ka ama ka tsela e sa tobang boemo ba mocheso ka har'a mefuta e mengata ea ho tima.

Moqapi oa Sisteme ea Exhaust

Karolo eaLiphetoho tsa Catalytic

Li-converter tsa Catalytic li bapala karolo ea bohlokoa ho fokotsa mesi e kotsi ka ho fetola likhase tse chefo hore e be lihlahisoa tse seng kotsi haholo. Leha ho le joalo, li-converter tsa catalytic li boetse li kenya mocheso o eketsehileng tsamaisong ea ho ntša metsi ka lebaka la liketso tse feteletseng tse etsahalang ka hare ho tsona. Ts'ebetso ena e kenyellelitsoeng ea mocheso ha e ame feela mocheso oa li-converter empa hape e ama mocheso o akaretsang oa mocheso ho pholletsa le bolelele bohle ba tsamaiso ea ho ntša metsi.

Tšusumetso ea Lihlooho le Lipeipi

Moralo le sebopeho sa thepa ea lihlooho le liphaephe li ama ka kotloloho tsela eo likhase tsa mouoane li phallang hantle ka har'a sistimi. Lihlooho tse nang le li-tubes tsa mantlha tsa bolelele bo lekanang li khothalletsa phallo e leka-lekaneng ea khase ho tloha moqomong o mong le o mong ho ea ho mokelli a le mong, ho fokotsa khatello ea morao le ho fokotsa phapang ea mocheso pakeng tsa li-cylinders. Ho feta moo, ho sebelisoamandrel-bent tubinge netefatsa liphetoho tse thellang bakeng sa likhase tse tsoang ntle le ho theha lithibelo tse sa hlokahaleng tse ka phahamisang mocheso sebakeng sa heno.

Ka ho nahana ka lintlha tsena tsa bohlokoa tse amangmefuta e mengata ea mocheso, beng ba likoloi ba ka fumana leseli la bohlokoa mabapi le ho ntlafatsa ts'ebetso ea enjine ha ba ntse ba netefatsa bophelo bo bolelele le ho ts'epahala tlas'a maemo a fapaneng a ts'ebetso.

Litekanyo tsa Mocheso oa 'Nete oa Lefatše

Maemo a Tloaelehileng a ho Khanna a sa sebetseng le a Tloaelehileng

Nengho felloa ke likhasephallang kaho felloa ke matla, ba tsamaea le masala a tukang, a ntša mocheso nakong eo. Nakong ea maemo a ho khanna a sa sebetseng kapa a tloaelehileng, lithempereichara tsena li fana ka leseli la bohlokoa mabapi le katleho le tšebetso ea enjene.

- Theexhaust portnakong ea lithempereichara tse sa sebetseng tse ka tlohang ho 275 ho isa ho 300 degrees Fahrenheit lienjineng tse ngata tsa stock. Sena se bontša mocheso o tsitsitseng oa ts'ebetso bakeng sa mefuta e mengata tlas'a mojaro o fokolang.

- Ka lehlakoreng le leng, lienjineri tsa ts'ebetso li bonts'a mocheso o phahameng hanyane, o fihlang ho likhato tse 325 Fahrenheit nakong ea ho se sebetse. Keketseho ena e bakoa ke ts'ebetso e matlafalitsoeng ea ho chesa mollo ka har'a litlhophiso tsena tse sebetsang hantle haholo.

Maemo a Ts'ebetso e Phahameng

Maemong a ts'ebetso e phahameng joalo ka maemo a mabelo kapa lits'ebetso tse boima, litlhoko tse behiloeng holim'a enjene li baka mocheso o phahameng ka har'a sistimi ea mosi. Maemo ana a feteletseng a sutumelletsa hoho felloa ke matlaho ea ka meeli ea eona, ho leka ho tšoarella ha eona le ho tiea ha mocheso.

- Maemo a mabelo a sutumelletsaho felloa ke mochesoho fihla bophahamong bo bocha, ka ho bala ho fetisisang1200 likhato tsa Fahrenheitmaemong a mang. Mocheso o matla o hlahisoang ke mabelo a lebelo le phahameng o phephetsa esita le thepa e matla ka ho fetisisa e sebelisoang kahong e mengata.

- Lits'ebetso tse boima, joalo ka ho hula meroalo e boima kapa ho kenya mochini oa liindasteri matla, li fana ka maikutlo a nako e telele ho mocheso o phahameng. Lithempereichara tse fetang 1000 degrees Fahrenheit li tloaelehile libakeng tsena tse boima.

Phapang ea Mocheso

Kabo ea mocheso ka har'a lisilindara tse fapaneng le mefuta ea likoloi e totobatsa sebopeho se rarahaneng sa matla a tsamaiso ea ho ntša metsi. Ho utloisisa liphapang tsena ho bohlokoa bakeng sa ho ntlafatsa ts'ebetso ea enjine le ho netefatsa ts'epo e tsitsitseng.

- Pakeng tsa li-cylinders, ho fapana hoho felloa ke mocheso oa khasee ka bonoa ka lebaka la lintlha tse kang lipaterone tsa ente ea mafura le litšobotsi tse ikhethileng tsa silindara. Phapang ena e ka lebisa ho phapano ea mocheso ho fihla ho likhato tse 100 tsa Fahrenheit lipakeng tsa lisilindara tse haufi.

- Ho pholletsa le mefuta e fapaneng ea likoloi, ho fapana ha moralo o mongata oa motlakase le litlhaloso tsa enjine li kenya letsoho ho profaele e fapaneng ea mocheso. Mohlala, likoloi tse nang le lienjine tsa turbocharged li ka bonts'a mocheso o phahameng oa mosi ha o bapisoa le lipalangoang tsa tlhaho tse lakatsehang ka lebaka la likhatello tse ntseng li eketseha.

Ka ho hlahloba litekanyo tsa mocheso oa 'nete oa lefats'e tlas'a maemo a fapaneng a ts'ebetso, beng ba likoloi ba ka fumana kananelo e tebileng bakeng sa liphephetso tsa mocheso tse tobaneng le tsona.ho felloa ke matla. Ho beha leihlo lithempereichara tsena ho fana ka lintlha tsa bohlokoa mabapi le bophelo ba enjine le maano a ho ntlafatsa ts'ebetso.

Liphello tsa Mocheso o Phahameng

Ts'ebetso ea Enjine

Bokhoni le Phallo ea Matla

Lithempereichara tse phahameng ka har'a mefuta e mengata ea ho ntša metsi li ka ama haholotshebetso ya enjeneka ho susumetsa bokgabane ba yona le tlhahiso ya matla. Ha likhase tsa ho qeta li fihla maemong a mocheso o feteletseng, li ka ama ts'ebetso ea mollo ka har'a li-cylinders, e leng se lebisang ts'ebetsong e sa lokelang ea enjene.

- Thebokgabaneea enjene e hokahane haufi-ufi le taolo ea mocheso ea likarolo tsa bohlokoa joalo ka manifold exhaust. Mocheso o feteletseng o ka senya maemo a loketseng bakeng sa ho tuka, ho fella ka ho chesa mafura ka mokhoa o sa fellang le ho fokotsa phetoho ea matla ho tloha ho mafura ho ea mosebetsing oa mechine.

- Ho latelatlhahiso ea matla, lithempereichara tse phahameng tsamaisong ea mosi oa mosi li ka sitisa enjene ho hlahisa matla a lekaneng bakeng sa ho khanna koloi. Khatello ea mocheso likarolong tse ka hare tse bakoang ke mocheso o phahameng o ka senya ho fana ka matla ka kakaretso, ho ama ho potlakisa le ho hula bokhoni.

- Ho boloka maemo a holimotshebetso ya enjene, ho bohlokoa ho beha leihlo lithempereichara tse ngata khafetsa le ho rarolla mathata leha e le afe a ka hlahang ka lebaka la ho eketseha ho feteletseng ha mocheso. Ka ho etsa bonnete ba hore ho na le mehato e nepahetseng ea ho pholisa le ho kenya letsoho, beng ba likoloi ba ka sireletsa bokhoni ba enjene ea bona le tlhahiso ea matla.

Ho phela nako e telele le ho tšoarella

Ho phela nako e telele le ho tšoarella ha enjene ho amana haufi-ufi le hore na e khona ho mamella mocheso o phahameng hakae libakeng tse mahlonoko tse kang mouoane o mongata. Ho pepesehela mocheso o feteletseng ka nako e telele ho ka potlakisa ho senyeha le ho taboha ha likaroloana, ho ka lebisang ho se sebetseng pele ho nako ha likarolo tsa bohlokoa tsa enjine.

- Ha nako e ntse e ea, ho pepesehela mocheso o phahameng khafetsa ho ka senya boleng ba sebopeho sa thepa e sebelisoang.ho felloa ke matla. Ho senyeha hona ho ka 'na ha bonahala e le mapetsong, ho soahlamana, kapa ho hola, ho senya matla a mangata a ho thibela le ho tsamaisa likhase tsa moholi ka katleho.

- Ho tšoarella ha enjene tlas'a maemo a mocheso o phahameng ke bopaki ba ho tiea ha eona khahlanong le khatello ea mocheso. Likarolo tse tlas'a mocheso o matla li tlameha ho bonts'a matla le ho hanyetsa deformation kapa mokhathala oa lintho tse bonahalang ho netefatsa ts'epo ea nako e telele.

- Ka ho etelletsa pele mekhoa ea tlhokomelo e fokotsang mocheso o mongata o feteletseng tsamaisong ea mosi, beng ba likoloi ba ka ntlafatsa bophelo bo bolelele le ho tšoarella ha enjine ea bona. Ho hlahlojoa khafetsa, ho lokisoa ka nako le lisebelisoa tse pholileng tse lekaneng li phetha karolo ea bohlokoa ho baballeng likarolo tsa enjene hore li se ke tsa senyeha pele ho nako.

Maikutlo a Tlhokomelo

Mehato ea Thibelo

Ho kenya ts'ebetsong maano a ts'ebetso ea tlhokomelo ho bohlokoa bakeng sa ho fokotsa litlamorao tse mpe tsa mocheso o phahamengho felloa ke matlale tshebetso ya enjene ka kakaretso. Ka ho nka mehato ea thibelo e reretsoeng taolo ea mocheso le ts'ireletso ea likaroloana, beng ba likoloi ba ka lelefatsa bophelo ba enjene ea bona le ho ntlafatsa ts'ebetso ea eona hantle.

- Litlhahlobo Tsa Kamehla: Etsa tlhahlobo ea ka mehla ea mosi oa mosi bakeng sa matšoao a ho fifala, mafome, kapa tšenyo ea 'mele e ka supang mathata a ho futhumala ho feteletseng.

- Tlhokomelo ea Mokhoa oa ho Pholisa: Netefatsa tšebetso e nepahetseng ea mochini oa ho pholisa koloing, ho kenyeletsoa le li-radiator flushes, licheke tsa boemo ba pholiso, le tlhahlobo ea thermostat.

- Ho kengoa ha Heat Shield: Nahana ka ho kenya lithebe tsa mocheso ho potoloha libaka tse tlokotsing haufi le mochini oa motlakase ho fokotsa mocheso o khanyang le ho sireletsa likarolo tse potolohileng.

- Lintlafatso tsa Sisteme ea Exhaust: Ntlafatsa likarolo tsa ho ntša metsi ka thepa e phahameng ea ho mamella mocheso kapa meralo e ntlafalitsoeng e ntlafatsang bokhoni ba ho qhala mocheso.

- Lisebelisoa tsa ho Hlahloba: Tsetela ho lisebelisoa tsa ho lekola mocheso kapa li-sensor tse fanang ka data ea nako ea nnete mabapi le mocheso o mongata oa mocheso nakong ea maemo a fapaneng a ho khanna.

- Tšebeletso ea Setsebi: Rulahanya linako tsa ho lokisoa ha nako le nako le litsebi tse tšoanelehang tse sebetsanang le ho hlahloba le ho rarolla mathata a amanang le maemo a mocheso o phahameng.

Matshwao a ho Fetela ho Feta

Ho lemoha matšoao a pele a ho futhumala ho feteletseng ha mochine oa enjene ke habohlokoa bakeng sa ho thibela tšenyo e ka bang teng kapa ho se sebetse hantle ho bakoang ke mocheso o feteletseng. Ka ho falimehela matšoao a tloaelehileng a temoso a amanang le likarolo tsa mocheso o feteletseng joalo ka manifold exhaust, beng ba likoloi ba ka nka khato e potlakileng ho qoba litokiso tse bitsang chelete e ngata kapa tse ling.

- Monko o sa Tloaelehang: Ela hloko menko leha e le efe e sa tloaelehang e tsoang phaposing ea enjene e ka bontšang thepa e chesang ho feta tekano kapa maro a lutlang.

- Keketseho ea Mosi oa Exhaust: Lekola liphetoho tsa 'mala oa mosi oa mosi oa mosi kapa bongata bo bongata kaha mesi e lefifi e ka bontša ho chesa oli kapa sepholi ka lebaka la mocheso o feteletseng.

- Ho Senyeha ha Enjine: Ela hloko bakeng sa ho se cha ho sa tloaelehang ha enjine kapa mekhoa e sa sebetseng hantle ea ho sebetsa e ka bakoang ke ts'ebetso e hlephileng ea ho tuka e amanang le mocheso o mongata o mongata.

- Ho Fokotsa Tšebeliso e Ntle ea Mafura: Latela liphapano tsa litekanyetso tsa tšebeliso ea mafura kaha tšebeliso e eketsehileng ea mafura ntle le phaello e tsamaellanang e ka fana ka maikutlo a ho tuka ho sa sebetseng ho bakoang ke ho futhumala ho feteletseng.

- Litemoso tsa Dashboard: Ela hloko mabone a tlhokomeliso ho dashboard a amanang le mocheso o pholileng kapa ho se sebetse hantle ha enjene ho ka lebisang ho mocheso o phahameng oa ts'ebetso ka har'a lisebelisoa tse mahlonoko.

Ka ho lula ba ipapisitse le matšoao ana a ho chesa ho feteletseng ka har'a sistimi ea mosi, beng ba likoloi ba ka khona ho rarolla mathata a mantlha pele ba ka ba mathata a tebileng a mochini. Ho beha pele mehato ea thibelo ho netefatsa ts'ebetso e nepahetseng ha ho ntse ho sireletsa khahlanong le likotsi tse ka bang teng tse amanang le mocheso o phahameng o amang likarolo tsa bohlokoa tsa enjine joalo ka mouoane oa motlakase.

- Ho akaretsa, ho utloisisa lintlha tse rarahaneng tsatlosa mocheso o mongatae bohlokoa bakeng sa ts'ebetso e nepahetseng ea enjine le bophelo bo bolelele. Ka ho beha leihlo lithempereichara tsena, beng ba likoloi ba ka khona ho rarolla mathata a ka bang teng le ho netefatsa hore lienjineri tsa bona li sebetsa hantle. Ho hlahlojoa khafetsa, tlhokomelo e nepahetseng ea tsamaiso ea ho pholisa, le ho kenya litšireletso tsa mocheso ke mehato ea bohlokoa ea thibelo ea ho sireletsa khahlanong le mocheso o feteletseng. Bakeng sa lintlha tse ling mabapi le ho boloka bophelo bo botle ba ho felloa ke matla le ho eketsa ts'ebetso e ntle ea enjene, ho khothaletsoa haholo ho hlahloba lisebelisoa tse eketsehileng mabapi le taolo ea mocheso lits'ebetsong tsa koloi. Lula u tseba ho boloka enjene ea hau e sebetsa hantle!

Nako ea poso: Jun-05-2024