Theho felloa ke matlae bapala karolo ea bohlokoa boenjinering ba likoloi ka ho bokella likhase tse tsoang ho lisilindara tse ngata le ho li kenya phala e le 'ngoe. Moralo oa li-exhaust manifolds o fetohile haholo,susumetsoa ke tlhokobakeng sa matla a eketsehileng a mafura lemelao e thata ea tlhahiso. Ho utloisisa leeto lena ho fana ka leseli la bohlokoa bakeng sa batho ba chesehelang likoloi le litsebi, ho totobatsa bohlokoa ba tsoelo-pele e tsoelang pele ho theknoloji e mengata ea motlakase.

Meetso ea Pele ea Mefuta e mengata ea Exhaust

Tsoalo ea Mehaho e Mengata ea Exhaust

Mehopolo ea Pele le Prototypes

Khopolo ea ho qeta nako e ngata e ile ea hlaha ka ho fihla ha lienjini tse nang le li-cylinder tse ngata. Meralo ea pele e ne e reretsoe ho tsamaisa likhase tse tsoang ho li-cylinders tse ngata ho ea phala e le 'ngoe. Baenjineri ba ile ba etsa liteko ka mefuta e fapaneng ea litlhophiso ho ntlafatsa phallo ea khase le ho fokotsa khatello ea morao. Mefuta ea pele e ne e le ea khale, hangata e entsoe ka letsoho, e bonts'a bokhoni bo fokolang ba nako eo.

Lisebelisoa le Mekhoa ea Tlhahiso

Tšepe ea tšepee ile ea e-ba thepa ea khetho bakeng sa mefuta e mengata ea ho qeta nako ea pele. Ho hanyetsa mocheso o phahameng le ho bola ho entse hore e be e loketseng ho sebetsana le maemo a thata ka har'a sebaka sa enjene. Ho tšoarella ha cast iron ho netefalitse hore likaroloana tsena li khona ho mamella ho pepesehela mocheso o feteletseng ntle le ho senyeha. Mekhoa ea tlhahiso e ne e kenyelletsa ho akhela tšepe e qhibilihisitsoeng ka har'a hlobo, e leng mokhoa o neng o lumella tlhahiso e ngata ha o ntse o boloka botšepehi ba sebopeho.

Mathata le Mefokolo

Mathata a Tshebetso

Mefuta e mengata ea ho qeta nako ea pele e ile ea tobana le mathata a maholo a tshebetso. Hangata moqapi o ne o fella ka phallo e sa lekaneng ea khase, e lebisang ho eketseha ha khatello ea morao. Ho se sebetse hona ho ile ha fokotsa ts'ebetso ea enjene le moruo oa mafura. Baenjiniere ba ile ba sokola ho etsa meralo e ka leka-lekanang tlhokahalo ea phallo e sebetsang ea khase le lithibelo tsa mekhoa e teng ea tlhahiso.

Matšoenyeho a ho tšoarella

Ho tšoarella ho ile ha hlahisa phephetso e 'ngoe e kholo bakeng sa mefuta e mengata ea mosi oa pele. Ho sa tsotellehe ho tiea ha tšepe e entsoeng ka tšepe, ho pepesehela mocheso ka nako e telele mochesong o phahameng le likhase tse senyang ho ile ha baka ho peperana le ho soahlamana ha nako e ntse e ea. Tlhokomelo le ho nchafatsoa ha likarolo tsena e ile ea e-ba ntho e hlokahalang khafetsa, e leng se ileng sa eketsa litšenyehelo tsa ho ba beng ba likoloi. Baenjineri ba 'nile ba batla litsela tsa ho ntlafatsa nako e telele ea ho qeta nako e ngata ka lisebelisoa tse ntlafalitsoeng le mekhoa e mecha ea meralo.

Phetoho ea Mekhahlelo e mengata ea Exhaust

Lintlafatso tsa Lekholong la Bo-20 la Bohareng

Kenyelletso ea Thepa e Ncha

Bohareng ba lekholo la bo20 la lilemo ho bile le phetoho e kholo ho nts'etsopele ea mosi oa metsi. Baenjiniere ba ile ba qala ho hlahloba lisebelisoa tse ncha ho ntlafatsa ts'ebetso le ho tšoarella. Ts'epe e sa hloekang e ile ea hlaha e le khetho e tummeng ka lebaka la ho hanyetsa mocheso o phahameng le ho bola. Boitsebiso bona bo ne bo lumella marako a fokolang, a fokotsa boima ba 'mele ha a ntse a boloka botšepehi ba sebopeho. Ho amoheloa ha tšepe e sa hloekang ho ile ha ntlafatsa katleho ea kakaretso ea tsamaiso ea ho qeta nako ka ho fokotsa tahlehelo ea mocheso.

Lintlafatso tsa Moralo le Sebetsa

Lintlafatso tsa moralo le tsona li bile le karolo ea bohlokoa nakong ena. Baenjiniere ba ile ba sebelisa mekhoa e tsoetseng pele ea tlhahiso ho etsa meralo e rarahaneng le e sebetsang hantle. Kenyelletso ea ho kobeha ha mandrel e ile ea nolofalletsa tlhahiso eaboreleli ba ho kobeha, ho fokotsa moferefere le khatello ea mokokotlo. Boqapi bona bo ntlafalitse haholo phallo ea khase e tsoang, ho matlafatsa ts'ebetso ea enjine le ho sebetsa hantle ha mafura. Tšebeliso ea lisebelisoa tsa ho etsisa li lumelletsoe ho etsa mohlala o nepahetseng oa matla a phallo ea khase, e lebisang homeralo e mengata e ntlafalitsoeng.

Tšusumetso ea Melao ea Phallo

Liphetoho ho Moralo ho Kopana le Maemo

Ho kengoa ts'ebetsong ha melao e thata ea ho ntša metsi karolong e qetellang ea lekholo la bo20 la lilemo ho ile ha hlokahala hore ho be le tsoelo-pele e eketsehileng ea theknoloji e mengata e fapaneng. Baetsi ba ile ba tlameha ho hlophisa bocha mekhoa e mengata ho fihlela litekanyetso tse ncha tsa ho fokotsa mesi e kotsi. Ho kenyelletsoa ha li-converter tsa catalytic tsamaisong ea mouoane ho ile ha hlokahala. Keketso ena e ne e hloka makhetlo a mangata ho mamella mocheso o phahameng le ho tšehetsa tšebetso e ntle ea lisebelisoa tsena. Baenjiniere ba tsepamisitse maikutlo ho theheng meralo e nolofalitseng ho futhumatsa ka potlako li-converter tsa catalytic, ho netefatsa ts'ebetso e nepahetseng.

Lintlafatso tsa Theknoloji tse Tsamaisitsoeng ke Melao

Lintlafatso tsa theknoloji tse tsamaellanang le melaoana ea mosi li lebisitse ho nts'etsopele ea litsamaiso tse ngata tse rarahaneng tsa mosi. Tšebeliso ea computational fluid dynamics (CFD) e ile ea ata, ea lumella baenjiniere ho etsisa le ho sekaseka boitšoaro ba khase e tsoang ka botlalo. Theknoloji ena e nolofalitse ho theoa ha mefuta e mengata e nang le lijeometri tse rarahaneng tse ileng tsa eketsa phallo ea khase le ho fokotsa mesi. Ho kopanngoa ha litsamaiso tsa turbocharging tse nang le manifolds a exhaust le tsona li fumane botumo. Lienjine tsa turbocharged li ne li hloka mefuta e mengata e khonang ho sebetsana le khatello e ntseng e eketseha le mocheso, e leng ho tsamaisang tsoelo-pele e eketsehileng mahlaleng a lintho tse bonahalang le moralo.

Litlhahiso tsa Sejoale-joale ka Mehaho e mengata ea Exhaust

Lisebelisoa tse Tsoetseng Pele le Liaparo

Li-Alloys tsa Ts'ebetso e Phahameng

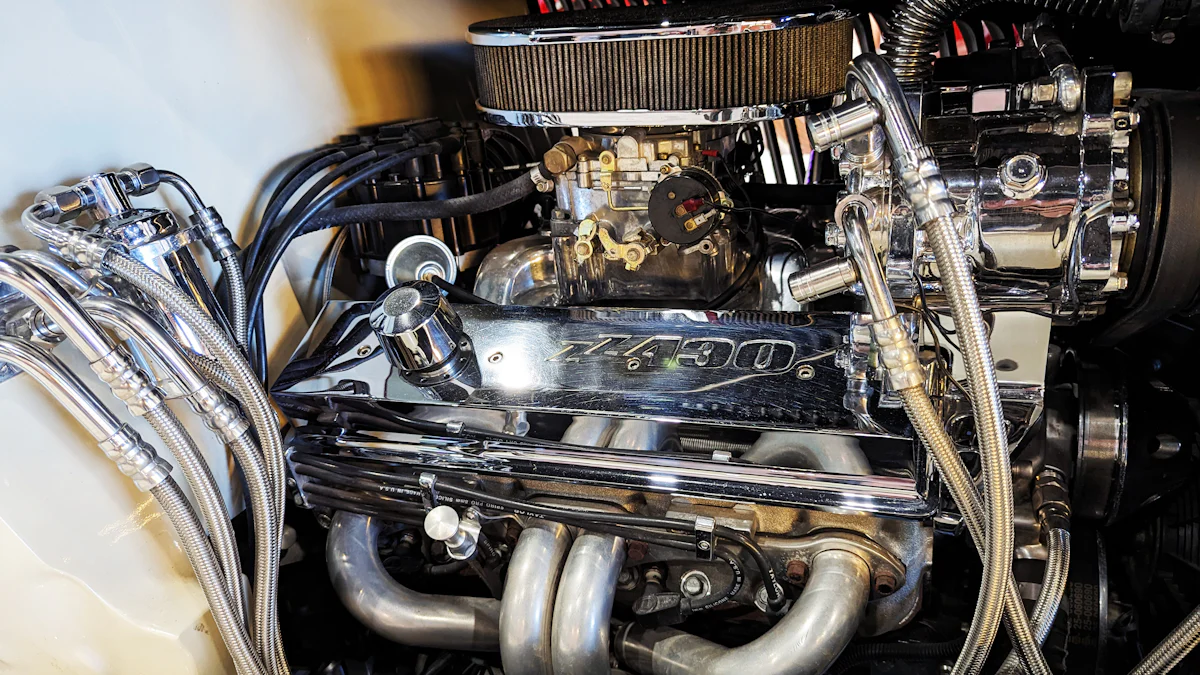

Hona joale bahlahisi ba likoloi ba sebelisa li-alloys tse sebetsang hantle ho matlafatsa ho tšoarella le ho sebetsa hantle ha mefuta e mengata ea ho ntša metsi. Lisebelisoa tsena tse tsoetseng pele li kenyelletsa tšepe e matla haholo, tšepe e sa hloekang le tšepe ea aluminiized. Mehaho e phahameng ka ho fetisisa ea li-alloys tsena e lumella mefuta e mengata ea ho ntša metsi ho mamella mocheso o feteletseng le likhase tse senyang. Boqapi bona bo ntlafalitse haholo ts'ebetso e akaretsang ea litsamaiso tsa mosi oa likoloi likoloing tsa sejoale-joale.

Liaparo tsa Ceramic

Liaparo tsa ceramic e se e le khetho e tsebahalang bakeng sa ho ntlafatsa ts'ebetso ea ho qeta nako e ngata. Liaparo tsena li fana ka tšireletso e ntle haholo ea mocheso, ho fokotsa ho fetisoa ha mocheso likarolong tse potolohileng tsa enjene. Liaparo tsa ceramic li boetse li fana ka khanyetso e phahameng ea ho senya le ho apara, ho lelefatsa nako ea bophelo ea mefuta e mengata ea ho qeta nako. Ka ho boloka mocheso o tlase oa holim'a metsi, liphahlo tsa ceramic li thusa ho ntlafatsa ts'ebetso ea enjene le ho fokotsa mesi.

Lintlafatso tsa Moqapi

Computational Fluid Dynamics (CFD) ka Moralo

Hona joale lienjiniere li sebelisa Computational Fluid Dynamics (CFD) ho ntlafatsa meralo e mengata ea ho ntša metsi. CFD e lumella papiso e qaqileng le tlhahlobo ea boitšoaro ba khase e tsoang ka har'a mefuta e mengata. Theknoloji ena e thusa ho theha li-geometri tse rarahaneng tse eketsang phallo ea khase le ho fokotsa khatello ea morao. Tšebeliso ea CFD e lebisitse ntlafatsong e kholo tšebetsong ea enjene le ho sebetsa hantle ha mafura.

Ho kopanya le Turbocharging Systems

Ho kopanngoa ha litsamaiso tsa turbocharging tse nang le manifolds a ho ntša metsi ho fetotse ts'ebetso ea enjine. Li-engines tsa turbocharged li hloka mefuta e mengata ea ho ntša metsi e khonang ho sebetsana le khatello e eketsehileng le mocheso. Lisebelisoa tse tsoetseng pele le meralo e ncha li netefatsa hore mefuta ena e mengata e khona ho tsamaisa likhase tse tsoang ho turbocharger hantle. Ho kopanya hona ho matlafatsa tlhahiso ea matla le ho ntlafatsa moruo oa mafura, ho etsa hore lienjene tsa turbocharged li sebetse hantle le ho arabela.

Malebela a Sebetsang a Tlhokomelo le Lintlafatso

Ho Khetholla Matšoao a ho Qhala le ho Tala

Ho hlahlojoa khafetsa ha li-exhaust manifolds ho bohlokoa bakeng sa ho boloka ts'ebetso e nepahetseng. Matšoao a ho senyeha a kenyelletsa mapetsong a bonahalang, mafome, le lerata le sa tloaelehang le tsoang tsamaisong ea ho ntša metsi. Ho fokotseha ha tšebetso ea enjine kapa ho eketseha ha tšebeliso ea mafura le hona ho ka supa mathata a mangata. Ho lemoha kapele le ho hlokomeloa ka nako ho ka thibela tšenyo e eketsehileng le litokiso tse bitsang chelete e ngata.

Ho Khetha Mokhoa o nepahetseng oa Aftermarket Manifold

Ho khetha mefuta e mengata e nepahetseng ea 'maraka oa morao-rao ho hloka hore ho nahanoe ka hloko lintlha tse' maloa. Ho lumellana le mohlala oa koloi ke habohlokoa ho etsa bonnete ba ho lekana hantle le ts'ebetso e nepahetseng. Lisebelisoa tsa boleng bo phahameng tse kang tšepe e sa hloekang kapa likhetho tse koahetsoeng ka ceramic li fana ka nako e telele le e sebetsang hantle. Ho buisana le litsebi tsa likoloi ho ka fana ka leseli le likhothaletso tsa bohlokoa bakeng sa ho khetha mefuta e mengata e mengata ea li-aftermarket.

Leeto la mefuta e mengata ea exhaust le bonts'a tsoelo-pele e makatsang ho tloha ho meralo ea pele ho isa ho tse ncha tsa sejoale-joale. Ntlafatso e tsoelang pele ea thepa le mekhoa ea tlhahiso e matlafalitse ts'ebetso le ho tšoarella haholo. Bohlokoa ba tsoelo-pele e tsoelang pele theknolojing e mengata ea ho felloa ke matla bo ke ke ba feteletsoa. Ho lula u tseba ka tsoelopele ea nako e tlang ho tla tsoela batho ba chesehelang likoloi le litsebi molemo.

Nako ea poso: Jul-22-2024