Theho felloa ke matlae bapala akarolo ea bohlokoa ts'ebetsong ea enjine. Karolo enae bokella likhase tsa mouoane ho tsoa lisilindareng tse ngataebe o li lebisa phala ea exhaust. Tlhokomelo ea kamehla ea mefuta e mengata ea ho tima e tiisaenjene e sebetsang hantlele ho phela nako e telele. Manifolds a hlokometsoeng hantle a thusa ho ntlafatsa tlhahiso ea enjene, ts'ebetso ea mafura, le ts'ebetso ea koloi ka kakaretso.

Ho utloisisa Mehala e mengata ea Exhaust

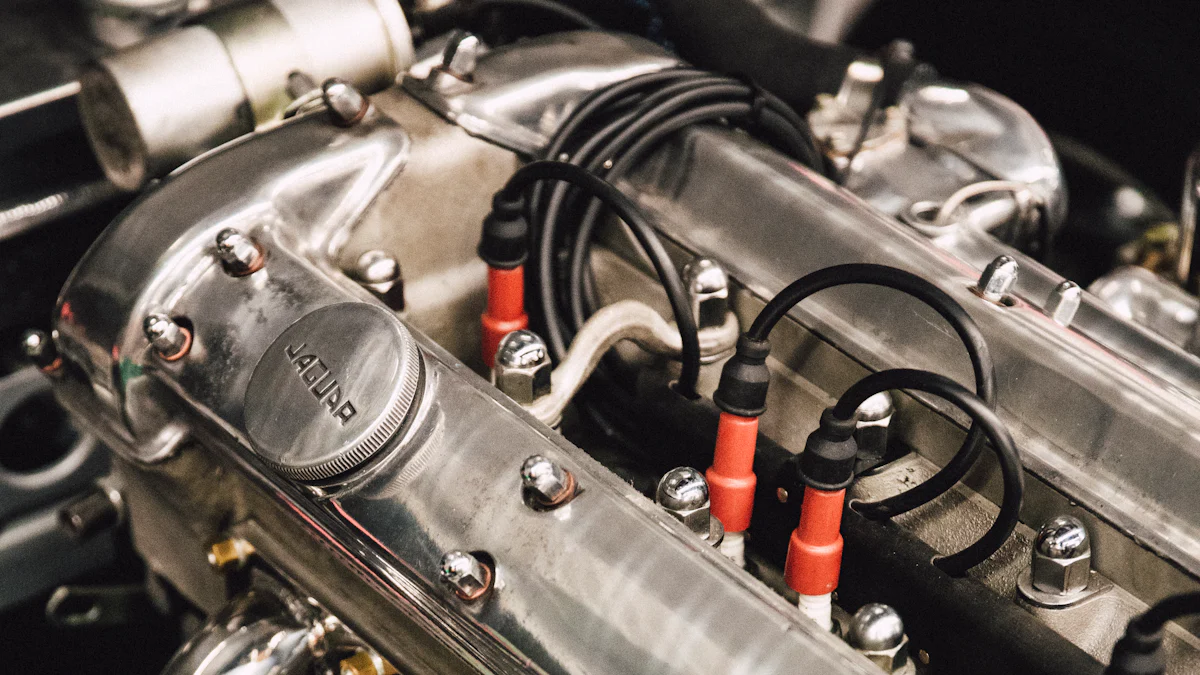

Likarolo tsa Exhaust Manifold

Li-tubes tsa mantlha

Li-tubes tsa mantlha ka har'a mokelikeli o mongata o kopanya moqomo o mong le o mong ho mokelli. Li-tubes tsena li sebetsana le mocheso o phahameng 'me li tsamaisa likhase tsa ho ntša metsi ka katleho. Lisebelisoa tsa li-tubes tse ka sehloohong li tiisa ho tšoarella le ho hanyetsa ho bola.

'Mokelli

Mopokelli o kopanya likhase ho tloha ho li-tubes tsa mantlha ho kena phala e le 'ngoe. Moralo ona o ntlafatsa phallo ea likhase tsa mouoane. Mokelli o fokotsa khatello ea morao-rao, e ntlafatsang ts'ebetso ea enjene le katleho ea mafura.

Li-flange

Li-flanges li sireletsa mokelikeli o mongata ho thibela enjene. Likarolo tsena li tiisa tiiso e tiileng ho thibela ho lutla. Li-flange tse kentsoeng hantle li boloka botšepehi ba tsamaiso ea ho qeta nako.

Mesebetsi ea Exhaust Manifold

Ho bokella Likhase tsa Exhaust

The exhaust manifolde bokella likhase ho li-cylinders tse ngata. Mokhoa ona oa pokello o tsamaisa likhase hore e be phala e le 'ngoe ea mosi. Pokello e sebetsang hantle ea khase e fokotsa kotsi ea ho khutlela morao.

Ho Fokotsa Mosi

Mohaho o mongata o bapala karolo ea ho fokotsa mesi. Ka ho tsamaisa likhase ka converter ea catalytic, manifold e thusa ho theola litšila tse kotsi. Mosebetsi ona o kenya letsoho ho sireletsa tikoloho.

Ho Ntlafatsa Bokhoni ba Enjene

Manifold exhaust e ntlafatsa ts'ebetso ea enjene ka ho ntlafatsa phallo ea mosi. Phallo e nepahetseng ea mosi e ntlafatsa ho tuka le ho fokotsa khatello ea enjene. Bokhoni bo ntlafetseng bo lebisa moruong o betere oa mafura le ts'ebetso ea koloi ka kakaretso.

Malebela a Tlhokomelo a Thibelo

Litlhahlobo Tsa Kamehla

Litlhahlobo tse bonoang bakeng sa Mapetso le ho lutla

Litlhahlobo tsa kamehla tsa pono li thusa ho tseba mathata a ka bang teng esale pele. Lekola mokelikeli o mongata bakeng sa mapetsong a bonahalang. Sheba matšoao leha e le afe a ho lutla ho pota-potileng flanges le gaskets. Mapetso le ho dutla ho ka lebisa mathateng a tshebetso ya enjene. Ho rarolla mathata ana hang-hang ho thibela tšenyo e eketsehileng.

Ho Mamela Melumo e sa Tloaelehang

Hangata melumo e sa tloaelehang e bontša hore ho na le mathata a ho ntša metsi. Mamela melumo ea ho tekena kapa e llang ha enjene e ntse e sebetsa. Melumo ena e ka 'na ea fana ka maikutlo a hore ho na le ho lutla kapa ho phunyeha ha mefuta e mengata. Ho lemoha kapele ho lumella ho lokisoa ka nako, ho boloka ts'ebetso e nepahetseng ea enjene.

Ho Hloekisa Mehala e mengata ea Exhaust

Ho Tlosa Lichelete tsa Khabone

Li-deposit tsa carbon li bokellana ka bongata ha nako e ntse e ea. Li-deposit tsena li ka sitisa phallo ea likhase tsa mouoane. Sebelisa borashe ba terata ho tlosa carbon buildup. Netefatsa hore enjene e pholile ka ho feletseng pele e hloekisa. Ho hloekisa ka mokhoa o nepahetseng ho ntlafatsa ts'ebetso ea sistimi ea ho tima.

Ho Sebelisa Lisebelisoa tse Loketseng Tsa ho Hloekisa

Khetha lisebelisoa tse loketseng tsa ho hloekisa bakeng sa mefuta e mengata ea ho ntša metsi. Qoba lik'hemik'hale tse bohale tse ka senyang bokaholimo ba mefuta e mengata. Sebelisa lihlahisoa tse entsoeng ka ho khetheha bakeng sa lisebelisoa tsa motlakase tsa likoloi. Ho latela litlhahiso tsa moetsi ho tiisa ho hloekisa ho bolokehileng le ho sebetsa hantle.

Ho etsa bonnete ba ho Kenyeha ka nepo

Ho hlahloba Bolts le Gaskets

Ho bohlokoa ho kenya mochini oa mosi ka nepo. Sheba liboutu le li-gaskets khafetsa ho netefatsa hore li lula li bolokehile. Liboutu tse hlephileng li ka baka ho lutla le ho fokotsa bokhoni ba enjene. Tiisa liboutu ho latela lintlha tsa moetsi ho boloka tiiso e nepahetseng.

Ho Hlophisa Manifold ka nepo

Ho lokisoa hantle ha mokelikeli o mongata hoa hlokahala. Ho se tsamaisane hantle ho ka lebisa ho lutla le khatello ea maikutlo e sa lekanang ho mefuta e mengata. Netefatsa hore manifold a hokahana hantle le boloko ba enjene nakong ea ho kenya. Khokahano e nepahetseng e eketsa nako ea bophelo ea mefuta e mengata ea ho tima le ho ntlafatsa ts'ebetso ka kakaretso.

Bopaki ba Setsebi:

Setsebi se Tšoanelehang, setsebi sa mekhoa ea ho qeta likoloi, e hatisa bohlokoa ba ho hlahlojoa kamehla le tlhokomelo e nepahetseng. Ak'u nahane ka ho ba le mochine oa exhaust o sebeletsoang ke setsebi se hloahloa se sebetsanang ka ho khetheha le tsamaiso ea mouoane oa likoloi.

Moetsi oa Setsebi, e tsejoang ka mokhoa o tloaelehileng oa ho qeta mekhoa e mengata, e totobatsa karolo ea passivation ho boloka mefuta e mengata. "Passivation ke ts'ebetso ea lik'hemik'hale e thusang ho tlosa litšila le likoli,ho matlafatsa kganetso ya kutu. Ka kakaretso, li-exhaust manifolds li pepesehela mocheso o phahameng le likhase tse senyang, ka hona li hloka hore motho a fete. Ts'ebetso ena e thusa ho etsa filimi e sireletsang holim'a lintho tse ngata, e e sireletsang likhaseng tse senyang, kahoo e ntlafatsa nako ea eona ea bophelo. "

Matšoao a Ho Hlōleha ka Metsi a Exhaust

Matšoao a Tloaelehileng

Li-Engine Mifire

Hangata ho fosa ha enjine ho bontša mathata a ho ntša metsi. Li-multifolds tse fosahetseng li ka senya motsoako oa mafura a moea. Tšitiso ena e baka mollo o sa fellang, o bakang mello e fosahetseng. Ho hlahlojoa khafetsa ho thusa ho tseba le ho rarolla mathata ana esale pele.

Ho Fokotsa Matla a Mafura

Phokotso ea tšebeliso ea mafura e sebetsa e le sesupo se seng sa ho hloleha ho felloa ke matla ka makhetlo a mangata. Ho dutla ka bongata ho dumella moya o sa lekanyetswang ho kena enjeneng. Moea ona o eketsehileng o ama ts'ebetso ea enjene le tšebeliso ea mafura. Ho lekola ts'ebetso ea mafura ho thusa ho lemoha mathata a mangata.

Melumo e sa tloaelehang

Melumo e sa tloaelehang e ka 'na ea bontša hore ho na le mefuta e mengata ea ho ntša metsi. Melumo ea ho ts'oara kapa ea mololi hangata e tsoa ho mapetsong kapa ho lutlang. Hangata lerata lena le bonahala haholo nakong ea ho potlakisa. Ho lemoha melumo ena esale pele ho lumella ho lokisoa ka nako.

Ho Hlahlobisisa Mathata

Ho Sebelisa Lisebelisoa tsa Tlhahlobo

Lisebelisoa tsa ho hlahloba li thusa ho khetholla mathata a mangata a mangata. Teko ea mosi e ka senola ho lutla ka bongata. Ho lekanya khatello ea mokhathala ho thusa ho lemoha li-blockages. Ho sebelisa lisebelisoa tsena ho netefatsa tlhahlobo e nepahetseng le tokiso e sebetsang.

Ho Buisana le Setsebi sa Mechini

Ho buisana le mochini oa setsebi ho fana ka leseli la litsebi mabapi le mathata a mangata a mangata. Mechine e na le lisebelisoa tse khethehileng bakeng sa tlhahlobo e phethahetseng. Ba ka khothaletsa ts'ebetso e ntlehali ea ho lokisoa kapa ho e ncha. Ho tšepa setsebi ho tiisa nako e telele le katleho ea tsamaiso ea ho qeta nako.

Mehato e khethehileng ea ho hlahloba

Tlhahlobo ea Pono

Ho hlahloba Li-Cracks le Rust

Lekola mokelikeli o mongata bakeng sa mapetsong a bonahalang le mafome. Mapetso a ka hlaha ka lebaka la mocheso o phahameng le khatello ea maikutlo. Mafome a hlaha ha mongobo o kopana le bokaholimo ba tšepe. Sebelisa toche ho hlahloba libaka tseo ho leng thata ho li bona. Ela hloko ka hloko li-tubes tse ka sehloohong le li-flanges. Shebana le matšoao afe kapa afe a tšenyo hang-hang ho thibela litaba tse ling.

Ho hlahloba Li-Gaskets le Litiiso

Li-gaskets le li-seal li bapala karolo ea bohlokoa ho boloka botšepehi ba mefuta e mengata ea ho ntša metsi. Lekola likarolo tsena hore na ha li senyehile. Sheba matšoao a ho lutla ho potoloha li-gaskets. Gasket e senyehileng e ka etsa hore likhase tsa mouoane li balehe, e leng se lebisang mathateng a ts'ebetso ea enjene. Kenya sebaka sa li-gaskets tse tsofetseng ho netefatsa tiiso e nepahetseng.

Teko ea Ts'ebetso

Ho Etsa Tlhahlobo ea Mosi

Teko ea mosi e thusa ho tseba ho lutla ha mosi oa mosi. Kenyelletsa mosi ka har'a sistimi ea ho ntša metsi 'me u shebe moo o tsoang teng. Ho lutla ho tla bonahala ha mosi o tsoa ka mapetsong kapa likheong. Tlhahlobo ena e fana ka pontšo e hlakileng ea moo ho lokisoang ho hlokahalang. Etsa tlhahlobo ea mosi sebakeng se nang le moea o motle bakeng sa polokeho.

Ho lekanya Khatello ea ho Exhaust

Ho lekanya khatello ea mokhathala ho thusa ho lemoha li-blockages ka har'a mefuta e mengata ea ho ntša metsi. Sebelisa tekanyo ea khatello ho lekanya khatello ea ho tsoa libakeng tse fapaneng. Bapisa lipalo le litlhaloso tsa moetsi. Khatello e phahameng e bontša ho thibela, ha khatello e tlaase e fana ka maikutlo a ho lutla. Litekanyo tse nepahetseng li netefatsa tlhahlobo e sebetsang le ho lokisoa.

Setsebi se Tšoanelehange hatisa bohlokoa ba ho hlahloba ka botlalo. “Keletso ea litsebi’me ho lokisoa ho hlokahalang kapa ho nkeloa sebaka ho ka lelefatsa bophelo ba mosi oa mosi.”

Litlhahlobo tsa khafetsa le tlhahlobo ea ts'ebetso li boloka ts'ebetso le nako e telele ea ho qeta nako e ngata. Tlhokomelo e nepahetseng e thibela ho lokisoa ho theko e boima mme e netefatsa ts'ebetso e nepahetseng ea enjene.

Ho boloka mefuta e mengata ea ho tima ho netefatsa ts'ebetso e nepahetseng ea enjene le bophelo bo bolelele. Ho hlahlojoa kamehla le tlhokomelo e nepahetseng ho thibela ho lokisoa ho bitsang chelete e ngata. Ho latela litlhahiso tse fanoeng ho tla thusa ho tseba mathata esale pele. Mohaho o mongata o hlokometsoeng hantle o ntlafatsa tšebetso ea mafura le ho fokotsa mesi. Tlhokomelo e tsitsitseng e ntlafatsa ts'ebetso ea koloi ka kakaretso. Etelletsa pele ho boloka lintho tse ngata tsa ho ntša metsi bakeng sa enjene e tšepahalang le e sebetsang hantle.

Nako ea poso: Jul-25-2024