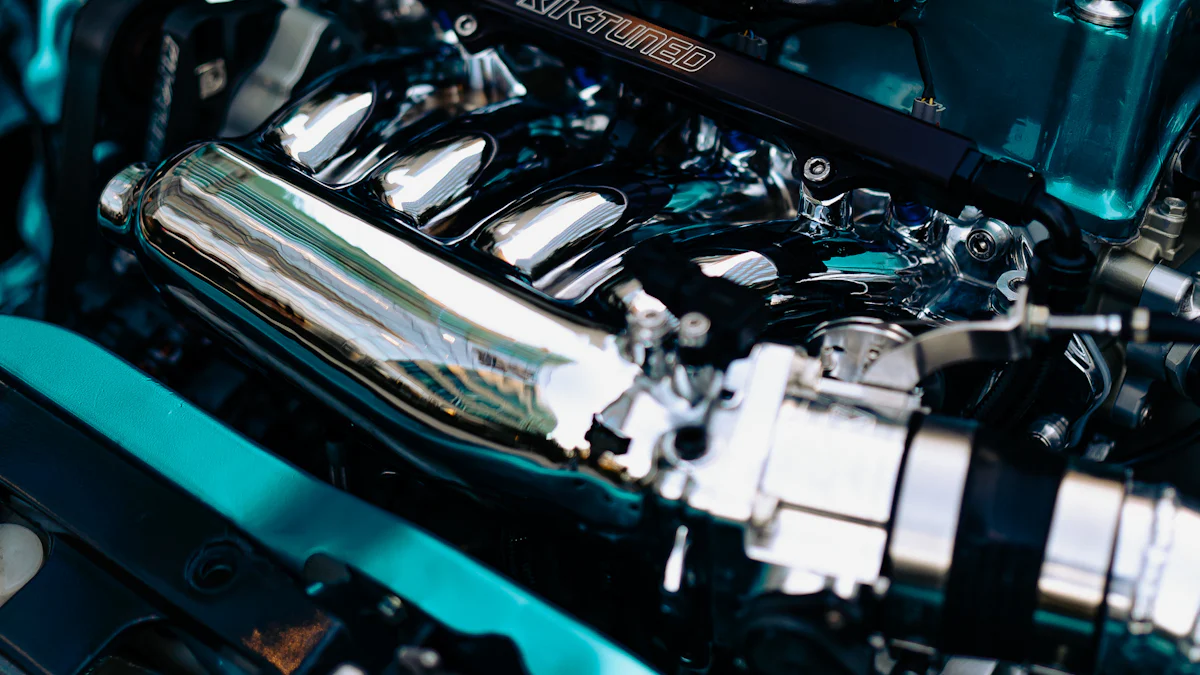

Ho hatisa bohlokoa balitlhaloso tse nepahetseng tsa torqueke ea bohlokoa ho netefatsa ts'ebetso e nepahetseng eaEngine Exhaust Manifold. Ho utloisisa li-nuances tsa6.0 LS enjenee bohlokoa hore batho ba chesehelang maikutlo le bo-mak'henike ka ho tšoanang ba ananele matla le bokhoni ba eona ka botlalo. Ka ho khomarela ka nepo6.0 LSExhaust Manifold Bolt Torque Specs, motho a ka notlolla melemo e mengata, ho kenyeletsoa nako e telele ea enjene le ho ntlafatsa katleho ka kakaretso.

Ho utloisisa mefuta e mengata ea Exhaust

Ha ho tluoa tabengMehaho e mengata ea ho ntša enjene, likarolo tsena li phetha karolo ea bohlokoa tšebetsong e ntle ea enjene. TheDormanExhaust Manifold Bolte bohlokoa bakeng sa ho boloka mefuta e mengata sebakeng sa eona le ho thibela ho lutla hofe kapa hofe ho ka amang ts'ebetso.

Exhaust Manifold ke eng?

Theho felloa ke matla ha enjenee sebetsa e le monyako oa ho ntša likhase tse tsoang ka har'a lisilindara tsa enjene. Mosebetsi oa eona o ka sehloohong ke ho bokella likhase tsena ho li-cylinders tse ngata le ho li tsamaisa ho ea phala ea exhaust bakeng sa ho tsoa. Ts'ebetso ena e netefatsa hore enjene e sebetsa hantle ntle le tšitiso ea ho khutla.

Mosebetsi le Bohlokoa

Bohlokoa ba hoho felloa ke matlae ipapisitse le bokhoni ba eona ba ho tsamaisa phallo ea likhase tsa mouoane, ho thibela tšitiso efe kapa efe lipakeng tsa meqomo. Ka ho tataisa likhase tsena ka katleho ho tsoa enjeneng, e ntlafatsa ts'ebetso e akaretsang le ts'ebetso ea mafura.

Mefuta e mengata ea Exhaust Manifolds

Ho na le mefuta e fapaneng eaho felloa ke matlae fumanehang, e 'ngoe le e' ngoe e iphelisa ka litlhoko tse khethehileng tsa enjene. Ho tloha likhethong tsa tšepe tse entsoeng ka tšepe tse tsejoang ka ho tšoarella ha tsona le ho boloka litšenyehelo homefuta e fapaneng ea tšepe e sa hloekange fana ka khanyetso ea kutu, ho khetha thepa e nepahetseng ho ka ama ts'ebetso ea koloi ea hau haholo.

Mehaho e mengata ea Exhaust e tšoarellang

Ho tsetela sebakeng se tšoarellangho felloa ke matlae ka tlisa melemo e mengata bakeng sa koloi ea hau. Ebang ke kaho e matla e mamellang mocheso o phahameng kapa nako e telele e netefatsang tšebeliso e telele, ho khetha thepa ea boleng bo holimo ho ka ntlafatsa ts'ebetso ea enjine ea hau.

Likarolo tsa Manifold Exhaust e tšoarellang

- Ho hanyetsa Mocheso: E mamella mocheso o phahameng ntle le ho senya ts'ebetso.

- Khanyetso ea Corrosion: Sireletsa khahlanong le mafome le ho senyeha ha nako e ntse e ea.

- Bophelo bo bolelele: Netefatsa tšebeliso ea nako e telele le ho ts'epahala ha koloi ea hau.

Melemo ea ho Sebelisa Mehaho e Melelele ea ho Exhaust

- Tshebetso e Ntlafetseng: Ntlafatsa bokhoni ba enjene le tlhahiso ea matla.

- Ho Tšepahala Nako E telele: Fokotsa litlhoko tsa tlhokomelo ka likarolo tse tšoarellang.

- Litšenyehelo-Ka katleho: Qoba ho nkela sebaka khafetsa ka ho tsetela likarolong tsa boleng.

Exhaust Liboutu Tse Ngata

Le hoja hangata e hlokomolohuoa,Exhaust Liboutu Tse Ngatake likarolo tsa bohlokoa tse tiisang hore bongata bo teng. Ho khetha mofuta o nepahetseng oa bolt ho netefatsa ho kengoa hantle le ho thibela ho lutla ho ka bang teng ho ka ama ts'ebetso ea enjine ea hau.

Karolo ea Exhaust Manifold Bolts

- Ka tsela e sireletsehileng tiisa monko o mongata oa ho ntša metsi ho thibela ho lutla.

- Boloka tumellano e nepahetseng pakeng tsa lihlooho tse ngata le li-cylinder.

Mefuta e meng ea li-Bolts tsa Exhaust Manifold

- Standard Steel Bolts: Khetho e tloaelehileng bakeng sa likopo tse akaretsang.

- Matla a Alloy Bolts a Phahameng: E loketse lienjineri tse boima kapa tse sebetsang hantle haholo.

Exhaust Manifold Hardware Kit

Ha ho tluoa tabengExhaust Manifold Hardware Kits, li kenyelletsa letoto la likarolo tsa bohlokoa bakeng sa ho boloka manifold oa ho tsoa. Hangata, lisebelisoa tsena li kenyelletsaliboutu, linate, li-washer, le lisebelisoa tse ling tse hlokahalang ho netefatsa khokahanyo e sireletsehileng le e ka tšeptjoang pakeng tsa mefuta e mengata le enjene.

Likaroloana tsa Exhaust Manifold Hardware Kit

- Liboutu: Tiisa matla a mangata a ho ntša metsi ka mokhoa o sireletsehileng ho thibela ho lutla.

- Linate: Fana ka tšehetso e eketsehileng le botsitso ho kopano.

- Lihlatsoa: Abela khatello ka ho lekana libakeng tsohle tsa khokahano.

- Li-gaskets: Tiisa likheo leha e le life kapa ho sa tsamaeeng hantle lipakeng tsa manifold le bokaholimo ba enjine.

Likarolo tsena li sebetsa 'moho ka mokhoa o ts'oanelang ho theha khokahano e matla le e tšoarellang e ka mamellang mocheso o phahameng le ho thothomela, ho netefatsa ts'ebetso e nepahetseng ea sistimi ea mouoane.

Bohlokoa ba ho Sebelisa Hardware ea Boleng bo Phahameng ea Exhaust Manifold

Ho tsetela hoboleng bo phahameng Exhaust Manifold Hardwareke ea bohlokoa ka mabaka a 'maloa. Taba ea pele, lisebelisoa tsa boleng bo holimo li tiisa ho lekana le ho sireletseha, ho thibela ho lutla hofe kapa hofe ho ka senyang ts'ebetso ea enjine. Taba ea bobeli, hardware e tšoarellang e ka mamella maemo a feteletseng, ho kenyelletsa le lipotoloho tsa mocheso le ho thothomela, ntle le ho lokoloha ha nako e ntse e ea.

Ka ho khetha lisebelisoa tsa boleng bo holimo ho tsoa ho bahlahisi ba tsebahalang joalo kaWerkwell, o netefatsa boenjiniere bo nepahetseng le ho tšepahala karolong e 'ngoe le e 'ngoe. Tšebeliso ea lisebelisoa tsa boleng ha e ntlafatse nako e telele ea tsamaiso ea hau ea ho qeta nako e telele empa hape e tlatsetsa katlehong ea koloi ka kakaretso.

6.0 LS Exhaust Manifold Bolt Torque Specs

Litlhaloso tse khethehileng tsa Torque bakeng sa 6.0 LS

Litlhaloso tsa Pele tsa Torque ea Pele

Ha u sireletsa6.0 LS e qeta liboutu tse ngatanakong ea phallo ea pele, ho bohlokoa ho sebelisa torque ea15 Nm (11 lb-ft). Tlhaloso ena e nepahetseng e tiisa hore liboutu li tiisitsoe ka ho lekaneng ntle le ho beha kotsi ea ho senya likarolo.

Litlhaloso tsa Final Pass Torque

Bakeng sa pasa ea ho qetela ea torquing thetlosa liboutu tse ngata, e kgothaletswa ho etsa kopo torque ea25 Nm (18 lb-ft). Mohato ona o tiileng o tiisa hore liboutu li tlameletsoe ka mokhoa o sireletsehileng, li tlatselletsa ts'ebetsong e nepahetseng ea enjene le ho phela nako e telele.

ChevroletPhehello ea Sepolesa sa Silverado

Lintlha tsa Torque bakeng saChevrolet Silverado Sepolesa Phehello

Boemong baChevrolet Silverado Police Pursuit likoloi, ho latela litlhaloso tse khethehileng tsa torque ke ntho ea bohlokoa bakeng sa ho boloka ts'ebetso e sebetsang hantle le polokeho. Torque e khothalletsoang bakeng satlosa liboutu tse ngatalikoloing tsena li tsamaisana le maemo a indasteri ho netefatsa ts'ebetso e tšepahalang tlasa maemo a boima.

Bohlokoa ba Torque e Loketseng Likoloing tsa Sepolesa

Bohlokoa ba ho latela lintlha tse nepahetseng tsa torque hoChevrolet Silverado Sepolesa Phehellolikoloi ha li khone ho fetelletsa litaba. Ka ho phunya bolt e 'ngoe le e' ngoe ka hloko ho latela litataiso tsa moetsi, mekhatlo ea ts'ebetso ea molao e ka ts'ehetsa ts'epahalo ea koloi, ho itokisetsa ts'ebetso, le polokeho ea liofisiri nakong ea mesebetsi e mahlonoko.

Super Cruise Deep Dive

Kameho ea Torque Specs ho Super Cruise

Ha u ntse u kena ka har'a mekhoa e rarahaneng eaTheknoloji ea Super Cruise, ho utloisisa phello ea litlhaloso tse nepahetseng tsa torque hoa totobala. Ts'ebetso e nepahetseng ea likarolo, ho kenyeletsoa liboutu tse ngata, e bapala karolo ea bohlokoa ho ts'ehetsa likarolo tse tsoetseng pele le ts'ebetso ea likoloi tse nang le Super Cruise.

Ho netefatsa Polokeho le Tshebetso

Ho netefatsa polokeho le ts'ebetso ea likoloi tse nang leTheknoloji ea Super Cruisee hloka tlhokomeliso e hlokolosi ho lintlha, haholo ha e hula likarolo tsa bohlokoa joalo ka liboutu tse ngata tsa ho ntša metsi. Ka ho latela litekanyetso tsa torque tse khothalelitsoeng, bakhanni ba ka ba le botsitso bo ntlafalitsoeng, taolo le boiphihlelo ka kakaretso ba ho khanna.

Lisebelisoa le Tokisetso

Lisebelisoa tse Hlokehang

Ha o itokisetsa ho sebetsana le mosebetsi oa ho thothomelatlosa liboutu tse ngatahao6.0 LS enjene, ho ba le lisebelisoa tse nepahetseng ho bohlokoa bakeng sa sephetho se atlehileng. Sesebelisoa sa mantlha seo u tla se hloka bakeng sa mosebetsi ona ke se tšepahalangWrench ea Torque. Sesebelisoa sena se nepahetseng se u lumella ho sebelisa matla a lekaneng a hlokahalang ho tiisa liboutu ho latela lintlha tsa moetsi ka nepo. Ho feta moo, etsa bonnete ba hore u na le lintlha tsohleLisebelisoa tse ling tsa Bohlokoatse sebetsang hantle, joalo ka sokete sete, ratchet, le likhalase tsa polokeho, ho thusa ts'ebetso e boreleli le e sebetsang hantle.

Mehato ea ho Itokisa

Pele o kenella ka har'a ts'ebetso ea torque, ho bohlokoa ho etsa mehato e phethahetseng ea ho itokisa ho netefatsa hore ntho e 'ngoe le e' ngoe e nepahetse bakeng sa ts'ebetso e se nang moeli. Qala kaHo lekola Mokhabiso oa Molumoka hloko bakeng sa matšoao leha e le afe a tšenyo, ho senyeha, kapa ho lutla ho ka hlokang tlhokomelo ea hang-hang. Hlokomela mapetsong, mafome, kapa likhokahano tse hlephileng tse ka amang ts'ebetso ea enjene ea hau. Hang ha u se u hlahlobile boemo ba mefuta e mengata, tsoela pele kaHo hloekisa le ho lokisa li-bolts. Sebelisa degreaser kapa tharollo ea ho hloekisa ho tlosa litšila, litšila kapa masala ho tsoa liboutung le libakeng tse haufi. Mohato ona o thusa ho thibela tšilafalo nakong ea ho kenya le ho netefatsa ho lekana ho sireletsehileng pakeng tsa lihlooho tse ngata le li-cylinder.

Ka ho latela mehato ena e hlokolosi ea ho itokisa le ho sebelisa lisebelisoa tse hlokahalang ka nepo, u itokisetsa katlehoho hula liboutu tsa hau tse ngata tsa ho tsoaka katleho.

Mokhoa oa mohato ka mohato oa Torque

Phetoho ea pele

Ho beha Koloi

Ho qala ts'ebetso ea torque ka katleho,Ho beha Koloike ea bohlokoa. Ho etsa bonnete ba hore ho na le motheo o tsitsitseng le o bolokehileng bakeng sa mosebetsi o larileng ka pele ho rala motheo oa ho phethahatsa ka nepo. Ka ho hokahanya koloi ka nepo, mechini e khona ho fihlella manifold ea ho tima habonolo, ho thusa ts'ebetso ea ho thothomela e se nang moeli.

Ho fihlella Mohala oa ho Exhaust

Hang ha koloi e se e eme hantle,Ho fihlella Mohala oa ho Exhauste fetoha mohato o latelang ts'ebetsong ea torque. Bo-machine ba tlameha ho tsamaea ka hloko ho potoloha phaposi ea enjene ho fihlela liboutu tse ngata tsa ho ntša metsi. Ho fihlella hona ho lumella ho hlahlojoa le ho itokisetsa ka botlalo pele o qala tatellano ea torquing.

Mokhoa oa Pele oa Torque

Ho sebelisa Torque ea Pele

Ka phihlello ea manifold exhaust e sirelelitsoeng,Ho sebelisa Torque ea Pelee tšoaea mohato oa bohlokoa oa ho netefatsa hore liboutu li tlamisoa ka nepo. Ka ho latela lintlha tsa moetsi le ho sebelisa sekontiri sa torque se behiloeng ho 15 Nm (11 lb-ft), mechini e ka tiisa bolt ka 'ngoe ho theha khokahano e sireletsehileng ea pele. Tšebeliso ena e nepahetseng ea matla e rala motheo bakeng sa mehato e latelang ea torquing.

Ho etsa bonnete ba ho tiisa

Ha mechini e ntse e tsoela peleHo etsa bonnete ba ho tiisa, ho ela hloko lintlha tse qaqileng ke ntho e ka sehloohong ho finyella tsitsipano e tšoanang ea bolt. Ka ho torque ka boutu ka 'ngoe kakhatello e tsitsitseng, likheo tse ka 'nang tsa e-ba teng kapa ho se lekane hoa fokotseha, ho khothalletsa kabo e leka-lekaneng ea matla ho pholletsa le likhokahano tsohle. Mokhoa ona o hlokolosi o ntlafatsa botsitso ka kakaretso le katleho ea ts'ebetso.

Mokhoa oa ho qetela oa Torque ea Pass

Ho sebelisa Torque ea ho qetela

Ho fetela hoHo sebelisa Torque ea ho qetelae bolela mokhahlelo oa ho qetela oa ho boloka liboutu tse ngata tsa ho ntša metsi. Ho beha wrench ea torque ho25 Nm (18 lb-ft)bakeng sa pase ena ea ho qetela e tiisa hore bolt e 'ngoe le e' ngoe e fumana tiiso e lekaneng bakeng sa ts'ebetso e nepahetseng. Ka ho latela mohato ona o hlakileng, mechini e tiisa bots'epehi ba likhokahano, e matlafatsa khahlano le ho hlephisa ho ka bang teng nakong ea ts'ebetso ea enjine.

Ho netefatsa Torque e nepahetseng

Mohato oa ho qetela oa ts'ebetso ea torque o kenyelletsaHo netefatsa Torque e nepahetsengho pholletsa le liboutu tse ngata tsa ho ntša metsi. Ka tlhahlobo e hlophisitsoeng le netefatso ea boleng ba torque, mechini e tiisa hore bolt ka 'ngoe e fihlela litlhoko tse boletsoeng bakeng sa ho tiisa le ts'ireletso. Ts'ebetso ena ea netefatso e sebetsa joalo ka mokhoa oa netefatso ea boleng, e netefatsang ho nepahala ha ho tiisa liboutu le ho fokotsa likotsi tsa mathata a ka hlahang.

Ka ho latela ka hloko ts'ebetso ena ea torque ea mohato ka mohato ka nepo le tlhokomelo, mechini e ts'ehetsa maemo a indasteri bakeng sa ho kenya lienjine tsa 6.0 LS. Qetello ea boiteko bona e fella ka ts'epo e ntlafalitsoeng ea enjine, ts'ebetso e ntlafalitsoeng ea ts'ebetso, le bophelo bo bolelele ba likarolo tsa bohlokoa ka har'a sistimi ea enjine.

Mathata a Tloaelehileng le Litharollo

Exhaust Manifold Bolt Tokiso

Ho Khetholla Bolts Tse Senyehileng

Ha o hlahlobaExhaust Liboutu Tse Ngatabakeng sa mathata a ka bang teng, bo-mak'henike ba tlameha ho ela hloko matšoao a ho tsofala, mafome, kapa ho senyeha. Lipontšo tsena tse bonahalang li ka bontša tšenyo e ka tlaase e ka senyang botšepehi ba khokahanyo ea liboutu. Sheba lintho tse sa tsitsang ka sebopeho, joalo ka ho kobeha kapa mapetsong, a ka fokolisang matla a sebopeho sa bolt mme a lebisa mathateng a ts'ebetso ha nako e ntse e ea.

Ho Sebelisa Setsi sa Tokiso ea Bolt e Mengata

Maemong ao liboutu tse senyehileng li khetholloang nakong ea tlhahlobo, ho sebelisoa aMehaho e mengata ea ho lokisa Bolte ba ea bohlokoa bakeng sa ho khutlisa botšepehi ba khokahano. Li-kits tsena hangata li kenyelletsa lisebelisoa tse khethehileng le lisebelisoa tse etselitsoeng ho rarolla mathata a tloaelehileng a bolt ka katleho. Ka ho latela litaelo tsa mohato ka mohato tse fanoeng ka kit, mechini e ka lokisa liboutu tse senyehileng ka mokhoa o se nang moeli 'me ea etsa bonnete ba hore ho na le sebaka se sireletsehileng pakeng tsa li-exhaust tse ngata le lihlooho tsa cylinder.

Exhaust Manifold Bolt Replacement

Nako ea ho Fetola Bolts

Ho tseba nako ea ho nkela sebakaExhaust Liboutu Tse Ngatae bohlokoa ho boloka tšebetso e nepahetseng ea enjine le ho thibela ho lutla ho ka bang teng. Haeba liboutu li bontšamats'oao a matla a ho tsofala, ho bola, kapa ho hlobola ho ke keng ha lokisoa, hoa hlokahala ho nkeloa sebaka. Ho phaella moo, haeba liboutu li hlōleha ho finyella litekanyetso tsa torque esita le ka mor'a boiteko ba ho lokisoa, ho molemo ho li nkela sebaka ho qoba mathata a mang.

Mehato ea ho Fetola

Ha ho etsoaExhaust Manifold Bolt Replacement, mechini e lokela ho latela mokhoa o hlophisitsoeng ho netefatsa ho kenya le ho tsamaisana hantle. Qala ka ho tlosa liboutu tsa khale ka hloko, u ele hloko maemo a tsona bakeng sa ho beha tse ncha ka nepo. Hloekisa masoba a libolu hantle ho tlosa litšila kapa masalla a ka amang ho lekana ha liboutu tse ncha. Ebe, tiisa liboutu tse ncha ka mokhoa o sireletsehileng u sebelisa litekanyetso tse khothalelitsoeng tsa torque ho netefatsa khokahano e tiileng le e sa lutleng.

Ho rarolla mathata a tloaelehileng

Li-Bolts tse hlephileng

Ketsahalo eaLi-Bolts tsa Exhaust tse hlephilenge ka lebisa litabeng tse fapaneng tse kang ho lutla ha mosi, lerata la enjine, le ho fokotseha ha ts'ebetso ea ts'ebetso. Ho sebetsana le liboutu tse hlephileng ka nepo, mechini e tlameha ho tiisa bolt e 'ngoe le e 'ngoe ka mokhoa o hlophisehileng ho latela litlhaloso tsa moetsi o sebelisa wrench ea torque. Ho netefatsa hore liboutu li tiea ka mokhoa o ts'oanang ho khothaletsa khokahanyo e sireletsehileng le ho thibela ho lokoloha nakong e tlang ka lebaka la ho thothomela ha enjine kapa ho fetoha ha mocheso.

Li-Bolts tse robehileng

Ho kopanaLi-Bolts tsa Exhaust tse Senyehilenge hlahisa mathata a bohlokoa nakong ea mesebetsi ea tlhokomelo 'me e hloka ho tšoaroa ka hloko ho qoba tšenyo e eketsehileng. Ha o tobane le liboutu tse robehileng, mechini e lokela ho sebelisa lisebelisoa tse khethehileng kapa mekhoa ea ho tlosa masala ka mokhoa o sireletsehileng ntle le ho baka kotsi ho likarolo tse haufi. Ha e se e tlositsoe, ho khutlisa liboutu tse robehileng hang-hang ka tse ncha ho netefatsa ts'ebetso e sa sitisoeng ea sistimi ea ho tima le ho thibela ho lutla ho ka bang teng ho ka ama ts'ebetso ea enjine.

Ho pheta lintlha tsa bohlokoa tseo ho buisanoeng ka tsona, ho netefatsae loketsenglitlhaloso tsa torquebakeng saExhaust Liboutu Tse Ngatake ea bohlokoahali. Ka ho latela litekanyetso tse nepahetseng tsa torque joalo ka15 Nm (11 lb-ft)le25 Nm (18 lb-ft), o netefatsa ts'ebetso e nepahetseng ea enjine le bophelo bo bolelele. Amohela lihlahisoa tsa boleng ho tlohaWerkwellho matlafatsa tshebetso ya koloi ya hao le ho tshepeha. Nka khato hona joale ho tseba ka litefiso tsa Werkwell le ho phahamisa boiphihlelo ba hau ba likoloi.

Nako ea poso: Jun-06-2024