Ukuqonda ii-Exhaust Manifolds

Iindidi ze-Exhaust Manifolds

Phosa iiManifolds zentsimbi

Ubuninzi bentsimbi yentsimbi bunika ukuqina kunye nokusebenza kakuhle kweendleko. Ezi manifolds zimelana nobushushu obuphezulu kwaye ziyaxhathisa ukuqhekeka. Nangona kunjalo, ubunzima babo obunzima bunokuchaphazela kakubi ukusebenza kwesithuthi. Ii-iron eziphindaphindekayo zentsimbi zihlala zivela kwiimodeli zezithuthi ezindala okanye ezijonga uhlahlo lwabiwo-mali.

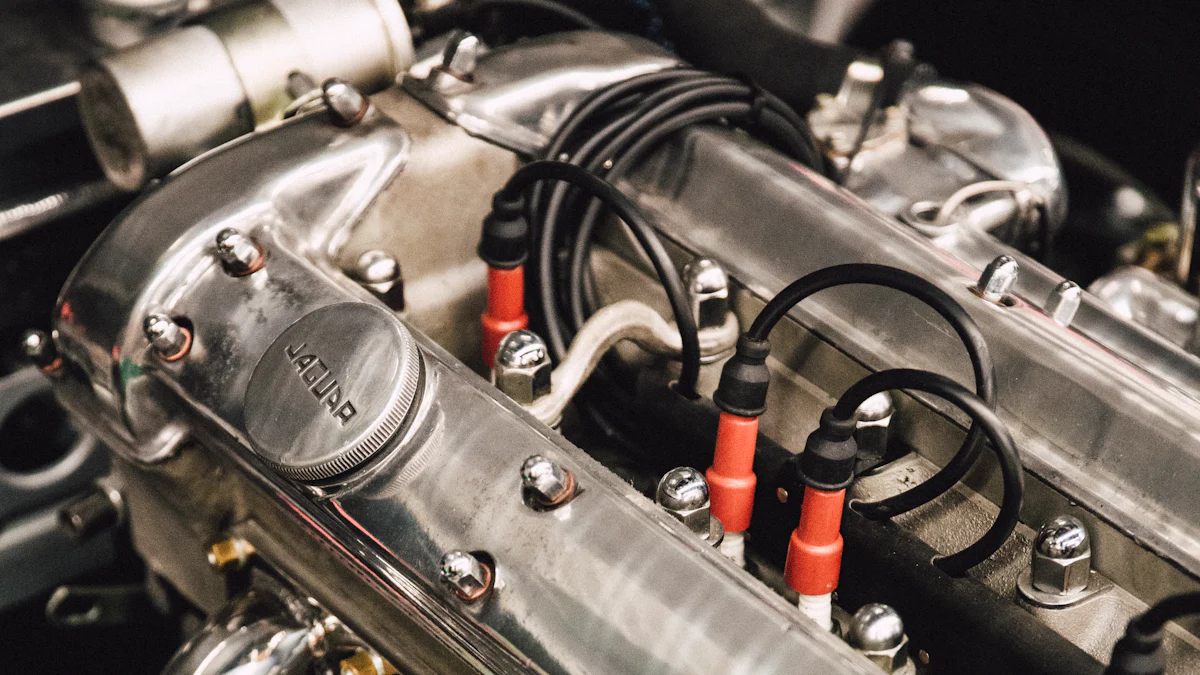

Ii-Manifolds zeNsimbi eNgatyiwayo

Ii-manifolds zensimbi ezingenasici zibonelela ngokulinganisela phakathi kwamandla kunye nobunzima. Ezi zininzi zixhathisa ukubola kwaye zigcina imfezeko yesakhiwo phantsi kweemeko ezinzima. Ubunzima obulula bensimbi engenasici buphucula ukusebenza kakuhle kwesithuthi. Iimoto ezininzi zanamhlanje zisebenzisa ii-manifolds zentsimbi engatyiwayo ukwenza umsebenzi ophuculweyo.

Ii-Tubular Manifolds

Ii-tubular manifolds, ezaziwa ngokuba zii-headers, zinemibhobho nganye kwi-cylinder nganye. Le mibhobho idibana ibe ngumqokeleli omnye. Ii-tubular manifolds zikhulisaukuphuma kwegesikunye nokunciphisa uxinzelelo lwasemva. Abathandi bentsebenzo bahlala bekhetha ii-tubular manifolds ukuze bakwazi ukonyusa amandla.

Umsebenzi kunye noYilo

Indima ekuFanelweni kweNjini

I-exhaust manifold idlala indima ebalulekileyo ekusebenzeni kwe-injini. Uyilo olufanelekileyo luqinisekisa ukuhamba kwegesi ephumayo egudileyo ukusuka kwiisilinda ze-injini ukuya kwinkqubo yokukhupha. Ukuhamba kwerhasi okusebenzayo kunciphisa umva woxinzelelo, okwandisa ukusebenza kwe-injini kunye noqoqosho lwamafutha. I-exhaust manifold ikwanceda ukulawula ubushushu be-injini ngokukhokelela iigesi ezishushu kude nebloko ye-injini.

Iingqwalasela zoyilo

Ukuyila i-exhaust manifold kubandakanya izinto ezininzi ezibalulekileyo. Iinjineli kufuneka zinike ingxelo malunga nokumila kunye nobude bemibhobho emininzi. Ubude obufanelekileyo bombhobho kunye nobubanzi buqinisekisa ukuhamba kwegesi ngokufanelekileyo kunye nokunciphisa i-turbulence. I-manifold kufuneka ilingane ngaphakathi kwe-injini bay ngaphandle kokuphazamisana namanye amalungu. Ukongeza, uyilo kufuneka luququzelele ukufakwa lula kunye nokugcinwa.

Ukukhethwa kwezinto

Ukukhethwa kwezinto eziphathekayo kuchaphazela kakhulu ukusebenza kwe-exhaust ephindaphindayo. Izinto ezikumgangatho ophezulu zimelana noxinzelelo lwe-thermal kunye noomatshini. Intsimbi yentsimbi, intsimbi engatyiwa, kunye noyilo lwetubula nganye ibonelela ngeenzuzo ezizodwa. Intsimbi yentsimbi inika ukuqina, ngelixa insimbi engenasici inika ibhalansi yamandla kunye nobunzima. Ii-tubular manifolds ziphucula ukusebenza ngokuqukunjelwa kokuhamba kwerhasi. Iinjineli kufuneka zikhethe izinto ezifanelekileyo ezisekelwe kwiimfuno ezithile zesithuthi.

Uhlalutyo lweMishini

Iintlobo zokukhutshwa

ICarbon monoxide (CO)

Iifom zekharbhon monoxide ngexesha lokutsha kwepetroli okungaphelelanga. Le gesi ibeka ingozi enkulu kwimpilo, kuquka intloko ebuhlungu kunye nesiyezi. Ubuninzi bombhobho kufuneka busebenze ngokufanelekileyo umjelo wokukhupha iigesi zokunciphisa ukukhutshwa kweCO. Uyilo olululo kunye nokukhethwa kwezinto eziphathekayo kudlala indima ebalulekileyo ekunciphiseni amanqanaba eCO.

Ii-Hydrocarbons (HC)

Iihydrocarbons ziphuma kwisibaso esingatshiswanga esibaleka kwigumbi lokutsha. Ezi khompawundi zinegalelo kwimiba yomsi neyokuphefumla. Uyilo oluninzi lwe-epousti luchaphazela isakhono se-injini sokutshisa amafutha ngokupheleleyo. Uyilo olulungiselelwe lunceda ukunciphisa ukukhutshwa kweHC ngokuqinisekisa ukuhamba kwerhasi ephumayo.

I-Nitrogen oxides (NOx)

Iioksidi zenitrojeni zenza kubushushu obuphezulu bokutsha. Ezi gesi zibangela iingxaki zendalo kunye nempilo, kuquka imvula eneasidi kunye nezigulo zokuphefumla. Ukukhupha okuninzi kuchaphazela ukukhutshwa kwe-NOx ngolawulo lobushushu. Uyilo olusebenzayo lunceda ukugcina ubushushu obuphantsi bokutsha, ngaloo ndlela bunciphisa ukubunjwa kwe-NOx.

Impembelelo ye-Exhaust Manifold kuMisi

Impembelelo yoyilo

Uyilo lwe-exhaust manifold luchaphazela ngokuthe ngqo ukukhutshwa. I-manifold eyilwe kakuhle iqinisekisa ukuhamba kakuhle kwegesi ephumayo, ukunciphisa uxinzelelo kunye nokuphucula ukusebenza kakuhle kokutsha. Uphando lubonisa ukubaUyilo lwe tapered luphucula ukusebenza by ukunciphisa umva woxinzelelo. Ukuhamba kwegesi okuphuculweyo kukhokelela ekukhutshweni okuphantsi kwe-CO, HC, kunye ne-NOx.

Impembelelo yezinto eziphathekayo

Ukukhethwa kwezinto eziphathekayo kuchaphazela kakhulu ukusebenza kwe-exhaust.Intsimbi yentsimbi kunye nentsimbi engatyiwayozizinto eziqhelekileyo ezisetyenziswa kulwakhiwo oluninzi. Intsimbi yokuphosa inika ukuqina kodwa inokonyusa ubunzima. Insimbi engenasici ibonelela ngokulinganisela phakathi kwamandla kunye nobunzima, ukuphucula ukusebenza kakuhle. Zombini izixhobo kufuneka zimelane noxinzelelo lwe-thermal kunye noomatshini ukugcina ukusebenza kakuhle kunye nokunciphisa ukukhutshwa.

Ulawulo lobushushu

Ulawulo lobushushu ludlala indima ebalulekileyo ekulawuleni izinto ezikhutshwayo. Umbhobho wokuphuma kufuneka ukhuphe ubushushu ngokufanelekileyo ukunqanda ubushushu obugqithisileyo bokutsha. Amaqondo obushushu aphezulu akhokelela ekwandeni kokubunjwa kwe-NOx. Ulawulo olusebenzayo lobushushu lunceda ukugcina amaqondo obushushu aphantsi okutsha, ngaloo ndlela kunciphisa ukukhutshwa kwe-NOx. Iimathiriyeli ezikwinqanaba eliphezulu kunye neengubo zokwaleka zinokwandisa ngakumbi isakhono se-manifold sokulawula ubushushu.

Uhlalutyo lwemveliso yamandla

Imiba echaphazela iSiphumo saMandla

I-Exhaust Flow Dynamics

I-Exhaust flow dynamics idlala indima ebalulekileyo ekusebenzeni kwe-injini. Uyilo lwe-exhaust manifold ichaphazela ngokuthe ngqo indlela esebenzayo yokukhupha iigesi eziphuma enjini. I-manifold eyilwe kakuhle iqinisekisa ukuhamba kakuhle kunye nokukhawuleza kwerhasi, ukunciphisa isiphithiphithi. Oku kubangela ukuphefumla kwe-injini okuphuculweyo kunye nokuphucula ukuphuma kwamandla. Iinjineli zihlala zilungisa imilo kunye nobude bemibhobho emininzi ukufikelela kwiimpawu zokuqukuqela ezifanelekileyo.

Uxinzelelo lwangasemva

Uxinzelelo lwangasemva lubhekisa kuxhathiso oludibana neegesi eziphumayo njengoko ziphuma enjini. Uxinzelelo lwangasemva oluphezulu lunokuthintela ukusebenza kwe-injini ngokunqanda ukuhamba kombhobho. Iiheader zokukhupha intsebenzo zijoliseukunciphisa ukumelana nokuhamba, ngokwandisa ukusebenza kakuhle kwe-volumetric ye-injini. I-backpressure ephantsi ivumela i-injini ukuba ikhuphe i-gases ephumayo ngokufanelekileyo, ekhokelela ekuzuzeni ukuveliswa kwamandla. Ii-exhaust eninzi eyakhiwe ngokutshaUyilo luhlala lujolise ekunciphiseni umva wokunyusa ukusebenza kwe-injini.

Ukugcinwa kobushushu

Ukugcinwa kobushushu ngaphakathi kobuninzi bokukhupha kuchaphazela ukusebenza kwe-injini kunye nokukhutshwa kwamandla. Ubushushu obugqithisileyo bunokukhokelela kubushushu obuphezulu bokutsha, obunokunciphisa ukusebenza kwe-injini. Ulawulo olusebenzayo lobushushu lunceda ukugcina amaqondo obushushu asebenzayo. Izinto eziphezulu kunye neengubo zokwaleka kulwakhiwo oluninzi lunokwandisa ukutshatyalaliswa kobushushu. Ukugcinwa kobushushu ngokufanelekileyo kuqinisekisa ukuba injini isebenza ngaphakathi koluhlu olufanelekileyo lobushushu, inyusa ukuphuma kwamandla.

Uvavanyo lokuSebenza

Uvavanyo lweDyno

Uvavanyo lweDyno lubonelela ngendawo elawulwayo ukulinganisa ukusebenza kobuninzi bokukhupha. Iinjineli zisebenzisa i-dynamometer ukulinganisa iimeko zokuqhuba zelizwe lokwenyani. Le ndlela yovavanyo ivavanya ifuthe lezinto ezininzi kwimveliso yamandla, itorque, kunye nokusebenza kakuhle kwamafutha. Uvavanyo lweDyno lunikeza idatha echanekileyo, eyenza ukuba iinjineli zenze izigqibo ezinolwazi malunga noyilo oluninzi kunye nokukhethwa kwezinto eziphathekayo.

Uvavanyo lwehlabathi lokwenyani

Uvavanyo lwehlabathi lokwenyani lugqibezela uvavanyo lwe-dyno ngokuvavanya i-exhaust manifold phantsi kweemeko zokwenyani zokuqhuba. Iinjineli zivavanya indlela ezisebenza ngayo izinto ezininzi kwiimeko ezahlukeneyo, ezinje ngokuqhuba esixekweni, ukuhamba ngoohola bendlela, kunye nokukhawulezisa okunamandla. Uvavanyo lwehlabathi lokwenyani lunceda ukuchonga nayiphi na imiba enokuthi ingabonakali kwindawo elawulwayo. Le ndlela ibanzi iqinisekisa ukuba i-exhaust manifold inikezela ukusebenza okufanayo kwiimeko ezahlukeneyo zokuqhuba.

Uhlalutyo lokuthelekisa

Uhlalutyo lothelekiso lubandakanya ukuphonononga uyilo olwahlukeneyo lokukhupha umbane ukumisela ifuthe lazo kwimveliso yamandla. Iinjineli zithelekisa izinto ezifana ne-exhaust flow dynamics, i-backpressure, kunye nokugcinwa kobushushu. Olu hlalutyo lunceda ukuchonga ezona ziyilo zisebenzayo zokuphucula ukusebenza kwe-injini. Ngokuthelekisa iindlela ezininzi ezahlukeneyo, iinjineli zinokukhomba amandla kunye nobuthathaka boyilo ngalunye. Le nkqubo ikhokelela kuphuculo oluqhubekayo kunye nokuveliswa kwezinto ezintsha kwitekhnoloji ephumayo.

Izinto ezintsha kunye neeNdlela zekamva

Izinto eziphucukileyo

Iingubo zeCeramic

Iingubo zeCeramic ziye zavela njengenkqubela phambili ebalulekileyo kwitekhnoloji yokukhupha izinto ezininzi. Ezi zogquma zibonelela ngokugqwesa ukugquma kwe-thermal, ukunciphisa ukuhanjiswa kobushushu kumacandelo enjini ajikelezileyo. Oku kugqunyelelwa kunceda ukugcina amaqondo obushushu enjini afanelekileyo, ukuphucula ukusebenza kunye nokuphila ixesha elide. Iingubo zeCeramic zikwanikezela ukuchasana okuphezulu kwi-corrosion kunye nokunxiba, ukuqinisekisa ukuqina kokukhupha okuninzi. Iinjineli zeemoto ziya zisanda kwamkela iingubo ze-ceramic ukuphucula ukusebenza kunye nokuthembeka kweenkqubo zokukhupha.

Izinto ezihlanganisiweyo

Imathiriyeli edityanisiweyo imele enye indlela entsha yoyilo lokukhupha izinto ezininzi. Ezi zixhobo zidibanisa izinto ezahlukeneyo ukuphumeza ukulingana kwamandla, ubunzima, kunye nokumelana nokushisa. Ngokomzekelo, i-carbon fiber composites inika umlinganiselo ophezulu wamandla-kuya-ubunzima, okwenza kube yinto efanelekileyo kwizicelo zokusebenza. Ukusetyenziswa kwezixhobo ezidibeneyo kunokunciphisa kakhulu ubunzima bombhobho wokukhupha, okukhokelela ekuphuculeni ukusebenza kwesithuthi kunye nokuphathwa. II-FluidForming iLightweight iStainless SteelUphononongo lwe-Exhaust Manifold Case Studyibonise ukutshintshwa okuyimpumelelo kwezinto ezininzi zentsimbi etyhidiweyo ngentsimbi ekhaphukhaphu, iqaqambisa iingenelo zemathiriyeli ephucukileyo kubunjineli beemoto.

Ukuyila izinto ezintsha

Iintlobo ezininzi zejiyometri eziguquguqukayo

Iijiyometri ezininzi eziguquguqukayo (i-VGM) zimele ukutsha okutsha kuyilo lokukhupha izinto ezininzi. Ii-VGMs zilungelelanisa ubume kunye nobude bemibhobho ephindaphindiweyo ngokusekelwe kwiimeko zokusebenza ze-injini. Oku kuguquguquka kwandisa ukuhamba kwegesi ephumayo, ukunciphisa uxinzelelo kunye nokuphucula ukusebenza kwe-injini. Ii-VGMs zinokuphucula ukusebenza kakuhle kwamafutha kunye nokunciphisa ukukhutshwa kwezinto ezikhutshwayo ngokugcina eyona dynamics ilungileyo yokukhupha kuzo zonke iimeko zokuqhuba. Abavelisi beemoto baphonononga ngakumbi ii-VGMs ukuhlangabezana nemithetho engqongqo yokukhutshwa kunye neemfuno zokusebenza.

Abaguquleli beCatalytic abadityanisiweyo

Ukudibanisa abaguquli be-catalytic ngokuthe ngqo kwi-exhaust manifold kubonelela ngeenzuzo ezininzi. Olu yilo lunciphisa umgama ohamba ngegesi ephumayo ngaphambi kokuba ufikelele kwi-converter ye-catalytic, iphucula ukusebenza kakuhle kokulawula ukukhutshwa. Iziguquli ezidityanisiweyo ze-catalytic zinceda ukufikelela ngokukhawuleza kwamaxesha okucima ukukhanya, ukunciphisa ukukhutshwa kokuqala okubandayo. Oku kudityaniswa kwenza kube lula ukuyila inkqubo yokukhupha, ukunciphisa ubunzima kunye nobunzima. Iimoto ezininzi zanamhlanje ngoku zineenguqu ezidityanisiweyo ze-catalytic ukuhlangabezana nemigangatho yokusingqongileyo ngelixa zigcina ukusebenza okuphezulu.

Uhlalutyo lubalaselisa indima ebalulekileyo yoyilo lokukhupha izinto ezininzi kunye nokukhetha izinto ekuphuculeni ukusebenza kwe-injini kunye nokunciphisa ukukhutshwa. Iziphumo eziphambili zibonisa ukuba imathiriyeli ephucukileyo efana nentsimbi engatyiwayo kunye neengubo zeceramic zongeza ukuqina nokusebenza kakuhle. Uyilo lokuyila okufana nokuguquguquka okuguquguqukayo kwejiyometri kunye neziguquli ezihlanganisiweyo ze-catalytic ziphucula ukusebenza kakuhle kwamafutha kunye nolawulo lokukhutshwa.

Ukuqhubela phambili kwezobuchwepheshe kunyeukutshintsha ukhetho lwabathengikuqhuba iziphumo ezibalulekileyo kushishino lweemoto.Iinkqubo ezisebenzayo zokukhuphakunye nezenzo zokuqhuba zinganciphisa ukukhutshwa kwezithuthi, ezinegalelo ekuzinzeni kokusingqongileyo. Uphando lwexesha elizayo kufuneka lugxininise ekuphuhliseni izixhobo ezikhaphukhaphu kunye noyilo oluyilayo ukuhlangabezana neemfuno eziguqukayo zolawulo kunye nokusebenza.

Ixesha lokuposa: Jul-31-2024