An ukukhupha okuninziisebenza njengenxalenye ebalulekileyo kwindlela yokukhupha isithuthi. Le nxalenye iqokelela iigesi eziphumayo kwiisilinda ze-injini kwaye zizithululele kumbhobho wokukhupha. Ukukhetha iuhlobo olufanelekileyo lokukhuphaiimpembelelo ezinkuluukusebenza injini, ukusebenza kakuhle kwamafutha, kunye nolawulo lokukhutshwa kwegesi. Uyilo olwahlukeneyo kunye nezinto ezihlangabezana neemfuno ezahlukeneyo, ukusuka ekuphuculeni amandla kwiimoto ezisebenza kakhulu ukuyaukuhlangabezana nemithetho engqongqo yongcolisekokwizithuthi eziqhelekileyo.

I-Iron Exhaust Manifolds

Isishwankathelo se-Cast Iron Exhaust Manifolds

Yintoni iCast Iron Exhaust Manifolds?

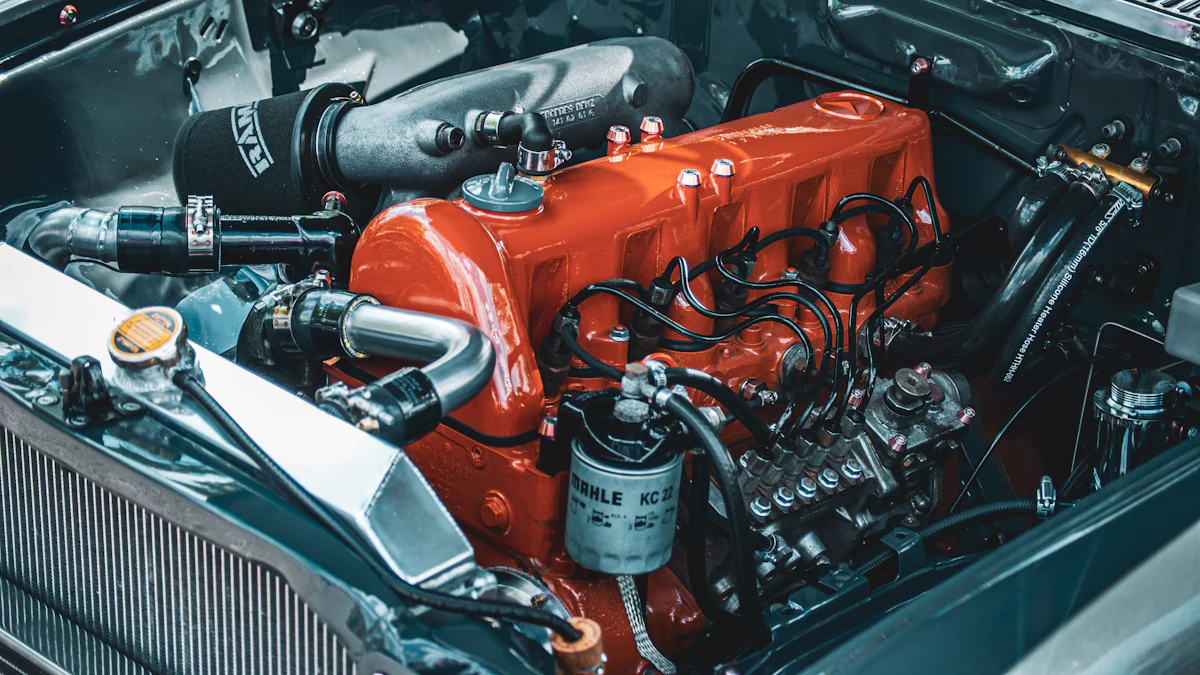

Ubuninzi bentsimbi yokukhupha intsimbi isebenza njengeyona nto ibalulekileyo kwiimoto ezininzi. Ezi manifolds ziqokelela igesi ephumayo kwi-cylinders ye-injini kwaye zikhokelela kwi-exhaust system. Abavelisi bahlala besebenzisa intsimbi etyhidiweyo ngenxa yokuqina kwayo kunye nokusebenza kakuhle kweendleko. Uyilo lubonisa iindlela ezimfutshane, ezingalinganiyo ezidibana zibe ngumqokeleli omnye.

Usetyenziso oluqhelekileyo lwe-Cast Iron Exhaust Manifolds

Uninzi lwabavelisi bezixhobo zoqobo (ii-OEMs) zisebenzisa iindlela zokukhupha intsimbiiimoto zemveliso rhoqo. Ezi manifolds zixhaphakile kwiimoto, iilori, kunye neeSUVs ngenxa yokomelela kwazo kunye nokukwazi ukumelana nobushushu obuphezulu. Ii-iron manifolds ezininzi zikwafumana usetyenziso kwiinjini zedizili, apho zinceda khona ukuphucula ukusebenza ngokulawula ukuhamba kwerhasi ephumayo.

IiPros zeCast Iron Exhaust Manifolds

Ukuqina

Ubuninzi bentsimbi yokukhupha intsimbi kunika ukuqina okukhethekileyo. Izinto eziphathekayo ziyakwazi ukumelana nokushisa okuphezulu kunye neemeko ezinzima ngaphandle kokukhubazeka okanye ukuqhekeka. Oku kwenza ukuba intsimbi ibe lolona khetho lufanelekileyo kwizithuthi ezifuna amacandelo ahlala ixesha elide.

Iindleko-Ukusebenza

Ukusebenza kweendleko zokukhupha isinyithi sentsimbi kubenza badume phakathi kwabavelisi. Ukuvelisa ezi manifolds kubandakanya iindleko eziphantsi xa kuthelekiswa nezinye izinto ezifana nentsimbi engatyiwa okanye ititanium. Oku kufikeleleka kuvumela abavelisi ukuba bagcine amaxabiso ezithuthi ekhuphisana ngelixa beqinisekisa ukusebenza okuthembekileyo.

Ii-Cons of Cast Iron Exhaust Manifolds

Ubunzima

Enye intsilelo ebalulekileyo yobuninzi bentsimbi yokukhupha intsimbi bubunzima bazo. Intsimbi yentsimbi inzima kakhulu kunezinye izinto ezifana nentsimbi engatyiwayo okanye ialuminiyam. Obu bunzima bongezelelweyo bunokuchaphazela kakubi ukusebenza kwesithuthi kunye nokusebenza kakuhle kwamafutha.

Ukugcinwa kobushushu

Ubuninzi bentsimbi yokukhupha intsimbi ikholisa ukugcina ubushushu ngaphezu kwezinye izinto. Oku kugcinwa kobushushu kunokukhokelela kubushushu obuphezulu be-injini, obunokuthi buchaphazele amanye amacandelo. Ukongeza, ubushushu obugqithisileyo bunokuba negalelo ekwakhekeni kweentanda ekuhambeni kwexesha, ukunciphisa ixesha lokuphila le-manifold.

Ii-Manifolds zokukhupha isinyithi esingenasici

Amagqabantshintshi eeManifolds zokuPhuma kwentsimbi engatyiwayo

Ziziphi iiManifolds zokukhupha iStainless Steel?

Iimanifolds zokukhupha intsimbi engenastainless zisebenza njengenye indlela ehambele phambili kwiindlela ezininzi zentsimbi. Ezi manifolds ziqokelela igesi ephumayo kwi-cylinders ye-injini kwaye zikhokelela kwi-exhaust system. Abavelisi basebenzisa insimbi engenasici ngenxa yeempawu zayo eziphezulu, kuquka ukuchasana nokugqwala kunye nokubola. Uyilo luhlala lubonisa iindlela zobude obulinganayo, ezinceda ukwandisa ukuhamba kwamanzi kunye nokuphucula ukusebenza kwe-injini.

Ukusetyenziswa okuqhelekileyo kweeManifolds zokukhupha intsimbi engatyiwayo

Izithuthi ezisebenza ngokuphezulu zihlala zisebenzisa i-stainless steel exhaust manifolds. Ezi manifolds zikwafumana usetyenziso kwiimoto zemidlalo kunye nezithuthi zodidi oluphezulu, apho ukusebenza kunye nobuhle bubalulekile. Uninzi lwabavelisi beendawo zentengiso yasemva kwentengiso babonelela ngezinto ezininzi zentsimbi engatyiwayo njengophuculo lwabashisekeli abajonge ukomeleza ukusebenza kwezithuthi zabo kunye nobomi obude.

IiPros ze-Stainless Steel Exhaust Manifolds

Ukunyangwa kokuMhlwa

Ii-manifolds zokukhupha intsimbi engenastainless zibonelela ngokugqwesileyoukumelana nomhlwa. Esi sixhobo sinokumelana neemeko ezibuhlungu zendalo ngaphandle kokugqwala, okwenza kube lula kwizithuthi ezivezwe kumswakama kunye netyuwa yendlela. Ukumelana nokubola kuqinisekisa ubomi obude xa kuthelekiswa nezinye izinto.

Ukunciphisa Ubunzima

Intsimbi emdaka ekhupha manifoldsngokuphawulekayo khaphukhaphukuneentsimbi ezityhidiweyo. Ubunzima obuncitshisiweyo bunegalelo ekusebenzeni kakuhle kwesithuthi kunye nokusebenza kakuhle kwamafutha. Amacandelo alula kwakhona anciphisa ubunzima obupheleleyo kwi-injini, ekhokelela ekuphuculeni ubomi obude kunye nokuthembeka.

Ii-Cons of Stainless Steel Exhaust Manifolds

Iindleko

I-drawback ephambili ye-stainless steel exhaust manifolds lixabiso labo. Ukwenziwa kwezi ntlobo zininzi kubandakanya iindleko eziphezulu ngenxa yeempawu zemathiriyeli kunye nobunzima benkqubo yemveliso. Le ndleko yonyukayo yenza ukuba izinto ezininzi zensimbi ezingenasici zifikeleleke kubathengi abaqaphela uhlahlo lwabiwo-mali.

Enokubakho kwi-cracking

I-stainless steel exhaust manifolds, ngelixa ihlala ihleli, inamandla okuqhekeka phantsi kweemeko ezinzima. Utshintsho olukhawulezayo lobushushu kunye neendawo ezinoxinzelelo oluphezulu zinokubangela ukuba insimbi engenasici iphuhlise iintanda ngokuhamba kwexesha. Ufakelo olufanelekileyo kunye nokugcinwa kunokunciphisa lo mngcipheko, kodwa luhlala luqwalaselwa kubasebenzisi.

Iintloko zeTubular

Isishwankathelo sezihloko zeTubular

Yintoni iTubular Headers?

Iintloko zeTubula, ezikwabizwa ngokuba zii-exhaust headers, zineetyhubhu ezizimeleyo ezidibanisa i-cylinder ye-injini nganye kumbhobho omnye wokuqokelela. Ezi zihloko zijolise ekwandiseni ukuhamba kweegesi zokukhupha,ukunciphisa uxinzelelo lwasemvakunye nokuphucula ukusebenza kwe-injini. Abavelisi bahlala besebenzisa imathiriyeli efana nentsimbi, intsimbi engatyiwa, i-titanium, okanye i-Inconel ukwenza iiheader ze-tubular. Uyilo ngokuqhelekileyo lubonisa iityhubhu zobude obulinganayo ukuqinisekisa ukuhamba kwegesi efanayo kwi-cylinder nganye.

Usetyenziso oluqhelekileyo lwezihloko zeTubular

Izithuthi ezisebenza ngokuphezulu zihlala zisebenzisa iiheader ze-tubular ukwandisa ukuphuma kwamandla. Ezi zihloko zikwafumana izicelo kwiimoto zemidlalo kunye nezithuthi zomdyarho apho yonke intwana yokusebenza ifumana imicimbi. Uninzi lwabantu abathanda iimoto bakhetha iiheader ze-tubular njengophuculo lwasemva kwentengiso ukuphucula amandla eemoto zabo kunye netorque.

IiPros zeTubular Headers

UkuPhuculwa koMsebenzi

Iintloko zeTubula zinika ukuphuculwa okubalulekileyo kokusebenza ngokunciphisa uxinzelelo lwasemva kwinkqubo yokukhupha. Oku kuncitshiswa kuvumela injini ukubaphefumla ngokulula, okukhokelela ekwandeni kwamandla eehashe kunye netorque. Uphando luye lwabonisa ukubaiiheader zetyhubhu ezinde, ngokukodwa, ukubonelela ngokukhupha ukuhamba ngokukhawuleza xa kuthelekiswa neentloko ze-tube ezimfutshane, ukuphucula ngakumbi ukusebenza. Izihloko nazo zinegalelongcono injini, okuvumela ixesha elide kunye nokwandiswa kokudityaniswa kwekhamera.

Ukunciphisa Ubunzima

Iiheader zetyhubhu zihlala zikhaphukhaphu kuneendlela zokukhupha intsimbi yesiko. Oku kunciphisa ubunzima kunegalelo ekuphuculeni ukusebenza kwesithuthi kunye nokusebenza kakuhle kwamafutha. Izinto ezikhaphukhaphu zibeka ubunzima obuncinci kwi-injini, ekhokelela kubomi obude kunye nokuthembeka. Intsimbi yentsimbi kunye neentloko zetitanium zibonelela ngogcino lobunzima olongezelelweyo ngaphandle kokubeka esichengeni ukuqina.

I-Cons ye-Tubular Headers

Iindleko

I-drawback ephambili yeentloko ze-tubular yindleko yazo. Ukuveliswa kwezi zihloko kubandakanya iindleko eziphezulu ngenxa yezinto ezisetyenzisiweyo kunye nobunzima boyilo. Izinto ezikumgangatho ophezulu njengensimbi engenasici kunye ne-titanium zongeza kwiindleko ezipheleleyo, okwenza iintloko ze-tubular zifikeleleke kubathengi abaqaphela uhlahlo lwabiwo-mali. Ngaphandle kwexabiso eliphezulu, abaninzi abanomdla bacinga iinzuzo zokusebenza ezixabisa utyalo-mali.

UkuFakelo Complexity

Ukufakela iiheader ze-tubular kunokuba nzima ngakumbi xa kuthelekiswa nee-manifolds zokukhupha eziqhelekileyo. Uyilo oluntsonkothileyo kunye neemfuno zokufaneleka ezichanekileyo zihlala zifuna ukufakelwa kobungcali. Ukufakela okungafanelekanga kunokukhokelela ekukhupheni ukuvuza kunye nokunciphisa ukusebenza. Ukongeza, imiqobo yokupakisha kwi-injini bay inokubangela imingeni ngexesha lofakelo. Ukucwangciswa okufanelekileyo kunye nobuchule kubalulekile ukuqinisekisa ukusebenza ngokufanelekileyo kunye nobude obude beentloko ze-tubular.

Izihloko ezicatyiswe ngeCeramic

Amagqabantshintshi eentloko ezineCeramic Coated

Ziziphi iiNhlokwana eziNcinciweyo ngeCeramic?

Izihloko ezigqunywe ngeCeramic zibonakalisa umaleko wemathiriyeli ye-ceramic efakwe kumphezulu weentloko zemveli zokukhupha. Olu tyaba lusebenza ngeenjongo ezininzi, kubandakanywa ukomeleza ukumelana nobushushu kunye nokuphucula ukuqina. Abavelisi basebenzisa iindlela eziphambili zokubopha umaleko we-ceramic kwi-substrate yesinyithi, ukuqinisekisa ukugqitywa okuqinileyo kunye nokuhlala ixesha elide. Ingubo ye-ceramic inokumelana nokushisa okugqithisileyo, okwenza kube yinto efanelekileyo kwizicelo eziphezulu zokusebenza.

Izicelo eziqhelekileyo zeCeramic Coated Headers

Izithuthi ezisebenza ngokuphezulu zihlala zisebenzisa iiheda ezigqunywe ngeceramic ukulawula ubushushu ngokufanelekileyo. Ezi zihloko zikwafumana izicelo kwiimoto zomdyarho kunye nezithuthi zesitrato ezilungisiweyo apho ukusebenza ngeyona ndlela kubalulekile. Uninzi lwabathandi beemoto bakhetha iintloko ezigqunywe ngeceramic njengophuculo lwasemva kwentengiso ukuze baphucule ukusebenza kunye nenkangeleko yeenkqubo zabo zokukhupha.

IiPros zeCeramic Coated Headers

Ulawulo lobushushu

Iintloko ezigqunywe ngeCeramic zigqwesa kulawulo lobushushu. Uluhlu lwe-ceramic lusebenza njenge-insulator, ukunciphisa ubuninzi bobushushu obuphuma kwinkqubo yokukhupha. Oku kunceda ukugcina amaqondo obushushu enjini asezantsi, anokukhusela amanye amacandelo kumonakalo wobushushu. Ulawulo oluphuculweyo lobushushu lukwanegalelo ekusebenzeni ngcono kwe-injini iyonke.

Ukuqina

Ukomelela kweeheda ezigqunywe ngeceramic ngaphaya koko kweeheader ezingagqunywanga. Uluhlu lwe-ceramic lubonelela ngomqobo okhuselayo wokubola kunye nokugqoka. Oku kwenza ukuba iiheader zixhathise ngakumbi kwiimeko ezinzima ezihlangabezana nazo ngexesha lokusebenza. Ukwaleka unako kwakhonaukumelana nomothuko we-thermal, ukuthintela ukuqhekeka kunye neetshiphusi naphantsi kokutshintsha kobushushu obugqithisileyo.

Ii-Cons of Ceramic Coated Headers

Iindleko

Iindleko zeeheda ezigqunywe ngeceramic zibonisa i-drawback ebalulekileyo. Inkqubo yokufaka i-coating ye-ceramic ibandakanya izixhobo ezikhethekileyo kunye nezixhobo, ezonyusa iindleko zemveliso. Oku kwenza ukuba iiheader ezicatyiswe ngeceramic zibe zibiza kakhulu kunezo zingagqunywanga. Abathengi abathathela ingqalelo uhlahlo lwabiwo-mali banokufumana ezi zihloko zifikeleleka lula ngenxa yexabiso eliphezulu.

Okunokwenzeka Ukonakala kweCoating

Izihloko ezigqunywe ngeCeramic zijongene nomonakalo wokwaleka. Umaleko weceramic, ngelixa womelele, unokubandezeleka ngenxa yokuqhekeka okanye ukuqhekeka ukuba uphantsi kweempembelelo zomzimba okanye ukuphathwa ngendlela engafanelekanga. Ukulungisa iingubo ezonakalisiweyo kunokuba ngumngeni kwaye kunokufuna ukungenelela kweengcali. Ukuqinisekisa ukufakela okufanelekileyo kunye nokugcinwa kunokunceda ukunciphisa umngcipheko womonakalo wokugquma.

Ii-manifolds zokukhuphela ziza kwiindidi ezahlukeneyo, nganye ineengenelo ezizodwa kunye nokungalunganga.

- I-Iron Exhaust Manifolds:

- IiPros: Ukuqina, ukuphumelela kweendleko

- Ububi: Ubunzima, ukugcinwa kobushushu

- Ii-Manifolds zokukhupha isinyithi esingenasici:

- IiPros: Ukumelana nokubola, ukunciphisa ubunzima

- Ububi: Iindleko, okunokwenzeka kokuqhekeka

- Iintloko zeTubular:

- IiPros: Ukuphucula ukusebenza, ukunciphisa ubunzima

- Ububi: Iindleko, ubunzima bofakelo

- Izihloko ezicatyiswe ngeCeramic:

- IiPros: Ulawulo lobushushu, ukuqina

- Ububi: Iindleko, ezinokubakho umonakalo wokwaleka

Ukukhetha ubuninzi obuchanekileyo bokukhupha kuxhomekeke kwiimfuno kunye neenjongo ezithile. Usetyenziso oluphezulu lunokuxhamla kwi-tubular okanye i-ceramic coated headers. Abathengi abajonga uhlahlo lwabiwo-mali banokukhetha intsimbi etyhidiweyo okanye iinketho zetsimbi engenasici. Ukukhetha uyilo olufanelekileyoikhulisa ukusebenza kwe-injinikunye nobomi obude.

Ixesha lokuposa: Jul-23-2024