Ukuqondakushushu kangakanani i-injini ephumayoUngafumanaibalulekile kubanini bezithuthi. Le bhlog ihlola ukubaluleka kokuqondaukukhupha okuninziamaqondo obushushu, ukunika ulwazi oluxabisekileyo kwiamaqondo obushushu agqithisileyo abandakanyekayo. Ukusuka kumanqanaba obushushu aqhelekileyo ukuya kumaqondo obushushu aphezulu agqithileyo1200 degrees Fahrenheit, abafundi baya kufumana ingqiqo ebanzi yalo mba ubalulekileyo wokusebenza kwe-injini.

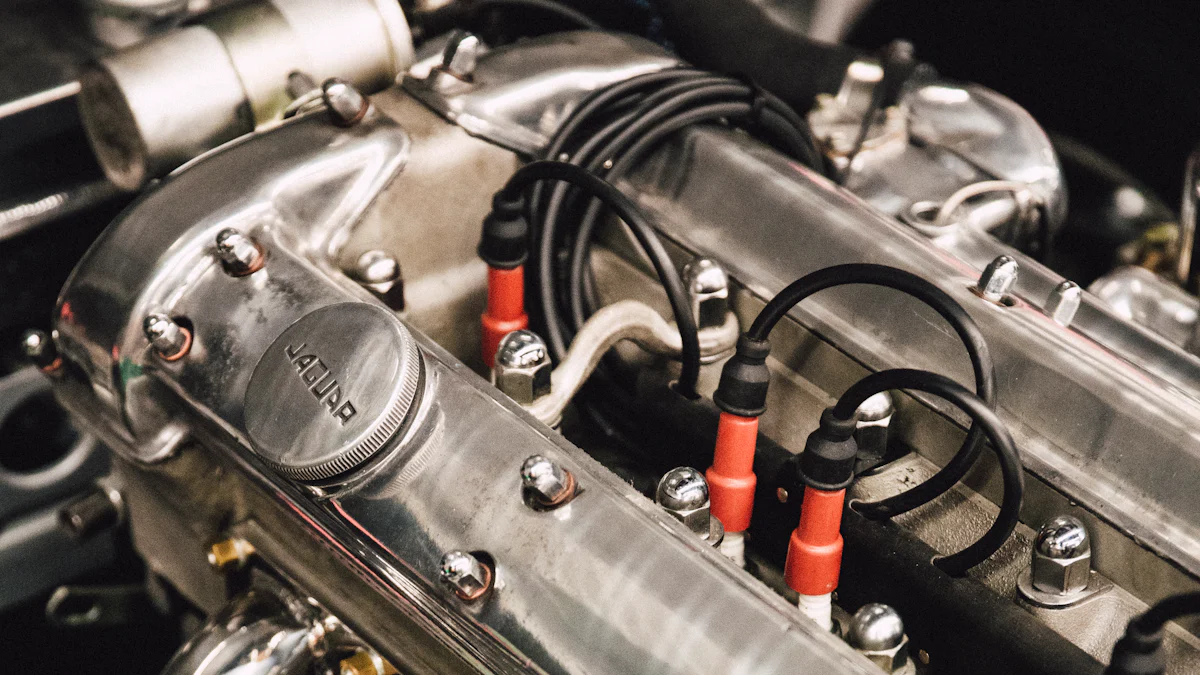

Ukuqonda ii-Exhaust Manifolds

Xa kuqwalaselwa iinjini ukukhupha okuninziyesithuthi, kubalulekile ukuba ubambe iinkcukacha zayo ezintsonkothileyo kunye nemisebenzi. Anukukhupha okuninziisebenza njengecandelo elibalulekileyo kwinkqubo yokukhupha i-injini, enoxanduva lokuqokelela iigesi zokukhupha kwiisilinda ezininzi kwaye zizisa kumbhobho wokukhupha umoya. Le nkqubo idlala indima ebalulekileyo ekugcineni ukusebenza kunye nokusebenza kakuhle kwe-injini.

Yintoni i-Exhaust Manifold?

Inkcazo kunye noMsebenzi

Iukukhupha okuninziinokuchazwa njengekhonkco elibalulekileyo phakathi kweesilinda ze-injini kunye nombhobho wokukhupha. Owona msebenzi wayo uphambili ubandakanya ukuqokelela iirhasi ezishushu, ezinetyhefu eziveliswa ngexesha lokutsha ngaphakathi kwicylinder nganye kwaye iziqondise kwi-catalytic converter okanye i-muffler yokulawula ukukhutshwa. Ngokuqokelela ngokufanelekileyo ezi gesi, iukukhupha okuninziinegalelo ekwandiseni ukusebenza kwe-injini kunye nokunciphisa izinto ezikhutshwayo eziyingozi.

Iindidi ze-Exhaust Manifolds

Kukho iintlobo ngeentlobo zegqiba ezininzi, nganye yenzelwe ukulungiselela ulungelelwaniso lwe-injini ethile kunye neemfuno zokusebenza. Izahluko eziqhelekileyo zibandakanya ii-iron manifolds, i-stainless steel manifolds, kunyeiiheader tubular. Ii-iron manifolds zentsimbi zaziwa ngokomelela kwazo kunye nokusebenza kakuhle kweendleko, ngelixa ii-manifolds zentsimbi engenakutyiwa zibonelela ngokumelana nomhlwa okuphezulu. Iiheader zeTubula, kwelinye icala, ziphucula ukusebenza kakuhle kokuphuma ngokunikezela ngemibhobho yentloko nganye yesilinda.

Ishushu kangakanani iExhaust Manifold?

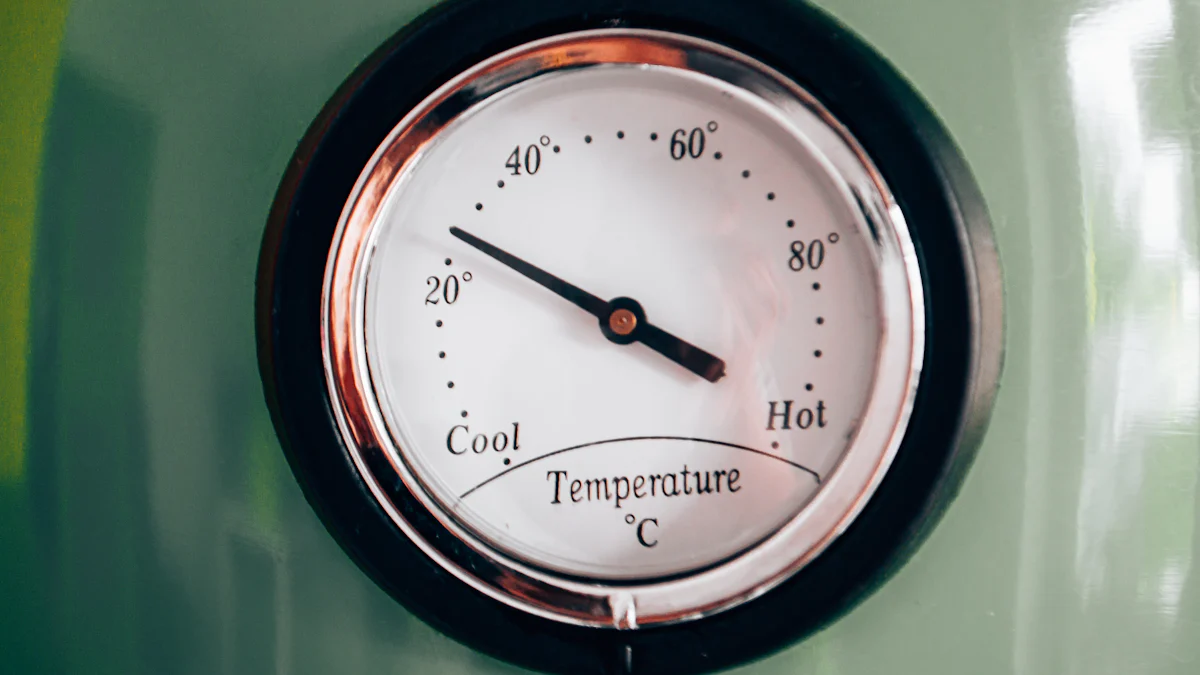

IiRange zoBubushushu obuqhelekileyo

Ikhupha ubushushu obuninziinokwahluka kakhulu ngokuxhomekeke kwiimeko zokuqhuba kunyeumthwalo wenjini. Ngaphantsi kweemeko eziqhelekileyo zokusebenza, ezininzi iinjini zesitokhwe zibonisa amaqondo okushisa ukusuka kwi-275 ukuya kwi-300 degrees Fahrenheit ngokungasebenzi. Nangona kunjalo, ngexeshaiimeko eziphezulu zokusebenzaezinjengomdyarho okanye izicelo ezinzima, la maqondo obushushu anokunyuka ngokukhawuleza.

Amaqondo obushushu aphezulu

Kwiimeko ezigqithisileyo, ezinje ngezithuthi ezisebenza kakhulu okanye oomatshini abanzima,gqiba ezininziinokufikelela kumaqondo obushushu angaphezu kwe-1200 degrees Fahrenheit. La mazinga obushushu agqithisileyo abeka imingeni ngokwemiqathango yokuqina kwezinto kunye nolawulo lobushushu ngaphakathi kwendawo ye-injini.

Ubuninzi beMoto yeMoto

Ukuqulunqwa kwezinto

Ngenxa yobume bemeko enzima abasebenza kuyo,gqiba ezininzizakhiwe kusetyenziswa imathiriyeliiimpawu zokumelana nobushushu obuphezulu. Izinto eziqhelekileyo ziquka intsimbi etyhidiweyo, insimbi engenasici, kunye nentsimbi epholileyo. Isixhobo ngasinye sinikezela ngeseti eyodwa yeenzuzo malunga nokunyamezela ubushushu kunye nokuphila ixesha elide.

Iingqwalasela zoyilo

Uyilo lweukukhupha okuninziidlala indima ebalulekileyo ekuphuculeni ukusebenza kwe-injini kunye neempawu zetorque. Izinto ezifana nobude bombhobho, ububanzi, amalungu, ii-welds, kunyeukuguda kwangaphakathiifuthe elibonakalayo lokuhamba kakuhle kwegesi. Ukongezelela, ukulinganisa okufanelekileyo kwamasebe amaninzi kubalulekile ukuqinisekisa ukubonakaliswa kwangexesha kwee-counter-pulses kumqokeleli.

Njengoko abavelisi bezama ukuphucula ukusebenza kwemoto ngelixa behlangabezana nemigangatho engqongqo yokukhutshwa, ukuqhubela phambili okuqhubekayoUkukhupha i-injini ngokuphindaphindiweyoUyilo lungqinwa kumacandelo ahlukeneyo eemoto.

Imiba echaphazela amaqondo obushushu obuninzi

Xa uphonononga iubushushuyobuninzi bombhobho, kubalulekile ukuqwalasela izinto ezahlukeneyo ezinokuchaphazela la mazinga obushushu agqithisileyo. Ukuqonda ukuba njaniumthwalo wenjinikunye nesantya,uhlobo lwamafuthakunye nomgangatho, ngokunjalouyilo lwenkqubo yokukhupha, idlala indima ebalulekileyo ekumiseleni ukusebenza kwe-thermal iyonke ye-manifold ibalulekile kubanini bezithuthi.

Injini yomthwalo kunye nesantya

Impembelelo yeeMeko zokuqhuba

Iimeko zokuqhuba zinempembelelo enkulu kwiqondo lobushushu le-exhaust manifold. Ngexesha lokuqhuba kwesantya esiphezulu, ukuhamba komoya okwandisiweyo kwikhompatimenti ye-injini kunokunceda ukukhupha ubushushu ngokufanelekileyo. Ngokuchaseneyo, kwindawo yokumisa nokuhamba yetrafikhi, apho injini isebenza ngesantya esisezantsi ixesha elide, ukwanda kobushushu phakathi kobuninzi kunokucaca ngakumbi.

Iimeko zoMsebenzi

Kwiimeko zokusebenza ezifana nokubaleka okanye ukutsala imithwalo enzima, iinjini zisebenza phantsi kwemithwalo ephezulu kunye nezantya, ezikhokelela ekwandeni.amaqondo obushushu okutsha. Oku kunyuswa koxinzelelo lwe-thermal kubangela ukuba phezulukhupha amaqondo obushushu erhasiephuma kwi-cylinders kwaye egeleza kwi-manifold. Ngenxa yoko, i-manifold kufuneka imelane nezi meko zinzima ngaphandle kokubeka esichengeni isidima sayo sesakhiwo.

Uhlobo lweFuel kunye noMgangatho

Ipetroli vs. Idizili

Uhlobo lwesibaso olusetyenziswa kwi-injini lunokuba nefuthe lokukhupha amaqondo obushushu ahlukeneyo. Iinjini zedizili zihlala zisebenza kubushushu obuphezulu bokutsha kuneenjini zepetroli ngenxa yenkqubo yazo yokutshisa. Ngenxa yoko, izithuthi ezisebenza nge-diesel zinokufumana ukuveliswa kobushushu obukhulu ngaphakathi kwenkqubo yokukhupha, kubandakanywa neninzi.

Impembelelo yeIzongezo zeFuel

Umgangatho wezongezo zepetroli ezisetyenzisiweyo unokuchaphazela ngakumbi amaqondo obushushu bombhobho. Ezinye izongezo ziyilelwe ukunyusa ukusebenza kakuhle kokutsha okanye ukucoceka kwezixhobo ze-injini, ezinokuthi ziguqule iimpawu ezishushu zokukhupha iigesi. Ngokuguqula iimpawu zokutsha, ezi zongezo zinokuphembelela ngokungathanga ngqo iprofayile yeqondo lobushushu ngaphakathi kokuninzi kokukhupha.

Uyilo lweNkqubo yokuPhuma

Indima yeAbaguquleli beCatalytic

Iziguquli zeCatalytic zidlala indima ebalulekileyo ekwehliseni izinto ezikhutshwayo eziyingozi ngokuguqula iigesi eziyityhefu zibe ziimveliso ezingenabungozi kangako. Nangona kunjalo, abaguquli be-catalytic bazisa ubushushu obongezelelweyo kwisixokelelwano sokukhupha ngenxa yokusabela okumangalisayo okwenzeka ngaphakathi kubo. Oku kuchaphazeleka komthwalo we-thermal akuchaphazeli kuphela ubushushu bomguquli kodwa ikwachaphazela ukuchithwa kobushushu ngokubanzi kubo bonke ubude benkqubo yokukhupha.

Impembelelo yeeheda kunye nemibhobho

Uyilo kunye nokubunjwa kwezinto eziphathekayo zeentloko kunye nemibhobho ichaphazela ngokuthe ngqo indlela igesi yokukhupha ngokufanelekileyo ihamba ngayo kwinkqubo. Iintloko ezineetyhubhu eziphambili ezinobude obulinganayo zikhuthaza ukuhamba kwegesi elinganayo ukusuka kwi-cylinder nganye ukuya kumqokeleli omnye, ukunciphisa i-backpressure kunye nokunciphisa ukuhluka kweqondo lokushisa phakathi kweesilinda. Ukongeza, ukusebenzisamandrel-bent ityhubhuiqinisekisa utshintsho olugudileyo lwegesi yokukhupha ngaphandle kokudala izithintelo ezingeyomfuneko ezinokunyusa amaqondo obushushu ekuhlaleni.

Ngokuqwalasela ezi zinto zibalulekileyo zichaphazelayoamaqondo obushushu amaninzi, abanini bezithuthi banokufumana ulwazi oluxabisekileyo ekuphuculeni ukusebenza kwe-injini ngelixa beqinisekisa ixesha elide kunye nokuthembeka phantsi kweemeko zokusebenza ezahlukeneyo.

Imilinganiselo yoBubushushu beHlabathi yokwenyani

Iimeko zokuqhuba ezingasebenziyo kunye neziQhelekileyo

Ninikhupha iigesiqukuqela kwiukukhupha okuninzi, zihamba nazo iintsalela zokutsha, ukukhulula ubushushu kwinkqubo. Ngexesha lokungenzi nto okanye iimeko eziqhelekileyo zokuqhuba, la maqondo obushushu anika ulwazi oluxabisekileyo malunga nokusebenza nokusebenza kwe-injini.

- Iizibuko lokukhuphangexesha lokubonisa okungasebenziyo kwamaqondo obushushu anokuqala ukusuka kwi-275 ukuya kwi-300 degrees Fahrenheit kwiinjini ezininzi zesitokhwe. Oku kubonisa ubushushu bokusebenza obuzinzileyo kwizinto ezininzi phantsi komthwalo omncinci.

- Ngokwahlukileyo koko, iinjini zokusebenza zibonisa amaqondo obushushu aphezulu kancinci, afikelela kuma-325 degrees Fahrenheit ngexesha lokungenzi nto. Oku kwanda kubangelwe kwiinkqubo zokutsha eziphuculweyo phakathi kolu seto lusebenza kakhulu.

Iimeko zoMsebenzi oPhezulu

Kwiimeko zokusebenza eziphezulu ezifana neemeko zomdyarho okanye izicelo ezinzima, iimfuno ezibekwe kwi-injini zikhokelela kumaqondo obushushu aphezulu ngaphakathi kwenkqubo yokukhupha umoya. Ezi meko zinzima zityhalaukukhupha okuninzikwimida yayo, ukuvavanya ukuqina kwayo kunye nokuqina kwe-thermal.

- Iimeko zomdyarho ziyatyhalaukukhupha amaqondo obushushuukuya kwiindawo eziphakamileyo, ezinokufundwa okugqwesileyo1200 degrees Fahrenheitkwezinye iimeko. Ubushushu obugqithisileyo obuveliswa ngexesha logqatso olunesantya esiphezulu lucela umngeni kwanezona mathiriyeli zinamandla ezisetyenziswa kulwakhiwo oluphindaphindeneyo.

- Usetyenziso olunzima, njengokutsala imithwalo enzima okanye ukunika amandla oomatshini bemizi-mveliso, baxhomekeke kwiindlela ezininzi zokuphuma kuvezo olude kumaqondo obushushu aphezulu. Amaqondo obushushu angaphezulu kwe-1000 degrees Fahrenheit awaqhelekanga kwezi ndawo zinemfuno.

Ukwahluka kobushushu

Ukusasazwa kobushushu kwiisilinda ezahlukeneyo kunye neemodeli zezithuthi kugqamisa ubunjani obuntsonkothileyo benkqubo yokukhupha amandla. Ukuqonda ezi yantlukwano kubalulekile ekuphuculeni ukusebenza kwe-injini kunye nokuqinisekisa ukuthembeka okungaguqukiyo.

- Phakathi kweesilinda, ukwahluka kwikhupha amaqondo obushushu erhasiinokujongwa ngenxa yezinto ezifana neepateni zokutofa kwamafutha kunye neempawu zokutsha ezithe ngqo kwisilinda. Lo mahluko unokukhokelela kukwahluka kobushushu ukuya kuthi ga kwi-100 degrees Fahrenheit phakathi kweesilinda ezikufutshane.

- Kuzo zonke iimodeli zezithuthi ezahlukeneyo, ukwahluka kuyilo lokukhupha izinto ezininzi kunye neenkcukacha zenjini zinegalelo kwiiprofayile ezahlukeneyo zobushushu. Umzekelo, iimoto ezineenjini ze-turbocharged zinokubonisa amaqondo obushushu aphezulu xa kuthelekiswa noogxa bendalo abanqwenelekayo ngenxa yokwanda koxinzelelo.

Ngokuphonononga imilinganiselo yobushushu behlabathi lokwenene phantsi kweemeko ezahlukeneyo zokusebenza, abanikazi bezithuthi banokufumana uxabiso olunzulu ngemingeni yobushushu abajongene nayo.gqiba ezininzi. Ukubeka iliso kula maqondo obushushu kunika ulwazi oluxabisekileyo kwimpilo ye-injini kunye nezicwangciso zokuphucula ukusebenza.

Iimpembelelo zamaqondo obushushu aphezulu

Ukusebenza kweNjini

UkuSebenza kunye neSiphumo saMandla

Amaqondo obushushu aphezulu kwi-exhaust manifold inokuchaphazela kakhuluukusebenza kwenjiningokuphembelela ukusebenza kwayo kunye nemveliso yamandla. Xa iigesi zokukhupha zifikelela kumanqanaba obushushu obugqithisileyo, zinokuchaphazela inkqubo yokutsha ngaphakathi kweesilinda, ezikhokelela ekusebenzeni kwe-injini encinci.

- Iukusebenza kakuhleye-injini ibotshelelwe ngokusondeleyo kulawulo lobushushu lwamacandelo abalulekileyo afana ne-exhaust manifold. Ukushisa okugqithisileyo kunokuphazamisa iimeko ezifanelekileyo zokutsha, okubangelwa ukutshiswa kwepetroli okungaphelelanga kunye nokunciphisa ukuguqulwa kwamandla ukusuka kumafutha ukuya kumsebenzi womatshini.

- Ngemimiselo yokubaimveliso yamandla, amaqondo obushushu aphakamileyo kwinkqubo yokukhupha umsi anokuthintela amandla e-injini ukuvelisa amandla aneleyo okuqhuba isithuthi. Uxinzelelo lwe-thermal kumacandelo angaphakathi okubangelwa ukushisa okuphezulu kunokuphazamisa ukunikezelwa kwamandla ngokubanzi, okuchaphazela ukukhawuleza kunye nokutsala amandla.

- Ukugcina ngokugqibeleleyoukusebenza injini, kubalulekile ukubeka esweni ukukhupha amaqondo obushushu amaninzi rhoqo kunye nokujongana nayo nayiphi na imiba enokuthi ivele ngenxa yokwanda kobushushu obugqithisileyo. Ngokuqinisekisa ukuba amanyathelo okupholisa okufanelekileyo kunye nokugquma akhona, abanini-zithuthi banokukhusela ukusebenza kakuhle kwe-injini kunye nokuphuma kwamandla.

Ubomi obude kunye noKuhlala ixesha elide

Ubomi obude kunye nokuqina kwe-injini kunxulunyaniswa ngokusondeleyo nendlela ekwazi ukumelana ngayo namaqondo obushushu aphezulu kwiindawo ezibaluleke kakhulu ezifana ne-exhaust manifold. Ukuba sesichengeni ixesha elide kumazinga obushushu obugqithisileyo kunokukhawulezisa ukuguga kunye nokukrazuka kwezinto, okunokukhokelela kukusilela kwangaphambi kwexesha kwamalungu abalulekileyo e-injini.

- Ngokuhamba kwexesha, ukuvezwa ngokuqhubekayo kumaqondo obushushu aphezulu kunokuthoba isidima sesakhiwo sezinto ezisetyenziswayogqiba ezininzi. Oku kuthotywa kunokubonakala njengokuqhekeka, ukujija, okanye ukubola, oko kubeka esichengeni amandla obuninzi bokuqulatha kunye nokukhokela iigesi zokukhupha ngokufanelekileyo.

- Ukuqina kwe-injini phantsi kweemeko zobushushu obuphezulu bubungqina bokuqina kwayo ngokuchasene noxinzelelo lobushushu. Amacandelo aphantsi kobushushu obukhulu kufuneka abonise ukomelela kunye nokuchasana ne-deformation okanye ukukhathala kwezinto eziphathekayo ukuqinisekisa ukuthembeka kwexesha elide.

- Ngokubeka phambili iinkqubo zogcino ezithomalalisa ukwanda kobushushu obugqithisileyo kwinkqubo yokukhupha umbhobho, abanini bezithuthi banokwandisa ubomi obude kunye nokuqina kweenjini zabo. Ukuhlolwa rhoqo, ulungiso olungexesha, kunye nezixhobo zokupholisa ezaneleyo zidlala indima ebalulekileyo ekulondolozeni amacandelo e-injini ekuwohlokeni kwangaphambi kwexesha.

Iingqwalasela zesondlo

Amanyathelo othintelo

Ukuphumeza izicwangciso zogcino olusebenzayo kubalulekile ekudambiseni iziphumo ezibi zamaqondo obushushu aphezulugqiba ezininzikunye nokusebenza kweenjini ngokubanzi. Ngokwamkela amanyathelo othintelo ajolise kulawulo lobushushu kunye nokukhuselwa kwecandelo, abanini bezithuthi banokwandisa ubomi beinjini zabo kwaye bandise ukusebenza kakuhle kwayo.

- Ukuhlolwa rhoqo: Yenza uhlolo oluqhelekileyo lwembonakalo ye-exhaust manifold ngeempawu zokuguquka kombala, umhlwa, okanye umonakalo obonakalayo onokuthi ubonise imiba yokushisa.

- Ukugcinwa kweNkqubo yokuPholisa: Qinisekisa ukusebenza ngendlela eyiyo kwesixokelelwano sokupholisa sesithuthi, kubandakanywa ukugungxulwa kweradiyetha, ukujongwa kwinqanaba lokupholisa, kunye nokuhlolwa kwe-thermostat.

- UFakelo lweShield lobushushu: Cinga ngokufakela izikhuselo zobushushu ezingqonge iindawo ezisesichengeni kufutshane nombhobho wokukhupha ubushushu ukunciphisa ugqithiso lobushushu obukhazimlayo kunye nokukhusela amalungu ajikelezileyo.

- Exhaust System Upgrades: Phucula iinxalenye zokukhupha izinto eziphezulu zokunyamezela ubushushu okanye uyilo oluphuculweyo oluphucula amandla okuchitha ubushushu.

- Izixhobo zokubeka iliso: Tyala imali kwizixhobo zokujonga ubushushu okanye izinzwa ezibonelela ngedatha yexesha lokwenyani malunga nokukhupha amaqondo obushushu amaninzi ngexesha leemeko ezahlukeneyo zokuqhuba.

- Inkonzo yobuNgcali: Cwangcisa ukuqeshwa kokugcinwa rhoqo kunye namagcisa aqeqeshiweyo agxile ekuxilongeni nasekulungiseni imiba enxulumene nobushushu obuphezulu.

Iimpawu zokutshisa

Ukuziqonda kwangethuba izikhombisi zokutshisa okugqithisileyo kwisixokelelwano sokukhupha i-injini kubalulekile ekuthinteleni umonakalo onokwenzeka okanye ukungasebenzi kakuhle okubangelwa bubushushu obugqithisileyo. Ngokuziphaphela iimpawu ezilumkiso eziqhelekileyo ezinxulumene nezinto ezitshisa ngokugqithisileyo ezifana ne-exhaust manifold, abanini-zithuthi banokuthatha inyathelo elikhawulezileyo ukunqanda ukulungiswa okuxabisa imali eninzi okanye ukutshintshwa.

- Ivumba Elingaqhelekanga: Nika ingqalelo kulo naliphi na ivumba elingaqhelekanga eliphuma kwikhompatimenti ye-injini elinokubonisa izinto ezishushu kakhulu okanye ulwelo oluvuzayo.

- Umsi Onyukayo Wokukhupha: Lawula utshintsho kumbala womsi wokuphuma okanye ubuninzi babo njengoko izinto ezikhutshwayo ezimnyama zinokubonisa i-oyile etshayo okanye into yokupholisa ngenxa yobushushu obugqithisileyo.

- I-Injini engasebenzi kakuhle: Kulumkele ukuvutha kakubi kwe-injini okanye iipateni ezirhabaxa ezinokubakho ngenxa yeenkqubo zokutsha ezisengozini ezidityaniswe namaqondo obushushu amaninzi.

- Ukuncitshiswa kokuSebenza kweFuel: Landela iinguqu kumazinga okusetyenziswa kwamafutha njengoko okonyukileyo kokusetyenziswa kwepetroli ngaphandle kweenzuzo zokusebenza ezihambelanayo kunokucebisa ukutsha okungasebenzi kakuhle okubangelwa kubushushu obugqithisileyo.

- IZilumkiso zeDashboard: Mamela izibane ezilumkisayo kwideshbhodi ezinxulumene nobushushu bokupholisa okanye ukungasebenzi kakuhle kwe-injini okunokukhomba kumaqondo obushushu aphakamileyo okusebenza ngaphakathi kwiinkqubo ezibalulekileyo.

Ngokuhlala behambelana nezi mpawu zokutshisa kakhulu ngaphakathi kwenkqubo yokukhupha umoya, abanini bezithuthi banokujongana ngokukhawuleza nemiba esisiseko ngaphambi kokuba banyukele kwiingxaki ezinzima kakhulu zoomatshini. Ukubeka phambili amanyathelo othintelo lolondolozo kuqinisekisa ukusebenza ngokugqibeleleyo ngelixa ukhuselwa kwiingozi ezinokubakho ezinxulumene namaqondo obushushu aphezulu achaphazela iinxalenye eziphambili ze-injini ezifana nombhobho omninzi.

- Ukushwankathela, ukuqonda iinkcukacha ezintsonkothileyo zekhupha amaqondo obushushu amaninziibalulekile ekusebenzeni kakuhle kwe-injini kunye nokuphila ixesha elide. Ngokubeka iliso kula maqondo obushushu, abanini-zithuthi banokujongana kwangaphambili nemiba enokwenzeka kwaye baqinisekise ukusebenza ngokufanelekileyo kweenjini zabo. Ukuhlolwa rhoqo, ukugcinwa ngendlela eyiyo kwenkqubo yokupholisa, kunye nokufakelwa kwezikhuseli zobushushu ngamanyathelo ayimfuneko okuthintela ubushushu bobushushu. Ukufumana ulwazi oluthe kratya malunga nokugcina impilo engapheliyo yokuphuma kwempilo kunye nokwandisa ukusebenza kakuhle kwe-injini, ukuhlola izixhobo ezongezelelweyo kulawulo lobushushu kwiinkqubo zezithuthi kucetyiswa kakhulu. Hlala unolwazi ukugcina injini yakho isebenza kakuhle!

Ixesha lokuposa: Jun-05-2024