Iukuthatha ngokuphindaphindiweyolicandelo elibalulekileyo kwi-injini, ngokubalulekileyoichaphazela ukusebenza kwayo nokusebenza kakuhle. Kwesi sikhokelo, abafundi baya kungena kwihlabathi elintsonkothileyo leukuthatha ngokuphindaphindiweyounxibelelwano, ukuqonda indima yabo ekwandiseni umsebenzi we-injini. Ibhlog iya kutyhila iziseko zeukuthatha ngokuphindaphindiweyoulwakhiwo, imathiriyeli esetyenzisiweyo, imiba eqhelekileyo ejongene nayo, kunye nokubonisa isifundo esisebenzayo sokusetyenziswa kwelizwe lokwenyani. Ekupheleni kokuisikhokelo, abaqalayo baya kuba nengqiqo eqinileyo yokuba njaniUkuThatha okuFanelekileyo kokuSebenza okuPhezuluimisebenzi kunye nokubaluleka kwabo kummandla weemoto. Ukongeza, ingcacisoumzobo wokuthatha ngokuphindaphindiweyoiya kubonelelwa ngoncedo olubonakalayo ekuqondeni unxibelelwano oluntsonkothileyo kunye namacandelo abandakanyekayo.

Ukuqonda i-Manifold yokuThatha

Yintoni i-Intake Manifold?

Inkcazo kunye nomsebenzi osisiseko

IUkuthatha okuninziisebenza njengecandelo elibalulekileyo kwi-injini, uxanduva lokusasazaumoyakwiisilinda zeenjini. Iqinisekisa ukuba umlinganiselo ochanekileyo womoya ufikelela kwi-cylinder nganye ukwenzela ukutshisa ngokufanelekileyo, ukuphuculainjiniukusebenza.

Umxholo wembali kunye nendaleko

Ukutyhubela imbali, iUkuthatha okuninziiye yaphucuka kakhuluinjiniukusebenza kakuhle. Ukwenziwa kwezinto ezintsha kuyilo kukhokelele kuguqulo lomoya olungcono kunye neenkqubo eziphuculweyo zemixube yepetroli, okunegalelo kwindalo yonke.ukuthatha ngokuphindaphindiweyoiteknoloji.

Amacandelo angundoqo oMninzi wokuThatha

Iplenum

IIplenumkwiUkuthatha okuninziisebenza njengegumbi eliphakathi eliqokelela umoya ongenayo ngaphambi kokuba liwusasaze kwiisilinda zomntu ngamnye. Idlala indima ebalulekileyo ekuqinisekiseni ukuhamba komoya ngokulinganayo kuzo zonke iisilinda, ukukhuthaza ukutsha okulinganayo.

Iimbaleki

Iimbalekiziiityhubhu ezizimeleyo zinwebekaukusuka kwiplenum ukuya kwindawo nganye yokungena kwintloko yesilinda. Ezi ziteshi zikhokela ukuhamba komoya ukusuka kwi-plenum ukuya kwiisilinda, ukwandisa ukuhanjiswa komoya kunye nokusebenza kakuhle kwamafutha ngaphakathi kwe-injini.

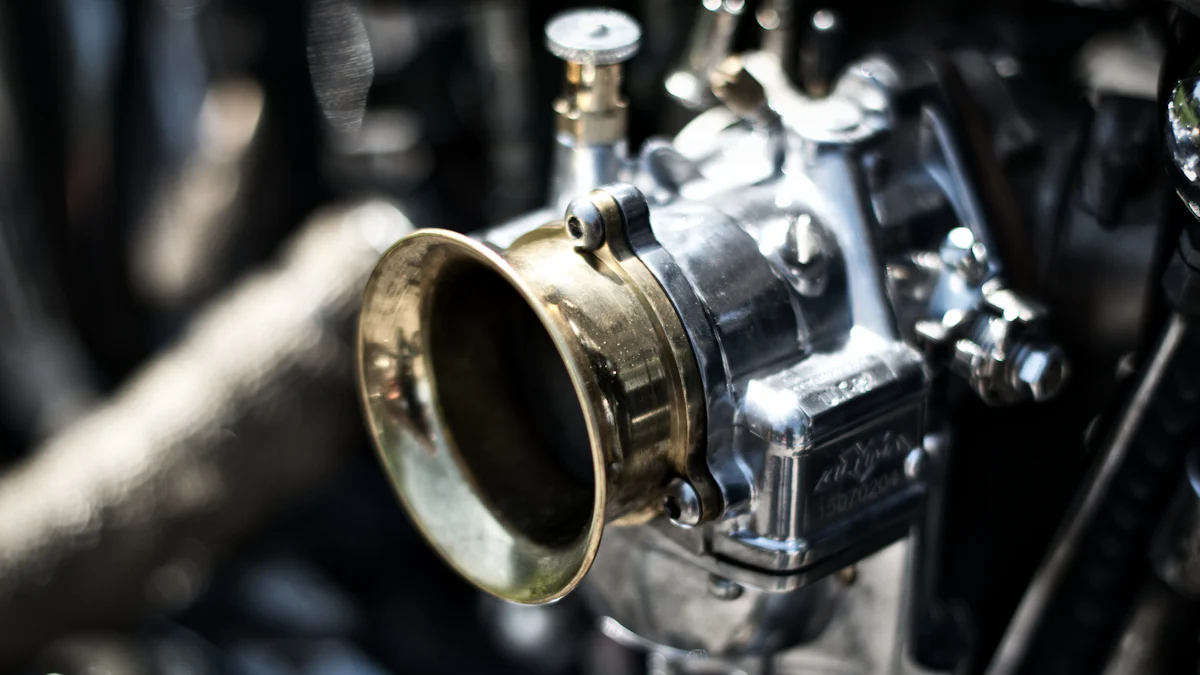

Umzimba we-Trottle

IUmzimba we-Trottleilawula ubungakanani bomoya ongena enjini ngokulawula indawo yepleyiti yomqala. Eli candelo lichaphazela ngokuthe ngqo ukuphuma kwamandla e-injini kunye nokuphendula ngokusekelwe kwigalelo lomqhubi, okwenza kube yinxalenye ebalulekileyo yenkqubo yokuthatha.

Indlela I-Intake Manifold isebenza ngayo

Ukuhanjiswa komoya

Uyilo oluntsonkothileyo lweUkuthatha okuninziiququzelelaUkuhamba komoya okugudileyongaphakathi enjinini. Ngokuqondisa ngononophelo umoya nge-plenum kunye neembaleki, i-turbulence iyancitshiswa, iqinisekisa ukutsha okusebenzayo kunye nokuphuma kwamandla aphezulu.

Inkqubo yokuxuba amafutha

Ngokuhambelana nokuhanjiswa komoya, iUkuthatha okuninziikwadlala indima ephambili ekuxubeni amafutha kunye nomoya ongenayo. Le nkqubo yenzeke ngaphakathi kwenkqubo yokuthatha ngaphambi kokufikelela kumagumbi okutsha, apho umlinganiselo olinganayo we-air-fuel uyimfuneko ekusebenzeni kakuhle kwe-injini.

Izixhobo ezisetyenziswa kwii-Intake Manifolds

Izinto eziqhelekileyo

Aluminiyam

- Aluminiyamlukhetho oludumileyo lweinlet manifoldsngenxa yobume bayo obukhaphukhaphu kunye neempawu ezibalaseleyo zokuphelisa ubushushu.

- Inika ukuqina kunye nokuthembeka, okwenza kube yinto ekhethiweyo yokusebenza okuphezuluiimoto.

- Ukusetyenziswa kwealuminiyam in ukungenisa ezininziinegalelo ekuphuculeni ukusebenza kakuhle kwamafutha kunye nokusebenza kweenjini ngokubanzi.

Iplastiki / iComposite

- Iplastiki / iCompositeimathiriyeli iqhele ukusetyenziswa kwimvelisoinlet manifoldsezahlukeneyoiimoto.

- Ezi zixhobo zibonelela ngesisombululo esineendleko ngelixa zibonelela ngokuqina okwaneleyo kwiimfuno zokuqhuba zemihla ngemihla.

- Ubume obukhaphukhaphu beiplastiki / imbumba ezininziinceda ekunciphiseni ubunzima bubonke besithuthi, ukuphucula uqoqosho lwamafutha.

Jula i-ayini

- Jula i-ayiniibisetyenziswa ngokwembali ngokwemveliinlet manifolds, eyaziwa ngokomelela kwayo kunye nokuphila ixesha elide.

- Ngelixa unzima xa kuthelekiswa nezinye izixhobo,Jula i-ayiniinikeza iipropati ezikhethekileyo zokugcina ubushushu, ezilungele ubumbeko oluthile lwe-injini.

- Ukusetyenziswa kweJula i-ayinikule mihlaukungenisa ezininziinika uzinzo kunye nokunyamezela phantsi kweemeko zokusebenza ezinzima.

IiPros and Cons of the Material nganye

Ukuqina

- Ukuqina kweukuthatha ngokuphindaphindiweyo, nokuba yenziwe ngealuminiyam, iplastiki / i-composite, okanye intsimbi etyhidiweyo, ibalulekile ekusebenzeni kwexesha elide le-injini.

- Ngelixaaluminiyamigqwesile kubunzima bokuqina,iplastiki / izinto ezidibeneyoukunika amandla aneleyo ngexabiso eliphantsi.

- Kwelinye icala, abantu abakholelwa kwizithethe basenokukuxabisa ukomelela kwentsimbi etyhidiweyo nangona inzima kakhulu.

Ubunzima

- Ubunzima budlala indima ebalulekileyo ekuqinisekiseni ukuba bukhali kunye nokusebenza kakuhle kwamafutha enkqubo ye-injini yesithuthi.

- Ukukhetha i-aluminiyam-based intake manifold inokunciphisa ngokubonakalayo ubunzima obupheleleyo bendibano ye-injini ngaphandle kokubeka esichengeni isidima solwakhiwo.

- Ngokwahlukileyo, isinyithi esityhidiweyo singongeza ubunzima kodwa sibonelela ngeenzuzo zokuzinza ezihambelana neemfuno ezithile zokusebenza.

Iindleko

- Ukuqwalaselwa kweendlekozibalulekile xa ukhetha imathiriyeli efanelekileyo kuninzi lokuthatha okusekwe kwimiqobo yohlahlo lwabiwo-mali kunye nolindelo lokusebenza.

- Ubuninzi be-aluminiyam yokuthatha i-aluminiyam inokuza ngeendleko eziphezulu zokuqala kodwa inikezela ngolondolozo lwexesha elide ngokuphucula uqoqosho lwamafutha kunye neenzuzo zokusebenza kakuhle.

- Iinketho zePlastiki/ezidibeneyo zibonakalisa enye indlela elungele uhlahlo lwabiwo-mali ngaphandle kokubeka esichengeni ukusebenza okusisiseko okanye ukuthembeka.

Imiba eqhelekileyo kunye nezisombululo

Iingxaki ezinokwenzeka

Ukuvuza

- Ukuvuzaimiba ekuthatheni okuninzi kunokukhokelela ekubeni umoya uphume kwinkqubo, echaphazela ukusebenza kwenjini.

- Ukulungisa intoukuvuzaNONE

- Ukufaka i-sealant kwindawo echaphazelekayo kunokunceda ukukhusela ukuvuza okungaphezulu kunye nokubuyisela ukusebenza kakuhle.

Iintanda

- Ubukho beiintandakubuninzi bokuthatha kunokubeka esichengeni isidima sayo solwakhiwo, kuchaphazele ukuhamba komoya kunye nokuhanjiswa kwamafutha.

- Xa usebenzisanaiintanda, qwalasela iinkonzo zokuhlola kunye nokulungiswa kweengcali ukuqinisekisa isisombululo esihlala sihleli.

- Kwiimeko ezimandundu, ukutshintshwa kwezinto ezininzi ezonakalisiweyo kungafuneka ukugcina ukusebenza kakuhle kwe-injini.

Ukwakhiwa kwekhabhoni

- Ukwakhiwa kwekhabhoningaphakathi kokuthatha okuninzi kunokuthintela ukuhamba komoya kunye nokuphazamisa inkqubo yokuxuba amafutha omoya.

- Ukugcinwa rhoqo, okufana nokucoca okanye ukusebenzisa izongezo zepetroli, kunokunceda ukuthintela ukuqokelelana kwekhabhoni eninzi.

- Ukuphumeza amanyathelo okuthintela kuya kukhusela imiba enokubakho yokusebenza ebangelwa yidiphozithi yekhabhoni.

Ukusombulula iingxaki kunye noLungiso

Ukuchonga iimpawu

- Ukuqaphela iimpawu zesilumkiso kwangethuba kubalulekile ekufumaniseni iingxaki ezininzi zokuthatha ngaphambi kokuba zinyuke.

- Jonga izikhombisi ezifana nengxolo yenjini engaqhelekanga, ukuphuma kwamandla okuhla, okanye iipateni ezingaqhelekanga zokungenzi nto.

- Ukuqhuba uhlolo lwesiqhelo kunokunceda ekuchongeni ngokukhawuleza nasekulungiseni imiba evelayo.

Ukulungisa iindlela

- Xa ujongana neenkxalabo ezininzi zokuthatha, landela iinkqubo ezicetyiswayo zokulungisa ezibonelelwa ziingcali zeemoto.

- Sebenzisa izixhobo ezifanelekileyo kunye nezixhobo zokuqhawula, ukuhlola, kunye nokulungisa izinto ezonakalisiweyo ngokufanelekileyo.

- Funa uncedo lwengcali ukuba awuqinisekanga malunga neendlela ezithile zokulungisa ukuphepha ukukhulisa iingxaki ezikhoyo.

Ukugcinwa kothintelo

- Ukuseka ishedyuli yokulondolozwa rhoqo ngundoqo ekuthinteleni imiba enokubakho kwizinto ezininzi.

- Hlola inkqubo ephindaphindwayo ngamaxesha athile ukuze ubone naziphi na iimpawu zokuguga, ukuvuza, okanye ukosuleleka.

- Ukuthobela izikhokelo zomenzi ngamaxesha olondolozo kuya kwandisa ubomi bokuthatha kwakho okuninzi.

Umzekelo: Umzekelo osebenzayo

Imeko yehlabathi yokwenyani

Inkcazo yomba

A Iprojekthi yeNgwamza Porscheijongene nengxaki edidayo ekusebenzeni kwayo kwenjini. Oomatshini bafumanisa izitenxo ekuhanjisweni komxube we-fuel-air, okukhokelela ekusebenzeni kakuhle kokutsha. Oyena nobangela walandwa emva kubuninzi bokuthatha, apho ukungahambelani kwi-airflow dynamics kwaphazamisa ukusebenza kwe-injini.

Amanyathelo athathiweyo ukuxilonga

- Kuqhutywe uhlolo olucokisekileyo lwesakhiwo esininzi kunye namacandelo.

- Kusetyenziswe izixhobo zokuxilonga ukuhlalutya iipatheni zokuhamba komoya kunye nokuchonga imiqobo enokubakho.

- Kuphunyezwe iimvavanyo zoxinzelelo zokuvavanya ukuthembeka kwezinto ezininzi phantsi kweemeko zokusebenza ezahlukeneyo.

- Isebenzisana neengcali zobunjineli ukulinganisa ukulinganisa ukuhamba komoya kunye nokukhomba iziphene zoyilo ezichaphazela ukusebenza.

Isisombululo siphunyeziwe

- Iinjineli uyila ngokutsha intakelelo yejiyometriukwandisa ukusasazwa komoya kuzo zonke iisilinda.

- Ilungiselelweubude bembaleki kunye nomthamo we-plenum wokuphucula ukusebenza kwe-volumetric.

- Isetyenzisiwe izixhobo eziphambiliukunciphisa isiphithiphithi kunye nokwandisa iimpawu zokuhamba kwe-cylinder.

- IphunyeziweUhlalutyo lweCFD lolungelelwaniso oluchanekileyo loyilo olutsha lokuthatha ngeendlela ezininzi.

- Ukushwankathela, ibhlog iphonononge izinto ezintsonkothileyo kunye nemisebenzi yoqhagamshelo lokuthatha okuninzi, inika ukukhanya kwindima yabo ebaluleke kakhulu ekusebenzeni kakuhle kwe-injini.

- Ukuqonda ama-nuances onxibelelwano oluninzi kubalulekile kwabo banomdla kunye nabaqalayo ngokufanayo, ukunika ulwazi malunga nokuphucula ukusebenza kakuhle kwe-injini kunye nokuphuma kwamandla.

- Abafundi bayakhuthazwa ukuba basebenzise ulwazi abalufumene kwesi sikhokelo ukuze bangene nzulu kwihlabathi elinomdla lobunjineli beemoto.

- U-Werkwell uyayamkela impendulo yakho kunye nemibuzo njengoko uqalisa uhambo lwakho lokutyhila ubunzima bonxibelelwano oluninzi.

Ixesha lokuposa: Jun-26-2024