Iukukhupha okuninziidlala indima ebalulekileyo kubunjineli beemoto ngokuqokelela iigesi zombhobho ophuma kwiisilinda ezininzi kwaye uzifake kumbhobho omnye. Uyilo lwe-exhaust manifolds luye lwavela kakhulu,iphenjelelwa yimfunekoukwandisa ukusebenza kakuhle kwamafutha kunyeimithetho engqongqo yokukhupha izinto. Ukuqonda olu hambo kubonelela ngolwazi oluxabisekileyo kubo bobabini abathanda iimoto kunye neengcali, kuqaqambisa ukubaluleka kokuqhubela phambili kwitekhnoloji yokuphelisa izinto ezininzi.

Uyilo lwangaphambili lwe-Exhaust Manifolds

Ukuzalwa kweExhaust Manifolds

Iingcinga zokuQala kunye neePrototypes

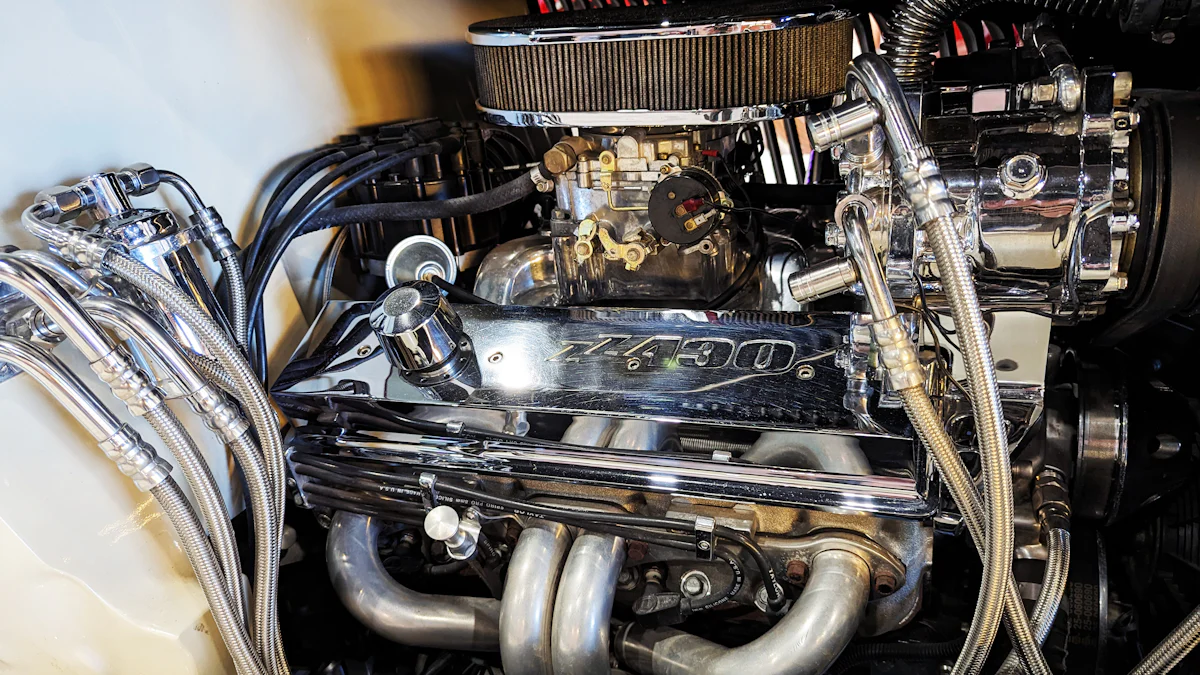

Ingcamango ye-exhaust manifold yavela ngokufika kweenjini ezininzi ze-cylinder. Uyilo lwangaphambili lujolise ekukhupheni iigesi ezivela kwiisilinda ezininzi kumbhobho omnye. Iinjineli ziye zazama iindlela ezahlukeneyo zokulungisa ukuhamba kwegesi kunye nokunciphisa uxinzelelo lwasemva. Iiprototypes zokuqala zaziqhelekile, zihlala ziyilwa ngesandla, zibonisa ubunakho bokuvelisa obunyiniweyo belo xesha.

Izixhobo kunye noBuchule bokuVelisa

Jula i-ayiniyaba yinto ekhethwayo kwiindlela ezininzi zokukhupha kwangaphambili. Ukuxhathisa kwayo ubushushu kunye nomhlwa kuyenze ilungele ukuphatha iimeko ezimaxongo ngaphakathi kwendawo yenjini. Ukomelela kwe-cast iron kuqinisekise ukuba la malungu anokumelana nokuvezwa ixesha elide kumaqondo obushushu agqithisileyo ngaphandle kokuthotywa. Ubugcisa bokuvelisa bubandakanya ukuphosa isinyithi esinyibilikisiweyo kwiimbumba, inkqubo evumela ukuveliswa kobuninzi ngelixa igcina imfezeko yesakhiwo.

Imingeni kunye neMida

Imiba yokuSebenza

Iindlela zokuphuma kwangoko zajongana nemingeni ebalulekileyo yokusebenza. Uyilo luhlala lukhokelela ekuhambeni kwerhasi engalinganiyo, okukhokelela ekunyukeni koxinzelelo lwangasemva. Oku kungasebenzi kakuhle kwehlise ukusebenza kwe-injini kunye noqoqosho lwamafutha. Iinjineli ziye zasokola ukwenza uyilo olunokuthi lulungelelanise imfuno yokuhamba kakuhle kwerhasi kunye nemiqobo yeendlela ezikhoyo zokuvelisa.

Iinkxalabo Zokuhlala ixesha elide

Ukomelela kubangele omnye umceli mngeni omkhulu kubuninzi bokuphuma kwangaphambili. Ngaphandle kokuqina kwesinyithi, ukuvezwa ixesha elide kumaqondo obushushu aphezulu kunye neegesi ezidliwayo zikhokelele ekuqhekekeni nasekujikeni ekuhambeni kwexesha. Ukugcinwa nokutshintshwa kwala macandelo kube yinto eyimfuneko rhoqo, okongeza kwiindleko zizonke zobunini bezithuthi. Iinjineli zithe gqolo zifuna iindlela zokuphucula ubomi obude bokukhupha izinto ezininzi ngokuphucuka kwezixhobo kunye noyilo loyilo.

I-Evolution ye-Exhaust Manifolds

Uphuhliso lwenkulungwane yama-20

Intshayelelo yeziXhobo eziNtsha

Embindini wenkulungwane yama-20 kuphawule utshintsho olubalulekileyo kuphuhliso olumandla ombane. Iinjineli zaqala ukujonga izixhobo ezitsha zokuphucula ukusebenza kunye nokuqina. Insimbi engenasici yavela njengokhetho oludumileyo ngenxa yokumelana nobushushu kunye nokubola. Esi sixhobo savumela iindonga ezinqabileyo, ukunciphisa ubunzima ngelixa ugcina ingqibelelo yesakhiwo. Ukwamkelwa kwensimbi engenasici kuphuculwe ukusebenza kakuhle kwenkqubo yokukhupha ngokunciphisa ukulahleka kobushushu.

Uphuculo kuYilo kunye nokusebenza ngokufanelekileyo

Uphuculo loyilo nalo ludlale indima ebalulekileyo ngeli xesha. Iinjineli ziye zasebenzisa iindlela zokuvelisa ezikumgangatho ophezulu ukwenza uyilo oluntsonkothileyo nolusebenzayo. Ukuqaliswa kwe-mandrel ukugoba kwenza ukuveliswa kweukugoba okugudileyo, ukunciphisa isiphithiphithi kunye noxinzelelo lwangasemva. Olu tshintsho luphucule kakhulu ukuhamba kwegesi yokukhupha, ukuphucula ukusebenza kwe-injini kunye nokusebenza kakuhle kwamafutha. Ukusetyenziswa kwezixhobo zokulinganisa ezivunyelweyo kwimodeli echanekileyo ye-gas flow dynamics, ekhokelelaUyilo olulungelelanisiweyo oluninzi.

Impembelelo yeMimiselo yokuPhuma

Utshintsho kuYilo lokuhlangabezana neMigangatho

Ukuphunyezwa kwemithetho engqongqo yokukhutshwa kwempahla kwisiqingatha sokugqibela senkulungwane yama-20 kuye kwafuna ukuqhubela phambili kwitekhnoloji yokukhutshwa kwezinto ezininzi. Abavelisi kuye kwafuneka bayile ngokutsha iindlela ezininzi ukuhlangabezana nemigangatho emitsha yokunciphisa izinto ezikhutshwayo eziyingozi. Ukufakwa kwabaguquli be-catalytic kwinkqubo yokukhupha ibe yinyanzeliso. Olu kongeza lufuna iindlela ezininzi zokumelana namaqondo obushushu aphezulu kunye nokuxhasa ukusebenza kakuhle kwezi zixhobo. Iinjineli zigxile ekudaleni uyilo oluququzelele ukufudumeza okukhawulezileyo kwabaguquli be-catalytic, ukuqinisekisa ukusebenza kakuhle.

Izinto ezintsha zobuGcisa eziqhutywa yiMithetho

Ukwenziwa kwezinto ezintsha zobuchwepheshe obuqhutywa yimithetho yokukhutshwa kwenkunkuma kukhokelele kuphuhliso lweenkqubo ezininzi ezintsonkothileyo zokukhupha umbhobho. Ukusetyenziswa kwe-computational fluid dynamics (CFD) yasasazeka, ivumela iinjineli ukuba zilinganise kwaye zihlalutye ukuziphatha kwegesi yokukhupha ngokweenkcukacha. Le teknoloji yenza ukuba kuyilwe ii-manifolds ezinejometri ezintsonkothileyo eziye zanyusa ukuhamba kwerhasi kunye nokunciphisa ukukhutshwa kwegesi. Ukudityaniswa kweenkqubo ze-turbocharging kunye ne-exhaust manifolds nazo zifumene ukuthandwa. Iinjini zeTurbocharged zifuna izinto ezininzi ezikwaziyo ukujongana noxinzelelo olongezelelekileyo kunye nobushushu, ziqhubela phambili ukuqhubela phambili kwisayensi kunye noyilo.

Izinto ezintsha zale mihla kwii-Exhaust Manifolds

Izinto eziPhezulu kunye neeNgqungquthela

I-High-Performance Alloys

Abavelisi beemoto ngoku basebenzisa i-alloys yokusebenza okuphezulu ukunyusa ukuqina kunye nokusebenza kakuhle kwe-exhaust manifolds. Ezi zinto zihamba phambili ziquka intsimbi ephezulu, insimbi engenasici, kunye nentsimbi ye-aluminum. Iipropathi ezigqwesileyo zoomatshini bezi ngxubevange zivumela i-exhaust manifolds ukuba imelane namaqondo obushushu agqithisileyo kunye neegesi ezidliwayo. Olu lutsha luye lwaphucula kakhulu ukusebenza ngokubanzi kweenkqubo zokukhupha kwizithuthi zanamhlanje.

Iingubo zeCeramic

Iingubo zeCeramic ziye zaba lukhetho oludumileyo lokuphucula ukusebenza ngokuphindaphindiweyo. Ezi zogquma zibonelela ngokugqwesa ukugquma kwe-thermal, ukunciphisa ukuhanjiswa kobushushu kumacandelo enjini ajikelezileyo. Iingubo zeCeramic zikwabonelela ngokuxhathisa okuphezulu kwi-corrosion kunye nokunxiba, ukwandisa ixesha lokuphila lokukhupha izinto ezininzi. Ngokugcina amaqondo obushushu aphantsi komhlaba, iingubo ze-ceramic zinceda ukuphucula ukusebenza kwe-injini kunye nokunciphisa ukukhutshwa.

Uphuculo loyilo

I-Computational Fluid Dynamics (CFD) kuYilo

Iinjineli ngoku zisebenzisa iComputational Fluid Dynamics (CFD) ukukhulisa uyilo lokukhupha izinto ezininzi. I-CFD ivumela ukulinganisa okuneenkcukacha kunye nohlalutyo lokuziphatha kwegesi yokukhupha ngaphakathi kweendlela ezininzi. Ubuchwephesha buvumela ukudalwa kweejometri ezintsonkothileyo ezandisa ukuhamba kwegesi kunye nokunciphisa uxinzelelo lwasemva. Ukusetyenziswa kwe-CFD kukhokelele kuphuculo olubonakalayo ekusebenzeni kwe-injini kunye nokusebenza kakuhle kwamafutha.

Ukudityaniswa neeNkqubo zeTurbocharging

Ukudityaniswa kweenkqubo ze-turbocharging kunye ne-exhaust manifolds kuguqule ukusebenza kwe-injini. Ii-injini zeTurbocharged zifuna ukukhupha okuninzi okukwaziyo ukuphatha uxinzelelo kunye nobushushu. Izinto eziphucukileyo kunye noyilo oluyilayo luqinisekisa ukuba ezi manifolds zinokukhupha iigesi ngokufanelekileyo kwi-turbocharger. Oku kudityaniswa konyusa amandla aphumayo kwaye kuphucula uqoqosho lwamafutha, kwenza iinjini ze-turbocharged zisebenze ngakumbi kwaye ziphendule.

Iingcebiso ezisebenzayo zokuLondoloza kunye noPhuculo

Ukuchongwa kweempawu zoKunxila kunye nokukrazula

Ukuhlolwa rhoqo kwee-exhausty manifolds kubalulekile ukugcina ukusebenza kakuhle. Iimpawu zokugqoka kunye nokukrazula ziquka ukuqhekeka okubonakalayo, ukugqwala, kunye nezandi ezingaqhelekanga ezivela kwinkqubo yokukhupha. Ukuncipha kokusebenza kwe-injini okanye ukonyuka kokusetyenziswa kwamafutha kusenokubonisa imiba emininzi. Ukufunyanwa kwangethuba kunye nokugcinwa kwangethuba kunokuthintela umonakalo ongakumbi kunye nokulungiswa kweendleko.

Ukukhetha i-Eright Aftermarket Manifold

Ukukhetha i-exhaust ye-aftermarket echanekileyo kufuna uqwalaselo ngononophelo lwemiba emininzi. Ukuhambelana nemodeli yesithuthi kubalulekile ukuqinisekisa ukufaneleka okufanelekileyo kunye nokusebenza ngokufanelekileyo. Izinto ezikumgangatho ophezulu ezifana nensimbi engenasici okanye i-ceramic-coated options zinika ukuqina okungcono kunye nokusebenza kakuhle. Ukubonisana neengcali zeemoto kunokubonelela ngolwazi oluxabisekileyo kunye neengcebiso zokukhetha eyona nto ibalaseleyo emva kwentengiso.

Uhambo lokuphuma kwezinto ezininzi lubonisa ukuqhubela phambili okumangalisayo ukusuka kuyilo lwangaphambili ukuya kwizinto ezintsha zale mihla. Ukuphuculwa okuqhubekayo kwezixhobo kunye nobuchule bokuvelisa kuye kwaphucula kakhulu ukusebenza kunye nokuqina. Ukubaluleka kwenkqubela phambili eqhubekayo kwitekhnoloji yokukhupha izinto ezininzi akunakubaxwa. Ukuhlala unolwazi malunga nophuhliso lwexesha elizayo kuya kunceda abo bathanda iimoto kunye neengcali.

Ixesha lokuposa: Jul-22-2024