Ukuqinisekiswa kwenkcazo yetorque kubaluleke kakhulu ekuqinisekiseni umgangatho wemveliso, ukhuseleko kunye nokuthembeka. Ukungahoyi ukuqinisa nokuba aiisenti ezintathu zokuqhobosha ngokwaneleyo zinokuba nesiphumokwiintsilelo eziyingozi. UkusebenzisaIzitshixo zetorque ngokukhuthala zithintela ukusilela kwebholithikunye nemiba yendibano, njengoko i-over-toquing ingakhokelela kwii-studs ezaphukileyo. Ukulandela imilinganiselo yetorque yei-injini ye-harmonic balanceriinxalenye zibalulekile ukukhusela umonakalo wokudinwa kunye nokuqinisekisa ukutywinwa okufanelekileyo. Ukuthembela okuchaziweyols itorque yebhawunti yebhawudi ye-harmonicamaxabiso ngundoqo, njengoko azimisele ngokucokisekileyo ukugcina ukusebenza kakuhle.

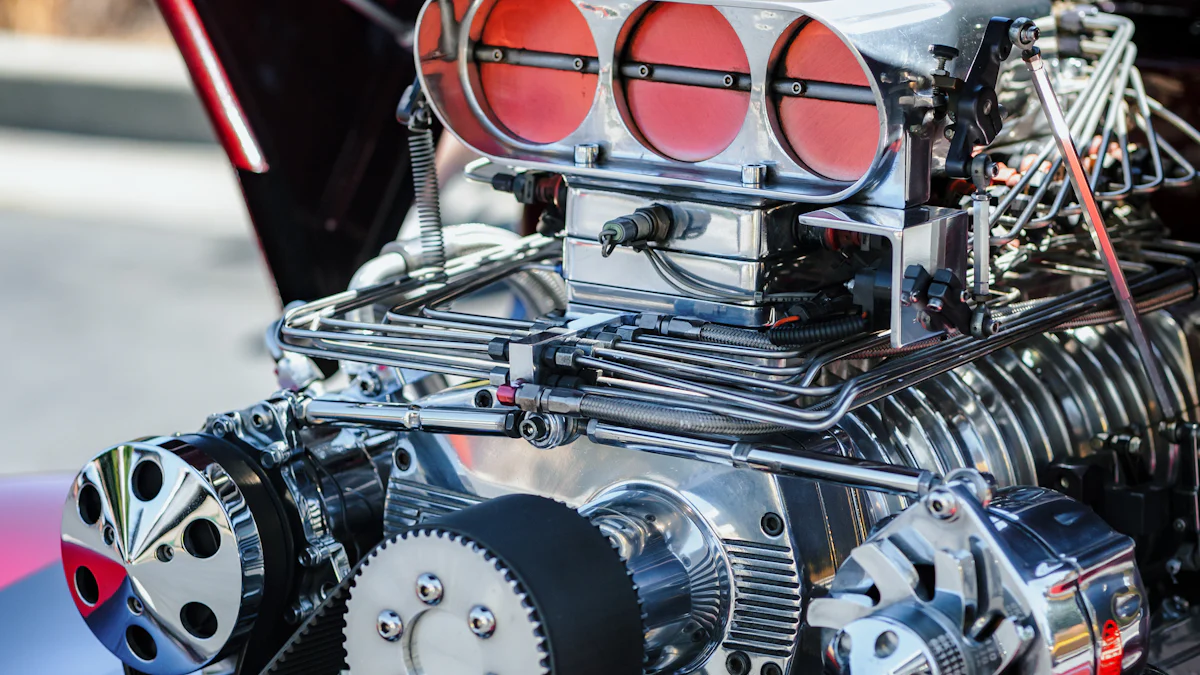

I-Harmonic BalancerIimpawu zeTorque

Xa kufikwa kwiI-Harmonic Balancer Torque Specs, ukuchaneka nokuchaneka kubaluleke kakhulu. Iukubaluleka kweempawu zetorqueazinakugqithiswa, njengoko ziqinisekisa ukusebenza ngokufanelekileyo kunye nobomi obude bezinto zenjini yakho. Ngokuthobela amaxabiso e-torque acetyiswayo, unokuthintela imiba efana nokungaphumeleli kwe-bolt kunye neengxaki zendibano. Makhe sihlolisise kwiinkcukacha zeiinkcukacha zetorque ngokubanzikwaye ujonge iinqobo eziqhelekileyo ezidlala indima ebalulekileyo ekugcineni impilo ye-injini yakho.

Iimpawu zeTorque ngokubanzi

Ukubaluleka kweeNkcazo zeTorque

Ukuqinisekisa ukuba ibholithi nganye iqinisiwe ngokweenkcukacha ezichanekileyo kubalulekile ekusebenzeni ngokubanzi kunye nokhuseleko lwe-injini yakho. IIimpawu ze torqueisebenza njengesikhokelo sokuthintela ukuqiniswa ngaphantsi okanye ngaphezulu, okunokukhokelela kwiziphumo ezibi. Ngokulandela le nkcazo ngenkuthalo, uqinisekisa ukuba icandelo ngalinye liqiniswe ngokukhuselekileyo, ukunciphisa umngcipheko wokungasebenzi kakuhle.

Imilinganiselo yeTorque eqhelekileyo

- Iibholiti zeSikhokelo seValve Lifterkuba LS2 zifuna 89 intshi lbs., ngelixa LS1/LS3/LS6/LS7 kufuneka 106 intshi lbs.

- Iibholiti ze-Coil-to-Bracketkufuneka ifakwe kwi-106 intshi ye-lbs. kuba LS1/LS6 kunye 89 intshi lbs. ye-LS2/LS3/LS7.

- Iibholiti zoMzimba weTrottleibango 106 intshi lbs. kuba LS1/LS6 kunye 89 intshi lbs. yeenjini ze-LS2/LS3/LS7.

- I-Oil Pan Closeout Cover Bolt(Icala lasekhohlo) lifuna i-intshi ezingama-106. kuba LS1/LS6 kunye 80 intshi lbs. ye LS2/LS7.

- I-Oil Pan Closeout Cover Bolt (Icala lasekunene) ichaza i-106 intshi yelbs. kuba LS1/LS6 kunye 80 intshi lbs. kwiinjini zeLS2/LS7.

Iimodeli ze-injini ezikhethekileyo

LS1/LS2/LS3 iiNjini

Kubaiimodeli ezithile zeenjininjenge-LS1, LS2, kunye ne-LS3, kubalulekile ukulandela imigaqo yetorque echongiweyo ngononophelo ukugcina amanqanaba okusebenza afanelekileyo. Imodeli nganye yeenjini ineemfuno ezizodwa ekufuneka zihlangatyezwane nazo ngexesha lofakelo ukuqinisekisa ukusebenza kakuhle kunye nokuphila ixesha elide.

LS7/LS9/LSA iiNjini

Kwelinye icala, ii-injini ezifana ne-LS7, LS9, kunye ne-LSA zineseti yazo yamaxabiso etorque ekufuneka ithotyelwe ngokungqongqo ngexesha lenkqubo yokuhlanganisa. Ezi njini zisebenza kakhulu zifuna usetyenziso oluchanekileyo lwetorque ukuqinisekisa ukusebenza kakuhle kunye nokuthembeka.

Izixhobo kunye nezixhobo

Izixhobo ezifunekayo

- I-torque wrench ethembekileyo iyimfuneko xa usebenza kwiibalancers ze-harmonic ukufezekisa ukuqiniswa ngokuchanekileyo ngokweenkcukacha.

- Iiseti zesokethi ezifanelekileyo ezinobukhulu obahlukeneyo ziyimfuneko ekufikeleleni kwiibholithi ezahlukeneyo ngaphakathi kwendawo yenjini ngokufanelekileyo.

- Imisonto yokuthambisa efanaLoctitezibalulekile ekukhuseleni iibholiti ngokufanelekileyo ngelixa zikhusela ukukhulula ngenxa yokungcangcazela.

Izixhobo ezicetyiswayo

- Iigaskets ezikumgangatho ophezuluidlala indima ebalulekileyo ekuqinisekiseni ukutywinwa okufanelekileyo phakathi kwamalungu, ukuthintela ukuvuza okunokuthi kubeke esichengeni ukusebenza kwenjini.

- Amalaphu acocekileyo okanye iitawuli zikulungele ukosula naziphi na izinto zokuthambisa ezigqithisileyo okanye inkunkuma ngexesha lofakelo.

- Iiglasi zokhuseleko zikhusela amehlo akho kwiingozi ezinokubakho njengenkunkuma okanye iikhemikhali ngelixa usebenza kwi-injini yakho.

Ngokuqonda ukubaluleka kwei-harmonic balancer torque specs, uzixhobise ngolwazi olufunekayo ukuze ugcine impilo ye-injini yakho ngokufanelekileyo ngokusebenzisa iinkqubo ezifanelekileyo zokufakela usebenzisa izixhobo ezifanelekileyo kunye nezixhobo.

LS Harmonic BalancerI-Bolt Torque

IiNkcazo zeTorque ezineenkcukacha

Xa kufikwa kwiLS Harmonic Balancer Bolt Torque, ukuchaneka kubaluleke kakhulu ekusebenzeni ngokufanelekileyo kwe-injini yakho. Ukuqonda iinkcukacha ze-torque ezicacileyo kuqinisekisa ukuba icandelo ngalinye liqiniswe ngokukhuselekileyo, ukunciphisa umngcipheko wokungasebenzi kakuhle kunye nokuqinisekisa ukusebenza kakuhle. Makhe sijonge kumzi-mveliso kunye neenkcukacha zasemva kwentengiso ukukukhokela kule nkqubo ibalulekileyo.

Iinkcukacha zefektri

Chevrolet Performanceinikeza umgangatho ophezuluIibholiti zeHarmonic Balancereyenziwe ngentsimbi ephethwe ngubushushu ukwenzela ukomelela okongeziweyo. Ezi bholithi ziyilelwe ukumelana nobunzima bokusebenza kwe-injini, zinentloko ye-hex ethintela ukutyibilika kwesokethi ngexesha lokuqina okanye ukukhulula. Kwiinjini ze-LS ezifana ne-LS1/LS2/LS6, iI-Crankshaft Balancer Boltkufuneka ikhutshelwe240 ft-lbsngexesha lofakelo ukuqinisekisa ukufakwa kwe-balancer epheleleyo.

IiNgcaciso ze-Aftermarket

Ngokhetho lwasemva kweemarike, cinga ukusebenzisaIibholiti zeHarmonic Balancerukusuka kwiibrendi ezihloniphekileyo njengeWerkwell. Ezi bholithi zenzelwe ukuhlangabezana nemigangatho yoshishino kunye nokubonelela ngokusebenza okuthembekileyo. Xa ulandela imiyalelo ye-ATI, kuyacetyiswa ukuba usebenzise i-Loctite 262 kunye ne-torque ibholithi ukuya kwi-230 ft-lbs yofakelo olukhuselekileyo.

Iinkqubo zoFakelo

Iinkqubo ezifanelekileyo zofakelo zibalulekile ekugcineni imfezeko yamacandelo enjini yakho. Ngokulandela isikhokelo sesinyathelo-nge-nyathelo kunye nokuphepha iimpazamo eziqhelekileyo, unokuqinisekisa ukuba i-harmonic balancer bolt iqiniswe ngokukhuselekileyo ukuze usebenze ngokufanelekileyo.

ISikhokelo seNyathelo ngeNyathelo

- Qala ngokulungiselela indawo yakho yokusebenza nazo zonke izixhobo eziyimfuneko kunye nemathiriyeli.

- Qinisekisa ukuba injini ixhaswa ngokufanelekileyo phambi kokuba uqalise inkqubo yokufakela.

- Sebenzisa i-torque wrench ethembekileyo ukuqinisa ibholiti ye-harmonic ye-balancer ngokwefektri okanye i-aftermarket specitions.

- Qinisekisa ukuba ibholithi ikhutshelwe kwixabiso elicetyiswayo usebenzisa iIsitshixo setorque esilinganisiweyo.

- Jonga kwakhona lonke uqhagamshelo kunye namalungu phambi kokuba uqhubeke nokuhlanganisa injini.

Iimpazamo eziqhelekileyo

- Enye impazamo eqhelekileyo ngexesha lofakelo lwebholiti ye-harmonic i-balancer bolt i-over-torquing, enokukhokelela kumonakalo wentambo okanye ukusilela kwecandelo.

- Ukusebenzisa ixabiso le-torque elingalunganga okanye ukungaphumeleli ukulandela iinkqubo ezifanelekileyo zofakelo kunokuphazamisa ingqibelelo yendibano ye-injini.

- Ukungahoywa kokuhlolwa rhoqo okanye ukugcinwa kweetshekhi kunokubangela iibholithi ezikhululekileyo okanye ukulungelelaniswa okungafanelekanga, okuchaphazela ukusebenza kwe-injini iyonke.

Iingcebiso zokuLondoloza

Ukugcinwa rhoqo kungundoqo ekuqinisekiseni ukuthembeka kwexesha elide kunye nokusebenza kumacandelo enjini yakho. Ngokwenza uhlolo lwesiqhelo kunye nokujongana nayo nayiphi na imiba ngokukhawuleza, unokuthintela iingxaki ezinokubakho kwaye wandise ubomi besithuthi sakho.

Ukuhlolwa rhoqo

- Ngamathuba athile jonga ukuqina kwebholiti ye-harmonic ye-balancer ukuqinisekisa ukuba ihlala ngaphakathi kwamaxabiso achaziweyo etorque.

- Jonga izinto ezingqongileyo malunga neempawu zokuguga okanye umonakalo onokuchaphazela ukhuseleko lwebholithi.

- Ukubeka iliso kwi-vibrations ye-injini kunye nengxolo engaqhelekanga enokuthi ibonise izibophelelo ezikhululekile okanye imiba yokungahambi kakuhle.

Imiba yokulungisa ingxaki

- Ukuba ufumana nabuphi na ubunzima ngebholiti yakho ye-harmonic, jongana nezikhokelo zomenzi okanye ufune uncedo lobuchwephesha.

- Jongana nazo naziphi na iimpawu ezingaqhelekanga ngokukhawuleza ukuthintela umonakalo ongakumbi okanye iingozi zokhuseleko ezinxulumene nezibophelelo ezikhululekileyo.

Ngokubambelela kwiinkcukacha zetorque, ngokulandela iinkqubo ezifanelekileyo zofakelo, kunye nokuphumeza iindlela zokugcinwa rhoqo, unokukhusela impilo ye-injini yakho kwaye ukwandise ukusebenza kwayo kwiminyaka ezayo.

Iingcebiso zoFakelo

Amanyathelo Okulungiselela

Xa kufikwa kuamanyathelo okulungiselelaukufakela ibholiti ye-harmonic ye-balancer, ukuqinisekisaamanyathelo okhuselekoyeyona nto iphambili. Oomatshini kunye nabathanda iimoto ngokufanayo bayakuqonda ukubaluleka kokwenza indawo ekhuselekileyo phambi kokuba ungene kuwo nawuphi na umsebenzi wenjini. Ngokulandela ezi zikhokelo zokhuseleko, unokuzikhusela wena kunye nabanye kwiingozi ezinokubakho.

Amanyathelo okhuseleko

- Beka phambili isiXhobo soKhuseleko soMntu (i-PPE) njengeeglavu zokhuseleko, iiglavu, kunye nempahla efanelekileyo ukuze uzikhusele kububutyobo okanye kwizinto eziyingozi.

- Khusela isithuthi kwindawo ezinzileyo usebenzisa izitendi zejekhi kunye nezitshixo zamavili ukuthintela nayiphi na intshukumo ngengozi ngexesha lofakelo.

- Nciphisa ibhetri ukunqanda ukungahambi kakuhle kombane ngelixa usebenza kumalungu enjini.

- Gcina indawo yakho yokusebenza inempepho ngokwaneleyo ukuze ukhuphe umsi okanye igesi ephumayo enokuthi iqokelele ngexesha lokusebenza kwenjini.

Ukusekwa kwendawo yokusebenza

Ukumisela indawo yakho yokusebenza ngokufanelekileyo kubalulekile kwinkqubo yokufakela egudileyo. Ukulungelelanisa izixhobo kunye nezixhobo zakho kwangaphambili kunokonga ixesha kwaye kuthintele ukulibaziseka okungeyomfuneko. Nanga amanye amacebiso okuphucula indlela yakhoukuseta indawo yokusebenza:

- Lungiselela izixhobo zakho ngendlela enocwangco ukuze uphephe ukuzikhangela phakathi komsebenzi.

- Sebenzisa indawo ecocekileyo nekhanyiswe kakuhle ukukhulisa ukubonakala ngelixa usebenza kwizinto ezintsonkothileyo ze-injini.

- Yandlala iimethi zokhuselo okanye izigqubuthelo zokukhusela iindawo ezibuthathaka zesithuthi ekonakalisweni ngengozi okanye imikrwelo.

- Yiba nesixhobo sokucima umlilo kufutshane njengenyathelo lokhuseleko kwimeko yongxamiseko.

Iindlela zokuFakelo

Ukulungelelaniswa okufanelekileyo kunye nokusetyenziswa kwe-torque echanekileyo yimiba ebalulekileyo yokufaka i-harmonic balancer bolt ngokuchanekileyo. Ukuqonda ukuntsonkotha kobu buchule kuqinisekisa ukuba injini yakho isebenza kakuhle ngaphandle kwemiba evela kwiindlela zokufakela ezingafanelekanga.

Ulungelelwaniso olufanelekileyo

Ukuphumelelaukulungelelaniswa okufanelekileyoxa ufaka ibholithi ye-harmonic ye-balancer ibalulekile ekugcineni ulungelelwaniso kunye nokuthembeka kwamacandelo e-injini. Ukungalungelelani kakuhle kunokukhokelela ekungcangcazeleni okugqithisileyo, ukunxiba kwangaphambi kwexesha, okanye kwanokusilela okuyingozi ezantsi komgca. Landela ezi zikhokelo zolungelelwaniso kuhlohlo oluyimpumelelo:

- Lungelelanisa indlela engundoqo kwi-crankshaft kunye ne-slot ehambelanayo kwi-balancer ye-harmonic ngaphambi kokuyikhusela endaweni.

- Sebenzisa izixhobo zokulungelelanisa okanye amanqaku anikezelwe ngabavelisi ukuqinisekisa ukubeka okuchanekileyo ngexesha lofakelo.

- Jonga kabini ulungelelwaniso amaxesha amaninzi kuyo yonke inkqubo ukuqinisekisa ukuchaneka ngaphambi kokuba kugqitywe isicelo setorque.

Isicelo seTorque

Ukusebenzisa i-torque ngokuchanekileyo kubaluleke kakhulu xa uqinisa i-harmonic balancer bolt kumaxabiso achaziweyo. Ukuqiniswa ngokugqithiseleyo kunokubangela umonakalo wentambo okanye ukusilela kwecandelo, ngelixa ukuqiniswa ngaphantsi kunokukhokelela ekudibaneni okuxekethileyo okuphazamisa ukusebenza kwe-injini.

- Sebenzisa i-calibrated torque wrench ebekwe kwixabiso elicetyiswayo elinikezelwe ngumenzi weenkcukacha zokuqinisa ngokuthe ngqo.

- Faka i-torque ngokuthe ngcembe kwizigaba ezinyukayo kunokuba zonke ngaxeshanye usasaze uxinzelelo ngokulinganayo kwimisonto kwaye uthintele utshintsho ngequbuliso kwintlupheko.

- Qinisekisa amaxabiso e-torque usebenzisa iigeyiji ezithembekileyo emva kwesicelo sokuqala ukuqinisekisa ukuqiniswa okufanelekileyo ngaphambi kokuba uqhubeke nemisebenzi eyongezelelweyo yendibano.

Iitshekhi emva koFakelo

Emva kokugqiba inkqubo yofakelo, ukutshekishwa ngokucokisekileyo kwasemva kofakelo kuqinisekisa ukuba yonke into iqiniswe ngokukhuselekileyo kwaye isebenza njengoko bekucetyiwe. Ukuqinisekisa amaxabiso etorque kunye nokwenza uvavanyo lokuqhuba ngamanyathelo ayimfuneko ekuqinisekiseni iziphumo zofakelo oluyimpumelelo.

Ukuqinisekisa iTorque

Nje ukuba uqinise ibholithi ye-harmonic ye-balancer ngokweenkcukacha, kubalulekile ukuqinisekisa ukuba isibophelelo ngasinye sidibana namaxabiso amiselweyo etorque ngokuchanekileyo.

- Phinda ubuye ujonge indawo nganye yoqhagamshelo kunye ne-calibrated torque wrench ukuze uqinisekise ukuba zonke iibholithi zifakwe ngokuchanekileyo ngaphandle kokutenxa.

- Khangela naziphi na iimpawu zokukhulula okanye izitenxo ezinokubonisa ukungaqini ngokwaneleyo ngexesha leenkqubo zofakelo lokuqala.

Uvavanyo luyabaleka

Ukuqhuba uvavanyo emva kokuqinisekisa amaxabiso etorque kunika uqinisekiso lwehlabathi lokwenyani lwemizamo yakho yokufaka. Olu vavanyo lovavanyo lukuvumela ukuba ubone ukuba injini yakho isebenza kakuhle kangakanani phantsi kweemeko zokusebenza emva kofakelo.

- Qala ngovavanyo olufutshane olubalekayo ngezantya ezahlukeneyo ukuvavanya ukusebenza kwenjini iyonke kwaye uchonge nakuphi na ukungcangcazela okungaqhelekanga okanye ingxolo.

- Ukubeka iliso kumanqanaba obushushu, ukuvuza kwamanzi, kunye nezinye izikhombisi ezinokubonisa imiba enokubakho enxulumene nokufakelwa kwebholiti ye-harmonic engafanelekanga.

Ngokuthobela ngokungqongqo kumanyathelo okulungiselela, ukuphumeza iindlela ezifanelekileyo zolungelelwaniso, ukusebenzisa iindlela ezichanekileyo zokusetyenziswa kwetorque, ukungqinisisa iitorque emva kofakelo, kunye nokuqhuba uvavanyo olucokisekileyo, uqinisekisa ukusebenza ngokupheleleyo kumacandelo enjini yakho akhuselweiibholiti ze-harmonic zokulinganisa.

Ubungqina:

- I-A&P eqinisekisiweyo:

"Iinkcazo zeTorque ngokusisiseko ziyivangeli kwihlabathi lam."

- Injineli:

"Ndiyinjineli ngamanye amaxesha iza ne-torque specs zamalungu enjini."

- Akwaziwa:

“Thembela amaxabiso etorque. Bayazi into esebenza ngcono kunawe. ”

Ngokuphindaphinda amanqaku aphambili kunye nokugxininisa ukubaluleka kokubambelela kumaxabiso e-torque achaziweyo, abantu ngabanye baqinisekisa ukusebenza kakuhle kwe-injini. Ukulandela ukucaciswa kwetorque ngenkuthalo kubalulekile ukukhusela ukusilela okunokwenzeka kunye nokugcina imfezeko yamacandelo enjini. Khumbula, ukuchaneka kokusetyenziswa kwetorque kubaluleke kakhulu ekugcineni impilo ye-injini kunye nobomi obude. Thembela kubuchule obusemva kwamaxabiso anikiweyo etorque; zizimisele ngokucokisekileyo kwimpilo yenjini yakho.

Ixesha lokuposa: Jun-04-2024