Ukubaluleka kokuqondaLS ibhalansi yeharmoniciisayizi zebholitiayinakubaxa. Ukuqinisekisa iukulingana ngokuchanekileyoibalulekile ekusebenzeni kakuhle kwe-injini kunye nokuphila ixesha elide. Kwesi sikhokelo sibanzi, abafundi baya kungena kwihlabathi elintsonkothileyo lei-injini ye-harmonic balanceriibholiti, ukuhlola ubungakanani obuqhelekileyo, ifuthe lobungakanani obuchanekileyo, kunye neengcebiso zeengcali zokhetho nokugcinwa.

Ukuqonda iLSI-Harmonic Balancer BoltUbukhulu

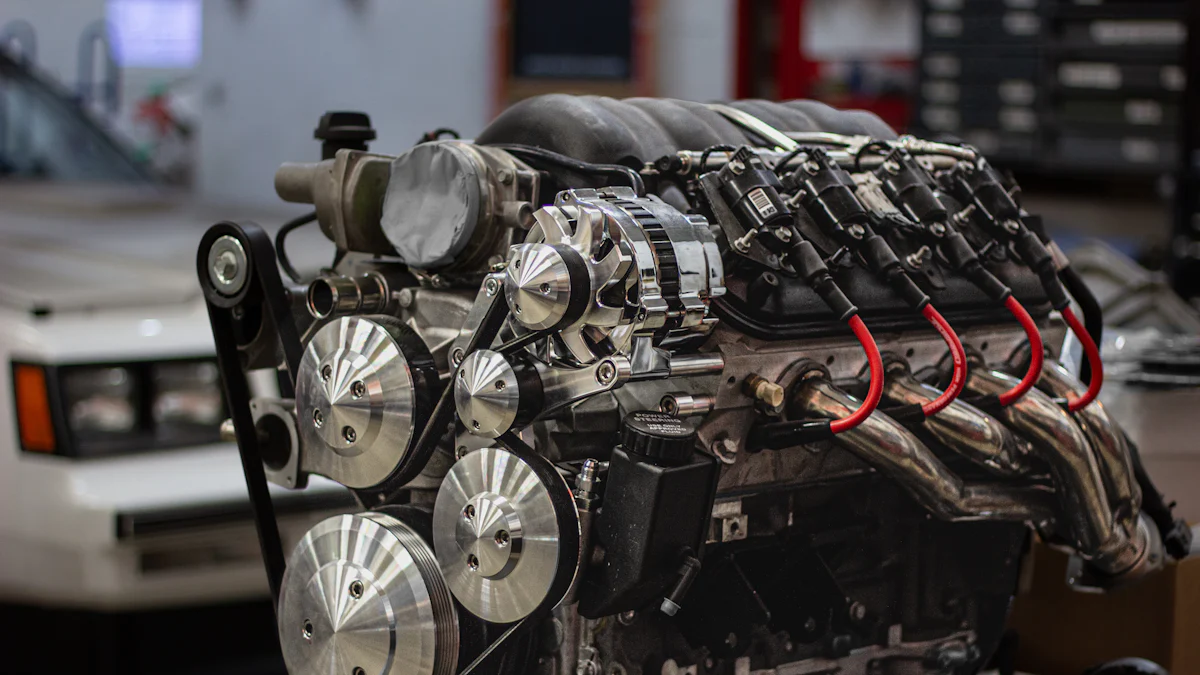

Xa uhlolisisa kummandla weI-LS ye-harmonic balancer bolt ubukhulu, kuyacaca ukuba ukuqonda imilinganiselo yomgangatho kubaluleke kakhulu ekusebenzeni kakuhle kwe-injini. Makhe siphonononge ubungakanani obuqhelekileyo beenjini ze-LS kwaye sicazulule iinuances ezahlula ezi bolt kwiimodeli ezahlukeneyo.

Ubungakanani obusemgangathweni

Ubungakanani obuqhelekileyo beeNjini zeLS

- IGM LS1/LS6iinjini zifuna iM16 x 2.0ibhawudi nge27mm ubukhulu bokukrazulakunye nephantsi kobude bentloko of 4.330″.

- Kuba Gen 3/4 LS iinjini ezifana4.8L, 5.3L, 5.7L, 6.0L, kunye ne-6.2L, a16mm x 2.0 GM Harmonic Balancer Boltkuyacetyiswa.

Umahluko phakathi kweeModeli

- NgamnyeInjini ye-LSimodeli isenokufuna ubungakanani obuthile bebholi yebhali ye-harmonic ukuqinisekisa ukufaneleka kunye nokusebenza okuchanekileyo.

- Kubalulekile ukuchonga ezona nkcukacha zebholiti ezifunekayo kumohluko wenjini yakho ye-LS ukunqanda imiba yokuhambelana.

Ukubaluleka kobungakanani obuchanekileyo

Impembelelo kwiNdlela yokuSebenza

- Ukusebenzisa i-harmonic balancer bolt ubukhulu bubalulekile njengoko buchaphazela ngokuthe ngqo ukuzinza kwe-injini kunye nokusebenza ngokubanzi.

- Ibholithi engafanelekanga okanye ekwisayizi engachanekanga inokukhokelela ekungcangcazeleni, okuchaphazela ukusebenza kakuhle kwe-injini kwaye inokubangela umonakalo wexesha elide.

Ukuthintela Umonakalo

- Ukukhetha ibholithi yobungakanani obufanelekileyo akuphuculi ukusebenza kuphela kodwa kukhuselisa ukwenzakala okunokubakho kumacandelo abalulekileyo einjini.

- Ukuqinisekisa ngokufanelekileyoiinkcukacha zetorquezidibene ngexesha lofakelo kunokuthintela imiba efana ne-slippage okanye ukungalingani kwindibano ye-harmonic balancer.

Ukufumana iBolt eLungileyo

Iimveliso ezicetyiswayo

- Xa ukhetha i-harmonic balancer bolt, iibrendi ezihloniphekileyo ezifanaWerkwellnikeza iinketho ezisemgangathweni eziyilelwe ukuhlangabezana nemigangatho engqongqo yoshishino.

- Ukukhetha uphawu oluthembekileyo kuqinisekisa ukuqina, ubunjineli obuchanekileyo, kunye nokuhambelana neemodeli ezahlukeneyo zeenjini ze-LS.

Indawo yokuthenga

- Iibholiti zeHarmonic ezilungelelanisiweyo ezenzelwe iinjini ze-LS ziyafumaneka kwinginginya yeevenkile ezikwi-intanethi ezilungiselela abantu abathanda iimoto kunye noomatshini abaziingcali.

- Nokuba ufuna ukutshintshwa kwe-OEM okanye ukuphuculwa kokusebenza okuphezulu, ezi bholithi zinokufumaneka ngokulula kubathengisi abagunyazisiweyo okanye abathengisi beemoto abakhethekileyo.

Ukukhetha iBolt eLungileyo

Izinto Emaziqwalaselwe

Xa ukhetha okufanelekileyoibholithiyakhoimodeli injini, kubalulekile ukuvavanya izinto ezithile eziza kuqinisekisa ukusebenza kakuhle kunye nokuphila ixesha elide. Ukuqonda iinuances zokwahluka kwenjini nganye kunokukukhokelela ekubeni wenze isigqibo esinolwazi esilungiselelwe iimfuno zesithuthi sakho.

Imodeli yeNjini

Ukuchonga ngokuthe ngqoI-LS ye-harmonic balancer bolt ubukhuluiyahambelana nemodeli yenjini yakho linyathelo lokuqala ekuphuculeni ukusebenza kwayo ngokubanzi. Ii-injini ze-LS ezahlukeneyo zisenokufuna ukucaciswa kwebholithi ethile ukuqinisekisa ukhuseleko olufanelekileyo nokusebenza okuthembekileyo. Ngokubhekiselele kwizikhokelo zomenzi okanye ngokudibana neengcaphephe zeemoto, ungakhomba eyona sayizi yebholithi ehambelana noyilo lwenjini yakho.

IiMfuno zokuSebenzisa

Ukuqwalasela yakhoiimfuno zokusetyenziswaKubalulekile xa umisela eyona bholithi ifanelekileyo yenjini yakho ye-LS. Nokuba usebenzisa isithuthi sakho ukuhamba yonke imihla, ukubaleka umdyarho, okanye ukubaleka endleleni, ukukhetha ibholithi ehlangabezana neemfuno zemikhwa yakho yokuqhuba yeyona nto iphambili. Izinto ezifana nomthamo we-torque, ukuqina, kunye nokuchasana nezinto zokusingqongileyo kufuneka zithathelwe ingqalelo ukuze kuqinisekiswe ukusebenza kakuhle phantsi kweemeko ezahlukeneyo.

Ukuthelekisa izinto zeBolt

Xa uphononongaizixhobo zebholithikwi-LS yakho ye-harmonic balancer assembly, ukuqonda ukuhlukana phakathi kwentsimbi kunye neenketho ze-alloy kunokunceda ekwenzeni ukhetho olunolwazi. Isixhobo ngasinye sibonelela ngeempawu ezizodwa ezihlangabezana neemfuno ezahlukeneyo zokusebenza kunye nokuqwalaselwa kohlahlo lwabiwo-mali.

Intsimbi vs. Ingxubevange

- Iibholiti zentsimbi: Eyaziwayo ngokomelela kunye namandla aphezulu okuqina, iibholiti zentsimbi zithandwa kwizicelo ezifuna ukuqina okukhethekileyo kunye nomthamo wokuthwala umthwalo. Ezi bhotshi zilungele iimeko zokusetyenziswa ezinzima apho ukuthembeka kunye nokuphila ixesha elide kubaluleke kakhulu.

- Iibholiti zengxubevange: Iibholiti ze-alloy zixabiswa ngenxa yolwakhiwo olukhaphukhaphu kunye neempawu zokumelana nomhlwa. Banikezela ngokulinganisela phakathi kwamandla kunye nokugcinwa kobunzima, okwenza ukuba bafanelekele izicelo apho ukunciphisa ubunzima ngaphandle kokuphazamisa ukunyaniseka kwesakhiwo kubalulekile.

Okuhle nokubi

- Iibholiti zentsimbi:

- IiPros: Amandla akhethekileyo, ukuqina, kunye nokufikeleleka.

- Ububi: Inzima kuneebholiti zealloyi, ichaphazeleka kukuhlwa ukuba ayityalwanga kakuhle okanye ayigcinwanga kakuhle.

- Iibholiti zengxubevange:

- IiPros: Uyilo oluKhaphukhaphu, ukuxhathisa ukubola, lulungele usetyenziso oluphezulu.

- Ububi: Iindleko eziphezulu xa kuthelekiswa neentsimbi zetsimbi, zinokufuna izixhobo ezikhethekileyo zokufakela.

IiNgcebiso zeNgcali

Ukufumana ulwazi kwiingcali ezinamava kwishishini leemoto kunokubonelela ngesikhokelo esixabisekileyo xa ukhetha ibholithi elungileyo kwindibano yakho ye-LS yeharmonic balancer. Ukusebenzisa iingcebiso zeengcaphephe kumava oomatshini kunye nokubandakanyeka kwiingxoxo zeforamu kunokunika iingcebiso ezisebenzayo ezilungiselelwe iimeko zehlabathi zokwenyani.

Mechanic Insights

Oomatshini abanamava bahlala bebelana ngeengcebiso ezingabalulekanga ekukhetheni iibholiti ze-harmonic ezisekwe kumava abo okusebenza ngeemodeli ezahlukeneyo zeenjini ze-LS. Ubuchwephesha babo kubuchule bokufaka, ukucaciswa kwetorque, kunye noqwalaselo lokuhambelana kunokukunceda ukuba ujonge inkqubo entsonkothileyo yokukhetha eyona bholithi ifanelekileyo kwiimfuno zakho zenjini.

Iingxoxo zeForam

Ukuthatha inxaxheba kwiingxoxo zeforam ezinikezelwe kwiinjini ze-LS kuvumela abantu abanomdla kunye noomatshini ngokufanayo ukuba batshintshiselane ngolwazi malunga nokhetho kunye nofakelo lwe-harmonic balancer bolts. La maqonga asebenza njengeendawo zolwazi apho abantu babelana ngophononongo lwemveliso, iingcebiso zokusombulula ingxaki, kunye neendlela ezifanelekileyo ezinxulumene nokugcina ukusebenza kakuhle kwe-injini ngokukhetha ibholiti efanelekileyo.

Iingcebiso zokuFakelo kunye noLondolozo

Iindlela ezifanelekileyo zokuFakela

Izixhobo ezifunekayo

- A isitshisi torquekubalulekile ukuqinisa ngokuchanekileyo ibholiti ye-harmonic ye-balancer kwiinkcukacha zomenzi, ukuqinisekisa ukusebenza kakuhle kwe-injini.

- Iseti yesokhethi: Ukuba neentlobo ezahlukeneyo zeesokethi ngobukhulu obahlukeneyo kuya kukuvumela ukuba ufikelele kwaye ukhusele i-bolt ngokuchanekileyo.

- Ilokha yomsonto: Ukusebenzisa i-thread locker kwimicu ye-bolt ngaphambi kokufakela kunokuthintela ukukhulula ngenxa yokunyakaza, ukuphucula ukuzinza ngokubanzi.

- Ratchet: Ukusebenzisa i-ratchet ngokubambisana ne-socket set iququzelele ukuqiniswa okusebenzayo kunye nokulawulwa kwe-harmonic balancer bolt.

- Iiglavu zokhuseleko kunye neiglavu: Ukubeka phambili ukhuseleko ngexesha lofakelo kubalulekile, kwaye ukunxiba izixhobo zokukhusela njengeeglavu kunye neeglavu kukukhusela kwiingozi ezinokubakho.

ISikhokelo seNyathelo ngeNyathelo

- Lungisa indawo yokusebenza: Qinisekisa ukuba injini ipholile phambi kokuba uqalise umsebenzi. Sula nayiphi na imiqobo ejikeleze indawo ye-harmonic ye-balancer ukufikelela ngokulula.

- Khusela isithuthi: Paka imoto yakho kwindawo esemgangathweni kwaye ubandakanye ibhuleki yokupaka ukuthintela nayiphi na intshukumo ngexesha lofakelo.

- Khangela ibholithi yeharmonic yokulinganisa: Chonga eyona ndawo yebholiti ye-harmonic kwi-injini yakho ye-LS yokufikelela ekujoliswe kuko.

- Susa nayiphi na imiqobo: Ukuba kuyimfuneko, susa amacandelo athintela ukufikelela ngokuthe ngqo kwi-harmonic balancer bolt, njengamabhanti okanye iipuli.

- Sebenzisa izixhobo ezifanelekileyo: Khetha ubungakanani besokethi obuchanekileyo obuhambelana nentloko yebholithi ukunqanda ukutyibilika okanye ukonakala ngexesha lokuqina.

- Faka isitshixo somsonto: Ngaphambi kokufaka ibholithi entsha, sebenzisa inani elincinci lelokhi yomsonto kwimisonto yayo ukuze uyikhusele ngokuqinileyo endaweni.

- Qinisa kwiinkcukacha zomenzi: Sebenzisa i-torque wrench ukuqinisa i-harmonic balancer bolt ngokweemfuno zetorque ezicetyisiweyo ngumenzi we-injini yakho.

- Yenza iitshekhi zokugqibela: Jonga kabini yonke imidibaniso, uqinisekise ukuba akukho zixhobo zishiywe zikhululekile okanye zilahlekile emva kokukhusela ibholiti yeharmonic.

- Uvavanyo lomsebenzi wenjini: Qala i-injini yakho kwaye ubeke iliso ekusebenzeni kwayo emva kofakelo ukuqinisekisa ukuba yonke into isebenza kakuhle ngaphandle kokungcangcazela okungaqhelekanga okanye izandi.

ULondolozo lweyona Nkqubo iLungileyo

Ukuhlolwa rhoqo

- Yenza uhlolo olubonwa ngamaxesha athile kwindibano yakho ye-harmonic ye-balancer ukubona naziphi na iimpawu zokuguga, ukubola, okanye ukungahambi kakuhle okungabonisa imiba enokubakho.

- Jonga ukungcangcazela okungaqhelekanga ngelixa uqhuba, njengoko oku kunokuba luphawu lwakwangoko lwebholithi ye-harmonic exekileyo okanye eyonakeleyo efuna ingqalelo ekhawulezileyo.

Iimpawu zokuNxitywa

- Khangela iintanda okanye ukukhubazeka okubonakalayo kumphezulu we-harmonic balancer assembly, ebonisa ubuthathaka besakhiwo obunokuthi buphazamise ukusebenza kwayo ekuhambeni kwexesha.

- Nika ingqalelo kuzo naziphi na ingxolo engaqhelekanga evela kwi-injini yakho, njengoko ezi zinokubonisa iingxaki ezisisiseko kwindibano yakho ye-harmonic ye-balancer efuna uvandlakanyo olukhawulezileyo.

Ukusombulula imiba eqhelekileyo

IiBolt ezikhululayo

- Ukuba uqaphela nakuphi na ukukhululeka kwindibano yakho ye-harmonic ye-balancer, jonga ngokukhawuleza kwaye uqinise iibholithi kwakhona usebenzisa isitshixo se-torque ukunqanda ezinye iingxaki.

- Ukujongana neebholiti ezikhululekileyo ngokukhawuleza kunokuthintela ukungcangcazela okugqithisileyo okunokukhokelela kumonakalo wecandelo ngaphakathi kwenkqubo ye-injini yakho.

Iingxaki zokungcangcazela

- Ukungcangcazela okuzingileyo ngexesha lokusebenza kwe-injini kungabonisa i-harmonics engalinganiyo ebangelwa yimpazamo okanye ifakwe ngokungalunganga indibano ye-harmonic balancer.

- Qhagamshelana nomkhandi oqeqeshiweyo ukuba ufumana imiba yokungcangcazela eqhubekayo emva kofakelo loxilongo olucokisekileyo kunye neendlela zokusombulula ezilungelelaniswe neemfuno zemodeli ye-injini yakho ye-LS.

- Ukushwankathela, ukuqinisekisa ukuba kuchanekileI-LS ye-harmonic balancer bolt ubukhuluyeyona nto ibalulekileyo ekusebenzeni kakuhle kwe-injini kunye nokuphila ixesha elide. Ukufaneleka okuchanekileyo kuthintela ukungcangcazela kunye nomonakalo onokuthi ube khona, ukukhusela amacandelo e-injini ebalulekileyo.

- Ukugxininisa ukubaluleka kokusebenzisa ibholithi entsha ukuseta ibhalansi ngokuchasene ne-crankshaft, eneemfuno ezithile zetorque, yongeza uzinzo ngokubanzi.

- Ukuqhubela phambili, ukuhlola rhoqo ukugcinwa kunye nokuthobela izikhokelo zomvelisi wokukhethwa kwebholithi kunye nokufakwa kunconywa ukuba kugcinwe ukusebenza kakuhle kwe-injini kunye nokuthembeka.

Ixesha lokuposa: Jun-04-2024