Uma ucubungula ukushintshaniswa kwenjini, ukukhetha kweI-LS swap exhaust manifoldsidlala indima ebalulekile ekusebenzeni okuphelele. Lawa manifold awawona nje ama-compounds kodwa kunalokho amasu abalulekile angaba nomthelela omkhulu ekusebenzeni kahle kwenjini nokuphuma kwamandla. Ukuqonda ama-nuances wokukhetha okulungileinjini yokukhipha igesi eningikubalulekile ukushintshanisa okuyimpumelelo. Kulo mhlahlandlela, singena ezinhlotsheni ezihlukene ze-LS swap exhaust manifolds, izinzuzo zazo, izithiyo, kanye nenqubo yokukhetha eyinhloko yokuqinisekisa ukusebenza kahle kuphrojekthi yakho.

Izinhlobo ze-LS Swap Exhaust Manifolds

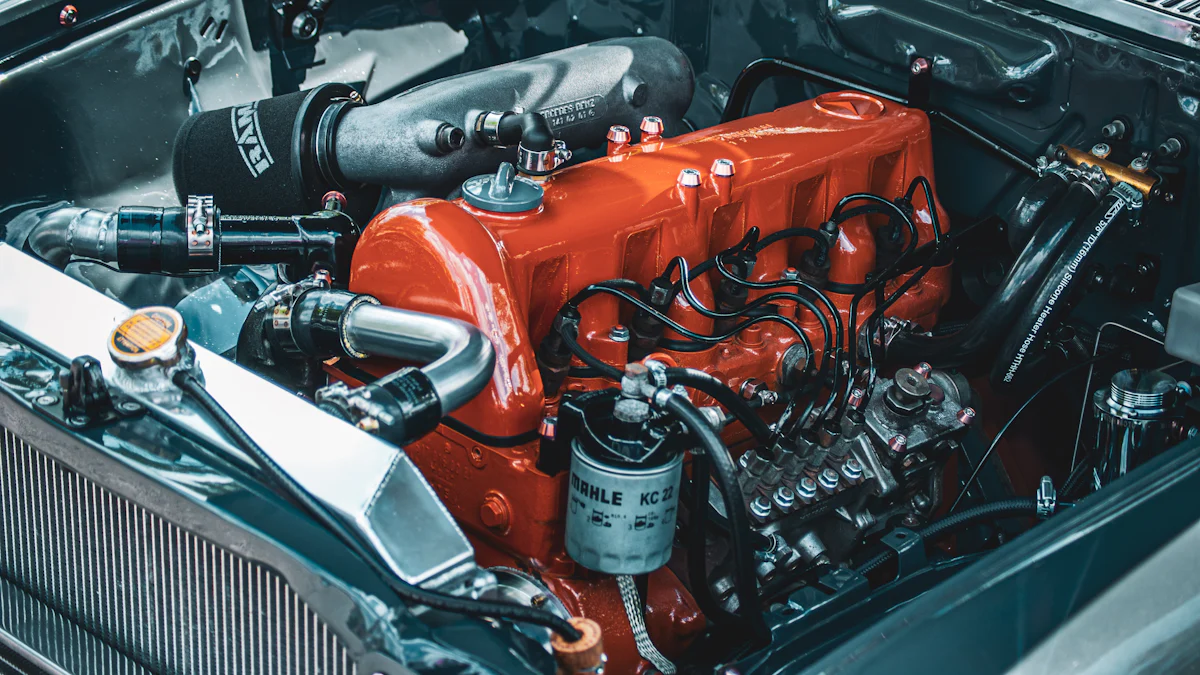

I-Cast Iron Manifolds

Uma kufikaI-LS swap exhaust manifolds, I-Cast Iron Manifoldskuyisinqumo esidumile phakathi kwabathandi. Lezi zinhlobonhlobo zinikeza inhlanganisela yeukuqinakanye nokusebenza kahle kwezindleko okubenza babe inketho engokoqobo yokushintshaniswa kwezinjini eziningi.

Izinzuzo

- Ukuqina: I-cast iron yaziwa ngokuqina kwayo, iqinisekisa ukuthi lezi zinhlobonhlobo zingakwazi ukumelana nobunzima bezinjini ezisebenza kahle kakhulu.

- Ukufinyeleleka: Uma kuqhathaniswa nezinye izinto ezisetshenziswayo, izinqwaba zensimbi ezisansimbi zivame ukusebenzisana nesabelomali, okuzenza zibe inketho ekhangayo kulabo abafuna ukuthuthukisa injini yabo ngaphandle kokuphula ibhange.

Amaphutha

- Isisindo: Enye yezingqinamba eziyinhloko ze-cast iron manifolds isisindo sazo. Ubunzima balezi zinhlobonhlobo bungangeza umthwalo owengeziwe emotweni.

- Ukugcina Ukushisa: I-cast iron ijwayele ukugcina ukushisa, okungase kuthinte izinga lokushisa lenjini lilonke uma lingaphathwa kahle.

I-Stainless Steel Manifolds

Kulabo abafuna ukulingana phakathi kokusebenza nokuphila isikhathi eside,I-Stainless Steel Manifoldsukunikeza isisombululo esicindezelayo. Lezi zinhlobonhlobo zinikeza ukumelana okuhle kakhulu nokugqwala nokushisa, okuzenza zilungele izinhlelo zokusebenza ezisebenza kahle kakhulu.

Izinzuzo

- Ukumelana Nokugqwala: Insimbi engagqwali imelana kakhulu nokugqwala nokugqwala, iqinisekisa ukuthi lezi zinhlobonhlobo zigcina ikhwalithi yazo ngokuhamba kwesikhathi.

- Ukuphathwa Kokushisa: Insimbi engagqwali inezinto eziphakeme zokuqeda ukushisa, isiza ukugcina izinga lokushisa lenjini liqinile ngesikhathi sokusebenza okukhulu.

Amaphutha

- Izindleko: Izinqwaba zensimbi engagqwali ngokuvamile zimba eqolo kunozakwabo bensimbi, okungase kuvimbe abakhi abaqaphela ibhajethi.

- I-Complex Fabrication: Ukusebenza ngensimbi engagqwali kudinga amathuluzi akhethekile namakhono, okufaka inkimbinkimbi enqubweni yokufaka.

Ama-Manifolds Enziwe Ngokwezifiso

Uma izinketho ezingekho eshalofini zingahlangabezani nezidingo zakho,Ama-Manifolds Enziwe Ngokwezifisonikeza isixazululo esilungiselelwe. Lezi zinhlobonhlobo ze-bespoke zenzelwe ukulingana nezimo ezithile zenjini kanye nemigomo yokusebenza.

Izinzuzo

- Ukufaneleka Okuhlanganisiwe: Ama-multifolded enziwe ngokwezifiso aqinisekisa ukulingana okunembile emotweni yakho, asusa izinkinga zokugunyazwa kanye nokusebenza kahle.

- Ukuthuthukisa Ukusebenza: Ngokwenza ngendlela oyifisayo idizayini yezinhlobonhlobo, abakhi bangashuna kahle ukugeleza kwe-exhaust ukuze bakhiphe amandla amaningi.

Amaphutha

- Kuyabiza: Ukwenziwa ngokwezifiso kufika ngentengo ephezulu uma kuqhathaniswa nezinketho ezikhiqizwe ngobuningi, okwenza kungafinyeleleki kancane ekwakhiweni kwesabelomali.

- Isikhathi esiholayo: Inqubo yokuklama nokwenza izinto eziningi ezihlukene ngokwezifiso ingadla isikhathi, ibambezele izikhathi zephrojekthi.

Imibandela Yokukhetha

Ukuhambisana Kwenjini

Uma kufikaI-LS swap exhaust manifolds, ukuqinisekisaUkuhambisana Kwenjinikubaluleke kakhulu ekushintsheni injini okuyimpumelelo. OkuhlukileLS uchungechunge izinjiniingase idinge ukuphindaphindeka okuthile ukuze kuthuthukiswe ukusebenza kahle nokusebenza kahle, kuyilapho ezinye izinhlobo zezinjini zingase zibe nezidingo ezihlukile ezidinga ukubhekwana nazo.

- LS Series Izinjini: Okwezinjini zochungechunge lwe-LS ezifana ne4.8, 5.3, kanye no-6.0okuhlukile, ukukhetha okuhlukahlukene okulungile kubalulekile. Injini ngayinye inezici zayo, futhi ukukhetha inqwaba ehambisanayo kungathuthukisa ukuphuma kwamandla nokusebenza kwenjini kukonke.

- Ezinye Izinhlobo Zenjini: Ezimeni lapho izinjini ezingezona eze-LS zishintshwa, ukucatshangelwa kokuhambisana kuba bucayi kakhulu. Ukulungisa i-LS swap exhaust manifolds ukuze ilingane izinjini ezinokucushwa okuhlukile kudinga ukuhlela okucophelelayo nokunaka imininingwane.

Isikhala Nokuhlanzeka

Isikhala Nokuhlanzekaokucatshangwayo kudlala indima enkulu ekunqumeni ukufaneleka kwe-LS swap exhaust manifolds kuphrojekthi yakho. Ubukhulu bechweba lenjini, kanye namandlaizinkinga zokufaneleka, kufanele ihlolwe ngokucophelela ukuze kuqinisekiswe inqubo yokufaka engenamthungo.

- Ukucatshangelwa kwe-Engine Bay: Ngaphambi kokukhetha inqwaba ye-exhaust, hlola isikhala esitholakalayo endaweni yenjini. Ezinye izinjini ze-LS zingase zidinge ukuguqulwa noma ukulungiswa ukuze kuhambisane nokuphindaphindeka okuthile ngendlela efanele. Ukuqinisekisa imvume eyanele kubalulekile ukuze uvimbele ukuphazamiseka nezinye izakhi.

- Izinkinga zokufaneleka: Izinkinga zokufaneleka zingavela lapho kufakwa i-aftermarket exhaust manifolds ekusetheni okungekona kwe-OEM. Kubalulekile ukubhekana nanoma yiziphi izinselele zokufaneleka ezingaba khona ekuqaleni kwesigaba sokuhlela ukuze ugweme izinkinga phakathi nokufakwa. Ukufakwa kahle kuqinisekisa ukusebenza okuhle nokuphila isikhathi eside kwesistimu yokukhipha umoya.

Imigomo Yokusebenza

Ukuchaza kucaceImigomo Yokusebenzakuyisihluthulelo lapho ukhetha i-LS swap exhaust manifolds yephrojekthi yakho. Kungakhathaliseki ukuthi uhlose ukukhulisa amandla okukhipha amandla noma ukuthuthukisa ukuphathwa kokushisa, ukuqondanisa imigomo yakho namandla ezinhlobonhlobo ezikhethiwe kubalulekile ukuze uzuze imiphumela oyifunayo.

- Okukhipha Amandla: Uma ukukhulisa amandla ehhashi netorque kuyinjongo eyinhloko, ukukhetha ukusebenza okuningi okuklanyelwe ukugeleza okuthuthukisiwe kungenza umehluko omkhulu. Idizayini kanye nokwakhiwa kwezinhlobo eziningi zegesi kuthinta ngqo isivinini segesi yokukhipha ugesi kanye nokusebenza kahle kokukhipha amanzi, okunomthelela ekuzuzweni kwawo wonke amandla.

- Ukuphathwa Kokushisa: Ukuphatha ukushisa okusebenzayo kubalulekile ukuze kugcinwe izinga lokushisa elilungile lenjini ngesikhathi sokusebenza. Ukukhetha i-multifold exhaust enezici eziphezulu zokukhipha ukushisa kungasiza ukuvimbela izinkinga zokushisa ngokweqile nokuqinisekisa ukusebenza okungaguquguquki ngaphansi kwezimo ezinzima.

Amathiphu okufaka

Ukulungiselela

Lapho ulungiselela ukufakwa kweI-LS swap exhaust manifolds, kubalulekile ukuthi ube namathuluzi afanele onawo. Ukulungiselela kahle kungenza inqubo ibe lula futhi iqinisekise umphumela oyimpumelelo.

Amathuluzi Ayadingeka

- Isethi ye-Wrench: Isethi yama-wrenches ngosayizi abahlukahlukene izodingeka ukuze ukhulule futhi uqinise amabhawodi ngokuphepha.

- Isethi yesokhethi: Ukuba nesethi yesokhethi enezilinganiso zombili zemethrikhi nezijwayelekile kungakusiza ukuthi ubhekane nezixhumi ezihlukene ku-manifold.

- I-Torque Wrench: Ukuqinisekisa ukuthi amabhawodi ayaqiniswa ngokwezicaciso zomkhiqizi, isikrufu setorque sibalulekile.

- I-Gasket Sealant: Ukusebenzisa i-gasket sealant kungasiza ekudaleni uphawu oluqinile phakathi kwe-multifold kanye nebhulokhi yenjini, ukuvimbela ukuvuza.

- Izibuko zokuphepha kanye namagilavu: Ukuvikela amehlo nezandla zakho ngesikhathi sokufakwa kubalulekile ukuze uphephe.

Izinyathelo Zokuphepha

Ukubeka phambiliukuphepha kuyo yonke inqubo yokufakaakuxoxiswana ngakho. Ngokulandela izinyathelo zokuphepha ezibalulekile, ungavimbela izingozi nokulimala, uqinisekise ukuhamba komsebenzi okushelelayo.

- Sebenza Endaweni Enomoya Okahle: Ukungena komoya owanele kubalulekile uma usebenza nezinto ezikhipha umoya ukuze ugweme ukuhogela intuthu eyingozi.

- Sebenzisa uJack Stands: Uma usebenza ngaphansi kwemoto, hlala uyisekele ngezitendi zojeke ukuze uvimbele izingozi ngenxa yokugudluka noma ukuwa.

- Vumela Isikhathi Sokupholisa: Ngaphambi kokuqala ukufaka, qiniseka ukuthi injini ipholile ngokwanele ukugwema ukusha okuvela ezintweni ezishisayo.

- Hlola kabili uxhumo: Ngemva kokufaka i-manifold entsha, hlola kabili zonke izixhumi nezixhumi ukuze uqinisekise ukuthi yonke into ivikelekile ngaphambi kokuqala injini.

Isinyathelo ngesinyathelo Umhlahlandlela

Ukulandela indlela ehlelekile phakathi nenqubo yokufaka kungakusiza ukuthi uzulazule esinyathelweni ngasinye ngempumelelo. Kusukela ekususeni i-manifold endala kuya ekufakeni entsha, nawu umhlahlandlela ophelele wokukusiza endleleni.

Isusa I-Old Manifold

- Qala ngokunqamula noma yiziphi izinzwa noma izintambo ezinamathiselwe ku-multifold ekhona.

- Khulula futhi ukhiphe wonke amabhawodi avikela ukuphindaphindeka kwenjini usebenzisa isikrufu esifanelekile noma isokhethi.

- Khipha ngokucophelela i-manifold endala enjinini, uqaphele noma yimaphi ama-gaskets noma ama-seal adinga ukushintshwa.

Ifaka I-Manifold Entsha

- Hlanza indawo ekhwezwayo kubhulokhi yenjini kahle ukuze uqinisekise ukunamathela okufanele kwe-multifold entsha.

- Beka i-gasket entsha phezu kwendawo ekhwezayo, uyiqondanise nezimbobo zamabholithi ukuze ibekwe kahle.

- Beka i-exhaust entsha eshintshashintshayo ye-LS kubhulokhi yenjini, uqinisekise ukuthi ihlezi ingqubuzana ne-gasket.

- Bopha ngokuphephile wonke amabhawudi ngephethini ye-crisscross, kancane kancane uwaqinise ngesikrufu setorque njengokucaciswa komkhiqizi ngamunye.

Ukuxazulula inkinga

Ukuhlangabezana nezinkinga phakathi nokufakwa akuvamile kodwa ukwazi ukuthi ungayixazulula kanjani inkinga kungonga isikhathi nokukhungatheka. Ngokuqonda izinkinga ezivamile nezixazululo zazo, ungakwazi ukunqoba izinselele ngaphandle komthungo.

Izinkinga Ezivamile

- Ukuvuza Around Seals: Uma ubona ukuvuza eduze kwe-seal noma ama-gaskets, hlola ukuqondanisa okufanele kanye nokucinana kwezibophelelo ngaphambi kokucabangela ukuphinda uvale.

- Ukufaneleka Okungalungile: Ezimeni lapho ukulingana kubonakala kuvaliwe, qinisekisa ukuthi zonke izingxenye ziyahambisana futhi zifakwe ngendlela efanele ngokuya ngemininingwane.

Izixazululo

- Hlola Umonakalo: Hlola ngokucophelela zonke izakhi ukuze uthole noma yiziphi izimpawu zokulimala noma ukuguga okungafaka engozini ubuqotho bokuvalwa.

- Qondisa Izingxenye: Uma ukungaboni ngaso linye kutholwa, qondisa kabusha izingxenye ngokucophelela uqinisekise ukuthi zihlala ndawonye ngaphambi kokuqinisa izibophelelo ngokuvikelekile.

Imikhiqizo Ethandwayo

Ihuka

Ibanga Lomkhiqizo

I-Hooker, ibhrendi edumile embonini yezimoto, inikeza uhla lwemikhiqizo ehlukahlukene ye-LS swap exhaust manifolds eklanyelwe ukuhlangabezana nezidingo zabathandi bokusebenza. Kusukela ku-cast iron kuya kuzinketho zensimbi engagqwali, i-Hooker ihlinzeka ngokuphindaphindeka kwekhwalithi ephezulu okudizayinelwe ukuthuthukisa ukusebenza kahle kwenjini nokuphuma kwamandla.

Izici Eziyinhloko

- Ubunjiniyela bokunemba: I-manifold ngayinye evela ku-Hooker ibhekana nezinqubo zobunjiniyela obucophelelayo ukuze kuqinisekiswe ukufaneleka okunembayo nokusebenza okuphelele.

- Ukuqina Okuthuthukisiwe: Ngokugxila ekuqineni, ama-Hooker manifolds akhelwe ukumelana nezinga lokushisa eliphezulu nezimo zokusebenza ezinzima.

- Ukugeleza Kwe-Exhaust Okuthuthukisiwe: Idizayini yama-Hooker manifolds ikhuthaza ukugeleza kwe-exhaust okusebenzayo, okunikela emandleni enjini athuthukisiwe kanye nokusabela.

Hedman

Ibanga Lomkhiqizo

U-Hedman ugqama emakethe ngohlu lwakhe lomkhiqizo olubanzi lwe-LS swap exhaust manifolds, ebhekelela inhlobonhlobo yezicelo zezimoto. Kungakhathaliseki ukuthi ufuna insimbi esakazwayo noma izixazululo ezenziwe ngokwezifiso, i-Hedman inikeza izinketho ezihlukahlukene ukuze zivumelane nokucushwa kwenjini okuhlukahlukene.

Izici Eziyinhloko

- Ukuvumelana Okubanzi: I-Hedman manifolds yakhelwe ukusebenzisana kwendawo yonke nezinjini ezihlukene zochungechunge lwe-LS, ihlinzeka ngokuguquguquka kokushintshwa kwezinjini.

- Ukusebenza Okulungiselelwe: Idizayini emisha ye-Hedman manifolds igxile ekwandiseni ukugeleza kwe-exhaust kanye nokusebenza kahle kokukhipha ukuze kuthuthukiswe ukusebenza kwenjini.

- Ukufaka Easy: Izinhlobonhlobo ze-Hedman zifaka izinqubo zokufaka ezisebenziseka kalula, ezivumela abathanda ukuthi bathuthukise amasistimu abo e-exhaust kalula.

Ukusebenza kwe-Patriot

Ibanga Lomkhiqizo

I-Patriot Performance iyaziqhenya ngomkhiqizo wayo okhethekile we-cast gray ductile iron LS swap exhaust manifolds, eklanyelwe izinduku zomgwaqo kanye nezimoto zemisipha. Lezi zinhlobonhlobo zihlanganisa ubuciko bekhwalithi nezici ezigxile ekusebenzeni ukuze kuthuthukiswe umuzwa wokushayela usuwonke.

Izici Eziyinhloko

- Idizayini Ehlanganisiwe: Izinhlobonhlobo ze-Patriot Performance zakhiwe ngobunono ukuze zinikeze ukulingana okuhambisanayo ezimotweni zakudala, okuqinisekisa ukuhlanganisa okungenazihibe ekusetheni okukhona.

- Izixazululo Zokulawula Ukushisa: Ngokugxila ekulawuleni ukushisa, ukuphindaphindeka kwe-Patriot Performance kusiza ukulawula amazinga okushisa enjini ngempumelelo phakathi nezikhathi zokusebenza ezinwetshiwe.

- Umsindo Wenjini Othuthukisiwe: Idizayini eyingqayizivele ye-Patriot Performance manifolds ayithuthukisi ukusebenza kuphela kodwa futhi ithuthukisa inothi yokukhipha umoya, yengeze iphrofayili yomsindo ehlukile emotweni yakho.

I-Recap ye-LS Swap Exhaust Manifolds:

- Uhla oluhlukahlukene lwe-LS eshintshashintshayo kaningi lokukhipha igesi, kusukela kunsimbi esakazwayo kuye kwensimbi engagqwali kanye nezinketho ezakhiwe ngokwezifiso, zibhekelela izidingo ezihlukahlukene ekushintsheni kwenjini.

Ukubaluleka Kokukhetha Okufanelekile Nokufakwa:

- Ukukhetha inqwaba efaneleibalulekile ekuthuthukiseni ukusebenza kwenjini nokusebenza kahle ngesikhathi sokushintshana. Ukufakwa ngendlela efanele kuqinisekisa ukuhlanganiswa okungenamthungo kanye nokusebenza kwesikhathi eside.

Okucatshangelwayo Nezincomo Ezizayo:

- Ukucabangela izici ezifana nokuhambisana, imikhawulo yesikhala, nemigomo yokusebenza kungaqondisa ukukhetha okuningana okuzayo. Izincomo zifaka ucwaningo olunzulu kanye nochwepheshe bokuxhumana ukuze bathole izixazululo ezihambisanayo.

Isikhathi sokuthumela: Jun-14-2024