Ukuqonda I-Exhaust Manifolds

Izinhlobo ze-Exhaust Manifolds

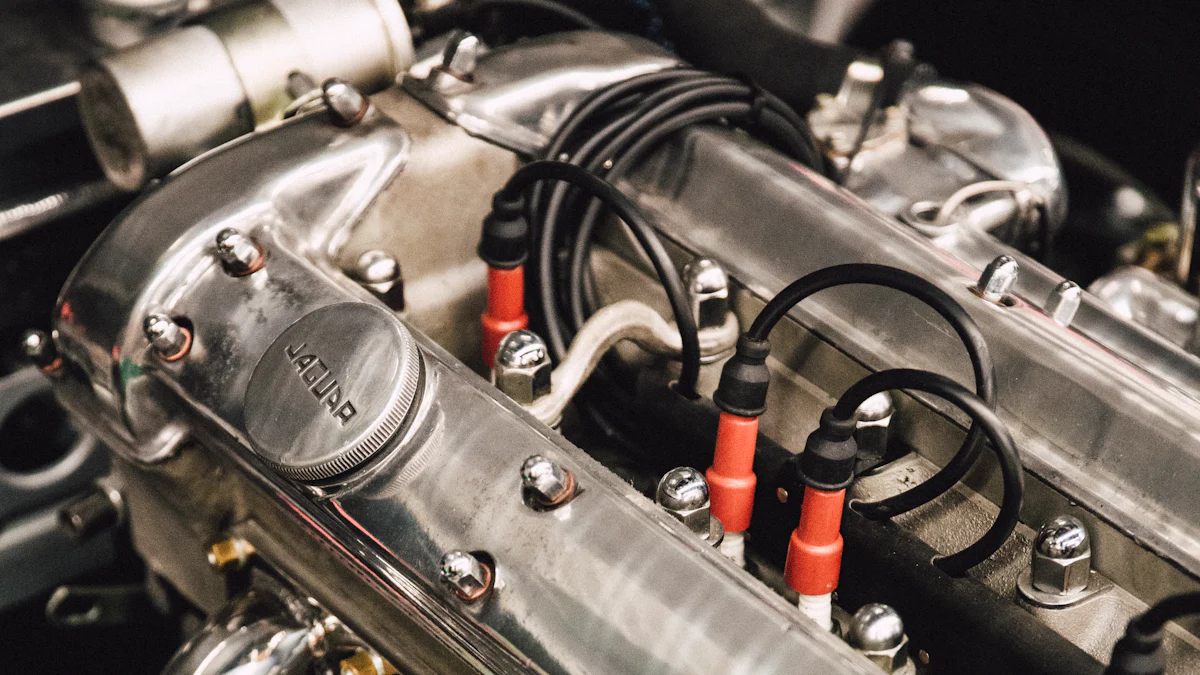

I-Cast Iron Manifolds

I-Cast iron manifolds inikeza ukuqina nokusebenza kahle kwezindleko. Lezi zinhlobonhlobo zimelana namazinga okushisa aphezulu futhi zimelana nokuqhekeka. Nokho, isisindo sabo esinzima singaba nomthelela omubi ekusebenzeni kwemoto. Ubuningi bensimbi ye-Cast ngokuvamile buvela kumamodeli emoto amadala noma aqaphela ibhajethi.

I-Stainless Steel Manifolds

Izinqwaba zensimbi engagqwali zinikeza ibhalansi phakathi kwamandla nesisindo. Lezi zinhlobonhlobo zimelana nokugqwala futhi zigcina ubuqotho besakhiwo ngaphansi kwezimo ezimbi kakhulu. Isisindo esilula sensimbi engagqwali sithuthukisa ukusebenza kahle kwemoto iyonke. Izimoto eziningi zesimanje zisebenzisa izinqwaba zensimbi engagqwali ukuze zisebenze kangcono.

I-Tubular Manifolds

I-Tubular manifolds, eyaziwa nangokuthi izihloko, iqukethe amapayipi angawodwana kusilinda ngasinye. Lamapayipi ahlangana abe yiqoqo elilodwa. I-Tubular manifolds ithuthukisaqeda ukugeleza kwegesifuthi wehlise i-backpressure. Abathandi bokusebenza bavame ukukhetha ukuphindaphindeka kwe-tubular ukuze bakwazi ukuthuthukisa ukuphuma kwamandla.

Umsebenzi kanye Nomklamo

Iqhaza Ekusebenzeni Kwenjini

I-exhaust manifold idlala indima ebalulekile ekusebenzeni kahle kwenjini. Idizayini efanele iqinisekisa ukugeleza kwegesi ephumayo ebushelelezi ukusuka kumasilinda enjini kuya kusistimu yokukhipha umoya. Ukugeleza kwegesi okusebenzayo kunciphisa ukucindezela emuva, okuthuthukisa ukusebenza kwenjini kanye nokonga kukaphethiloli. I-exhaust manifold isiza futhi ukulawula izinga lokushisa kwenjini ngokuqondisa amagesi ashisayo kude nebhulokhi yenjini.

Ukucatshangelwa kokuklama

Ukuklama i-exhaust manifold kuhilela ukucatshangelwa okuningana okubalulekile. Onjiniyela kufanele balandise ngesimo nobude bamapayipi ahlukahlukene. Ubude obufanele bepayipi nobubanzi buqinisekisa ukuhamba kahle kwegesi futhi kunciphisa ukuxokozela. I-manifold kufanele futhi ingene ngaphakathi kwendawo yenjini ngaphandle kokuphazamisa ezinye izinto. Ukwengeza, umklamo kufanele wenze lula ukufakwa nokugcinwa kalula.

Ukukhetha Okubalulekile

Ukukhethwa kwezinto kuthinta kakhulu ukusebenza kwe-exhaust eningi. Izinto ezisezingeni eliphezulu zimelana nezingcindezi ezishisayo nezemishini. I-Cast iron, insimbi engagqwali, nemiklamo ye-tubula ngayinye inikeza izinzuzo ezihlukile. I-cast iron inikeza ukuqina, kuyilapho insimbi engagqwali inikeza ibhalansi yamandla nesisindo. Ama-tubular manifolds athuthukisa ukusebenza ngokugeleza kwegesi okulungiselelwe. Onjiniyela kufanele bakhethe izinto ezifanele ngokuya ngezidingo ezithile zemoto.

Ukuhlaziywa Kwezinto Ezikhishwayo

Izinhlobo Zokukhishelwa

I-Carbon Monoxide (CO)

I-carbon monoxide yakha ngesikhathi sokushiswa kukaphethiloli okungaphelele. Le gesi idala izingozi ezinkulu zempilo, okuhlanganisa ikhanda nesiyezi. I-exhaust manifold kufanele ishaye amagesi kagesi ngendlela ephumelelayo ukuze kuncishiswe ukukhishwa kwe-CO. Idizayini efanele nokukhetha okubalulekile kudlala indima ebalulekile ekwehliseni amazinga e-CO.

I-Hydrocarbons (HC)

Ama-hydrocarbons avela kuphethiloli ongashisiwe ophuma endaweni evuthayo. Lezi zinhlanganisela zinomthelela ezindabeni zentuthu kanye nokuphefumula. Idizayini ye-exhaust manifold ithinta ikhono lenjini ukushisa uphethiloli ngokuphelele. Amadizayini alungiselelwe asiza ukunciphisa ukukhishwa kwe-HC ngokuqinisekisa ukugeleza kwegesi ekhiphayo esebenzayo.

I-Nitrogen oxides (NOx)

Ama-nitrogen oxide akheka emazingeni okushisa aphezulu omlilo. La magesi adala izinkinga zemvelo nempilo, okuhlanganisa imvula ene-asidi nesifo sokuphefumula. I-exhaust eningi ithonya ukukhishwa kwe-NOx ngokuphathwa kwezinga lokushisa. Imiklamo esebenzayo isiza ukugcina izinga lokushisa eliphansi lokuvutha, ngaleyo ndlela yehlise ukwakheka kwe-NOx.

Umthelela we-Exhaust Manifold on Emissions

Ithonya Lomklamo

Idizayini ye-exhaust manifold ithinta ngqo ukukhishwa kwegesi. I-manifold eklanywe kahle iqinisekisa ukugeleza kwegesi ephumayo ebushelelezi, inciphisa ukucindezela emuva futhi ithuthukise ukusebenza kahle komlilo. Ucwaningo lubonisa lokhoimiklamo tapered ithuthukisa ukusebenza by ukwehla kwe-backpressure. Ukugeleza kwegesi okuthuthukisiwe kuholela ekukhishweni okuphansi kwe-CO, HC, ne-NOx.

Ithonya Elibonakalayo

Ukukhethwa kwezinto kuthinta kakhulu ukusebenza kwe-exhaust eningi.Insimbi yensimbi nensimbi engagqwaliyizinto ezivamile ezisetshenziswa ekwakhiweni okuhlukahlukene. I-cast iron inikeza ukuqina kodwa ingase inyuse isisindo. Insimbi engagqwali inikeza ibhalansi phakathi kwamandla nesisindo, ithuthukisa ukusebenza kahle okuphelele. Zombili izinto ezisetshenziswayo kufanele zimelane nezingcindezi ezishisayo nezomshini ukuze kugcinwe ukusebenza kahle nokunciphisa ukukhishwa kwekhabhoni.

Ukuphathwa Kwezinga Lokushisa

Ukuphathwa kwezinga lokushisa kudlala indima ebalulekile ekulawuleni ukukhishwa kwekhabhoni. I-nifold exhaust kufanele iqede ukushisa ngempumelelo ukuze kuvinjwe amazinga okushisa omlilo amaningi. Amazinga okushisa aphezulu aholela ekwandeni kokwakheka kwe-NOx. Ukuphatha izinga lokushisa okusebenzayo kusiza ukugcina izinga lokushisa eliphansi lokuvutha, ngaleyo ndlela kunciphisa ukukhishwa kwe-NOx. Izinto ezithuthukisiwe nezimbozwe zingathuthukisa ikhono le-multifold lokuphatha ukushisa.

Ukuhlaziywa Kokuphuma Kwamandla

Izinto Ezithinta Okukhiphayo Amandla

I-Exhaust Flow Dynamics

I-Exhaust flow dynamics idlala indima ebalulekile ekusebenzeni kwenjini. Idizayini ye-exhaust manifold ithonya ngokuqondile indlela amagesi akhipha umoya aphuma ngayo enjinini. I-manifold eklanywe kahle iqinisekisa ukugeleza kwegesi okushelelayo nokusheshayo, kunciphisa ukuxokozela. Lokhu kubangela ukuphefumula kwenjini okuthuthukisiwe kanye nokuphuma kwamandla okuthuthukisiwe. Onjiniyela bavame ukuthuthukisa ukuma nobude bamapayipi amaningi ukuze bathole izici zokugeleza ezifanele.

I-backpressure

I-Backpressure ibhekisela ekuphikiseni amagesi akhipha umoya lapho ephuma enjinini. I-backpressure ephezulu ingaphazamisa ukusebenza kwenjini ngokukhawulela ukugeleza kwe-exhaust. Izihloko ze-exhaust zokusebenza zihlosenciphisa ukumelana nokugeleza, ngaleyo ndlela kwandise ukusebenza kahle kwevolumu yenjini. I-backpressure ephansi ivumela injini ukuthi ikhiphe amagesi e-exhaust ngokuphumelelayo, okuholela ekuzuzeni kokuphuma kwamandla. Ii-exhaust eningi esanda kwakhiwaimiklamo ivame ukugxila ekunciphiseni i-backpressure ukuze kukhuliswe ukusebenza kwenjini.

Ukugcina Ukushisa

Ukugcina ukushisa ngaphakathi kwe-multifold exhaust kuthinta ukusebenza kahle kwenjini nokuphuma kwamandla. Ukushisa okudlulele kungaholela emazingeni okushisa aphezulu, okungase kwehlise ukusebenza kwenjini. Ukuphatha ukushisa okusebenzayo kusiza ukugcina izinga lokushisa elilungile lokusebenza. Izinto ezithuthukisiwe kanye nezingubo ekwakhiweni okuhlukahlukene kungathuthukisa ukuchithwa kokushisa. Ukugcina ukushisa okulungile kuqinisekisa ukuthi injini isebenza ngaphakathi kwebanga elifanele lokushisa, okwandisa ukuphuma kwamandla.

Ukuhlolwa kokusebenza

Ukuhlolwa kwe-Dyno

Ukuhlolwa kwe-Dyno kunikeza indawo elawulwayo ukukala ukusebenza kwe-multifold exhaust. Onjiniyela basebenzisa i-dynamometer ukuze balingise izimo zokushayela zomhlaba wangempela. Le ndlela yokuhlola ihlola umthelela we-multifold ekuphumeni kwamandla, i-torque, nokusebenza kahle kukaphethiloli. Ukuhlolwa kwe-Dyno kunikeza idatha enembile, okuvumela onjiniyela benze izinqumo ezinolwazi mayelana nemiklamo ehlukahlukene kanye nokukhetha kwezinto ezibonakalayo.

Ukuhlolwa Komhlaba Wangempela

Ukuhlolwa komhlaba wangempela kuhambisana nokuhlolwa kwe-dyno ngokuhlola i-exhaust eningi ngaphansi kwezimo zangempela zokushayela. Onjiniyela bahlola ukuthi i-multifold isebenza kanjani ezimeni ezahlukahlukene, njengokushayela edolobheni, ukuhamba ngomgwaqo omkhulu, kanye nokusheshisa okunamandla. Ukuhlola umhlaba wangempela kusiza ukukhomba noma yiziphi izinkinga ezingase zingabonakali endaweni elawulwayo. Le ndlela ebanzi iqinisekisa ukuthi i-exhaust manifold iletha ukusebenza okungaguquki kuzo zonke izimo zokushayela ezihlukene.

Ukuhlaziya Ngokuqhathanisa

Ukuhlaziya okuqhathanisayo kuhilela ukuhlola amadizayini ahlukahlukene e-ehausi ukuze kutholwe umthelela wawo ekuphumeni kwamandla. Onjiniyela baqhathanisa izici ezifana nokugeleza kwe-exhaust, i-backpressure, nokugcinwa kokushisa. Lokhu kuhlaziya kusiza ukukhomba imiklamo ephumelela kakhulu yokuthuthukisa ukusebenza kwenjini. Ngokuqhathanisa ukuphindaphindeka okuhlukahlukene, onjiniyela bangakhomba amandla nobuthakathaka bomklamo ngamunye. Le nqubo iholela ekuthuthukisweni okuqhubekayo kanye nokuqanjwa okusha kubuchwepheshe obuhlukahlukene bokukhipha amandla.

Amasu amasha kanye namathrendi esikhathi esizayo

Izinto Ezithuthukile

I-Ceramic Coatings

Izembatho ze-Ceramic ziye zavela njengentuthuko enkulu kubuchwepheshe obuhlukahlukene bokuqeda amandla. Lezi zembatho zinikeza ukufakwa okuhle kakhulu kokushisa, kunciphisa ukudluliswa kokushisa ezingxenyeni zenjini ezizungezile. Lokhu ukwahlukanisa kusiza ukugcina izinga lokushisa elilungile lenjini, kuthuthukisa ukusebenza nokuphila isikhathi eside. Izembatho ze-Ceramic nazo zinikeza ukumelana okuphakeme kokugqwala nokugqoka, okuqinisekisa ukuqina kwe-exhaust manifold. Onjiniyela bezimoto baya ngokuya besebenzisa ama-ceramics ukuze bathuthukise ukusebenza kahle nokuthembeka kwezinhlelo zokukhipha umoya.

Izinto Ezihlanganisiwe

Izinto ezihlanganisiwe zimelela enye indlela entsha ekwakhiweni kokukhipha okuningi. Lezi zinto zihlanganisa izinto ezahlukene ukuze kuzuzwe ibhalansi yamandla, isisindo, nokumelana nokushisa. Isibonelo, izinhlanganisela ze-carbon fiber zinikeza izilinganiso eziphezulu zamandla nesisindo, okuzenza zilungele izinhlelo zokusebenza zokusebenza. Ukusetshenziswa kwezinto ezihlanganisiwe kunganciphisa kakhulu isisindo se-exhaust manifold, okuholela ekusebenzeni okuthuthukisiwe kwemoto nokuphatha. II-FluidForming Insimbi Engagqwali EngasindiI-Exhaust Manifold Case Studyibonise ukushintshwa okuyimpumelelo kwezinqwaba zensimbi ezisindayo ngensimbi engagqwali engasindi, igqamisa izinzuzo zezinto ezithuthukisiwe kubunjiniyela bezimoto.

Design Innovations

Izinhlobonhlobo zeJiyomethri eziguquguqukayo

Izinhlobonhlobo zejiyomethri eziguquguqukayo (VGM) zimelela ukuqanjwa kabusha okuphambili ekwakhiweni kokukhipha okuningi. Ama-VGM alungisa ukuma nobude bamapayipi ahlukahlukene ngokusekelwe ezimeni zokusebenza kwenjini. Lokhu kuvumelana nezimo kuthuthukisa ukugeleza kwegesi ephumayo, kunciphisa umfutho ongemuva futhi kuthuthukise ukusebenza kwenjini. Ama-VGM angathuthukisa ukusebenza kahle kukaphethiloli futhi anciphise ukukhishwa kwekhabhoni ngokugcina amandla okukhipha amandla afanele kuzo zonke izimo zokushayela ezihlukahlukene. Abakhiqizi bezimoto baya ngokuya behlola ama-VGM ukuze bahlangabezane nemithetho eqinile yokukhipha umoya kanye nezidingo zokusebenza.

Iziguquli ze-Catalytic ezihlanganisiwe

Ukuhlanganisa iziguquli ze-catalytic ngqo ku-exhaust manifold kunikeza izinzuzo ezimbalwa. Lo mklamo wehlisa ibanga elihanjwa yi-exhaust gases ngaphambi kokufinyelela kusiguquli se-catalytic, sithuthukisa ukusebenza kahle kokulawula ukungcola. Iziguquli ze-catalytic ezididiyelwe zisiza ukufeza izikhathi zokucisha ukukhanya ngokushesha, zehlise ukukhishwa kwesiqalo esibandayo. Lokhu kuhlanganiswa kwenza kube lula ukwakheka kwesistimu yokukhipha umoya, kunciphisa isisindo nokuba yinkimbinkimbi. Izimoto eziningi zesimanje manje zineziguquli ezididiyelwe ze-catalytic ukuze zihlangabezane namazinga emvelo kuyilapho zigcina ukusebenza okuphezulu.

Ukuhlaziywa kugqamisa indima ebalulekile yedizayini ye-exhaust ehlukahlukene kanye nokukhetha kwezinto ezibonakalayo ekuthuthukiseni ukusebenza kwenjini nokunciphisa ukukhishwa kwekhabhoni. Okutholakele okubalulekile kukhombisa ukuthi izinto ezithuthukisiwe njengensimbi engagqwali nezimbotshana zobumba zithuthukisa ukuqina nokusebenza kahle. Idizayini emisha efana nokuhlukahluka kwejiyomethri kanye neziguquli ezididiyelwe ze-catalytic zithuthukisa ukusebenza kahle kukaphethiloli nokulawula ukungcola.

Ukuthuthuka kwezobuchwepheshe kanyeukushintsha izintandokazi zabathenginomthelela omkhulu embonini yezimoto.Amasistimu wokuqeda amandlakanye nezinqubo zokushayela zinganciphisa ukukhishwa kwezimoto, kube nomthelela ekusimameni kwemvelo. Ucwaningo lwesikhathi esizayo kufanele lugxile ekuthuthukiseni izinto ezingasindi kanye nemiklamo emisha ukuze kuhlangatshezwane nezidingo ezikhulayo zokulawula nokusebenza.

Isikhathi sokuthumela: Jul-31-2024