A ibhalansi ye-harmonic inciphisa ama-harmonics e-torsional crankshaftkanye ne-resonance. Ubude benjini buhlala bubalulekile kubanikazi bezimoto nabakhiqizi. Izilinganisi ze-harmonic ezisebenza kahle kakhuluvikela izinjini ngaphansi kwezimo ezimbi kakhulu, ukuqinisekisa ukuphila isikhathi eside. Ukulinganisa kahle izingxenye zenjini yangaphakathi kunciphisa ukudlidliza futhi kuvimbela ukuphuka kwe-crankshaft. Ukuxhumana phakathi kwezilinganisi ze-harmonic nokuphila isikhathi eside kwenjini kugqamisa ukubaluleka kwazo ekugcineni impilo yenjini.

Ukuqonda i-Harmonic Balancers

Yiziphi i-Harmonic Balancers?

Incazelo kanye Nomsebenzi

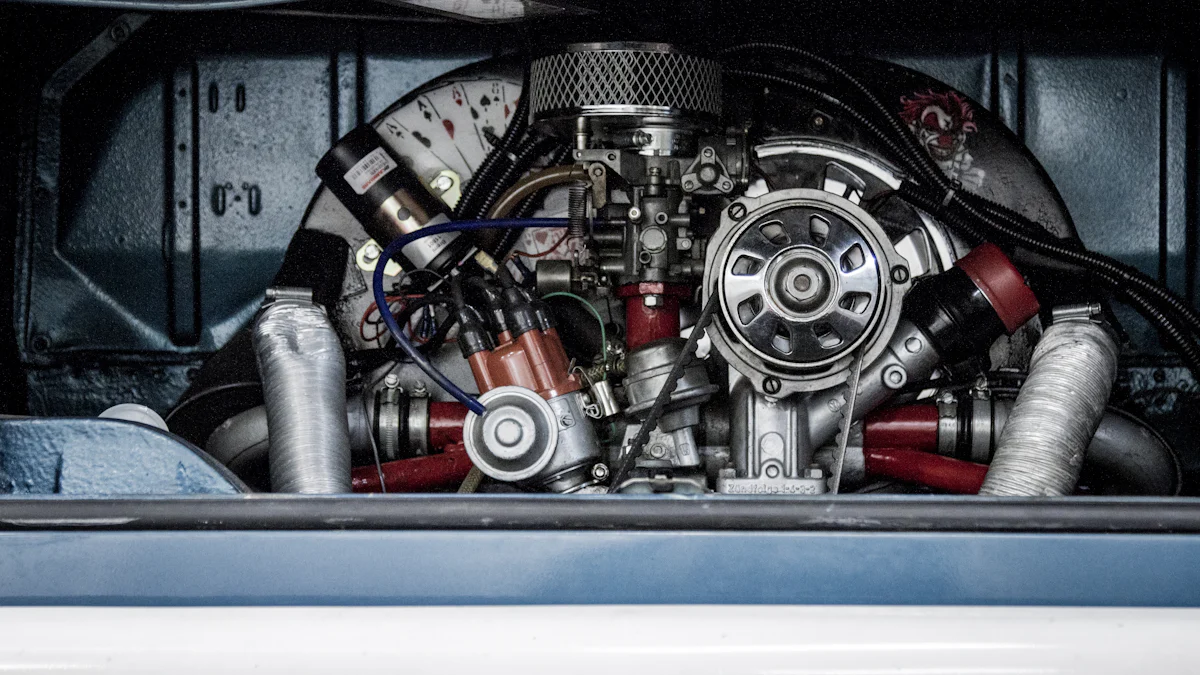

A ibhalansi ye-harmonickuyingxenye ebalulekile enjinini. Itinciphisa ama-harmonics e-torsional crankshaftkanye ne-resonance. Onjiniyela baklama isilinganisi se-harmonic ukuze simelane nokunyakaza kwe-torsional crank kusetshenziswa i-inertia mass kanye nento elahla amandla. Le divayisi iphinde isebenze njenge-pulley yamabhande e-accessory drive. Umsebenzi oyinhloko we-harmonic balancer uhilelaukunciphisa i-amplitude yeziqongo zokudlidliza kwe-torsionalemazingeni amukelekayo, ikakhulukazi ezinjinini ezisebenza kahle kakhulu.

Izinhlobo ze-Harmonic Balancers

Kunezinhlobo eziningana zama-balancers e-harmonic. Izinhlobo ezivame kakhulu zihlanganisa i-elastomeric, i-viscous, ne-fluid-damper balancers. Izilinganisi ze-elastomeric zisebenzisa irabha ukuze zimunce ukudlidliza. Izilinganisi ze-viscous ziqukethe uketshezi oluwugqinsi oludambisa ukudlidliza. Izilinganisi ze-Fluid-damper zisebenzisa inhlanganisela yamaringi e-inertia noketshezi lwe-silicone ukunciphisa ukudlidliza. Uhlobo ngalunye lunezinzuzo eziyingqayizivele kanye nezinhlelo zokusebenza kuye ngezidingo zenjini.

Indlela I-Harmonic Balancers Esebenza Ngayo

Ama-Mechanics Wokunciphisa Ukudlidliza

Imishini yokunciphisa ukudlidliza ku-aibhalansi ye-harmonickubandakanya ukulwa nokudlidliza kwe-torsional. I-balancer imunca futhi ihlakaze lokhu kudlidliza ngesisindo sayo se-inetia nezinto ezichitha amandla. Le nqubo inciphisa ukucindezeleka ku-crankshaft nezinye izingxenye zenjini. Izilinganisi eziklanywe kahle ze-harmonic zivikela isiphetho esingezansi senjini ngokumunca ama-harmonic ayingozi nokudlidliza.

Iqhaza Ekusebenzeni Kwenjini

Indima ye-ibhalansi ye-harmonicekusebenzeni kwenjini kubalulekile. Ngokunciphisa ukudlidliza, isilinganisi siqinisekisa ukusebenza kahle kwenjini. Lokhu kuholela ekusebenzeni okuthuthukisiwe kwenjini nokuphila isikhathi eside. Izilinganisi ze-harmonic ezisebenza kahle zibalulekile ezinjinini ezisebenza ngaphansi kwezimo ezimbi kakhulu. Lezi zilinganisi zisiza ukugcina ibhalansi yenjini futhi zivikele izingxenye ezibalulekile ekulimaleni.

Ukubaluleka Kokuphila Kwenjini Isikhathi Eside

Izinto Ezithinta Ubude Bokuphila Kwenjini

Gqoka nezinyembezi

Ukuguga nokuklebhuka kunomthelela omkhulu empilweni ende yenjini. Ukusebenza okuqhubekayo kubangela ukungqubuzana phakathi kwezingxenye ezihambayo. Lokhu kungqubuzana kubangela ukuwohloka kancane kancane. Ngokuhamba kwesikhathi, izingxenye ezifana nama-pistons, ama-bearing, nama-valve ahlangabezana nokuguga. I-balancer ye-harmonic idlala indima ebalulekile ekwehliseni lokhu kugqoka. Ngokunciphisa ukudlidliza, i-harmonic balancer inciphisa ingcindezi kulezi zingxenye. Lokhu kuncipha kokucindezeleka kusiza ukwandisa impilo yenjini.

Imikhuba Yesondlo

Izindlela zokunakekela ezifanele zibalulekileinweba impilo yenjini. Ukushintsha uwoyela okuvamile kuqinisekisa ukugcotshwa kwezingxenye zenjini. Amafutha ahlanzekile anciphisa ukungqubuzana futhi avimbele ukushisa ngokweqile. Ukushintshwa ngesikhathi kwezingxenye ezigugile kugcina injini isebenza kahle. Abalinganisi be-Harmonic badinga ukuhlolwa ngezikhathi ezithile. Ukuqinisekisa ukuthi ibhalansi ye-harmonic isebenza kahle kuvimbela ukudlidliza okukhulu. Lo mkhuba wokulungisa unomthelela empilweni yenjini iyonke.

Izinzuzo Zempilo Yenjini Ende

Ukonga Izindleko

Ukuphila kwenjini okude kunikeza ukonga kwezindleko okubalulekile. Ukuguga okuncishisiwe kusho ukulungiswa okumbalwa. Abanikazi bezimoto bachitha imali encane ezingxenyeni ezishintshwayo. Izinjini ezisebenzayo zidla uphethiloli omncane. Ukusetshenziswa kukaphethiloli okuphansi kuhumusha ekongeni ngokwezimali. Ukutshala imali kuizinga le-harmonic balancersithuthukisa ukuqina kwenjini. Lokhu kutshalwa kwezimali kunciphisa izindleko zokunakekela zesikhathi eside.

Umthelela Wezemvelo

Ukwelula impilo yenjini kunomthelela omuhle endaweni ezungezile. Izinjini ezisebenzayo zikhiqiza ukukhishwa okuncane. Ukukhishwa okuncishisiwe kunomthelela emoyeni ohlanzekile. Ukuphila isikhathi eside kwenjini kusho izinjini ezimbalwa ezilahliwe. Lokhu kuncipha kwemfucuza kuzuzisa imvelo.Izilinganisi ze-harmonic zekhwalithiukusiza ukufeza lezi zinzuzo zemvelo. Ngokuqinisekisa ukusebenza kwenjini okushelelayo, izilinganisi ze-harmonic zisekela imikhuba eco-friendly.

Umthelela wama-Harmonic Balancers ku-Engine Longevity

Ukwehliswa kwe-Engine Wear

Ukunciphisa Ukulimala Kwe-Vibration

A ibhalansi ye-harmonicidlala indima ebalulekile ekwehliseni umonakalo wokudlidliza ngaphakathi kwenjini. Ukudlidliza kwe-torsional, okwenzeka ngenxa yokusonteka kwe-crankshaft, kungaholela ekugugeni okuphawulekayo ezingxenyeni zenjini. I-harmonic balancer imunca lokhu kudlidliza, ikuvimbele ekubaleni umonakalo. Lokhu kumuncwa kunciphisa ingcindezi ku-crankshaft nezinye izingxenye ezibucayi, ngaleyo ndlela andise ubude bazo bempilo. Ngokugcina ukusebenza okulinganiselayo nokushelelayo, ibhalansi ye-harmonic iqinisekisa ukuthi izingxenye zenjini azihlushwa ukugqoka ngaphambi kwesikhathi.

Ithuthukisa Ukuqina Kwengxenye

Ukuqina kwezingxenye zenjini kuhlobana ngqo nokusebenza kwe-ibhalansi ye-harmonic. Izilinganisi ezisebenza kahle kakhulu, ikakhulukazi lezo eziklanyelwe izinjini ezisebenza ngaphansi kwezimo ezibucayi, zihlinzeka ngokudambisa ukudlidliza okuphakeme. Leli khono elithuthukisiwe lokumanzisa livikela izingxenye ezibalulekile zenjini njengama-bearing, ama-piston, nama-valve. Ukwehliswa kokudlidliza kusho ukuthi lezi zingxenye zithola ingcindezi encane yokusebenza, okuhumushela ekuphileni okude kokusebenza. Ukutshala imali ku-balancer yekhwalithi ye-harmonic kuba yinto ebalulekile kunoma ubani ofuna ukukhulisa ukuqina kwenjini nokuphila isikhathi eside.

Ukuthuthukiswa Kokusebenza Kwenjini

Ukusebenza Okushelelayo

A esebenza kahleibhalansi ye-harmonickunomthelela omkhulu ekusebenzeni kahle kwenjini. Ngokunciphisa ukudlidliza kwe-torsional, i-balancer iqinisekisa ukuthi injini isebenza kahle kakhulu. Lokhu kusebenza okushelelayo akugcini nje ngokuthuthukisa ulwazi lokushayela kodwa futhi kunciphisa amathuba okuhluleka kwemishini. I-harmonic balancer isebenza njengamandla azinzile, iqinisekisa ukuthi injini isebenza ngaphandle komsindo owedlulele noma ukhahlo. Umphumela uwukusebenza okuthembeke kakhudlwana nokujabulisayo, kungakhathaliseki ukuthi ushayela kwansuku zonke noma ezindaweni ezinengcindezi ephezulu.

Ukusebenza Kwengeziwe

Izinzuzo zokusebenza kahle zimelela enye inzuzo ebalulekile ehlinzekwa aibhalansi ye-harmonic. Izinjini ezisebenza ngokudlidliza okuncane zivame ukusebenza kahle kakhulu. I-balancer ye-harmonic isiza ukufeza lokhu ngokugcina ibhalansi efanele kanye nokunciphisa ukulahleka kwamandla okubangelwa ukungqubuzana okubangelwa ukudlidliza. Izinjini ezisebenza kahle zisebenzisa uphethiloli omncane futhi zikhiqiza umoya omncane, okufaka isandla kukho kokubili ukonga nezinzuzo zemvelo.Izilinganisi ze-harmonic ezisebenza kahle kakhulu, ikakhulukazi lezo ezisetshenziswa emijahweni noma izicelo ezisindayo, zenzelwe ukuphatha amandla anyusiwe kanye namazinga e-RPM, ukuqinisekisa ukuthi injini ihlala isebenza kahle ngisho nangaphansi kwezimo ezinzima.

I-Case Studies kanye Nezibonelo Zomhlaba Wangempela

Izindaba Zempumelelo

Imboni Yezimoto

Imboni yezimoto ibone ukuthuthuka okuphawulekayo ekusebenzeni kwenjini nokuphila isikhathi eside ngenxa yokusetshenziswa kwezilinganisi eziphezulu ze-harmonic. Isibonelo, ukusebenzisana phakathi kwamaqembu e-Fluidampr kanye ne-Vibratech TVD kuholele ekwakhiweni kwesidambisi manzi esine-viscous.11% ukululakunomshini wokuqala we-elastomer harmonic balancer. Lokhu okusha akuthuthukisi ukulawula kwe-NVH (Umsindo, Ukudlidliza, Ukuqina) kuphela kodwa futhi kwathuthukisa ukuqina. Abakhiqizi abaningi bezimoto manje bathembele kulawa ma-dampers athuthukile ukuze baqinisekise ukuthi izinjini zabo zisebenza kahle ngaphansi kwezimo ezahlukahlukene.

Amadampasi e-Premium viscous nawo abonisiweimpilo yomkhiqizo ephakemeezindaweni ezimbi kakhulu, njengomjaho wokukhuthazela wamahora angama-24. Lezi zilinganisi ze-harmonic ezisebenza kahle zihlinzeka ngokudambisa ukudlidliza okukhethekile, okubalulekile ezinjinini ezisebenza kuma-RPM aphezulu kanye namazinga wamandla. Impumelelo yala ma-dampers emidlalweni yezimoto igqamisa ukubaluleka kokutshala imali ezingxenyeni ezisezingeni eliphezulu ukuze kuzuzwe ukwethembeka nokusebenza kahle kwenjini isikhathi eside.

Imishini Enzima

Emkhakheni wemishini esindayo, ukusetshenziswa kwezilinganisi eziqinile ze-harmonic kufakazelwe kubalulekile ekugcineni impilo yenjini nempilo ende. Imishini enzima ivamise ukusebenza ngaphansi kwezimo ezimbi kakhulu, ezingaholela ekugugekeni okukhulu kwezingxenye zenjini. Amabhalansi e-harmonic asebenza kahle kakhulu asiza ukunciphisa lokhu kugqoka ngokumunca ukudlidliza okuyingozi nokunciphisa ingcindezi ezingxenyeni ezibucayi.

Isibonelo, abakhiqizi bezinto zokwakha babike impilo yenjini enwetshiwe futhi banciphisa izindleko zokuyilungisa ngemva kokufaka izilinganisi ezithuthukisiwe ze-harmonic emiklamo yabo. Lezi zilinganisi ziqinisekisa ukusebenza okushelelayo, okuhumusheka ekuqhekekeni okumbalwa kanye nokwanda kokukhiqiza. Imboni yemishini esindayo iyaqhubeka nokuhlomula ngokuqina nokusebenza kahle okuhlinzekwa ngabalinganisi bekhwalithi ephezulu be-harmonic.

Izifundo Ezifundiwe

Izindlela Ezinhle Kakhulu

Izindlela eziningi ezinhle kakhulu ziye zavela ekusetshenzisweni ngempumelelo kwezilinganisi ze-harmonic ezimbonini ezihlukahlukene. Okokuqala, ukuhlolwa nokugcinwa njalo kwe-harmonic balancer kubalulekile. Ukuqinisekisa ukuthi isilinganisi sisebenza ngendlela efanele kuvimbela ukudlidliza okudlulele kanye nokulimala okungaba khona ezingxenyeni zenjini. Okwesibili, ukukhetha uhlobo olufanele lwe-harmonic balancer ngokusekelwe ezidingweni zenjini kubalulekile. Izinjini ezihlukene zingazuza kuzilinganisi ze-elastomeric, viscous, noma fluid-damper, kuye ngezidingo zazo ezithile.

Omunye umkhuba ongcono kakhulu uhilela ukusebenzisa izilinganisi ze-harmonic ezisebenza kahle ezinjinini ezisebenza ngaphansi kwezimo ezimbi kakhulu. Lezi zilinganisi zinikeza ukuncibilika kokudlidliza okuphezulu nokuqina, okubalulekile ekugcineni impilo yenjini nempilo ende. Ukutshala imali kumabhalansi wekhwalithi we-harmonic kungaholela ekongeni kwezindleko ezibalulekile kanye nokusebenza okuthuthukisiwe kwenjini ngokuhamba kwesikhathi.

Izingibe Ezivamile

Naphezu kwezinzuzo zokusebenzisa i-harmonic balancers, izingibe eziningana ezivamile zingahlehlisa ukusebenza kwazo. Inkinga eyodwa evamile ukunganaki ukunakekela nokuhlolwa kwebhalansi. Ngokuhamba kwesikhathi, izilinganisi ze-harmonic zingaguga noma zilimale, okuholela ekwandeni kokudlidliza kwenjini kanye nokwehluleka kwengxenye okungenzeka. Ukuhlolwa okuvamile nokushintshwa okufika ngesikhathi kuyadingeka ukuze kugwenywe lezi zinkinga.

Omunye umgodi uhilela ukusebenzisa uhlobo olungalungile lwe-harmonic balancer yenjini. Izilinganisi ezingafani zingehluleka ukuhlinzeka ngokuncibilika okwanele kokudlidliza, okuholela ekwenyukeni kokuguga kanye nokudabuka kwezingxenye zenjini. Ukuqinisekisa ukuthi isilinganisi se-harmonic sifana namandla enjini nezimo zokusebenza kubalulekile ekusebenzeni kahle.

Okokugcina, abanye abasebenzisi bangase bangakunaki ukubaluleka kokutshala imali kumabhalansi e-harmonic ekhwalithi ephezulu. Nakuba ezinye izindlela ezishibhile zingase zibonakale zibiza kakhulu ekuqaleni, ngokuvamile azikwazi ukuqina nokusebenza okudingekayo empilweni yesikhathi eside yenjini. Ukukhetha izilinganisi ze-harmonic ze-premium kungavimbela ukulungiswa okumba eqolo futhi kunwebe ubude bempilo yenjini.

Iibhalansi ye-harmonicidlala indima ebalulekile ekuqinisekiseni impilo ende yenjini. Nguukunciphisa ukudlidliza kwe-torsional, i-balancer inciphisa ukuguga nokudabuka ezingxenyeni ezibucayi zenjini. Lokhu kuncipha kuholela ekusebenzeni kahle kanye nokusebenza kahle okwandisiwe.Amabhalansi asebenza kahle kakhulu, ikakhulukazi lezo eziklanyelwe izimo ezimbi kakhulu, zinikeza ukuvikeleka okuphezulu nokuqina. Ukugcinwa okuvamile nokukhethwa okufanele kwezilinganisi ze-harmonic kubalulekile empilweni yenjini. Ukutshala imali kumabhalansi wekhwalithi we-harmonic hhayi kuphelainweba impilo yenjinikodwa futhi inikeza ukonga izindleko ezibalulekile kanye nezinzuzo zemvelo.

Isikhathi sokuthumela: Jul-22-2024