Iqeda ngokuphindaphindiweidlala indima ebalulekile kubunjiniyela bezimoto ngokuqoqa amagesi e-exhaust kumasilinda amaningi futhi awafake epayipini elilodwa. Idizayini ye-exhaust manifolds iguquke kakhulu,ethonywe isidingoukwandisa ukusebenza kahle kukaphethiloli kanyeimithetho eqinile yokukhipha umoya. Ukuqonda lolu hambo kunikeza imininingwane ebalulekile kubo bobabili abathanda izimoto nezingcweti, okugqamisa ukubaluleka kwentuthuko eqhubekayo kubuchwepheshe obuhlukahlukene bokukhipha amandla.

Imiklamo Yakuqala Yezinto Eziningi Exhaust

Ukuzalwa kwe-Exhaust Manifolds

Imiqondo yokuqala kanye nama-Prototypes

Umqondo we-exhaust manifold uqhamuke ngokufika kwezinjini ezingama-multi-cylinder. Imiklamo yangaphambili ihloselwe ukuhambisa amagesi akhipha umoya asuka kumasilinda amaningi abe yipayipi elilodwa. Onjiniyela bazame ukucupha okuhlukahlukene ukuze bathuthukise ukugeleza kwegesi nokunciphisa umfutho obuya emuva. Ama-prototypes okuqala ayengajwayelekile, ngokuvamile enziwa ngesandla, ebonisa amakhono alinganiselwe okukhiqiza angaleso sikhathi.

Izinto zokwakha kanye namasu okukhiqiza

Insimbikwaba yizinto ezikhethwayo zokuqeda amandla amaningi. Ukumelana kwayo nokushisa nokugqwala okuphezulu kuyenze yafaneleka ukubhekana nezimo ezinzima ngaphakathi kwendawo yenjini. Ukuqina kwe-cast iron kuqinisekise ukuthi lezi zingxenye zingamelana nokuchayeka isikhathi eside kumazinga okushisa adlulele ngaphandle kokuwohloka. Amasu okukhiqiza abandakanya ukujikijela insimbi encibilikisiwe esikhunjeni, inqubo eyayivumela ukukhiqizwa ngobuningi kuyilapho kugcinwa ubuqotho besakhiwo.

Izinselelo Nemikhawulo

Izinkinga Zokusebenza

Izinhlobonhlobo ze-exhaust zangaphambi kwesikhathi zibhekane nezinselelo ezinkulu zokusebenza. Umklamo wawuvame ukuholela ekugelezeni kwegesi okungalingani, okuholela ekwenyukeni kwengcindezi emuva. Lokhu kungasebenzi kwehlise ukusebenza kwenjini nokonga kukaphethiloli. Onjiniyela bazabalaza ukwenza imiklamo engalinganisa isidingo sokugeleza kwegesi okusebenzayo kanye nezingqinamba zezindlela ezikhona zokukhiqiza.

Ukuqina Okukhathazayo

Ukuqina kudale enye inselele enkulu kuma-nifold exhaust yakuqala. Naphezu kokuqina kwe-cast iron, ukuchayeka isikhathi eside emazingeni okushisa aphezulu namagesi abolayo kwaholela ekuqhekekeni nasekujikeni ngokuhamba kwesikhathi. Ukugcinwa nokushintshwa kwalezi zingxenye kwaba yisidingo esivamile, okwengeza kuzo zonke izindleko zobunikazi bemoto. Onjiniyela ngokuqhubekayo bafuna izindlela zokuthuthukisa impilo ende ye-exhaust manifolds ngokusebenzisa izinto ezithuthukisiwe kanye nemiklamo emisha.

Ukuvela kwe-Exhaust Manifolds

Intuthuko Yekhulu Lama-20

Ukwethulwa Kwezinto Ezintsha

Maphakathi nekhulu lama-20 kwaphawula ushintsho olukhulu ekuthuthukisweni okuhlukahlukene kokukhipha igesi. Onjiniyela baqala ukuhlola izinto ezintsha zokuthuthukisa ukusebenza nokuqina. Insimbi engagqwali yavela njengenketho ethandwayo ngenxa yokumelana kwayo okuphakeme nokushisa nokugqwala. Lokhu okuqukethwe kuvunyelwe izindonga ezincane, ukunciphisa isisindo ngenkathi kugcinwa ubuqotho besakhiwo. Ukwamukelwa kwensimbi engagqwali kuthuthukise ukusebenza kahle okuphelele kwesistimu yokukhipha umoya ngokunciphisa ukulahlekelwa ukushisa.

Ukuthuthukiswa Kokuklama Nokusebenza Kahle

Ukuthuthukiswa kwedizayini nakho kudlale indima ebalulekile ngalesi sikhathi. Onjiniyela basebenzise amasu okukhiqiza athuthukile ukuze bakhe imiklamo eyinkimbinkimbi futhi esebenza kahle. Ukwethulwa kwe-mandrel ukugoba kwenza ukukhiqizwa kweukugoba okubushelelezi, ukunciphisa isiyaluyalu nokucindezela emuva. Lokhu okusha kuthuthukise kakhulu ukugeleza kwegesi yokukhipha umoya, kwathuthukisa ukusebenza kwenjini nokusebenza kahle kukaphethiloli. Ukusetshenziswa kwamathuluzi okulingisa avunyelwe ukwenza imodeli enembile ye-gas flow dynamics, okuholela kuimiklamo eminingi elungiselelwe.

Umthelela Wezimiso Zokungcoliswa Kokungcola

Izinguquko Kudizayini Ukuhlangabezana Namazinga

Ukuqaliswa kwemithethonqubo eqinile yokukhipha umoya engxenyeni yokugcina yekhulu lama-20 kwadinga intuthuko eyengeziwe kubuchwepheshe obuhlukahlukene bokukhipha umoya. Abakhiqizi bekufanele badizayine kabusha ama-multifolds ukuze bahlangabezane namazinga amasha okunciphisa ukungcola okuyingozi. Ukufakwa kweziguquli ze-catalytic ohlelweni lwe-exhaust kwaba yimpoqo. Lokhu okungeziwe bekudinga ukuphindaphindeka ukuze kumelane nezinga lokushisa eliphezulu futhi kusekele ukusebenza kahle kwalawa madivayisi. Onjiniyela bagxile ekudaleni amadizayini asiza ukushisisa okusheshayo kweziguquli ze-catalytic, okuqinisekisa ukusebenza kahle.

Izindlela Ezintsha Zezobuchwepheshe Eziqhutshwa Imithethonqubo

Izindlela ezintsha zobuchwepheshe eziqhutshwa yimithethonqubo yokukhipha umoya ziholele ekuthuthukisweni kwezinhlelo eziningi zokuphuma komoya ezingcolile. Ukusetshenziswa kwe-computational fluid dynamics (CFD) kwasabalala, kwavumela onjiniyela ukuba balingise futhi bahlaziye ukuziphatha kwegesi ekhishwayo ngokuningiliziwe. Lobu buchwepheshe bunikeze amandla ukudalwa kwama-manifold anamajiyometri ayinkimbinkimbi akhulisa ukugeleza kwegesi futhi anciphisa ukukhishwa kwekhabhoni. Ukuhlanganiswa kwamasistimu e-turbocharging ane-exhaust manifolds nakho kwazuza ukuduma. Izinjini ezine-Turbocharged zidinga ukuphindaphindeka okukwazi ukuphatha ingcindezi ekhuphukayo nezinga lokushisa, okuqhubekisela phambili intuthuko kusayensi yezinto ezibonakalayo nokuklama.

Ukuqamba Okusha Kwesimanje Ku-Exhaust Manifolds

Izinto Ezithuthukile Nezingubo Zokugcotshwa

I-High-Performance Alloys

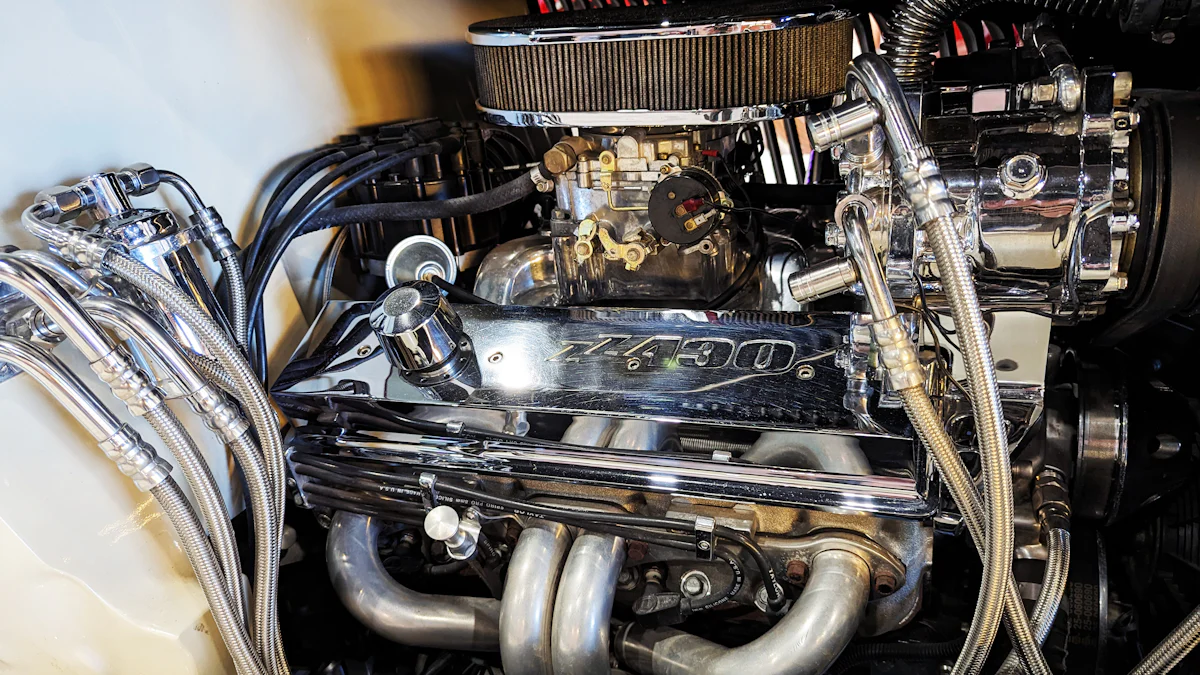

Abakhiqizi bezimoto manje basebenzisa ama-alloys asebenza kahle kakhulu ukuze bathuthukise ukuqina nokusebenza kahle kwama-nifold exhaust. Lezi zinto ezithuthukisiwe zifaka insimbi enamandla amakhulu, insimbi engagqwali, nensimbi e-aluminum. Izici ezingcono kakhulu zemishini zalawa ma-alloys zivumela ama-nifold exhaust ukuthi amelane namazinga okushisa aphakeme kanye namagesi abolayo. Lokhu kuqanjwa kuthuthukise kakhulu ukusebenza kwezinhlelo zokukhipha umoya ezimotweni zesimanje.

I-Ceramic Coatings

Izembatho ze-Ceramic seziphenduke inketho ethandwayo yokuthuthukisa ukusebenza kokukhipha okuningi. Lezi zembatho zinikeza ukufakwa okuhle kakhulu kokushisa, kunciphisa ukudluliswa kokushisa ezingxenyeni zenjini ezizungezile. Izembatho ze-Ceramic nazo zinikeza ukumelana okuphezulu kokugqwala nokuguga, okunweba isikhathi sokuphila se-exhaust manifolds. Ngokugcina amazinga okushisa aphansi angaphezulu, izimbotshana ze-ceramic zisiza ukuthuthukisa ukusebenza kahle kwenjini nokunciphisa ukukhishwa kwekhabhoni.

Izithuthukisi Zomklamo

I-Computational Fluid Dynamics (CFD) Esakhiweni

Onjiniyela manje basebenzisa i-Computational Fluid Dynamics (CFD) ukuze bathuthukise imiklamo eminingi yokukhipha umoya. I-CFD ivumela ukulingiswa okuningiliziwe kanye nokuhlaziywa kokuziphatha kwegesi ekhishwayo ngaphakathi kokuningi. Lobu buchwepheshe buvumela ukudalwa kwamajiyometri ayinkimbinkimbi akhulisa ukugeleza kwegesi futhi anciphise ukucindezelwa emuva. Ukusetshenziswa kwe-CFD kuholele ekuthuthukisweni okukhulu ekusebenzeni kwenjini nokusebenza kahle kukaphethiloli.

Ukuhlanganiswa ne-Turbocharging Systems

Ukuhlanganiswa kwamasistimu e-turbocharging nama-multifold exhaust kuguqule ukusebenza kwenjini. Izinjini ezine-Turbocharged zidinga i-exhaust manifolds ekwazi ukuphatha ingcindezi eyengeziwe nezinga lokushisa. Izinto ezithuthukisiwe kanye nemiklamo emisha iqinisekisa ukuthi lezi zinhlobonhlobo zingakwazi ukukhipha amagesi ku-turbocharger. Lokhu kuhlanganiswa kuthuthukisa ukuphuma kwamandla futhi kuthuthukisa ukonga kukaphethiloli, kwenza izinjini ezine-turbocharged zisebenze kahle futhi ziphendule.

Amathiphu Awusizo Okunakekela Nokuthuthukisa

Ukuhlonza Izimpawu Zokuguga Nokukhala

Ukuhlolwa njalo kwe-exhaust manifolds kubalulekile ekugcineni ukusebenza kahle. Izimpawu zokuguga zihlanganisa imifantu ebonakalayo, ukugqwala, nomsindo ongavamile ovela ohlelweni lwe-exhaust. Ukuncipha kokusebenza kwenjini noma ukwanda kokusetshenziswa kukaphethiloli kungase futhi kubonise izinkinga eziningi. Ukutholwa kusenesikhathi nokunakekelwa ngesikhathi kungavimbela omunye umonakalo kanye nokulungiswa okumba eqolo.

Ukukhetha I-Aftermarket Manifold Elungile

Ukukhetha i-aftermarket exhaust eningi ngokuphindaphindiwe kudinga ukucatshangelwa ngokucophelela kwezinto ezimbalwa. Ukuhambisana nemodeli yemoto kubalulekile ukuze kuqinisekiswe ukulingana okufanele nokusebenza kahle. Izinto ezisezingeni eliphezulu njengensimbi engagqwali noma izinketho ezimbozwe nge-ceramic zinikeza ukuqina nokusebenza kahle okungcono. Ukubonisana nezingcweti zezimoto kunganikeza imininingwane ebalulekile nezincomo zokukhetha inqwaba yemakethe yangemuva.

Uhambo lwe-exhaust eningi lubonisa intuthuko emangalisayo kusukela kumiklamo yakuqala ukuya emisha yesimanjemanje. Ukuthuthukiswa okuqhubekayo kwezinto zokwakha kanye namasu okukhiqiza kuthuthukise kakhulu ukusebenza nokuqina. Ukubaluleka kwentuthuko eqhubekayo kubuchwepheshe be-exhaust obuningi abunakugcizelelwa. Ukuhlala unolwazi mayelana nentuthuko yesikhathi esizayo kuzozuzisa kokubili abathanda izimoto kanye nezingcweti.

Isikhathi sokuthumela: Jul-22-2024