Ukuqinisekiswa kokucaciswa kwetorque kubaluleke kakhulu ekuqinisekiseni ikhwalithi yomkhiqizo, ukuphepha, nokwethembeka. Ukudebesela ukuqinisa ngisho akungaba umphumela wokuqinisa amasenti amathathu ngokwaneleekuhlulekeni okuyinhlekelele. Ukusebenzisaama-torque wrenches avimbela ngenkuthalo ukwehluleka kwebhawodikanye nezindaba zomhlangano, njengoba ukucindezela ngokweqile kungaholela ekulimazeni okuphukile. Ukulandela imininingwane ye-torque yeinjini ye-harmonic balancerizingxenye zibalulekile ukuvimbela ukulimala kokukhathala nokuqinisekisa ukuvaleka okufanele. Ukwethemba okucacisiwels I-torque yebhawudi yebhawudi ye-harmonicamanani abalulekile, njengoba enqunywa ngokucophelela ukugcina ukusebenza okuphezulu.

I-Harmonic BalancerImininingwane ye-torque

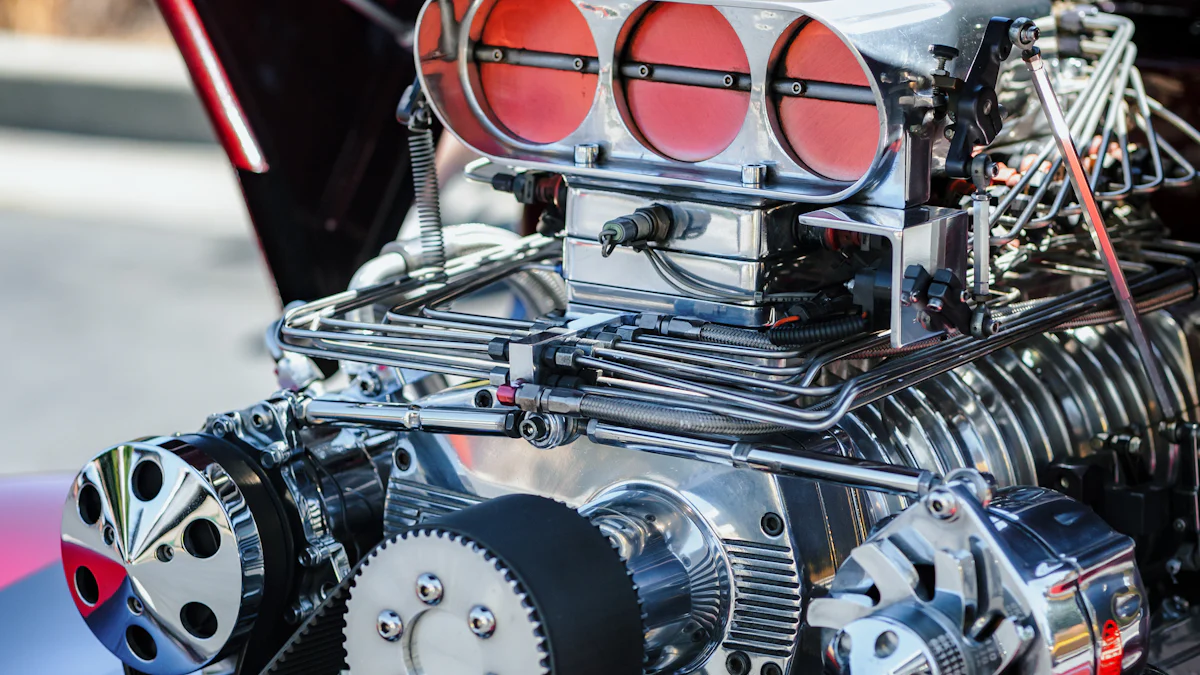

Uma kuziwa ku-I-Harmonic Balancer Torque Specs, ukunemba nokunemba kubaluleke kakhulu. Iukubaluleka kwe-torque specsazikwazi ukweqiwa, njengoba ziqinisekisa ukusebenza kahle nokuphila isikhathi eside kwezingxenye zenjini yakho. Ngokunamathela kumanani we-torque anconyiwe, ungavimbela izinkinga ezinjengokwehluleka kwebhawodi kanye nezinkinga zokuhlanganisa. Ake sihlole imininingwane yeImininingwane ye-torque ejwayelekilefuthi uhlole amanani avamile adlala indima ebalulekile ekugcineni impilo yenjini yakho.

I-General Torque Specs

Ukubaluleka kwe-Torque Specs

Ukuqinisekisa ukuthi yonke ibhawudi iqiniswa ngendlela efanele kubalulekile ekusebenzeni kwakho konke nokuphepha kwenjini yakho. Iimininingwane ye-torqueisebenza njengesiqondiso sokuvimbela ukuqinisa ngaphansi noma ngokweqile, okungaholela emiphumeleni emibi kakhulu. Ngokulandela lezi zicaciso ngenkuthalo, uqinisekisa ukuthi ingxenye ngayinye iboshelwe ngokuvikelekile, unciphisa ubungozi bokungasebenzi kahle.

Amanani Avamile weTorque

- Valve Lifter Umhlahlandlela Boltskwe-LS2 idinga ama-intshi angu-89 lbs., kuyilapho i-LS1/LS3/LS6/LS7 idinga ama-intshi angu-106 lbs.

- I-Ignition Coil-to-Bracket Boltskufanele ithotshiswe ku-106 inch lbs. nge-LS1/LS6 kanye ne-89 intshi lbs. kwe-LS2/LS3/LS7.

- I-Throttle Bolt Boltsfuna 106 intshi lbs. nge-LS1/LS6 kanye ne-89 intshi lbs. ngezinjini ze-LS2/LS3/LS7.

- I-Oil Pan Closeout Cover Bolt(Uhlangothi Lwesobunxele) ludinga ama-intshi angu-106 lbs. nge-LS1/LS6 kanye nama-intshi angu-80 lbs. kwe-LS2/LS7.

- I-Oil Pan Closeout Cover Bolt (Uhlangothi Lwesokudla) icacisa u-106 inch lbs. nge-LS1/LS6 kanye nama-intshi angu-80 lbs. ngezinjini ze-LS2/LS7.

Specific Engine Models

LS1/LS2/LS3 Izinjini

Ngobaamamodeli enjini athilenjenge-LS1, LS2, ne-LS3, kubalulekile ukulandela imininingwane ebekiwe yetorque ngokucophelela ukuze ugcine amazinga okusebenza alungile. Imodeli ngayinye yenjini inezidingo ezihlukile okufanele zihlangatshezwe ngesikhathi sokufakwa ukuze kuqinisekiswe ukusebenza kahle nokuphila isikhathi eside.

LS7/LS9/LSA Izinjini

Ngakolunye uhlangothi, izinjini ezifana ne-LS7, LS9, kanye ne-LSA zinesethi yazo yamanani we-torque okufanele ilandelwe ngokuqinile phakathi nezinqubo zokuhlanganisa. Lezi zinjini ezisebenza kahle zidinga ukusetshenziswa kwetorque okunembe ukuze kuqinisekiswe ukusebenza kahle okuphezulu nokuthembeka.

Amathuluzi Nezinto Zokusebenza

Amathuluzi Adingekayo

- I-wrench ye-torque ethembekile ibalulekile lapho usebenza kuma-balancers e-harmonic ukuze uzuze ukuqina okunembile ngokuya ngokucaciswa.

- Amasethi amasokhethi afanelekile anosayizi abahlukahlukene ayadingeka ukuze ufinyelele amabhawodi ahlukene ngaphakathi kwekhompathimenti yenjini ngokuphumelelayo.

- Ama-lubricant angama-thread afanaI-Loctiteabalulekile ekuvikeleni amabhawodi ngempumelelo ngenkathi kuvimbela ukuxega ngenxa yokudlidliza.

Izinto Ezinconyiwe

- Izinga eliphezulu gasketsidlala indima ebalulekile ekuqinisekiseni ukuvaleka okufanele phakathi kwezingxenye, ukuvimbela ukuvuza okungaphazamisa ukusebenza kwenjini.

- Amanikiniki ahlanzekile noma amathawula ayasebenza ekusuleni noma yimaphi ama-lubricant noma imfucumfucu eyengeziwe phakathi nenqubo yokufaka.

- Izibuko zokuphepha zivikela amehlo akho ezingozini ezingaba khona njengemfucumfucu noma amakhemikhali ngenkathi usebenza enjinini yakho.

Ngokuqonda ukubalulekaImininingwane ye-torque ye-harmonic, uzihlomisa ngolwazi oludingekayo ukuze ulondoloze impilo yenjini yakho ngempumelelo ngezinqubo ezifanele zokuyifaka usebenzisa amathuluzi nezinto zokwakha ezifanele.

I-LS Harmonic BalancerI-Bolt Torque

Imininingwane ye-Torque Specs

Uma kuziwa ku-I-LS Harmonic Balancer Bolt Torque, ukunemba kubalulekile ekusebenzeni kahle kwenjini yakho. Ukuqonda ukucaciswa kwetorque enemininingwane kuqinisekisa ukuthi ingxenye ngayinye iboshelwe ngokuvikelekile, kunciphisa ubungozi bokungasebenzi kahle kanye nokuqinisekisa ukusebenza kahle. Ake singene sijule emibhalweni yefekthri kanye ne-aftermarket ukuze sikuqondise kule nqubo ebalulekile.

Imininingwane Yemboni

Ukusebenza kweChevroletinikeza izinga eliphezuluI-Harmonic Balancer Boltseyenziwe ngensimbi ephethwe ukushisa ukuze uthole amandla engeziwe. Lawa mabhawodi aklanyelwe ukumelana nobunzima bokusebenza kwenjini, anekhanda le-hex elivimbela ukushelela kwesokhethi ngesikhathi sokuqina noma ukuxegiswa. Ezinjini ze-LS ezifana ne-LS1/LS2/LS6, iI-Crankshaft Balancer Boltkufanele i-torque240 ft-lbsngesikhathi sokufakwa ukuqinisekisa ukufakwa okuphelele kwe-balancer.

I-Aftermarket Specifications

Ngezinketho ze-aftermarket, cabanga ukusebenzisaI-Harmonic Balancer Boltskusuka kumabhrendi ahloniphekile afanaWerkwell. Lawa mabhawodi akhiwe ukuze ahlangabezane nezindinganiso zomkhakha futhi anikeze ukusebenza okuthembekile. Uma ulandela imiyalelo ye-ATI, kuyanconywa ukuthi usebenzise i-Loctite 262 futhi ufake i-torque ibhawodi libe ngu-230 ft-lbs ukuze kufakwe okuphephile.

Izinqubo zokufaka

Izinqubo zokufaka ezifanele zibalulekile ekugcineni ubuqotho bezingxenye zenjini yakho. Ngokulandela umhlahlandlela wesinyathelo ngesinyathelo futhi ugweme amaphutha ajwayelekile, ungaqinisekisa ukuthi i-harmonic balancer bolt iboshwe ngokuvikelekile ukuze isebenze kahle.

Isinyathelo ngesinyathelo Umhlahlandlela

- Qala ngokulungiselela indawo yakho yokusebenza ngawo wonke amathuluzi nezinto zokwakha ezidingekayo.

- Qinisekisa ukuthi injini isekelwe ngendlela efanele ngaphambi kokuqala inqubo yokufaka.

- Sebenzisa i-torque wrench ethembekile ukuze uqinise ibhawudi yebhalansi ye-harmonic ngokuya ngezicaciso zefekthri noma ze-aftermarket.

- Qinisekisa ukuthi ibhawudi ifakwe inani elinconyiwe usebenzisa ai-torque wrench elinganisiwe.

- Hlola kabili konke ukuxhumana nezingxenye ngaphambi kokuqhubeka nokuhlanganisa injini.

Amaphutha Ajwayelekile

- Iphutha elilodwa elivamile ngesikhathi sokufakwa kwebhawudi ye-harmonic balancer ukudonsa ngokweqile, okungaholela ekulimaleni kwentambo noma ukwehluleka kwengxenye.

- Ukusebenzisa ivelu yetorque engalungile noma ukwehluleka ukulandela izinqubo ezifanele zokufaka kungase kuphazamise ubuqotho bokuhlanganiswa kwenjini.

- Ukudebeselela ukuhlola okuvamile noma ukuhlola ukulungiswa kungase kubangele amabhawodi axegayo noma ukuhleleka ngendlela engafanele, kuthinte ukusebenza kwenjini kukonke.

Amathiphu Okunakekela

Ukunakekelwa okuvamile kuyisihluthulelo sokuqinisekisa ukwethembeka nokusebenza kwesikhathi eside okuvela ezingxenyeni zenjini yakho. Ngokwenza ukuhlola okujwayelekile kanye nokulungisa noma yiziphi izinkinga ngokushesha, ungakwazi ukuvimbela izinkinga ezingase zibe khona futhi welule isikhathi sempilo yemoto yakho.

Ukuhlola Okuvamile

- Hlola ngezikhathi ezithile ukuqina kwebhawodi yebhalansi ye-harmonic ukuze uqinisekise ukuthi ihlala ngaphakathi kwamanani etorque acacisiwe.

- Hlola izingxenye ezizungezile ukuze uthole izimpawu zokuguga noma zokonakala ezingase zithinte ukuphepha kwebhawodi.

- Gada ukudlidliza kwenjini nomsindo ongajwayelekile ongabonisa izixhumi ezixegayo noma izinkinga zokungaqondani kahle.

Ukuxazulula Izinkinga

- Uma uhlangabezana nanoma yibuphi ubunzima ngebhawodi yakho ye-harmonic balancer, thintana nezinkombandlela zomkhiqizi noma ufune usizo lochwepheshe.

- Bhekana nanoma yiziphi izimpawu ezingavamile ngokushesha ukuze uvimbele omunye umonakalo noma izingozi zokuphepha ezihlobene nezibophelelo ezixegayo.

Ngokuthobela ukucaciswa kwetorque enemininingwane, ulandela izinqubo ezifanele zokufaka, nokusebenzisa izinqubo zokuyilungisa njalo, ungakwazi ukuvikela impilo yenjini yakho futhi uthuthukise ukusebenza kwayo iminyaka eminingi ezayo.

Amathiphu okufaka

Izinyathelo Zokulungiselela

Uma kufikaizinyathelo zokulungiselelangokufaka ibhawudi yebhalansi ye-harmonic, eqinisekisaizinyathelo zokuphephayiyona ehamba phambili. Omakhenikha nabathanda izimoto ngokufanayo bayakuqonda ukubaluleka kokudala indawo evikelekile ngaphambi kokutshuza kunoma yimuphi umsebenzi wenjini. Ngokulandela lezi ziqondiso zokuphepha, ungazivikela wena nabanye ezingozini ezingaba khona.

Izinyathelo Zokuphepha

- Beka kuqala Izimpahla Zokuzivikela Zomuntu Siqu (i-PPE) njengezibuko zokuphepha, amagilavu, nezingubo ezifanele ukuze uzivikele emfucumfucwini noma ezintweni eziyingozi.

- Vikela imoto endaweni ezinzile usebenzisa izitendi zojeke namasondo amasondo ukuze uvimbele ukunyakaza ngengozi phakathi nenqubo yokufaka.

- Nqamula ibhethri ukuze ugweme iphutha likagesi ngenkathi usebenza ezingxenyeni zenjini.

- Gcina indawo yakho yokusebenza inomoya omuhle ukuze ukhiphe intuthu noma amagesi akhipha umoya anganqwabelana phakathi nokusebenza kwenjini.

Ukusethwa kwendawo yokusebenza

Ukusetha indawo yakho yokusebenza kahle kubalulekile ukuze kube nenqubo yokufaka eshelelayo. Ukuhlela amathuluzi akho nezinto zokwakha kusenesikhathi kungonga isikhathi futhi kuvimbele ukubambezeleka okungadingekile. Nawa amanye amathiphu okuthuthukisa ikhono lakhoukusethwa kwendawo yokusebenza:

- Hlela amathuluzi akho ngendlela ehlelekile lapho ungafinyeleleka khona ukuze ugweme ukuwacinga phakathi nomsebenzi.

- Sebenzisa indawo ehlanzekile nekhanyiswe kahle ukuze uthuthukise ukubonakala ngenkathi usebenza ezingxenyeni zenjini eziyinkimbinkimbi.

- Beka amacansi noma izembozo zokuvikela ukuze uvikele izingxenye ezizwelayo zemoto ekulimaleni kwengozi noma imihuzuko.

- Yiba nesicishamlilo eduze njengesinyathelo sokuzivikela ezimeni eziphuthumayo.

Amasu okufaka

Ukuqondanisa okufanele kanye nokusetshenziswa kwetorque okunembayo kuyizici ezibalulekile zokufaka ibholidi ye-harmonic balancer ngendlela efanele. Ukuqonda ubunkimbinkimbi balezi zindlela kuqinisekisa ukuthi injini yakho isebenza kahle ngaphandle kwezinkinga ezivela ezindleleni zokufaka ezingafanele.

Ukuqondanisa Okufanelekile

Ukuzuzaukuqondanisa okufanelelapho ufaka i-harmonic balancer bolt ibalulekile ekugcineni ibhalansi nobuqotho bezingxenye zenjini. Ukungaqondi kahle kungaholela ekudlidlizeni okukhulu, ukugqoka ngaphambi kwesikhathi, noma ngisho nokwehluleka okuyinhlekelele phansi komugqa. Landela le mihlahlandlela yokuqondanisa ukuze ufake ngempumelelo:

- Qondanisa ukhiye ku-crankshaft nesikhala esihambisanayo kusilinganisi se-harmonic ngaphambi kokuyivikela endaweni.

- Sebenzisa amathuluzi okuqondanisa noma amamaki anikezwe abakhiqizi ukuze uqinisekise ukuma okunembile ngesikhathi sokufakwa.

- Hlola kabili ukuqondanisa izikhathi eziningi kuyo yonke inqubo ukuze uqinisekise ukunemba ngaphambi kokuphothula isicelo setorque.

Uhlelo lokusebenza lwe-torque

Ukusebenzisa i-torque ngendlela efanele kubalulekile uma ubophela ibhawudi yebhalansi ye-harmonic kumanani ashiwo. Ukuqinisa kakhulu kungabangela ukulimala kwentambo noma ukwehluleka kwengxenye, kuyilapho ukuqina kancane kungase kuphumele ekuxhumekeni okuxekethile okuphazamisa ukusebenza kwenjini.

- Sebenzisa isikrufu setorque esilinganisiwe esisethwe ngenani elinconyiwe elinikezwe imininingwane yomkhiqizi ukuze kuqiniswe okunembile.

- Faka i-torque kancane kancane ngezigaba ezikhuphukayo kunokuba wenze konke ngesikhathi esisodwa ukuze usabalalise ingcindezi ngokulinganayo kuyo yonke imicu futhi uvimbele ukushintsha okungazelelwe kokungezwani.

- Qinisekisa amanani we-torque usebenzisa amageji athembekile ngemva kokufaka isicelo sokuqala ukuze uqinisekise ukuqiniswa okufanele ngaphambi kokuqhubeka nemisebenzi eyengeziwe yomhlangano.

Ukuhlola Ngemva Kokufaka

Ngemva kokuphothula inqubo yokufaka, ukwenza amasheke aphelele ngemva kokufaka kuqinisekisa ukuthi yonke into iboshelwe ngokuphephile futhi isebenza ngendlela ehlosiwe. Ukuqinisekisa amanani we-torque nokwenza imigijimo yokuhlola kuyizinyathelo ezibalulekile zokuqinisekisa imiphumela eyimpumelelo yokufaka.

Iqinisekisa i-Torque

Uma usuqinise ibhawudo lebhalansi ye-harmonic ngokuya ngokucaciswa, kubalulekile ukuqinisekisa ukuthi isibambiso ngasinye sihlangabezana namanani etorque anqunyiwe ngokunembile.

- Phinda uvakashele iphoyinti lokuxhuma ngalinye ngesikrufu setorque esilinganisiwe ukuze uqinisekise ukuthi wonke amabhawodi athotshiswe ngendlela efanele ngaphandle kokuchezuka.

- Hlola noma yiziphi izimpawu zokuxega noma ukungahambi kahle ezingase zibonise ukuqiniswa okwanele phakathi nezinqubo zokufaka zokuqala.

I-Test Runs

Ukuqhuba ukuhlola ngemva kokuqinisekisa amanani etorque kunikeza ukuqinisekiswa komhlaba wangempela kwemizamo yakho yokufaka. Lokhu kuhlolwa kokuhlola kukuvumela ukuthi ubone ukuthi injini yakho isebenza kahle kangakanani ngaphansi kwezimo zokusebenza ngemva kokufakwa.

- Qala ngokugijima kokuhlola okufushane ngesivinini esihlukile ukuze uhlole ukusebenza kwenjini kukonke futhi ukhombe noma yikuphi ukudlidliza okungajwayelekile noma imisindo.

- Gada amazinga okushisa, ukuvuza koketshezi, nezinye izinkomba ezingabonisa izinkinga ezingaba khona ezihlobene nokufakwa okungafanele kwebhawudi yebhalansi ye-harmonic.

Ngokunamathela ngokuqinile ezinyathelweni zokulungiselela, ukusebenzisa amasu okuqondanisa afanele, ukusebenzisa izindlela ezinembile zokufaka itorque, ukuqinisekisa ukufakwa kwama-torque ngemva kokufakwa, kanye nokuqhuba ukuhlola okuphelele, uqinisekisa ukusebenza okuphelele okuvela ezingxenyeni zenjini yakho ezivikelweama-harmonic balancer bolts.

Ubufakazi:

- I-A&P eqinisekisiwe:

"Ama-torque specs empeleni ayivangeli emhlabeni wami."

- Unjiniyela:

“Ngingunjiniyela kwesinye isikhathi oqhamuka nama-torque specs ezingxenyeni zenjini.”

- Akwaziwa:

“Themba amanani wetorque. Bayazi ukuthi yini esebenza kangcono kunawe.”

Ngokuphindaphinda amaphuzu abalulekile futhi ugcizelele ukubaluleka kokunamathela kumanani we-torque acacisiwe, abantu ngabanye baqinisekisa ukusebenza kwenjini okuphelele. Ukulandela ukucaciswa kwe-torque ngenkuthalo kubalulekile ukuze uvimbele ukwehluleka okungenzeka futhi ugcine ubuqotho bezingxenye zenjini. Khumbula, ukunemba ekusetshenzisweni kwetorque kubaluleke kakhulu ekusimamiseni impilo yenjini nokuphila isikhathi eside. Themba ubuhlakani obusemuva kwamanani wetorque anikeziwe; zinqunywa ngokucophelela ngenhlalakahle yenjini yakho.

Isikhathi sokuthumela: Jun-04-2024